Intelligas 100 Series User manual

Intelligas takes every care in ensuring these products reach you in perfect working order.

Each system is tested on dispatch and site induced damage is easily detectable.

Ensure the operation of this unit is explained fully to the kitchen staff.

24 hour technical support line - 02381 290444

100 Series Gas Ventilation

Interlock System

INTELLIGAS

Gas safety & control systems

INSTALLATION

GUIDE

intelligas.co.uk

INSTALLATION

GUIDE

100 Series Gas Ventilation Interlock System

INTELLIGAS

Gas safety & control systems

Introduction

Thank you for choosing an Intelligas product. Please follow these instructions to ensure a safe, functional and

long-lasting installation.

This information is important and should be read and understood before attempting installation.

If you are unsure of the terminations and their design voltages or function then refer to this guide or our technical

support line, you can call 02381 290444 or you can text 07952269791 and we’ll get back to you as soon as we’re

available.

Siting the panel

Choose a suitable mounting position for the control unit. Mount the unit away from sources of extreme heat. Ensure the panel is

placed in a position where mechanical damage is unlikely and where it can be easily accessed for use and maintenance.

Fix the panel using the marked enclosure holes only. Take care not to damage the internal wiring or PCB of the unit when drilling.

Under no circumstances should wiring be routed behind the PCB of the control panel.

Control panel supply

All our control panels (except the KVM-SF) should be supplied via a fused spur connection unit. The fuse should be changed to one

that’s rated at 5amps.

KVM-SF ONLY if the panel is supplying the fans directly from the PCB then it should be supplied via a 16amp single phase isolator.

If the panel is controlling Inverters and only the output signals are being used then, as above, the panel should be supplied by a 5amp

fused spur.

intelligas.co.uk

INTELLIGAS

Gas safety & control systems intelligas.co.uk

Field wiring

All wiring from the supply and to the gas valve carries mains voltage (230v ac nominal). The current edition of the IEE Wiring

Regulations should be strictly adhered to, wiring and connections should be made by a suitably qualified electrician or competent

person.

The field wiring voltage to the interlock inputs is reduced to 24 volts, do not connect mains to the air pressure switch terminals,

e-stop, analogue input/output 0-10v control, gas detector or fire alarm terminals.

Please follow the first fix wiring schedule set out below:

1) Main supply 2 core + E 1.5mm (as per regulatory requirements)

2) Gas valve 2 core + E 1.5mm (as per regulatory requirements)

3) Pressure switches 2 core + E 1.5mm (YY type cable)

4) Fire alarm interlock (if req) 2 core + E 1.5mm (FP type cable)

5) Emergency stops 2 core + E 1.5mm (YY type cable)

6) Gas detection equipment, If fitted, 3 core screened (CY type cable)

7) Gas pressure switch, if fitted, 2 core + E 1.0mm (YY type cable)

8) 0-10v signal wiring, if fitted, 2 core 1.0mm (CY type cable)

Where multiple supplies enter a control panel, perhaps in a current sensing interlock. It is preferable that each supply is on the

same phase. If this can’t be achieved, then additional warning labels should fixed in a suitable location on the control panel.

The advice given on these instruction pages, specifically to cable types and ratings may change depending on cable lengths and

installation conditions. If you are not sure about any of the cable types or ratings then contact our technical support team.

INSTALLATION

GUIDE

100 Series Gas Ventilation Interlock System

Peripheral items installation

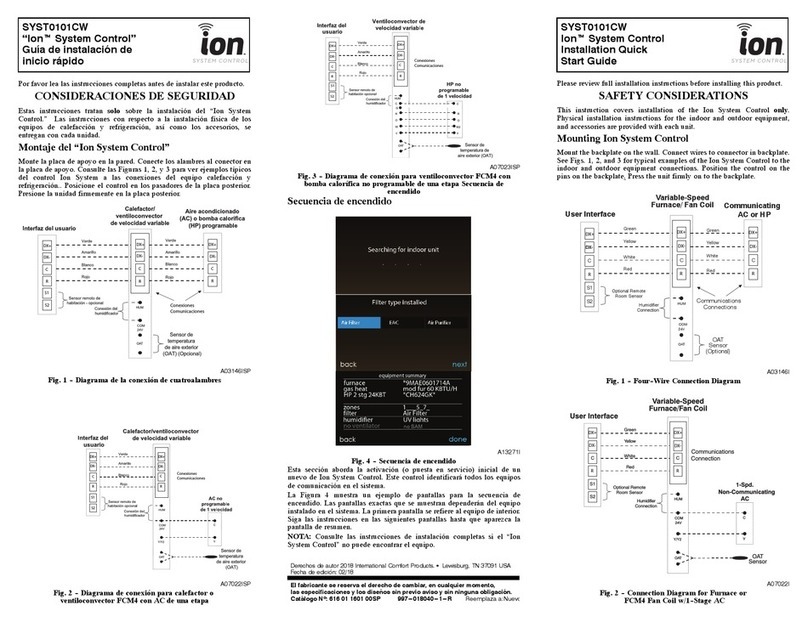

Airflow switches (electrical installation)

