Digitroll SEED MASTER Plus 8.6 Series User manual

SEED MASTER

Plus

(version 8.6x and 8.7x)

DIGITROLL

SEED MASTER

Plus

seeding control system for

PLANTERS

USER’S MANUAL

DIGITROLL Ltd. Tel: +36 52/ 557-480 Web: www.digitroll.hu

Fax: +36 52/ 557-482 Email: info@digitroll.hu

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

910 11 12 13 14 15 16

SENSORS

ALL-IN-ONE

IN TE L L I G EN T S EN S O R T E C H N OL O GY

STOP

DIS PLAY

TEST

INFO

A

B

C

D

100%

150%

50%

0%

OUT

A B C D

+1

L

R

max.

STOP

DIGITROLL

86000 */ha

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

Ã

Å

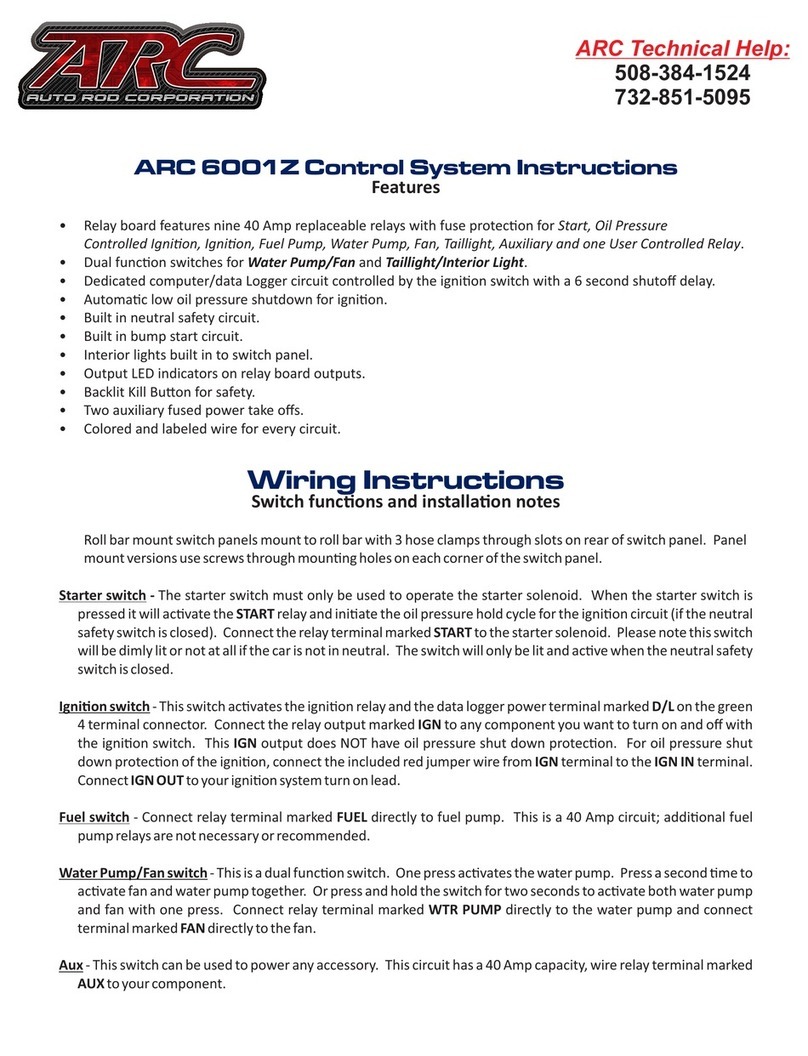

SYSTEM DRAFT

2

SYSTEM DRAFT

Seeding control system for planters 1-16 rows with area counter

AKKU

PIROS KÉK

OPTO MODUL

OPTO MODUL

SPEED MODUL

OPTO MODUL

OPTO MODUL

OPTO MODUL

3.1. 2. 4. MAX.

16.

RADAR-II

DSI-18J

RAD/HIR/4

5m

2m

6m

DA 02

SPEED MODUL

12VDC

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

910 11 12 13 14 15 16

SENSORS

ALL-IN-ONE

IN TELL IGENT SEN SO R TE CH N OL OGY

STOP

DISP LAY

TEST

INFO

A

B

C

D

100%

150%

50%

0%

OUT

A B C D

+1

L

R

max.

