ENGLISH

2

1. TABLE OF CONTENTS

1.

TABLE OF CONTENTS....................................................................................................... 2

2.

GENERAL INFORMATION.................................................................................................. 4

2.1

S

COPE OF THE MANUAL

....................................................................................................... 4

2.2

I

DENTIFICATION OF THE MACHINE

......................................................................................... 5

2.3

D

OCUMENTATION ANNEXED TO THE MACHINE

....................................................................... 5

3.

TECHNICAL INFORMATION............................................................................................... 5

3.1

G

ENERAL DESCRIPTION

...................................................................................................... 5

3.2

L

EGEND

............................................................................................................................. 5

3.3

D

ANGER AREAS

.................................................................................................................. 6

3.4

A

CCESSORIES

.................................................................................................................... 6

4.

INFORMATION ON SAFETY............................................................................................... 6

4.1

S

AFETY STANDARDS

........................................................................................................... 6

5.

HANDLING AND INSTALLATION....................................................................................... 8

5.1

L

IFTING AND CARRYING THE PACKED MACHINE

..................................................................... 8

5.2

C

HECKING THE MACHINE ON DELIVERY

................................................................................ 9

5.3

U

NPACKING

........................................................................................................................ 9

5.4

E

LECTRIC CONNECTIONS AND GROUNDING

(

MODELS WITH CABLE

) ........................................ 9

5.5

F

EEDING BATTERIES

(

MODELS WITH BATTERY

)................................................................... 10

5.5.1

Batteries: preparation................................................................................................. 10

5.5.2

Batteries: installation and connection......................................................................... 10

5.6

T

HE BATTERY

-

CHARGER

(

MODELS WITH BATTERY

)............................................................. 11

5.6.1

Choosing the battery-charger..................................................................................... 11

5.6.2

Preparing the battery-charger.................................................................................... 11

5.7

L

IFTING AND HANDLING THE MACHINE

................................................................................ 11

6.

