Integra LifeSciences MAYFIELD Infinity XR2 A2079 User manual

Manufacturer:

Integra LifeSciences Corporation

4900 Charlemar Drive, Building A

Cincinnati, OH 45227, USA

Tel: 513-533-7979

Fax: 513-271-1915

integralife.com

Integra LifeSciences Services

Immeuble Séquoïa 2

97 allée Alexandre Borodine

Parc Technologique de la Porte des Alpes

69800 Saint Priest - France

Tel: 33 (0) 4 37 47 59 10

MAYFIELD® Infinity

XR2 Base Units

(A2079, A2079E)

Instruction Manual

1

Table of Contents

EN – English� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �2

FR – Français � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �21

IT – Italiano � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �41

DE – Deutsch � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �61

ES – Español� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �81

NL – Nederlands � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �101

EN – English

2

Meaning Of Symbols Used In This Manual - ENGLISH

CAUTION!

Hazards which could result in equipment or property damage.

WARNING!

Hazards which could result in severe personal injury or death.

Caution, consult accompaning documents

Product complies with the requirements of MDR 2017/745

Manufacturing site

European Representative

Caution: Federal (USA) Law restricts this Device to sale by or on the order of

a Licensed practitioner

Product catalog number

This device is not indicated for use in MR environment

No tools

Medical Device

EN – English

3

Inspection

Always inspect instruments before and aer use. If a component appears damaged and/or does not

seem to function properly, do not use the device and immediately send the instrument to Integra

LifeSciences, Cincinnati, Ohio or an authorized Integra repair center for evaluation, repair or

replacement.