STOP

DIGITROLL

86000 */ha

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

Ã

Å

DS 1000 -custom designed for seeder type, placed in seed tube

DS 2000 - custom designed for seeder type, placed in coulter

RED

BLUE

3

CONTENT

SYSTEM DRAFT ........................................................................................................... 2

GENERAL DESCRIPTION ........................................................................................... 4

MOUNTING ................................................................................................................... 6

MONITOR FRONT ........................................................................................................ 7

SWITCH ON .................................................................................................................. 7

SYSTEM TEST .............................................................................................................. 8

MENU ............................................................................................................................. 9

SETTING BASIC DATA ............................................................................................. 10

MONITOR SETTINGS ................................................................................................ 13

CONTROL OF SEEDER SETTINGS .......................................................................... 14

SEEDING CONTROL .................................................................................................. 16

STORED SEEDING DATA ......................................................................................... 19

DISTANCE MEASUREMENT ................................................................................... 20

TROUBLESHOOTING ................................................................................................ 21

MAINTENANCE, STORAGE ..................................................................................... 24

WARRANTY PROVIDED .......................................................................................... 24

GENERAL DESCRIPTION

4

GENERAL DESCRIPTION

SEED MASTER

Plus

MONITOR

· illuminated LCD display

· massive aluminium housing

· audible and visual alarms

· adjustable horn volume

· 8 selectable languages

· nonvolatile memory for safe storage of measured and adjusted data

SYSTEM CONSTRUCTION

· infrared sensation

· connected in linear string system up to 16 rows

· modules are exchangeable, their sequence is determined automatically

when connected

· harness-free network - easy cabling and mounting

SYSTEM TEST

Sensordiagnostics.

· automatic recognition and readiness test of photosensors

· dusty or blockaged sensor display

CONTROL OF SEEDER SETTINGS

· Statistics of 100 expected/seeded grains

· Average seeded grains (Population ratio control)

SEEDING CONTROL

· Simultaneously detected seeding continuity on all rows

· Selectable seed dize and shape

· Adjustable missing seed time interval for error signal

· Skip continuously unused rows

· display hold function helps analyze actual seeding situation

· Individually adjustable seed spacing for each row

· Seed counting

· Easy to use seeding blockage control mode. Unnecessary any settings.

· Population ratio control with bar diagram

· row display setting

HECTARE COUNTING

· Measure and store total and partial seeded area to 999,99 ha

· Distance measurement to 65 000 m

· Start/stop measuring by signal of photosensors

· If photosensors are not applied, the counting is continuously.

GENERAL DESCRIPTION

5

STORED SEEDING DATA

· Number of seeded grains

· Hectare

· Average population/hectare

SYMBOLS APPLIED

*

Seed

B

Recognized photosensor

N

Dusty photosensor

x

Fully endusted, clogged or defected photosensor

.

Skipped row

Oo

Small, large grains (for DS 2000 photosensors)

J

Bar diagram for population ratio control

M

Total area

L

Partial area

RS

Horn volume

TU

Tractor

The seeding control system and its technical characteristics described in this manual

are under patent process.

Any means of recording or public use of principles, images, system drafts are subject

to prior written contribution of DIGITROLL Kft.

MOUNTING

6

4-6 mm

Útjeladó

Csavarfej

MOUNTING

MONITOR

Place the monitor on a clearly visible place in the tractor cabine and fix it with

the U-bracket and bolts, up or bottom position to avoid direct sunlight on

LCD. The display is illuminated which enables nighttime use with superb

visibility

• The monitor is connected optimally after a fuse (max. 3A) on 12 VDC,

taking care of the right polarity.

• Connect the extension cable of moduls to the monitor.

• Do not connect in line with other disturbing signal emitter

devices.

• Welding works are allowed only when both power cables of

the monitor are disconnected from the tractor’s electronic

system.

SPEED SENSOR FOR HECTARE COUNT

Mount speed sensor in front of a non-slipping wheel.

The best is a freewheel which sized to give at lest 1

signal in a distance traveled between 0,2 – 0,99 m.

The speed sensor gives you information about the

distance traveled.

