INOXPA S.A.U. · 01.650.30.02EN · (A) 2021/01 3

1. Table of Contents

1. Table of Contents

2. Generalities

2.1. Instructions manual........................................................................................................................................................4

2.2. Compliance with the instructions ...................................................................................................................................4

2.3. Warranty........................................................................................................................................................................4

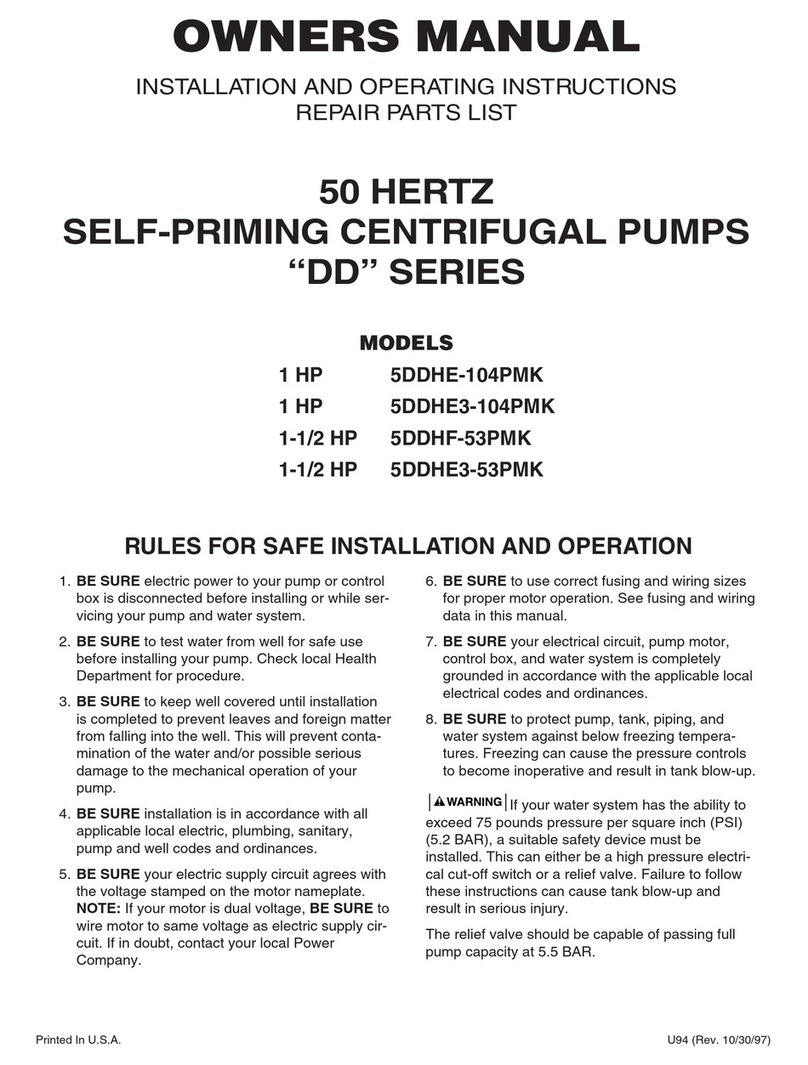

3. Safety

3.1. Warning symbols...........................................................................................................................................................5

3.2. General safety instructions ............................................................................................................................................5

4. General Information

4.1. Description.....................................................................................................................................................................6

4.2. Application.....................................................................................................................................................................6