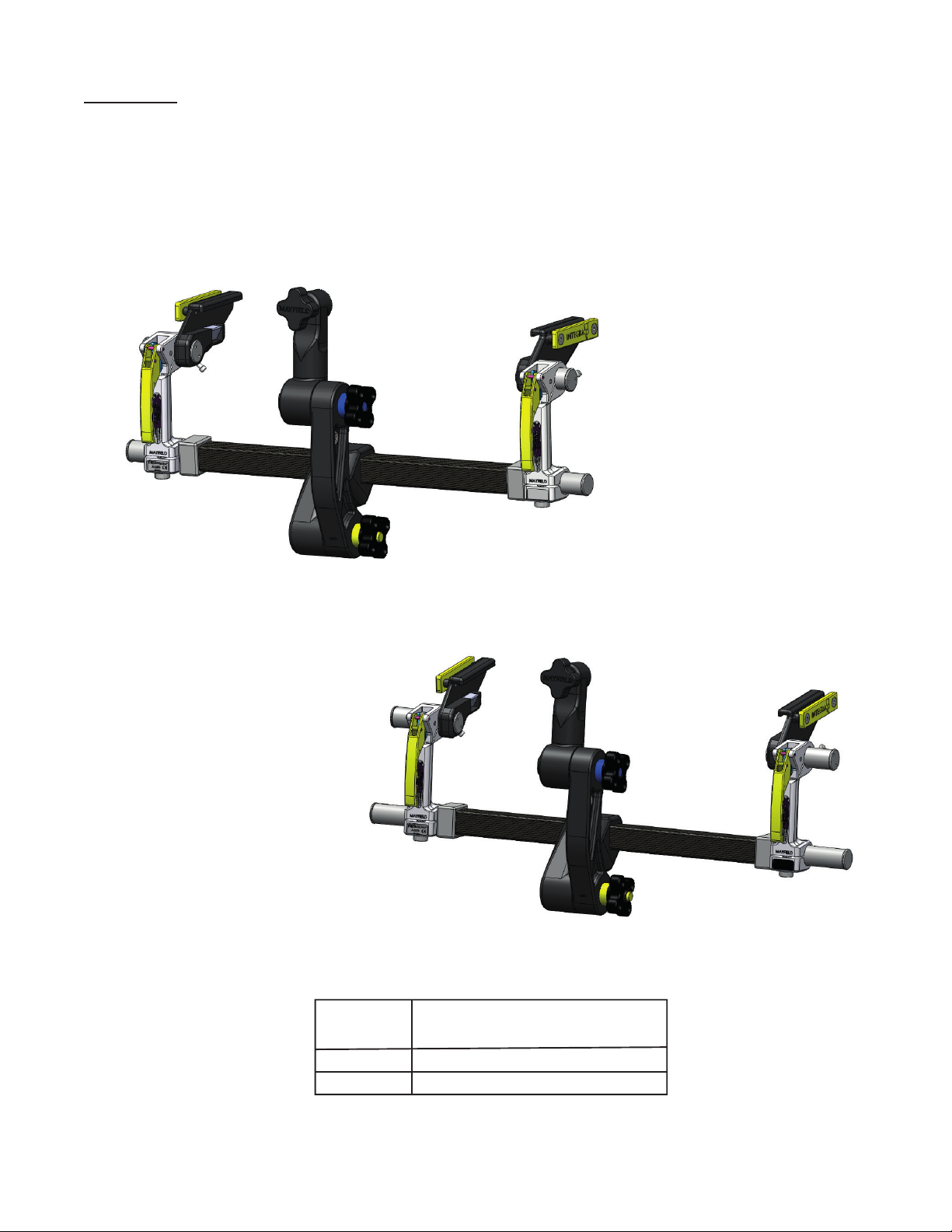

XR2 Radiolucent Base Unit, Standard 2079

XR2 Radiolucent Base Unit, Extended 2079E

Item No. OR Table Width(s)

(Side rail to side rail)

A2079

A2079E

19.5in to 24in (49.6 cm to 61 cm)

22in to 28in (55.9 cm to 71.1 cm)

Figure 1 Infinity XR2 Base Unit Catalog Numbers

EN – English

4

1. Skull Clamp/Headrest Locking Knob

2. Swivel Adaptor

3. Link Arm Locking Knobs

4. Yoke

5. Crossbar

6. Base Handle

7. Side Rail Bracket

8. Locking Lever

9. Base Handle Adjustment Knob

10. Auxiliary Side Rail

11. Side Rail Bracket Locking Knob

4

10

7

6

3

3

5

2

9

1

811

Figure 1A A2079 Infinity XR2 Base Unit Components

EN – English

5

Indication For Use/Intended Purpose

The Infinity XR2 Base Unit is intended to be used to support a patient during diagnostic

examination and/or surgical procedures where a rigid support between surgical table and

headrest, or skull clamp is necessary, positional freedom is required and where X-ray imaging

modalities will be used.

WARNING!

Failure to read and follow instructions furnished in this product insert may result in

skull pin slippage and serious patient injury, such as scalp lacerations, skull fracture,

or even death.

Do not steam sterilize; components may be damaged by high heat leading to device

damage and reduced performance.

The headrest or skull clamp must be securely fastened to the base unit. Failure to

properly position patient and to fully tighten and secure all adjustable portions of

this or any similar device may result in skull pin slippage and serious patient injury,

such as scalp laceration, skull fracture, or even death.

The user must make sure that any threaded connections are secure and

starbursts have meshed (where applicable) aer adjustments are complete. Failure

to do so may result in serious patient injury.

CAUTION!

Always make sure the base unit is properly secured to the operating table.

The base unit must not be used if the device appears to be damaged or

functioning incorrectly.

Over-tightening the mechanisms adjustment screws may result in damage to the

unit.

Over extending or overloading the base unit may result in unintended

movement, shortened product life and/or damage to the unit.

Do not alter the construction of this device as it may result in serious patient injury.

Intended Population

MAYFIELD Skull Clamp fixation devices are not recommended for use on children under five (5) years of

age. Extreme caution should be exercised in pediatric cases because of the thin skull.

EN – English

6

Description

The MAYFIELD®Infinity XR2 Base Unit is designed to provide aachment from the operating room

table to MAYFIELD Skull Clamps for rigid skeletal fixation or MAYFIELD Horseshoe Headrests for proce-

dures where support only is required and not rigid fixation. The XR2 Base Unit is designed for patient

positioning in the prone, lateral or supine positions for aachment to either a skull clamp or a

horseshoe headrest. It aaches to the OR table side rails with easy adjustment for tables of a variety of

widths.

The Infinity XR2 Base Unit is suitable for Digital Subtraction Angiography (DSA), Fluoroscopy and CT

imaging modalities.

The components of the XR2 Base Unit are color-coded for easy assembly for use and disassembly for

cleaning and storage. A separate storage case is provided with the base unit for safe-keeping between

procedures and for use to ship the product in for repair or maintenance.

A separate, optional Tri-Star Swivel Adaptor (A2111) is available for use with the XR2 Base Unit when im-

age-guided surgery (IGS) systems are used in the procedures. The Tri-Star Swivel Adaptor provides two

extra starbursts for aachment of the ancillary IGS equipment. See the separate Instruction

Manual for the A2111 for information.