Speed sensors are inductive sensors, in proximity of an iron part e.g. bolt

heads give a signal. If distance between sensing bolt heads would be more

than 1 meter, additional bolt signallers has to be mounted. This way, during

calibration the distance traveled in 100 bolt signals remains under 100 meters.

Checking operation:

• red LED at the end of speed sensor

• a symbol of speed sensor is blinking on monitor front

Important: when planning the placement of speed sensor regard the risk

Very important to adjust speed

sensor within the sensing distance,

generally between 4-6 mm from bolt

head.

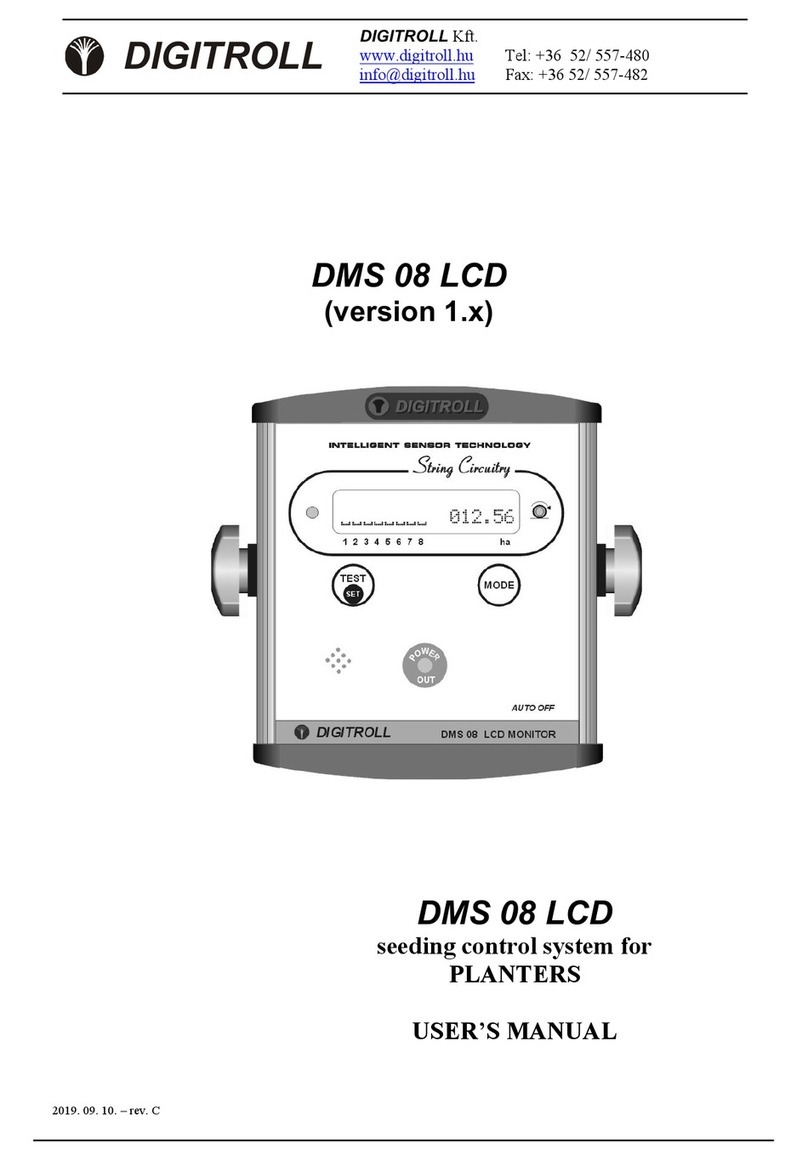

MONITOR FRONT

7

Seed Counting Pro

v8.71

DIGITROLL Ltd.

of straw residues or pebbles, they may hurt the sensor.

MONITOR FRONT

Every push of a button is accompanied by a short beep in case the button is

operative in that function.

SWITCH ON

Then appear the system test, which is followed by the display of test

results.

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

910 11 12 13 14 15 16

SENSORS

ALL-I N-ONE

IN TEL LIG EN T S EN SO R TEC H N OLO GY

STOP

DISP LAY

TEST

INFO

A

B

C

D

100%

150%

50%

0%

OUT

A B C D

+1

L

R

max.

