Maintenance

18 INOXPA S.A.U. · 01.030.30.05EN · (0) 2021/01

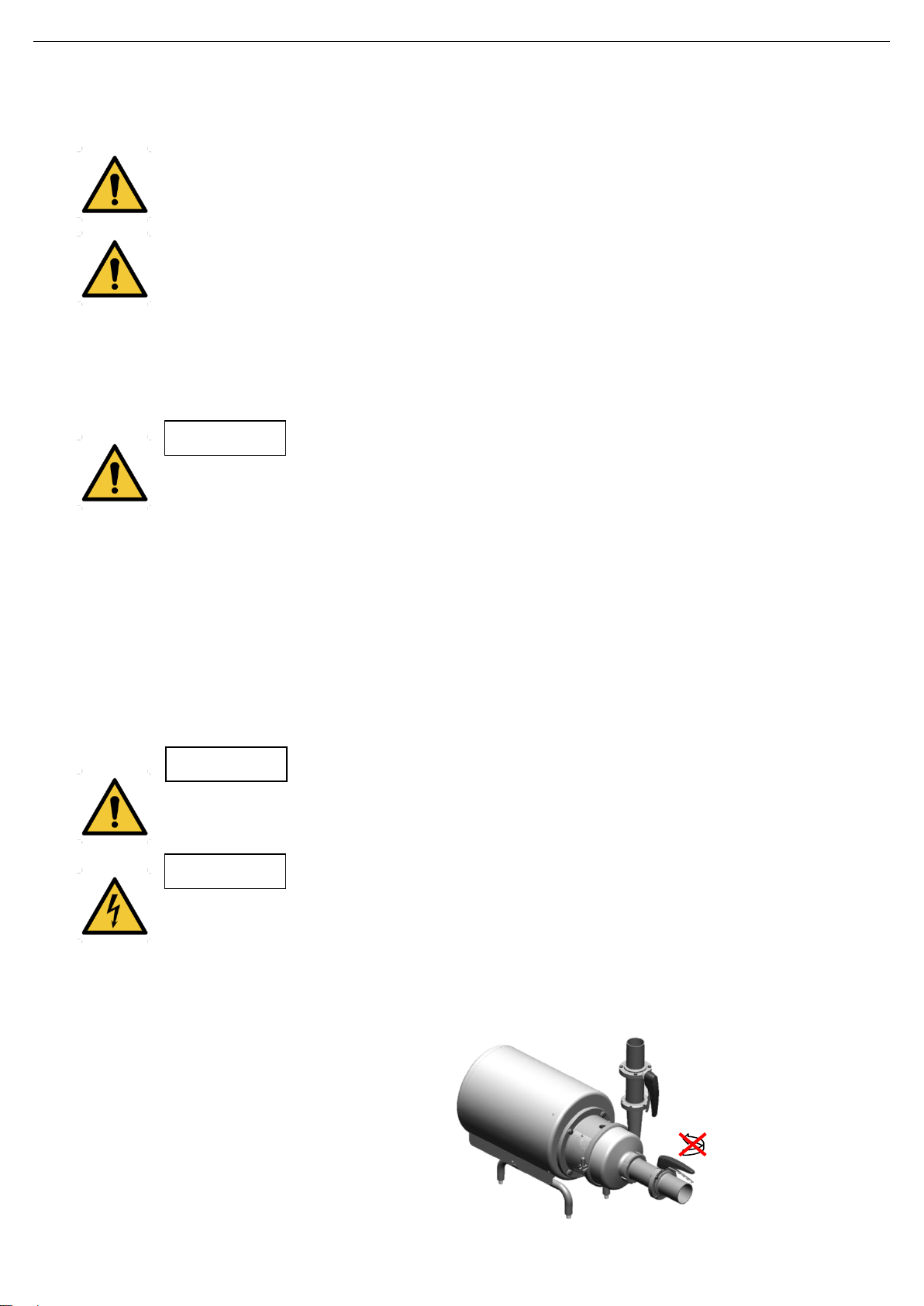

3. Mount the pump cover (03) on the lantern (04) and secure it

with the screws (51A).

4. Fit the stationary part of the seal (08) on the pump cover

(03) with the fingers. Make sure that the anti-rotation tabs

match the slots on the seal.

5. Fit the rotating part of the mechanical seal (08) on the rear

side of the impeller (02) and make sure that it is level.