The Infinity XR2 Base Unit is designed for use with the following equipment:

A2114 MAYFIELD Infinity XR2 Skull Clamp

A2002 MAYFIELD 2000 Radiolucent Skull Clamp

A2111 MAYFIELD Infinity XR2 Tri-Star Swivel Adaptor

A1058 MAYFIELD Radiolucent Skull Clamp

A2010 MAYFIELD Radiolucent Horseshoe Headrest

A2011 MAYFIELD Pediatric Radiolucent Horseshoe Headrest

437A2224 5 inch XR2 Extension Arm Assembly (12.7 cm)

437A2225 7 inch XR2 Extension Arm Assembly (17.8 cm)

NOTE: Use of MAYFIELD products and accessories in conjunction with other

manufacturer’s stabilization equipment is not recommended.

The MAYFIELD Infinity XR2 Base Unit (A2079) includes:

(1) MAYFIELD XR2 Base Unit

(2) MAYFIELD XR2 Link Arm Assembly 437A2222

(3) MAYFIELD XR2 Swivel Adaptor 437A2400

EN – English

7

Set-up Instructions:

1. Yoke (Yellow tip to Link Arm Locking Knob with Yellow Sleeve)

2. Link Arm Assembly

3. Swivel Adaptor (Blue tip to Link Arm Knob with Blue Sleeve)

3

2

1

Figure 2 Base Unit Set-up

EN – English

8

Aachment to Operating Room Table

1. Open Base Unit Locking Levers.

2. Loosen knobs on link arm assembly.

3. Grasp auxiliary side rails on the side rail brackets and carefully place unit on the table’s side rails.

4. Align Base Unit with the operating table side rails and slide on.

5. Ensure operating table side rails protrude fully through the Base Unit auxiliary rails and lock into

place by tightening the side rail bracket locking knobs.

NOTE: For best alignment results, ensure the operating table side rails protrude evenly on both

sides of the Side Rail Brackets.