STOP

DIGITROLL

86000 */ha

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

ÿ

Ã

Å

wheel-LED

display

hold

system

test

population ratio

control

information,

data entry

seed stoppage

control

horn

spin up &

down

settings

module current

supply control

LED (blinks or

get dark when

shortcut

occurs)

>

RS...

>

<Normal >

Jf?e

~

20.0 cm

TU<J* * *

J>

Following switch on the console presents

running software version,

selected horn volume,

seed spacing values,

and offers instant setting options.

SYSTEM TEST

8

SYSTEM TEST

The system test is executed:

• every switch on,

• by pressed button on screen of any seed control mode

• automatically by change settings of photosensors.

During test process the monitor detects:

• which modules are connected to the system (photosensors, speed

module),

• what is the readiness for operation of connected photosensors

(operability, dust level check),

• Sends data to adjustable modules (DS2000).

Having the test finished, the ‘found’ modules are presented on display:

After photosensor test the seed blockage control screen appears. After

simply switch on, the monitor is ready to control seeding blockage! This

function is available without entering any date. See detailed description at

the CONTROL OF SEEDING BLOCKAGE.

TEST

SENSOR

TEST

.........

* No photosensors!

1 2 3 4 5 6

1.50 sec

x N

B B B B B B

B Operating sensor

N dusty sensor

x seeding blockage

TEST function may be used when there is

no seeding in progress!

unsuccessful test result

MENU

9

MENU

INFO

POPULATION RATIO

DISPLAY, ACTUAL

SEED/HA

PARTIAL SEEDS AND PARTIAL

AREA

AVERAGE SEED/HA

TOTAL SEEDS AND TOTAL

AREA

AVERAGE SEED/HA

ENTRY OF WORKING WIDTH

SETTING OPTIMAL SEED

SPACING

Normal or Hybrid

SETTING MIN. AND MAX.

LIMITS FOR POPULATION

CONTROL

SELECTION OF SEED

SEED SIZE SHAPE

ENTRY OF DISTANCE

TRAVELED IN 100 SPEED

SIGNALS

100 SPEED SIGNAL COUNT

SETTING DISPLAY

LANGUAGE SELECTION

ADJUSTMENT OF HORN

VOLUME

CONTROL OF SEEDING

BLOCKAGE ADJUSTABLE

SENSITIVITY

STATISTICS OF 100

SEEDED GRAINS

2 sec.

TE S T

STATISTICS OF 100

SEEDED GRAINS

2 sec.

TE S T

DISTANCE MEASUREMENT

SETTING ROW SKIP

SETTING BASIC DATA

10

SETTING BASIC DATA

SETTING OPTIMAL SEED SPACING

Two options are available:

Normal

One spacing value can be entered.

Hybrid

Select hybrid spacing when seed spacings are not desired to be the same in all

rows. The monitor program gives here the option to set individual spacing

value for each row.

Spacing value can be set directly after switch on, too.

SETTING MIN. AND MAX. LIMITS FOR POPULATION

CONTROL

c Maximum limit: alarms when population get over set value.

d Minimum limit: alarms when population get under set value.

Disable audible alarm: c151%

d0%

Shift to Hybrid

STOP

DISPLAY

<Normal >

Jf?e~20.0 cm

TU<J* * *

J>

Spinner up & down

Adjustment between 3,0 - 45,0 cm

Shift to Normal

STOP

DISPLAY

<Hybrid >

f?e~20.0 cm

1. * *

<BGBBBBBBBBCCCCCC>

Spinner up & down

aRS >

e120%c90000 */ha

100%= 75000 */ha

< 80%d60000 */ha>

Shift between

values

TE S T

Spinner up & down

SETTING BASIC DATA

11

SELECTION OF SEED SIZE AND SHAPE

In order to reach more precise seed detection when using DS 2000

optomodules, main seed characteristics like size and shape must be entered. It

brings more efficiency in recognition of double or triple seed drops.

Changes made in this menu are followed by a system test.

EDITING ROW SKIP

In case rows equipped with photosensors are temporarily not in use,

continuous alarm can be embarrasing. To eliminate this problem, switch off

control in that row.

After system test all connected sensors are displayed (regardless of being

switched on or off).

However, skipped rows are not involved in seeding control and are indicated

by a (.) character.

