MSC-10

Page 8

5. Electrical Grounding. The shields of all cables should be connected

the MSC-10 power ground only, except for the cable connected to a PC

interface (PCI-20 or RCM-40) where the shield should be connected as

instructed in the PCI-20 or RCM-40 document.

6. Safety Control Backup. The use of a safety control backup is

strongly recommended to ensure a safe environment. The use of an alarm,

warning device or other backup devices which can detect equipment failure,

blown fuses and/or tripped breakers would help prevent harm or damage to

the content of the building. The safety control backup wiring (see Figure 2-1)

and the following guidelines are given for a safety control backup:

a) Backup Power Source. A backup relay (DPDT) connects to the

power source 1 in normal operation but will switch to the power

source 2 if the source 1 is disabled. The backup relay should be

selected to ensure it is capable of supporting the power load

required.

b) Backup Thermostat. It is also strongly recommended

to put a thermostat to at least one fan in parallel to the MSC

module output. If the Multistage Computer fails,

the backup thermostat will activate the dedicated fan at

full speed when the temperature will reach the set point

of the thermostat. The thermostat should be accessible

for its adjustment and should be set at 3 to 5 degrees

above the fan relative set point.

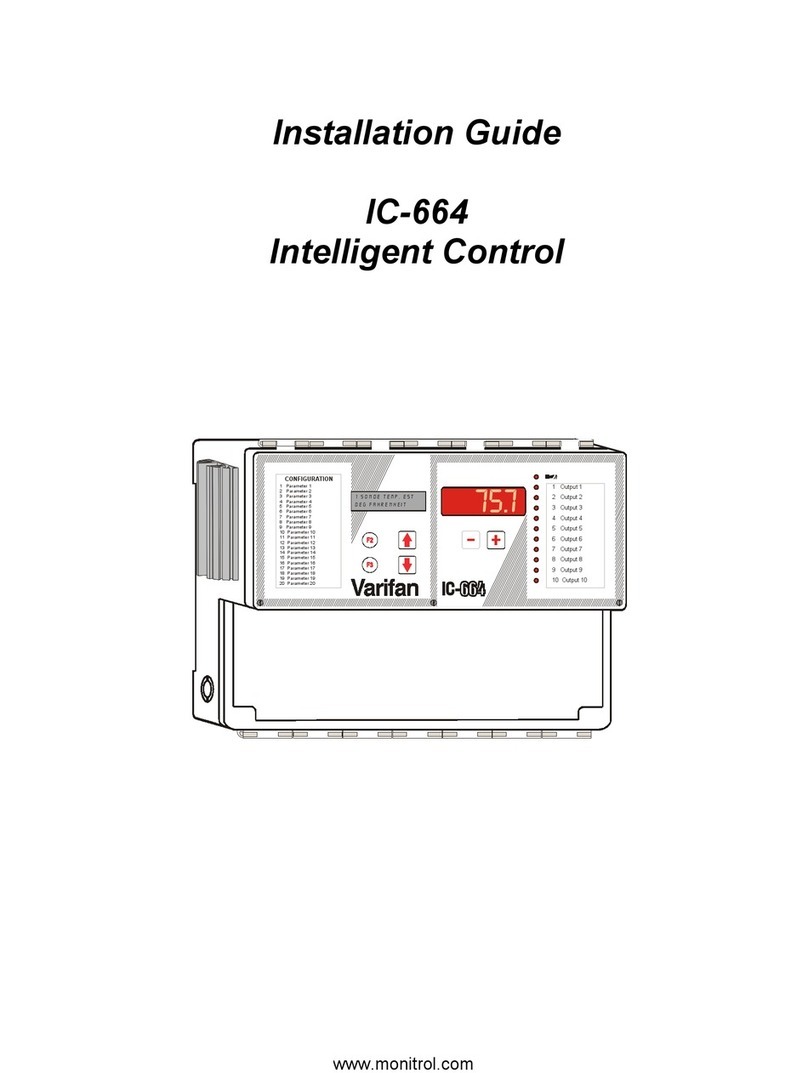

7. Terminal Block Connections. The MSC-10 terminal block is

equipped with numbered connections for ten control modules. Each module

must be connected (wired) to its proper terminals. Refer to the configuration

documents and wiring diagrams supplied for your equipment.

NOTE

Each multistage computer is shipped with a configuration

document and its wiring diagrams to show the connection

points of each control module and sensor. The correct

sequence of the various stages require the modules to be

connected in their proper order.

Chapter 2 - Installation