Tighten Side

Rail Locking

Knobs

Operating

Table

Side Rail

Side Rail

Bracket

Open Locking Levers

Loosen

Link Arm

Knobs

Side

Rail

Brackets

Figure 3 Mounting Base Unit to Operating Table

EN – English

9

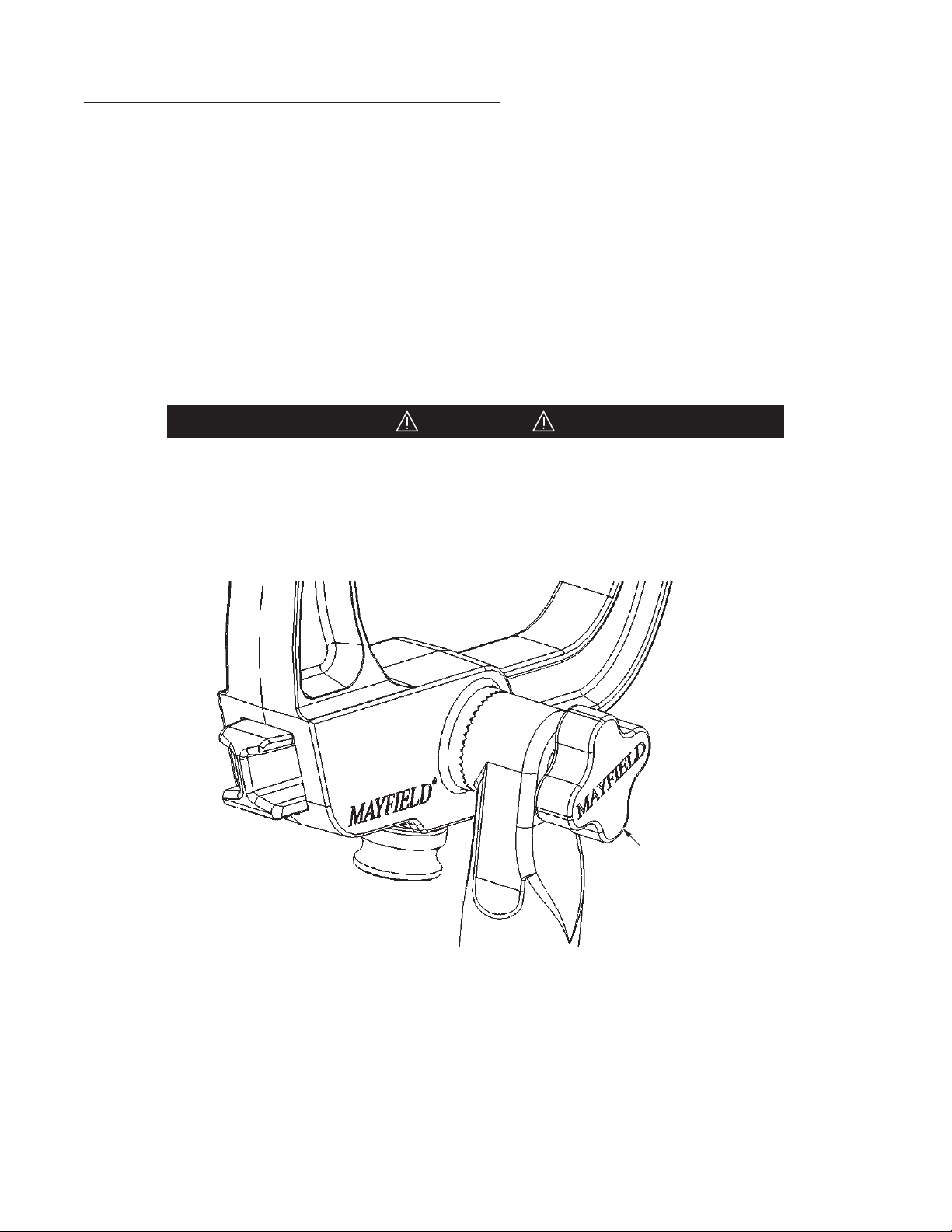

CAUTION: Keep fingers clear of hinge points when closing the Base Unit

Locking Levers. See Figure 4 below. It is recommended that the levers be closed using the

palm of the hand.

Figure 4 Locking Mechanism

CAUTION: Always be sure the Locking mechanisms are secure aer

completing table adjustments. Verify that the Locking Lever is secure by

confirming that the Latch is engaged.

EN – English

10

Aachment of The Skull Clamp to The Base Unit

Once the skull clamp is applied to the patient’s skull, the surgeon will maneuver the patient to the

surgical position that is required for the procedure. With the patient in this position, the surgeon will

hold the patient’s head and the skull clamp and request that the components for the base unit be

brought up for aachment.

1. The base unit should be brought up for aachment to the skull clamp. The mounting screw of

the large starburst on the swivel adaptor should be inserted into the large starburst of the skull

clamp and turned clockwise and tightened. Care should be taken to maintain the position of the

patient’s head as requested by the surgeon.

2. Securely fasten the skull clamp to the MAYFIELD base unit by aachment to the Swivel Adaptor.

Close Locking Levers. Turn clockwise all of the Locking Knobs of the other components of the

base unit making certain all starburst teeth are fully meshed (where applicable) on all joints of

the base unit aer adjustments are complete.

CAUTION!

Before fully tightening, always be certain that the starburst teeth of the Swivel

Adaptor and other starburst fiings are the same size and properly mesh.

Failure to do so may damage fiings. Figure 5 shows a typical starburst connection

and proper meshing of teeth.