SEEDING ROW DISPLAY SETTING

Enhanced visibility can be reached by doubling the distances of the displayed

seed sensors on screen (up to 8 rows).

If seeder has more than 8 rows, a short warning alarms you at expansion

attempt. This case the program automatically reset short row display.

Selection of seed shape

(round or long)

DS2000 *: 6-9mm>

DS2000/HR

DS2000/HR *: o >

Selection of seed size

(3-5 / 6-9 mm)

<

BBBHBB..BBBB 4>

STOP

DISPLAY

Row skip on/off

Step row

BBBBBBBBe

12345678 >

B B B B B B B Bf

1 2 3 4 5 6 7 8 >

SETTING BASIC DATA

12

ENTRY OF WORKING WIDTH

Seeding machine working width is adjustable between 0.75-30 metres

This constant is needed for area count.

Working width can be calculated: row number multiplied by row spacing.

100 SPEED SIGNAL COUNT

This is a side function to get information about distance traveled in 100 speed

signals.

Pull/tow seeding machine on field until 100 speed signals are counted, then

measure distance traveled between 0. and 100. signals with a measure

tape on the ground. Enter distance value in the monitor in centimeters. A

warning beep sounds from 90. speed sensor signal to slow down.

Speed sensor is an inductive sensor which detects bolt heads of a driven

wheel.

In case of individual installation the number of signalling bolt heads must be

enough to provide at least one signal at every 30-60 cms distance traveled

and it may not exceed 100 cms.

Readiness for operation is indicated by a flashing SPEED SENSOR LED

on the monitor. Accurate measurement can be reached if speed sensor exactly

aligns bolt head when starting calibration. Besides signal counter on screen

watch this red LED as well, which shows you how sharply the sensor aligns

the bolt head, both at start and end points.

Measurement of distance traveled between 0-100. speed signals:

JX>

TU<J|? 4.50 m

JY

>

Spinner up & down

TU

100|Ü------------|0

START>

TU

100|Ü------------|0

START>

TU

100|Ü------------|0

100

START>

0.

90.

100.

Nomber of speed

signals =

Distance travelled = ??? cm

Csavarok

wheel sensor

START

SLOW DOWN

STOP

MONITOR SETTINGS

13

• In case of individual installation find a possibly non-driven wheel for

speed sensor, where slip rarely occurs.

• In order to reach maximum accuracy in calibration take soil conditions,

tyre pressure, hopper weight (ideally half filled),...etc. into consideration

to create similar conditions to real circumstances.

• Adjust distance between DSI-18 speed sensor (M18 thred) and bolt head

to 4-5 millimeters and consider accidental lateral wheel movement, as

well.

• Proper speed sensor adjustment has vital importance, it should signal at

the proximity of each bolt head. LED indicates it by blinking both on the

sensor and the monitor!

SETTING OF DISTANCE TRAVELED IN 100 SPEED SENSOR

SIGNAL

The distance traveled can be determined either:

• by MEASUREMENT: with a measure tape ( it is always more

accurate method since average slip is also included)

• by CALCULATION: × wheel perimeter (cm)

MONITOR SETTINGS

ADJUSTMENT OF HORN VOLUME

LANGUAGE SELECTION

TU ? >

|Ü------------Û|

60.0 m

>

spinner up &

down

>

RS))..

>

Magyar

Change language>

100

number of

bolt heads

The program enables the selection of

one language out of the 8 followings:

Hungarian, Slovakian, Ukrainian,

English, German, French, Italian,

Spanish.

CONTROL OF SEEDER SETTINGS

14

CONTROL OF SEEDER SETTINGS

STATISTICS OF 100 EXPECTED/SEEDED GRAINS

To reach this function push button for at least 2 seconds.

The appliance calculates the seeding time of 100 seeds on the basis of the

given distance, the optimal seed spacing and current speed. During this time it

counts tha actual number of the seeds in each row (in max 6 rows), and it

monitors the distance between the seeds while giving feedback. The result is

displayed after the measuring time is up.

M*- total measured seeds

** - number of double seed drops

*O- number of missing seeds

Holding the constant speed precisely is a condition of exact masuring

The data of the next row is visible after each measuring cycle.