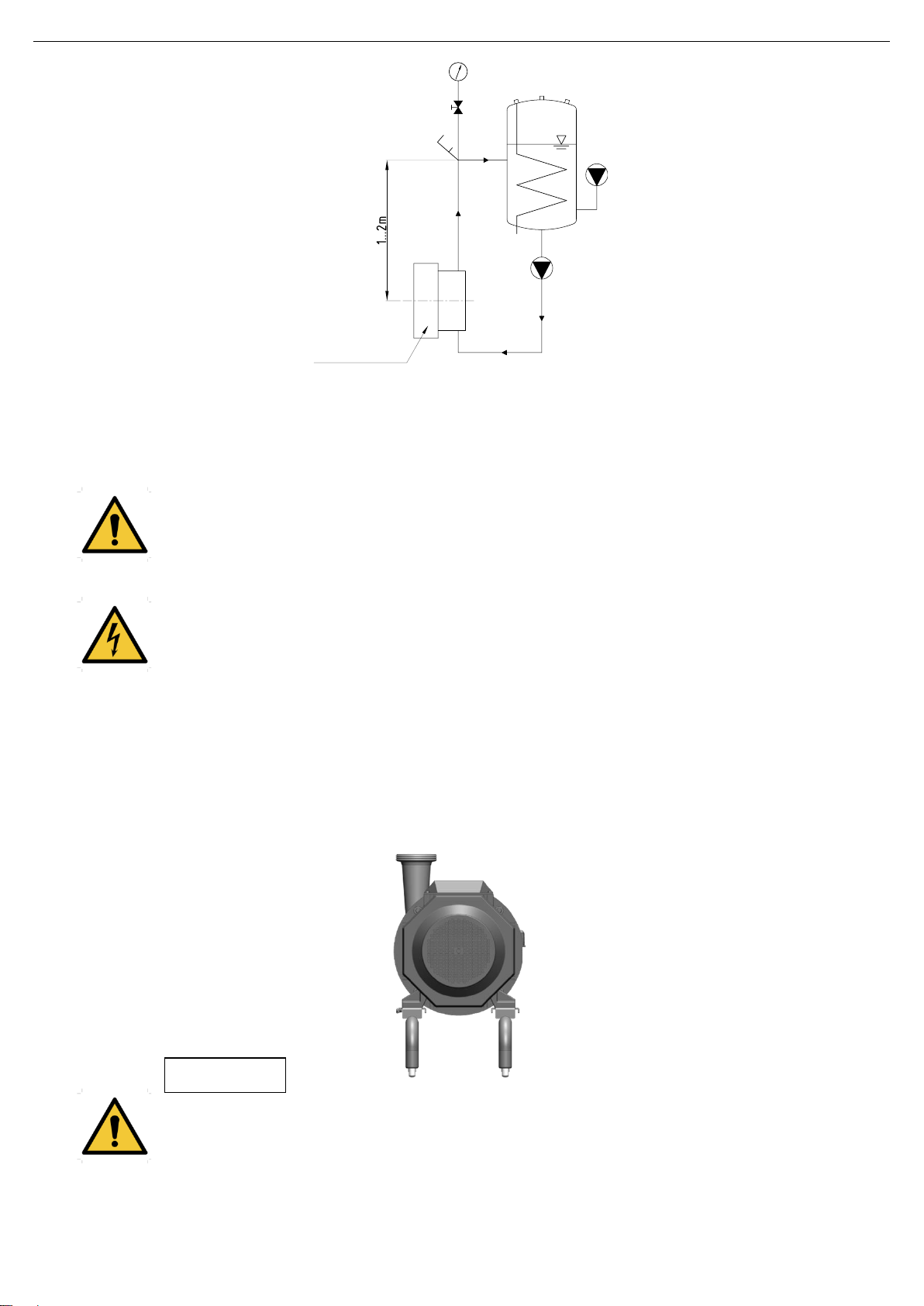

6. Place the O-ring (80A) in the slot of the impeller nut (45).

7. Place an open-end wrench on the flat sides of the shaft (05)

to prevent it from rotating.

8. Insert the impeller (02) on the pump shaft (05) and secure

with the nut (45).

9. Mount the pump casing (01) to the pump cover (03) and fix

it with the clamping ring (15).

10.Finally, reassembly the lanterns protections (47) on the

lantern (04) and fix them with the protector screws (50).

When installing the new seal, use soapy water when fitting the different parts and gaskets to allow

them to slide better. Apply it to the stationary as well as the rotating parts.

8.7.2. Double mechanical seal

Disassembly

1. Remove the main seal following the instructions in chapter 8.6.1. Pump and single mechanical seal up to

point 8.