Skull Clamp/Headr

est

locking knob

of the Swivel

Adaptor

Figure 5 Aachment of Skull Clamp

EN – English

11

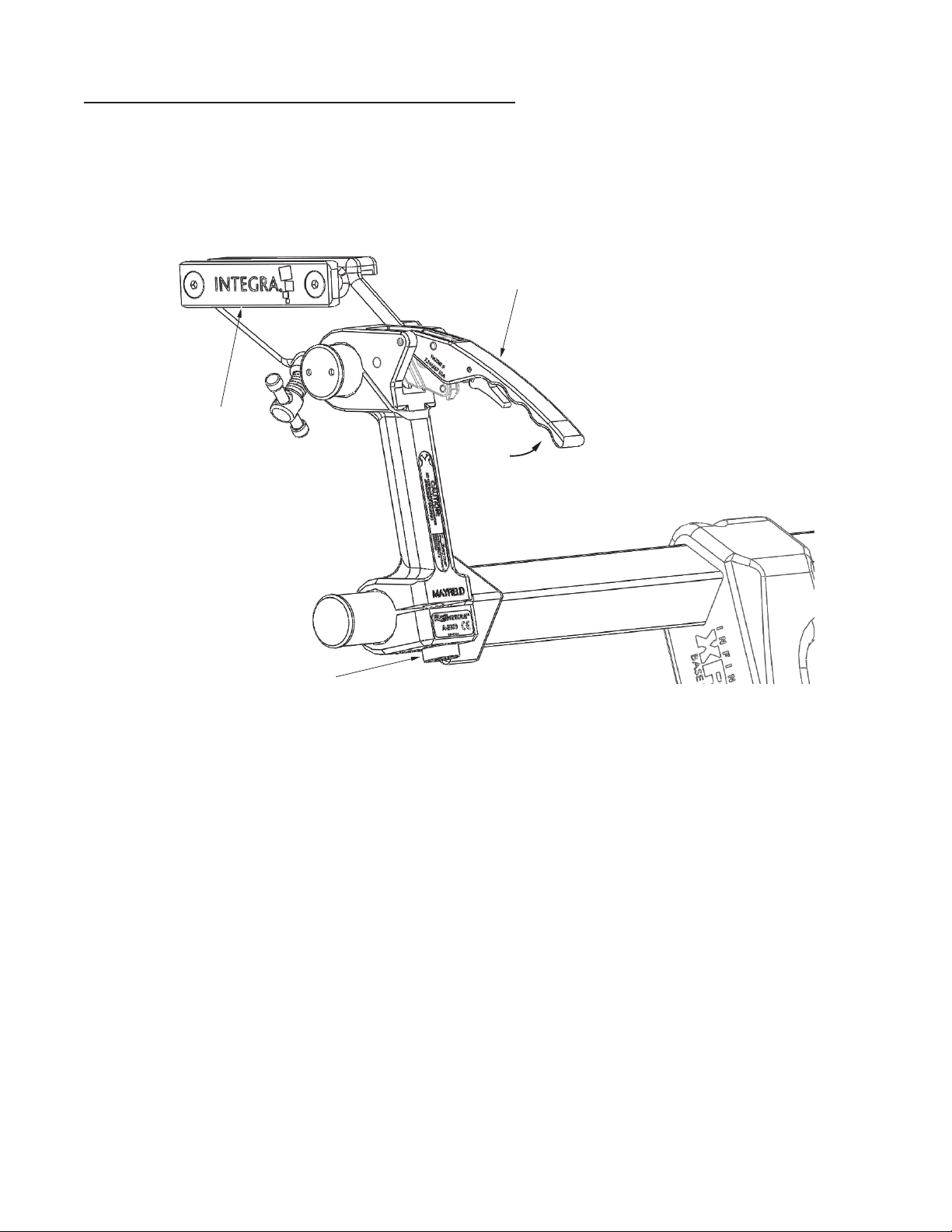

Aachment of Accessories (A2111 Tri-Star Swivel Adaptor)

1. Position base unit Swivel Adaptor to desired position.

2. Insert the XR2 TriStar Swivel Adaptor retaining screw into the Link Arm Locking Knob and rotate

knob clockwise.

3. When the XR2 TriStar Swivel Adaptor is set to the desired position, engage starburst teeth and

turn the Link Arm Locking Knob clockwise to secure.

NOTE: Refer to the Tri-Star Swivel Adaptor Instruction For Use manual for proper use and care.