While measuring the appliance also counts the seeds and measures the

hectares.

v8.6x program

Rows can be stepping manually only between two measure.

v8.7x program

The measuring is paused by pressing button. Row stepping manually is

possible only at this time.

TE S T

<STOP 100 opt.* TU

M*:000 f-

**:000

*O:000 2.>

step row

STOP

DISPLAY

2 sec.

TE S T

STOP

DISPLAY

pause

< 100 opt.* TU

M*:000 fM

**:000

*O:000 2.

< 1. 100 opt.* TU

M*:000 f-

**:000

*O:000 Start>

STOP

DISPLAY

step row

The measuring is started by

keypress.

The measuring is

continuous.

CONTROL OF SEEDER SETTINGS

15

If time interval between seed drops is smaller than expected:

• Use of unsuitable seed disk results homogenous, but too dense seed

drops. This case the program does not interpret it as double drop, but

the number of measured seeds will be higher than 100.

• Too high vacuum causes the pick up of two or more seeds in one seed

disk hole. Incorrect singulator adjustment leads to similar problems

that result in multiple seed drops. This case time interval between

drops is very close, the program indicates double drop and seed count

is also more than 100.

If interval (=distance) between seeds is more than double of expected, the

program interpret is as missing seed. Actually either seeds are missing or

seed spacing is inhomogeneous.

To determine real problem source, total seed count can help:

• Total seeds are around 100: inhomogeneous seed spacing (improper

seed separation, hindered seed drop…etc.)

• Total seeds are less than 100: seeds cannot be picked up from seed

feeder (inadequate air pressure, low hopper level, wrong selection of

seed disk hole diameter…etc.

In case of mixed symptoms (both multiple seed drops and missing seeds) total

seed count may indicate the resultant of the two factors.

STATISTICS OF AVERAGE SEEDED GRAINS

In order to observe seeding homogenitiy in a longer period and analize related

seeder settings, an effective tool is the bar graph display method. The monitor

collects and displays data on the average of 40 m.

Numeric values of rows are accessible by pushing button repeatedly.

Analizing these data even slowly developing processes, tendencies can be

observed (loosing pressure, lowering seed level in hopper, increasing dust

layer on photosensors…etc.).

(See detailed description at CONTROL OF POPULATION RATIO.)

STOP

DISPLAY

SEEDING CONTROL

16

SEEDING CONTROL

CONTROL OF SEEDING BLOCKAGE

The monitor simultaneously detects seeding continuity in all rows. Where seed

drop is missing for longer time than preset limit value, seed symbol of that row

(*) will disappear from display and alarm sounds in according length.

You can set missing seed time interval between 0.25 – 2.00 seconds in 6 steps.

During the turnings at landmarks alarm is disabled automatically.

This function mode is recommended when

• Small (less than 5 mm diameter), hardly detectable seeds are sown

• Necessary basic data are not entered in the monitor

• Speed sensor is damaged

• Sensor performance wanted to check at stopped seeder position

Push button to freeze display (alarm sounds haltingly) and analize actual

seeding situation even when seeding machine is stopped.

Example of display at a 6-row planter:

Missing time

interval

adjustment

STOP

DISPLAY

2.00 sec

****************

BBBBBBBBBBBBBBBB

STOP

DISPLAY

1 2 3 4 5 6

1.50 sec

* * * *

B B B B B B

Rows 1,3,5 and 6 are contineously

seeding within preset limit value.

In rows 2 and 4 seeds are missing within

the 1.5 seconds preset limit value.

SEEDING CONTROL

17

084500 */ha

JJJJJJJJJJJJJJJJ

JJJJJJJJJJJJJJJJ

CONTROL OF POPULATION RATIO

You can read the ratio of the desired and the actually measured population in

each row, displayed with bar graphs.

Use this function for seeds that can be detected precisely by the photoelectric

cells (seeds larger than 5 mm, such as maize, sunflower, sugar beet, etc)

Necessary basic data

• Optimal seed spacing

• Distance traveled in 100 speed signals

• Working width

Any measurement results true values only if basic data are entered correctly!

Start

:

Display

Do not mix up the actual seed/ha value displayed here with the total area seed/ha,

which is shown by pushing the INFO button! See also STORED SEEDING DATA.

