10 MSK-101| Advanced configuration manual v1.8 APR 2019 |msk-101_advanced-config_en_wo v1.8|© 2017-2019 Inxpect SpA

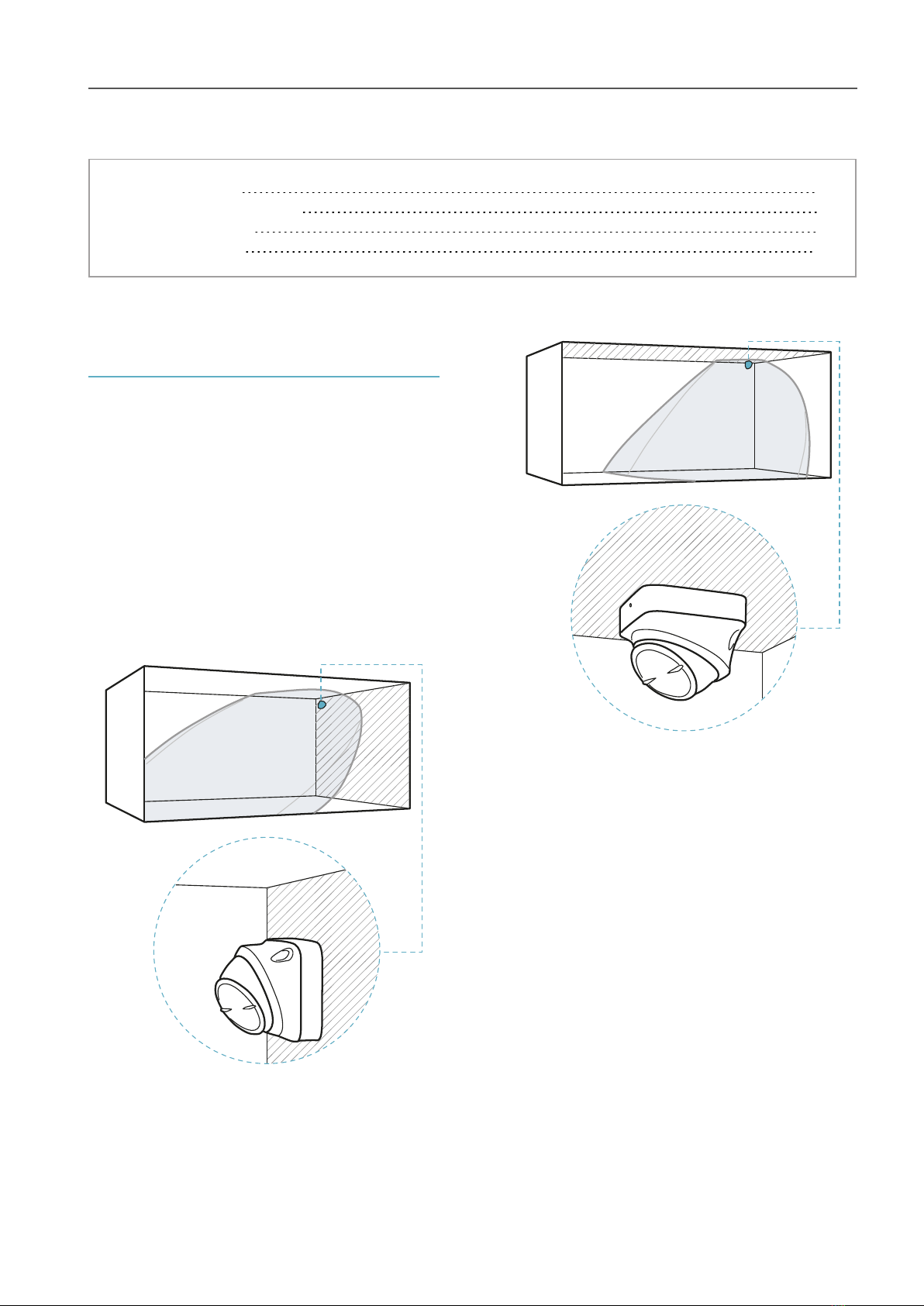

Side view.

2.3.2 Range of the field with

vertical sensor direction (barrier)

In this installation the visual field of the sensor is

approximately 30° along the horizontal plane and

70° on the vertical plane. It extends for a

maximum of 20 m, following the radiation pattern

of the antenna.

Top view.

Side view.

2.3.3 Calculation of the field of

vision

The actual field of vision of the sensor (detection

start and end, s1and s3) depends on:

lsensor installation height (h)

lsensor direction (horizontal or vertical)

lsensor inclination (α)

Within the field of vision, discernment of animals

is guaranteed up to a certain distance from the

sensor (s2). For details about discerning animals,

see "Set the tolerance level for animals" on

page24.

Based on a specific installation height, there are

direction and inclination combinations that

guarantee optimum performance. Some

examples to better explain the effects of height

and inclination are presented as follows.

2.3.4 Sensor installation height

The sensor can be installed at any distance from

the plane to be monitored, from 0.5 and 3 m

(from 1.6 to 10 ft). For example, it can be installed

at 2 m from the floor or 0.5 m from the jamb of

the window frame.

When installing the sensor, consider the risk of a

blind spot: if the sensor is too high, it must be

tilted downwards to reduce the undetected area.

However, this also reduces the maximum

detected distance. If the sensor is too low, the

blind spot is minimal, but it increases the risk of

masking caused by accidental passage of people.

2.3.5 Examples of the field of

vision with horizontal sensor

direction (volumetric)

NOTICE: the detection start and end values do not

guarantee detection of a standing person. The

reported values may slightly vary based on the

installation conditions.

Note: only some heights are reported, but every

intermediate value is allowed and guarantees optimum

performance.

The dimensions of the field of vision expressed in

meters and feet are as follows.

h (m) α (°) s1(m) s2(m) s3(m)

1 0 0.5 * 20

1.5 0 0.5 20 20

2 -15 2.5 16 16

2 -30 2 7.5 10

2.5 -15 3 17 17

2.5 -30 2.5 7 10

2.5 -45 2 6.5 6.5

3 -30 2.5 7 10

3 -45 2 4.5 6.5

h (ft) α (°) s1(ft) s2(ft) s3(ft)

3.2 0 1.6 * 65

4.9 0 1.6 65 65

6.5 -15 8.2 52 52

6.5 -30 6.5 25 32

8.2 -15 9.8 55 55

8.2 -30 8.2 23 32

8.2 -45 6.5 21 21

10 -30 8.2 23 32

10 -45 6.5 15 21

Note *: discernment of animals is not guaranteed in the

entire field of vision.

2. Useful information for design