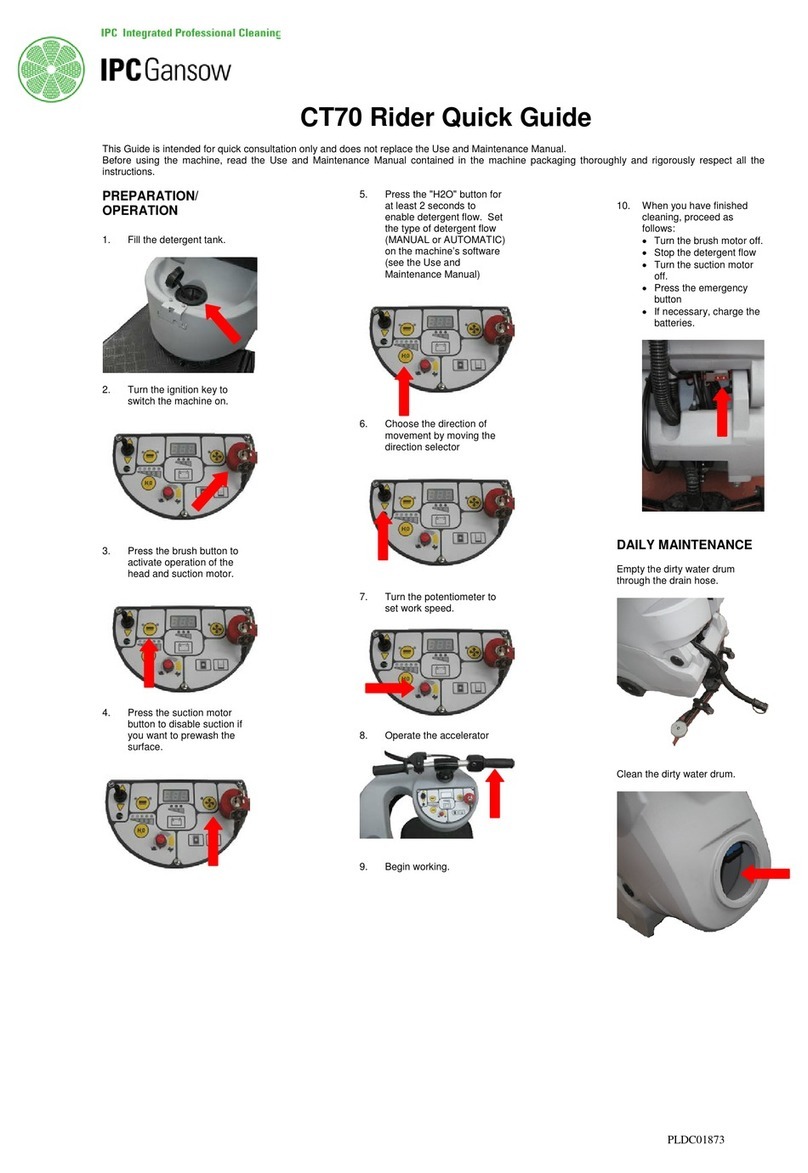

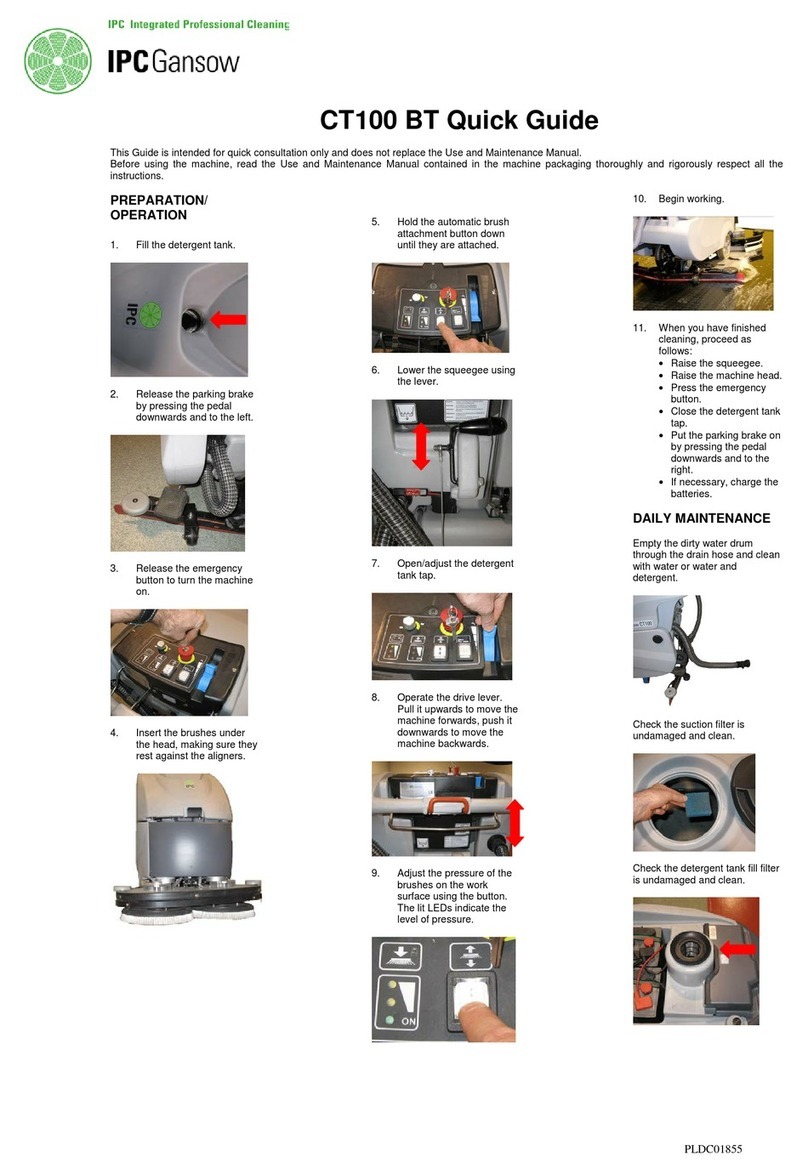

PRACTICAL GUIDE FOR THE USER............................................................................... 12

6.1

C

ONTROL DEVICES

-

D

ESCRIPTION

.................................................................................... 12

6.2

I

NSTALLING AND ADJUSTING THE SQUEEGEE

...................................................................... 13

6.3

M

OVEMENT OF THE MACHINE WHEN NOT OPERATING

.......................................................... 13

6.4

F

ITTING AND CHANGING THE BRUSHES

/

DRIVE DISCS

/

ROLLERS

......................................... 13

6.4.1 Brush head (models 50-55-60) .................................................................................. 13

6.4.2 Roller head (roller models R) ..................................................................................... 14

6.5

D

ETERGENTS

-

U

SE

.......................................................................................................... 14

6.6

S

ETTING UP THE MACHINE

................................................................................................. 15

6.7

W

ORK

.............................................................................................................................. 15

6.7.1

Additional functions (versions with electrical drive).................................................... 16

6.8

S

OME USEFUL SUGGESTIONS FOR THE OPTIMAL USE OF THE MACHINE

................................ 17

6.8.1

Pre-washing............................................................................................................... 17

6.8.2

Drying......................................................................................................................... 17

6.9

D

RAINING OFF DIRTY WATER

............................................................................................. 17

6.10

D

RAINING OFF CLEAN WATER

............................................................................................ 18

7.

PERIODS OF INACTIVITY................................................................................................. 18

8.

MAINTENANCE AND BATTERY RECHARGING ............................................................. 19

8.1

R

ECHARGING PROCEDURES

.............................................................................................. 19

9.

INSTRUCTIONS FOR MAINTENANCE............................................................................. 20

9.1

M

AINTENANCE

–

G

ENERAL RULES

..................................................................................... 20

9.2

R

OUTINE MAINTENANCE

.................................................................................................... 20

9.2.1

Suction air filter and floating rod: cleaning ................................................................. 20

9.2.2

Basket filter: cleaning................................................................................................. 20

9.2.3

Detergent solution filter: cleaning............................................................................... 20

9.2.4

Squeegee blades: replacement ................................................................................. 21

9.2.5

Fuses: replacement.................................................................................................... 21

9.3

P

ERIODIC MAINTENANCE

................................................................................................... 22

9.3.1

Daily maintenance...................................................................................................... 22