Alarm

The monitor alarms you when difference goes beyond min. or max. limit

values. (See detailed description at SETTING MIN. AND MAX. LIMITS FOR

POPULATION CONTROL.)

If the row error is sustained, the audible error signal is continuously. If a row

is excluded from seeding, must skip it from controlling too. (See SETTING

ROW SKIP)

J

JDJ

When you start this function this screen

appears until sufficient data for displaying are

collected (cca.10 meters).

The accuracy of seeding can be surveyed

simply and visibly from 0-150 % with a

resolution of 6.25 %. Bar graphs and actual

seed/ha value are calculated over seeded

grains in cca. 40 meters distance traveled.

SEEDING CONTROL

18

Display hold

To ease analysis, display can be freezed (fixed) any time, even when seeder is

stopped.. In this case the monitor scans row diagrams and their values are

shown numerically.

Turning

Stoppage

An example of displaying on a 12-row planter:

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

STOP

DISPLAY

084500 */ha 3.

Á120%

JJJJJJEJJJJJJJJJ˙

JJJJJJJJJJJJJJJJSTOP

1 2 3 4 5 6 7 8 9 10 11 12

086000 */ha

D

JJ JJJJJJ JJ

JJJJJJJJJJBJJ

Push button again to

return seeding control mode.

J

JDJ

At landmarks, when every row stop

seeding, the console stores seeding data

and, according to preset limit time, displays

missing seeds and sounds alarm shortly.

When seeding is restarted the screen

displays saved data

084500 */ha STOP

˙

BBBBBBBBBBBBBBBB

If seeder stops or speed sensor is damaged,

the monitor delete screen display and

shows the symbol of population ratio

control and the fact of seeding stoppage.

• Rows 1,2,4,5,7,8,9,11 and 12 perform

seeding at 100%

• Row 3 seeds half quantity (cca. 50%)

• Row 6 overseeds with more than 19 %

• Row 10 stopped seeding

STOP

DISPLAY

STORED SEEDING DATA

19

STORED SEEDING DATA

SEEDED GRAINS AND AREA COUNTS

The SEED MASTER Plus monitor continuously measures here (and in both

seeding control mode) the seeded area and the number of total seeded grains.

The area count controlled (start/stop) by signals of photosensors. If

photosensors are not applied, the counting is continuously.

The seed/ha value, as a dividend of total seeded grains and total area, is

displayed after 0.5 hectares seeded area, until this point a “???” symbol

displayed.

You have the option to measure

¢ - Total (accumulated) and

¡ - Partial area.

Partial area counts and seeded grains are added to the totals and can be

cancelled together or separated.

In both cases area can be measured up to 999,99 hectares and relevant seeded

grain number up to 1 billion seeds.

Cancel data

• Push reset button continuously ( for cca.2 seconds), until the result of

cancellation appears on display.

• Seeded grains and area values are deleted together.

• Deleting partial area does not reset total area value.

• Deleting total area cancels partial area, too.

INFO

M: 221000 */ha

014884200 *

<0 067.39 ha

3Avarage seed/ha

3Seeded grains (rounded up to 100)

3Hectare

L: 221100 */ha

004884000 *

<0 013.25 ha

TE S T

DISTANCE MEASUREMENT

20

DISTANCE MEASUREMENT

The date of distance traveled in 100 speed signal is used here.

Measurement begins when START button pushed, appears new display on

screen, and it ends by the next push of the button.

Deletion of measured distance: push button lastingly for approx.2

seconds.

<0 TU

|Ü------------Û|

0 m

START>

STOP

DISPLAY

Deletion

up to 65.500 meters

<0 TU

|Ü------------Û|

600 m

STOP>

STOP

DISPLAY

This manual suits for next models

1

Table of contents

Other Digitroll Control System manuals

Popular Control System manuals by other brands

Distech Controls

Distech Controls DA-020S Series Hardware installation guide

GE

GE Mark VIe System guide

Toshiba

Toshiba TOSVERT VF-PS1 instruction manual

DEEP SEA ELECTRONICS

DEEP SEA ELECTRONICS DSE8610 MKII Operator's manual

Arjo

Arjo Alpha Active 4 Instructions for use

Mitsubishi Electric

Mitsubishi Electric AT-50B Instruction book