Link

Arm

Lockin

g

Knob

Link

Arm

XR2

TriStar

S

wivel

Adaptor

Starburst Teeth

Figure 6 Mounting XR2 Tri-Star Swivel Adaptor

EN – English

12

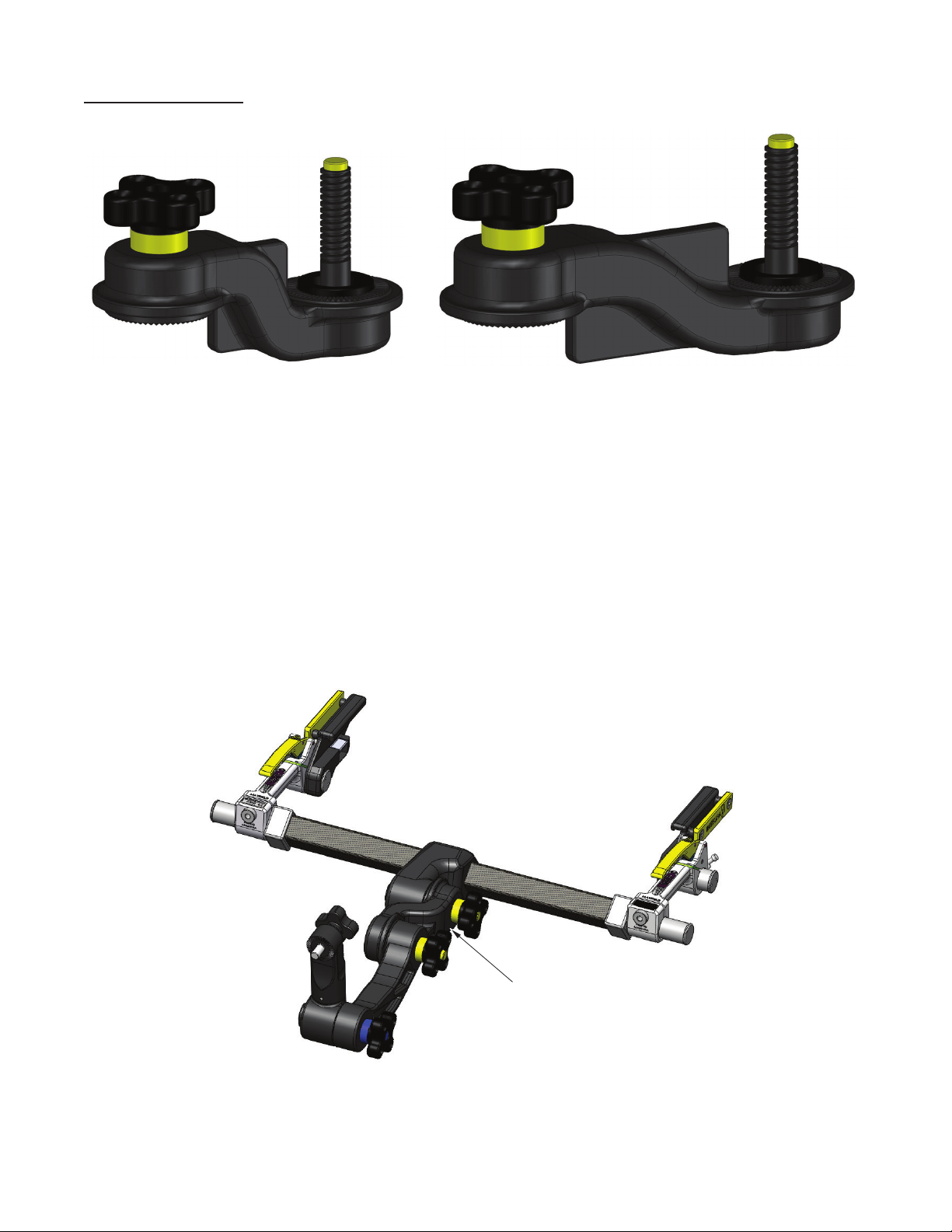

Optional Products

5 inch Extension Arm (437A2224) 7 inch Extension Arm (437A2225)

Figure 7 XR2 Extension Arm Assemblies (5 Inch (437A2224), 7 Inch (437A2225))

The MAYFIELD XR2 Extension Arm Assemblies can provide an additional 5 inches (12.7 cm) or

7 inches (17.8 cm) of reach to the components of the XR2 Base Units (A2079, A2079E). Using one of the

extensions will allow the non-radiolucent components of the XR2 base unit to be positioned away from

metal-sensitive imaging systems. Interfacing with some of the new intra-operative imaging systems

can be easier with these new Extension Arm Assemblies.

Note: By design, only one of the Extension Arm Assemblies can be used at a time.

7 Inch Extension Arm (437A2225)

Figure 8 XR2 Base Unit shown with the 7 Inch Extension Arm (437A2225)

EN – English

13

Cleaning of the MAYFIELD Infinity XR2 Base Unit

Follow the cleaning instructions outlined in the Cleaning of the MAYFIELD Infinity XR2 Base Unit.

WARNING!

Do Not Steam Sterilize! The carbon Fiber material and plastic components may be

damaged by heat.

Following these steps is recommended:

1. Remove base unit from operating table support rails.

2. Remove Swivel Adaptor, and Link Arm Assembly from base unit

3. The Infinity XR2 Base Unit should be thoroughly cleaned aer each use. Scrub each component

with a so brush and use only a pH-neutral detergent. Clean thoroughly to remove any traces

of blood and/or debris and to prevent such blood or debris from interfering with function or

movement. Rinse thoroughly with clean water.

4. Dry all components with a so dry towel.

5. Aer components are totally dry, re-assemble the components. Unit is ready for next use.

EN – English

14

Optional Automatic Wash Cycle:

CAUTION!

Any deviation from this guideline could result in damage to equipment as well as

improper cleaning results. Parameters given below must be followed exactly in order

to assure proper cleaning and avoid damage to the equipment.

• Disassemble the device as indicated in section Cleaning of the MAYFIELD Infinity XR2 Base

Unit.

• Rinse components under warm tap water prior to placing in washer.

• Arrange device in a way to avoid contact between components.

• Select instrument cycle and ensure proper programming.

Table 1 Instrument Cycle

Phase Time in minutes Water

Temperature

Detergent type &

Concentration

Pre-Wash 1 04:00 Cold tap H2O N/A

* Hot Tap water not to exceed 82.2C

** Optional phase for disinfection of components

Thermal Rinse**

Rinse 1

Wash 1

Enzyme Wash 04:00

10:00

00:30

02:00

Hot tap H2O*

60° C

Hot tap H2O*

82.2° C

Endozime® AW

Triple plus w/

A.P.A., 1:128 ratio

Renu-Klenz™,

1:256 ratio

N/A

N/A

Table 1 Instrument Cycle

• Remove from washer and dry completely if needed.

• Inspect all components to ensure there is no visible organic debris or residue from cleaning

agent. Repeat process if any visible debris or residue is detected.