2. Loosen the allen screws (51A) and carefully remove the pump cover (03) taking care not to damage the

stationary part of the secondary seal located therein.

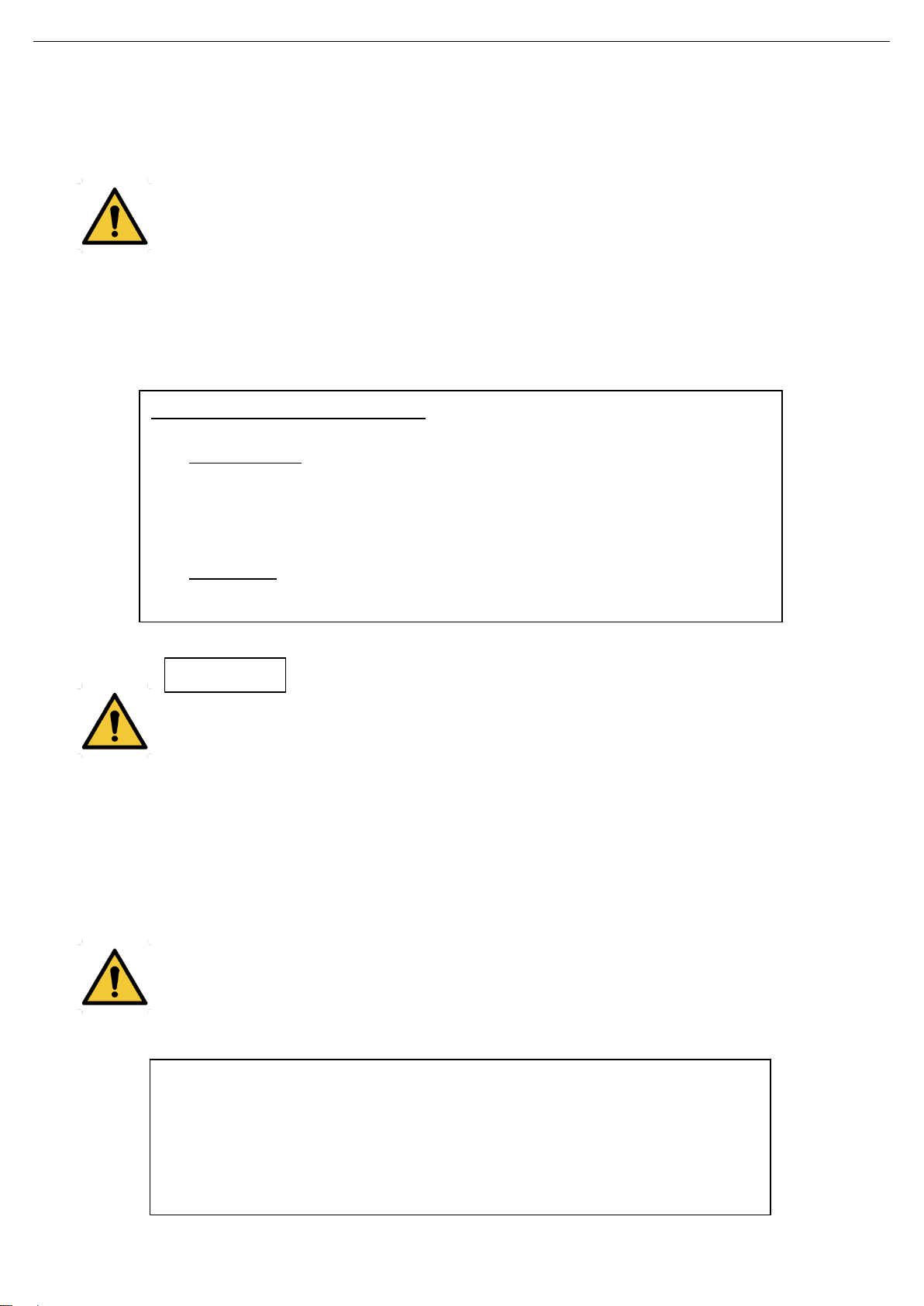

3. Loosen the allen screws (51B) and remove the double seal cover (10) together with the stationary part of the

secondary seal of the pump cover (03). Remove the spring and thrust washers.

4. Manually, remove the stationary part of the secondary seal (08) which is located in the double seal cover

(10) as well as the O-ring (80C).

5. Loosen the set screw (55) and remove the double seal ring (30) on the shaft (05) along with the rotating part

of the secondary seal.

6. Remove the rotating part of the secondary seal and the O-ring (80D) from the double seal ring.

Assembly

1. Install the rotating part of the new secondary seal and the O-ring (80) on the double seal ring (30). Slide the

assembly over the pump shaft (05).

2. Fit the stationary part of the secondary seal (08) and the O-ring (80C) with your fingers on the double seal

cover (10).

3. Place the thrust washer of the primary seal (08) on the pump cover (03).Make sure that the four tabs centring

the spring are facing outward.

4. Fit the spring on the thrust washer within the centring tabls. Place the thrust washer of secondary seal on the

spring. Make sure that the four tabs centring the spring are pointing inward.

5. Place the double seal cover (10) together with the secondary stationary part and the O-ring (80C) on the

pump cover (03) and move it until the thrust tabs on the washers of the primary and secondary seals match

the slots of the stationary part of the secondary seal. Secure it with the allen screws (51B).

6. Mount the assembly of the pump cover (03) and the stationary part of the secondary seal to the lantern (04)

and fasten with the screws (51A).

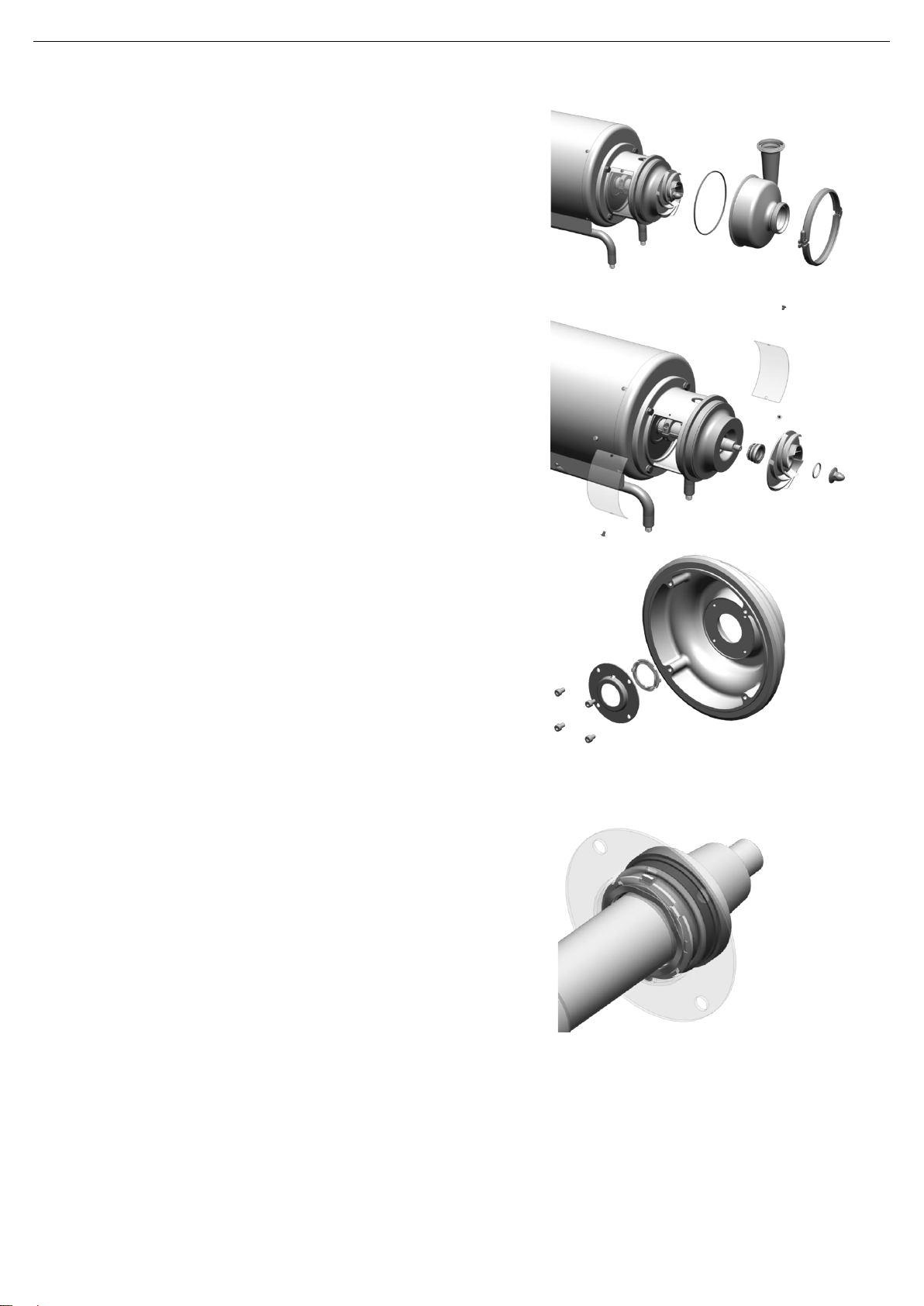

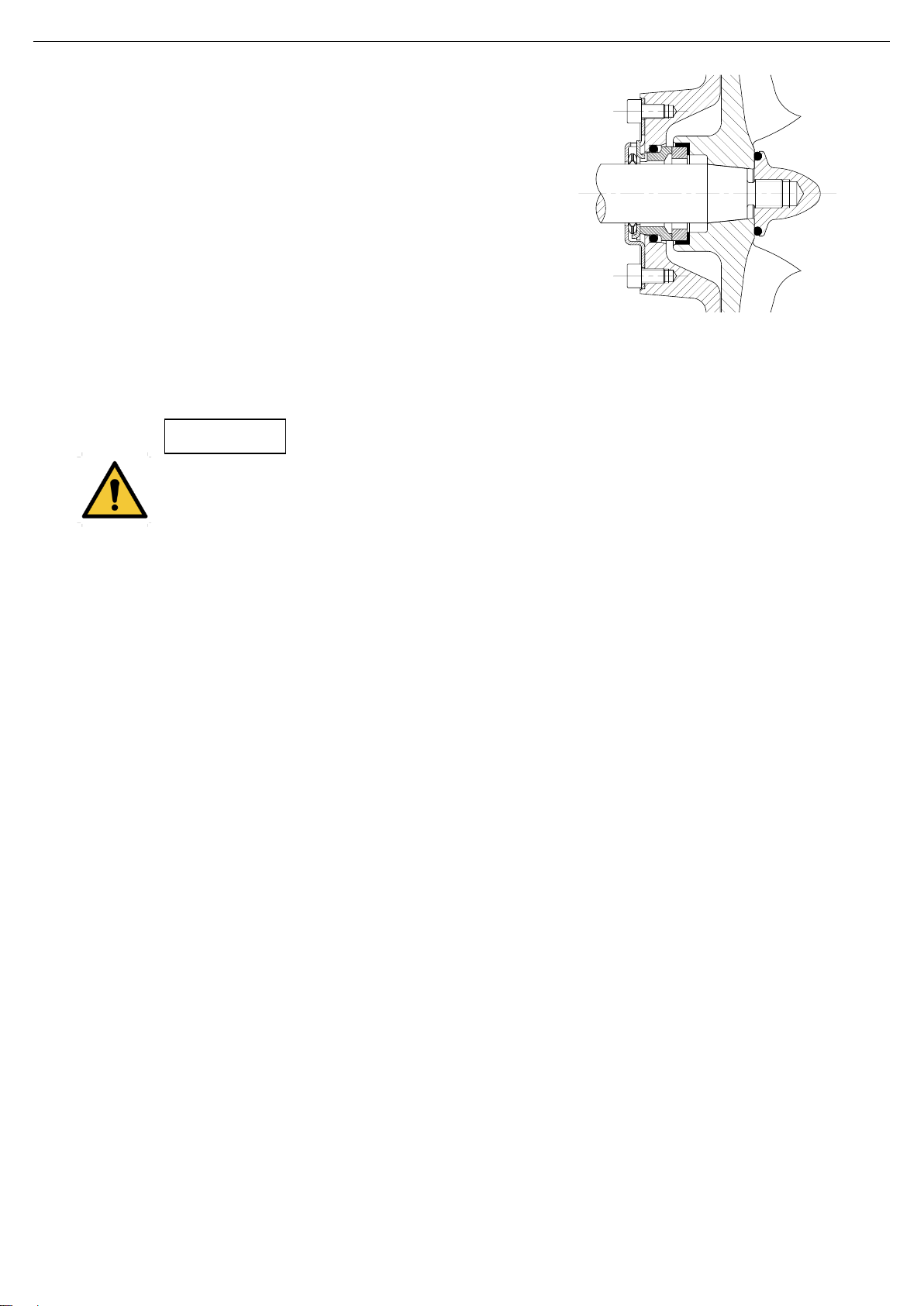

7. Slide the double seal ring (30) on the shaft (05), checking that the distances between the ring and the double

seal cover are as shown below and tighten the set screw (55).