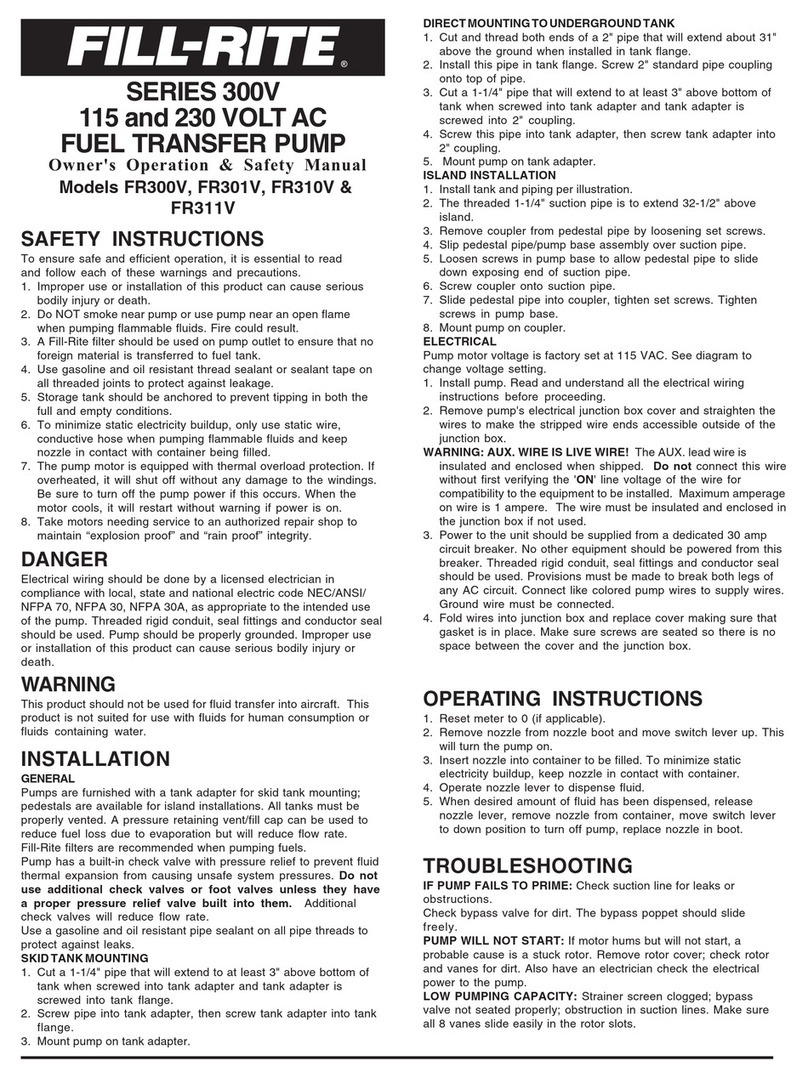

5. Installation

5.1. Reception of the pump...................................................................................................................................................7

5.2. Identification of the pump...............................................................................................................................................7

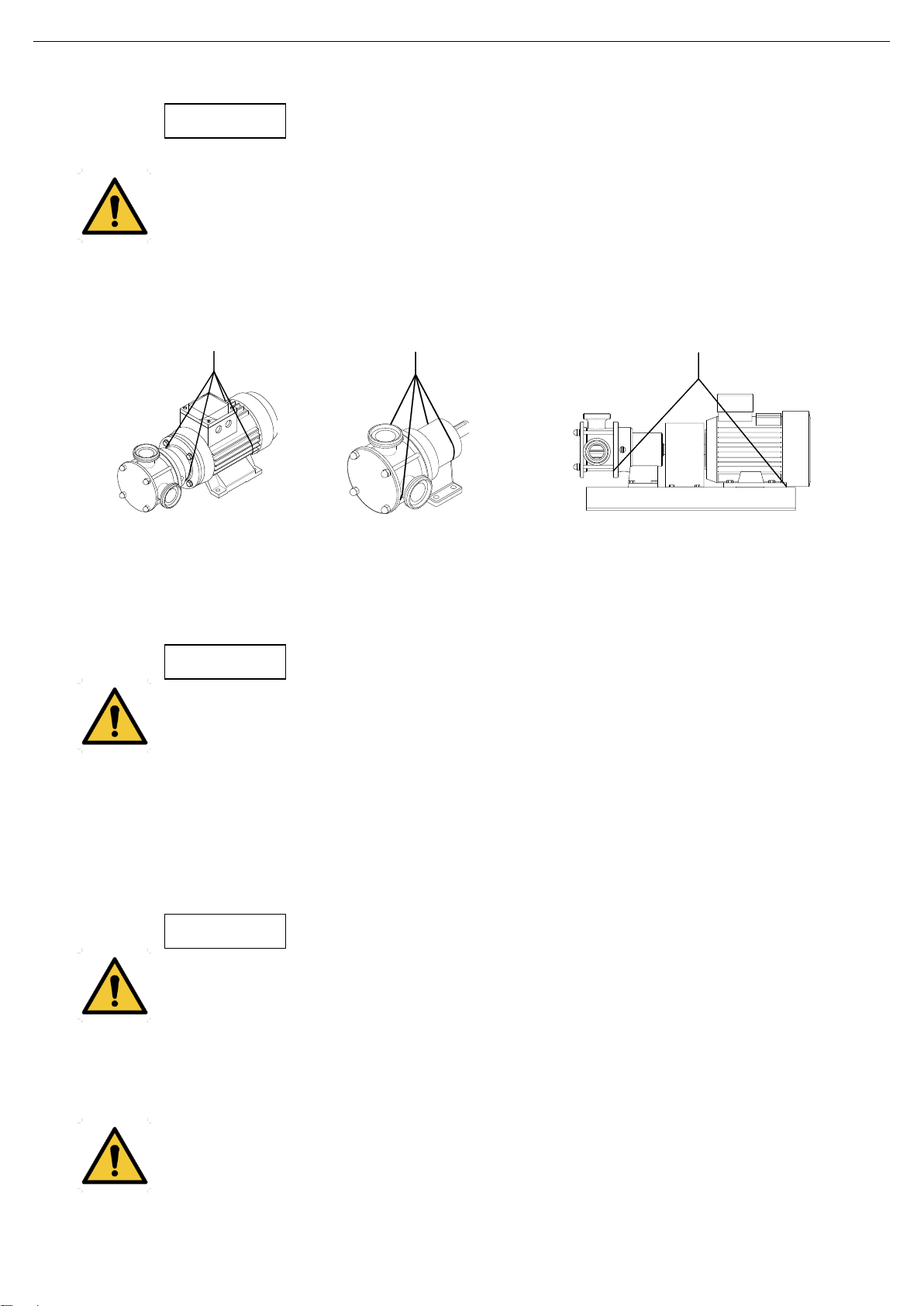

5.3. Transport and storage ...................................................................................................................................................8

5.4. Location.........................................................................................................................................................................8

5.5. Pipes..............................................................................................................................................................................9

5.6. Electrical installation ......................................................................................................................................................9

6. Start-up

6.1. Checks before starting the pump.................................................................................................................................10

6.2. Checks when starting the pump...................................................................................................................................10

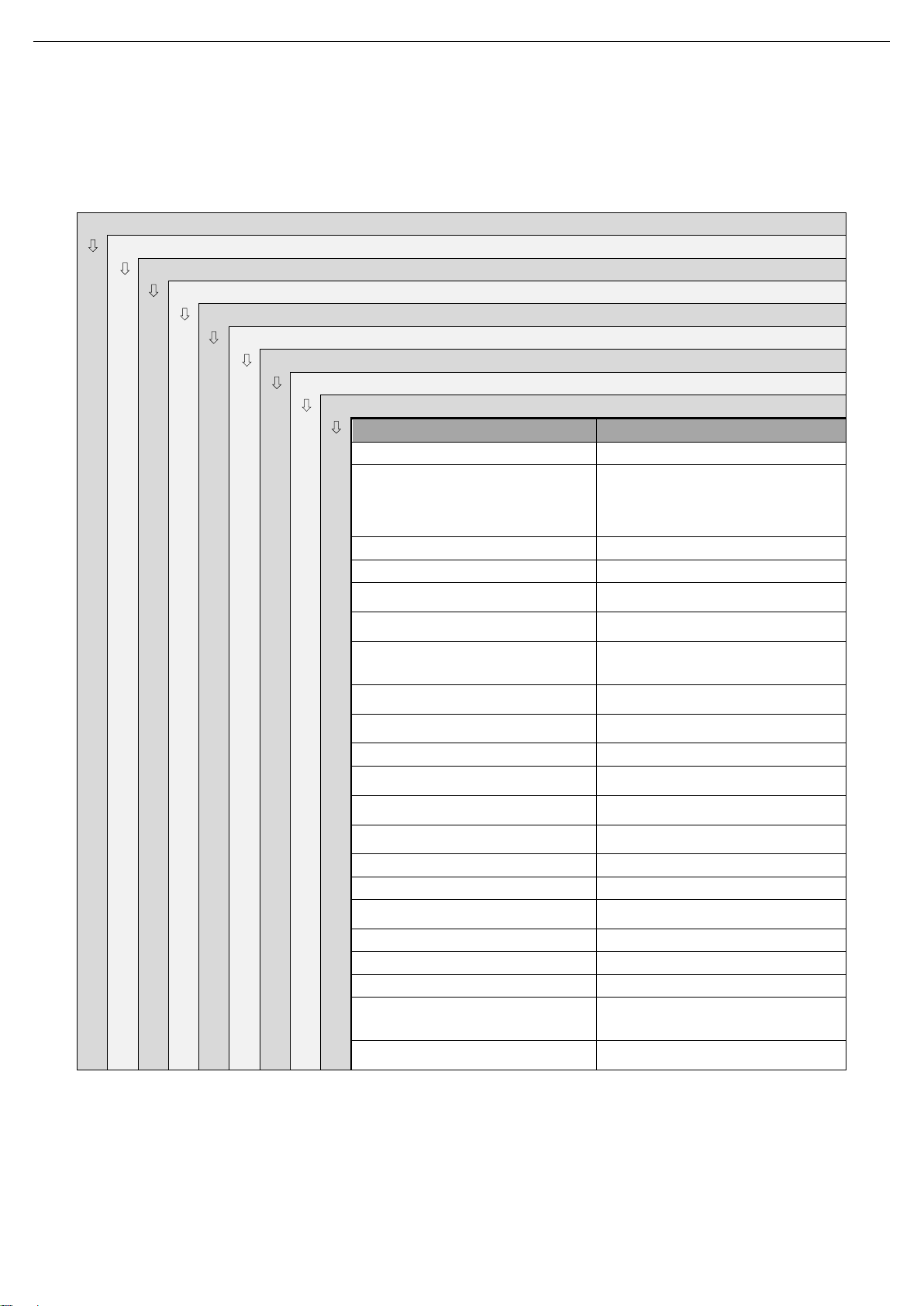

7. Troubleshooting

8. Maintenance

8.1. General considerations................................................................................................................................................13

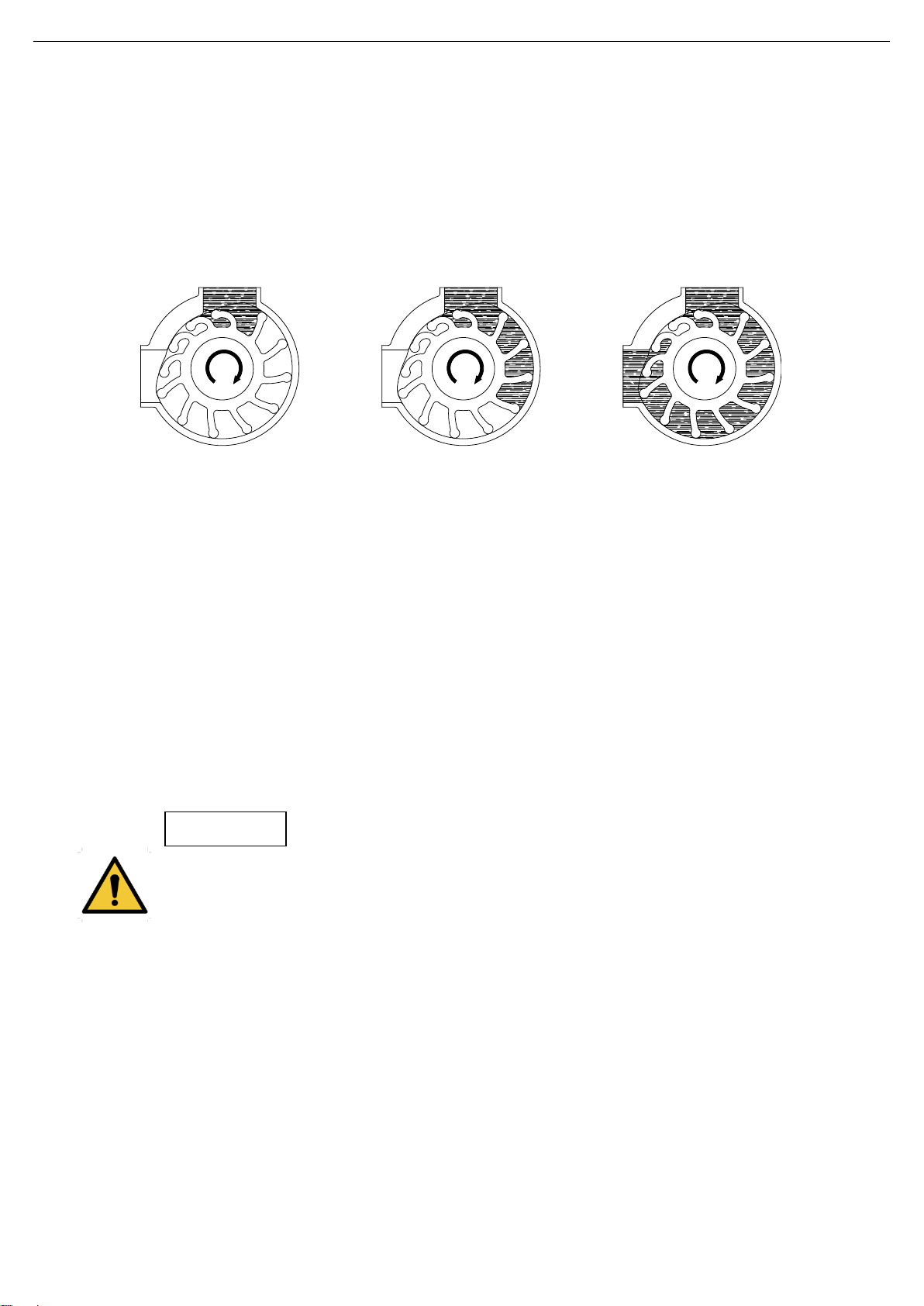

8.2. Check the mechanical seal..........................................................................................................................................13

8.3. Tightening torque.........................................................................................................................................................13

8.4. Storage........................................................................................................................................................................13

8.5. Bearing maintenance...................................................................................................................................................13

8.6. Cleaning.......................................................................................................................................................................13

8.7. Disassembly and assembly of the pump .....................................................................................................................15

9. Technical Specifications

9.1. Weight..........................................................................................................................................................................19