EN – English

15

Disinfection

Further disinfection of device components may be achieved using one of the following methods.

Method 1: Chemical

• With device cleaned and still disassembled, wipe all surfaces with sterile gauze moistened with

70% Isopropyl Alcohol (IPA). Be sure to achieve even coverage on all surfaces.

• Assure the device stays wet with the 70% IPA for a minimum of 10 minutes.

• Dry the device with a sterile lint free cloth or blow dry with filtered pressurized air.

Method 2: Thermal Rinse

• A Thermal Disinfection phase maybe added aer the rinse cycle as indicated in table 1.

Maintenance and Care:

The Infinity XR2 Base Unit should be returned to its storage case aer each use.

NOTE: Ensure all components have completely dried aer cleaning before returning to case.

CAUTION!

If unit is dropped or mishandled, it should be inspected for damage.

(REF Inspection section of this instruction manual) If damage occurs, do not use;

return the complete device immediately to Integra LifeSciences for inspection.

The life expectancy of the MAYFIELD products is expected to be as long as 7 years.

To ensure proper function and to extend the life and performance of the equipment, Integra

LifeSciences recommends the following:

Recommended Action Recommended Frequency

Return the device to the Integra LifeSciences Repairs

department for detailed inspection and servicing.

Once / year

Request that Integra NeuroSpecialists perform routine

inspections of the device.

Twice / year

In the absence of proper care and servicing of the device, negative effects may be seen aer repeated

processing over time which may lead to reduced performance.

Contact information: See the Service and Repair section for contact information on how to return your

device for periodic servicing and to request periodic inspections.

See Inspection and /or Service notes section for routine checks to be performed on the device.

NOTE: Any serious incident that has occurred in relation to the device for the user and/or the patient

should be reported to the manufacturer and the competent authority of the member state in which the

user and/or patient is established.

Device Disposal

NOTE : Follow hospital procedures for disposal of this device.

EN – English

16

Inspection of Components

A routine inspection of the components of the MAYFIELD Infinity XR2 Base Unit should be made before

each and every procedure to assist in keeping it in good functional condition and to avoid problems the

day of surgery. This check should include the following:

1. Check to see that all the components of the base unit are available for assembly. Use the

Inspection section of this Instruction Manual for a complete list of components. ALL

components must be available and ready for assembly or the base unit should not be used.

2. Check the adjustment of the base locking handles by following these steps.

a. Aach the base unit to an OR table and lock to the side rails.

b. Raise the Crossbar to be even with the top of the OR table, locking the handles.

c. With your hands on either ends of the Crossbar, push down on the Crossbar aempting to

move it. If with minimal force, the Crossbar moves, adjustment to increase the locking power

of the Locking Handles should be made as outlined in this manual.

d. If the handles are too hard to close, adjustment to decrease the locking power of the Locking

Handles should be made as outlined in this manual.

3. With the Locking Handles unlocked and all the components aached but loose, raise and lower

the base unit, rotating all joints. All should freely rotate without any “ratcheting” noise

(starburst teeth hiing together as rotated). If this ratcheting noise is heard, loosen the joint

that is causing the noise.

4. Check the other components for function

a. Again, with the base unit Crossbar raised to be level with the top of the OR table, lock the

locking handles.

b. Lock the link arm locking knobs

c. Verify that all starbursts are fully engaged and locked

d. With these knobs locked, the total base unit should be locked into place and no movement

should be seen.

e. Exert force to each component to detect any movement. There should be no lateral or

rotational movement with the knobs of the Link Arm totally tightened. If movement is seen,

re-tighten the knobs and check again.

5. Perform visual check of all components (Start at one side of the base unit and systematically

review each component as you make your way to the other side to assure that you do not miss a

component)

a. Check all connections to be free of debris that might impair the function of that component

or the one that connects to that component.

b. Examine all components for cracks on all surfaces.

c. Check the side rails to be securely fastened to the Side Rail Brackets

d. Check that the Shock Cushion is present and in proper position on both Locking Handle

assemblies.

e. Slide the yoke from side to side on the crossbar to make certain that the surface is smooth

and free of debris or anything that would impede its movement.

EN – English

17

Base Locking Lever Handle Adjustment Procedure

Periodically it is necessary to adjust the tension in the Base Handle Assemblies to compensate for

changes due to normal use.

1. Open Locking Lever. For safety, the tension Adjustment Knob is not adjustable while the Locking

Lever is closed.