For airflow pressure

switches use PCB

terminals marked either

intake or extract fan,

these interlocks have a

time delay in the

software to prevent the

effects of pressure

switch flutter.

For emergency stop switches use PCB

terminals marked Estop

Fire alarm interface (if used)

If fire alarm interface is not to be used then

link as shown.

This termination is low voltage and no isolation

relay between the Intelligas panel and the

building fire alarm is required.

1

23

P2

Airflow direction.

Site sensor in negative air*

*suction side of fan

INSTALLATION

GUIDE

100 Series Gas Ventilation Interlock System

Flow DirectionFlow Direction

On to appliances

or gas taps

To comply with gas regulations manual

isolation points, purge points and test

nipples may be required. This drawing is

for information only and the necessity of

the above items should be checked to

ensure compliance with the current

regulations.

INTELLIGAS

Gas safety & control systems intelligas.co.uk

Intelligas gas proving system mechanical layout

INSTALLATION

GUIDE

100 Series Gas Ventilation Interlock System

Installation Schematic

- basic install, shown in kitchen Mains rated wiring 2 core

Mains rated wiring 2core + earth

KEY

PANEL

Air flow pressure switch,

repeat on fresh air make up

fan if fitted (always try to site

in negative pressure)

To Fire Alarm panel

if required.

230v power

supply

Main valve

Gas solenoid must be installed by

gas safe engineer

COOK LINE

APPLIANCES

CANOPY

Remote emergency

Stop buttons

intelligas.co.uk

INSTALLATION

GUIDE

100 Series Gas Ventilation Interlock System

Commissioning

Double check all terminations have been made and checked for tightness, check all peripheral equipment such as emergency stops

and pressure switches are connected and the covers are in place. The power may now be applied

After initial power up start all fans and set any speed controllers to minimum, assuming the minimum fan speed still satisfies

minimum ventilation levels in the kitchen continue and set the pressure differential switches. This can be done by slowly increasing

the Pascal setting on the pressure differential switch until it clicks off, then turn it back down in 5 Pascal increments waiting 30

seconds each time until it makes again. Repeat this procedure for each pressure switch installed.

Once the pressure switches have been set up and all emergency stops are reset press the reset button, the two top LEDS will show

green and the unit will beep 3 times to indicate that all the interlocks are ok. The bottom LED will illuminate amber requesting the

reset button to be re-pressed to enable the gas valve. Once re-pressed the bottom LED will change to green to show the gas valve

output is energised.

There is a delay on the fan pressure switch inputs, this is to overcome high winds momentarily effecting the operation of the switch,

the panel will show any fault immediately as it happens but the gas will not be shut off or warning beeper operated until the 20

second timer has elapsed

The unit is now commissioned and ready for use.

24 hour Technical Support 02381 290444

INTELLIGAS

Gas safety & control systems intelligas.co.uk

INSTALLATION

GUIDE

100 Series Gas Ventilation Interlock System

Table of contents

Other Intelligas Control System manuals

Popular Control System manuals by other brands

Digitroll

Digitroll SEED MASTER Plus 8.6 Series user manual

Varifan

Varifan MSC-10 user guide

Leviton

Leviton Dimensions D3200 System installation manual

Kemper

Kemper KHS Mini System Control Installation and operating instructions

Varifan

Varifan IC-68ND installation guide

BECKWITH ELECTRIC

BECKWITH ELECTRIC M-6280A Instruction book

Meritor

Meritor TACTX HMIS Maintenance manual

Bentel Security

Bentel Security EasyGate 3 Installation and user manual

Laguna Tools

Laguna Tools SmartShop Maker owner's manual

Rain Bird

Rain Bird Freedom System for Maxicom2 user manual

Sutter Instrument

Sutter Instrument Lambda 10-2 Operation manuals

Niko

Niko Semaphor manual