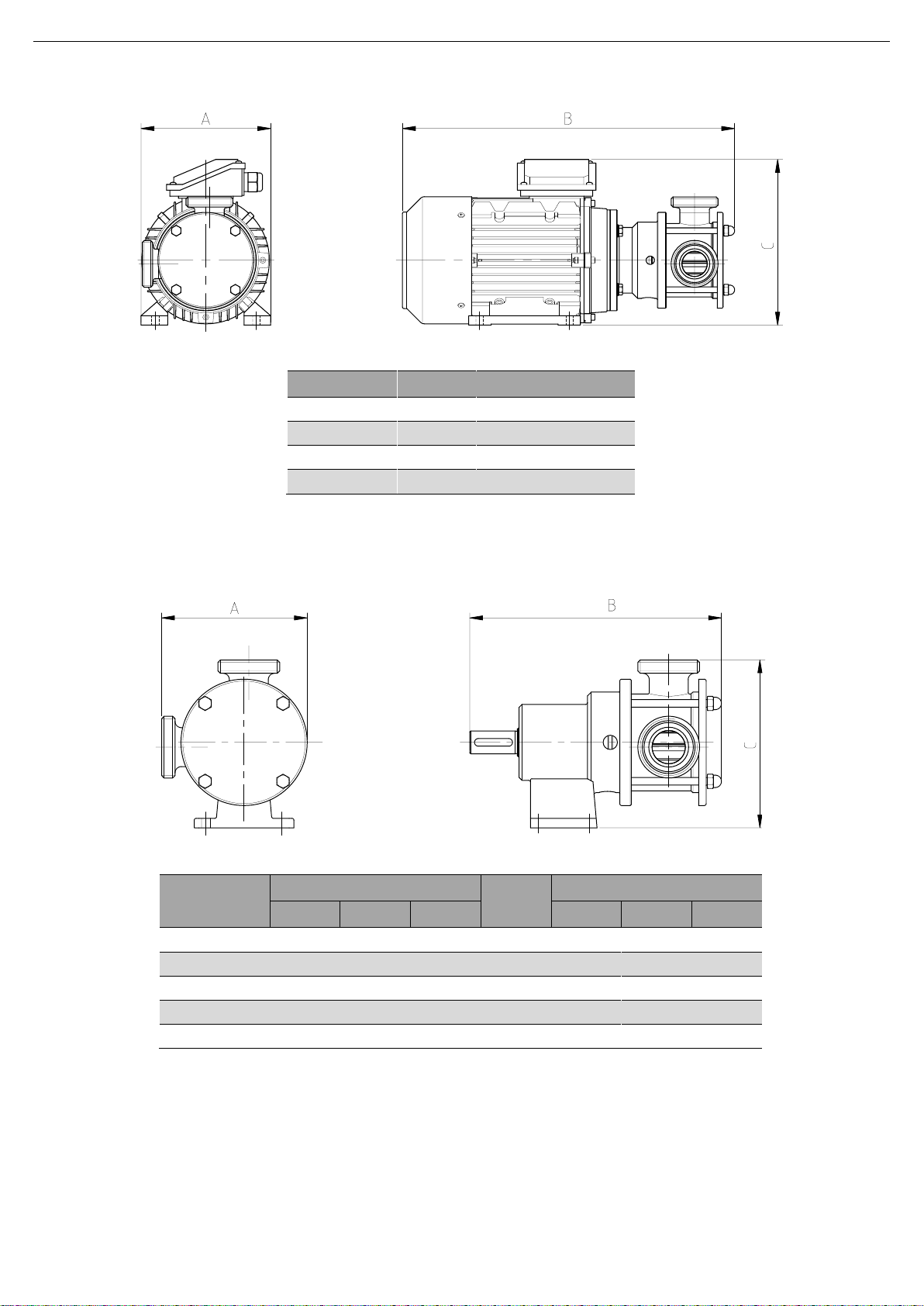

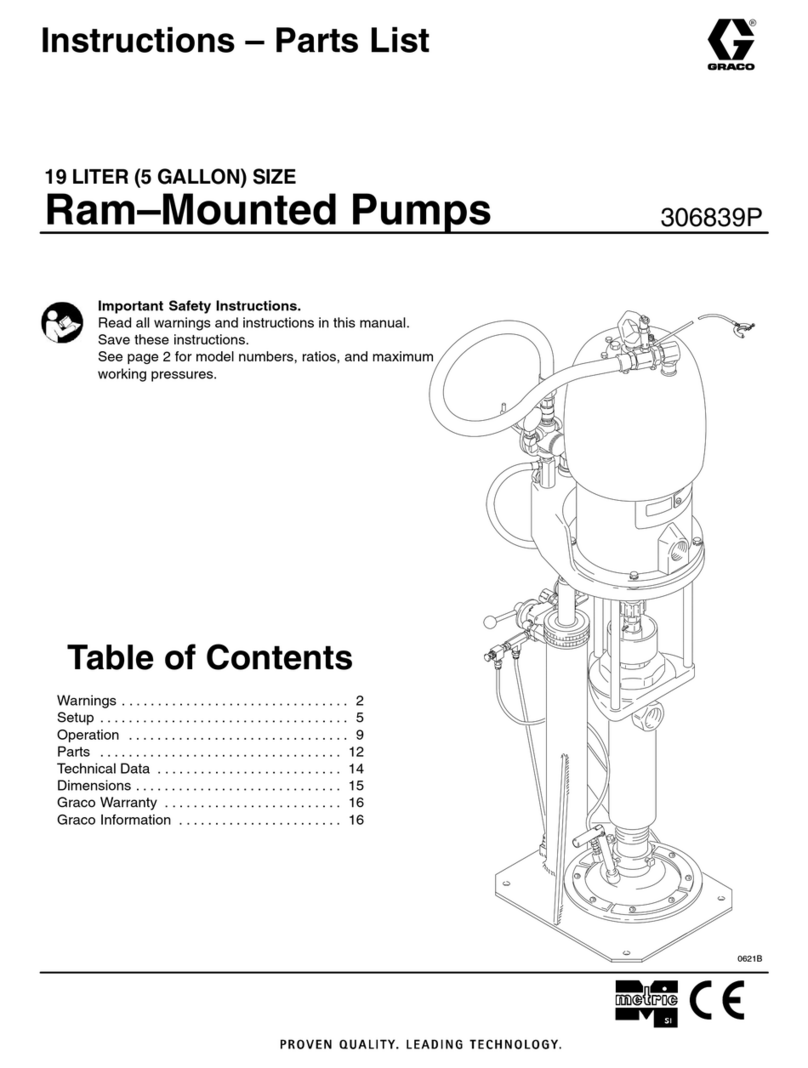

9.2. RF pump dimensions (monoblock)..............................................................................................................................20

9.3. RF pump dimensions (bare shaft)................................................................................................................................20

9.4. Exploded drawing of RF pump.....................................................................................................................................21

9.5. Cross section of RF pump (monoblock).......................................................................................................................22

9.6. Parts list of RF pump (monoblock)...............................................................................................................................22

9.7. Cross section of RF pump (bare shaft)........................................................................................................................23

9.8. Parts list of RF pump (bare shaft)................................................................................................................................23