Locking Lever

Auxiliary Side Rail

Tension

Adjustment Knob

Locking

Lever

Opened

Figure 9 Opening Locking Lever

EN – English

18

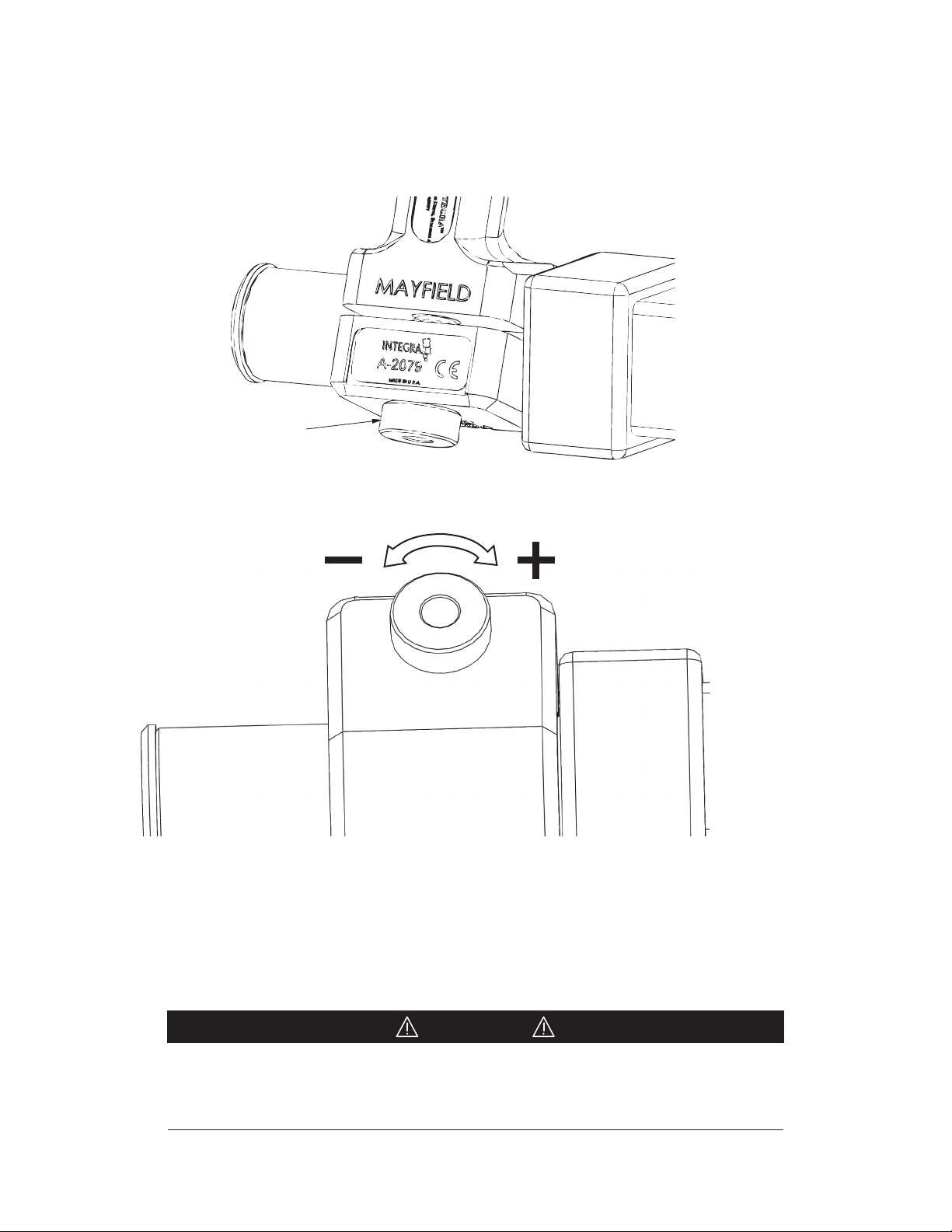

2. Grasp the Adjustment Knob and pull it away from the Locking Bracket to unlock.

3. Holding the Adjustment Knob in its unlocked position, rotate it in the desired direction to

adjust tension. Clockwise (+ plus) direction to increase tension, or Counterclockwise (- minus)

direction to decrease tension.

Adjustment Knob

Increase Locking

Lever Tension

Decrease Locking

Lever Tension

Figure 10 Adjustment Knob

4. Test the operation of the handle. With the Locking Lever fully opened, the Locking Bracket

should rotate freely. With the Locking Lever closed, the Locking Bracket should not rotate.

NOTE: Once the desired seing is achieved confirm the Adjustment Knob is in the locked, seat-

ed position.

CAUTION!

It is possible to adjust the handle to the point that the Locking Lever requires

excessive force to close. Do not exert excessive force as this may result in damage

to the device if the lever is forced closed.

This manual suits for next models

1

Table of contents

Languages:

Other Integra LifeSciences Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual