To reduce the risk of injury, use proper guards and use only accessories rated at least equal to the

maximum speed marked on the tool.

To reduce the risk of injury always wear eye protection

To reduce the risk of injury, use only accessories rated at least equal to the maximum speed

marked on the tool

To reduce the risk of injury, always use proper guards when working.

Fire hazard. Do not use in the presence of flammable liquids or materials.

Hold power tools by insulated gripping surfaces, when performing an operation where the cutting

tool may contact hidden wiring or its own cord.

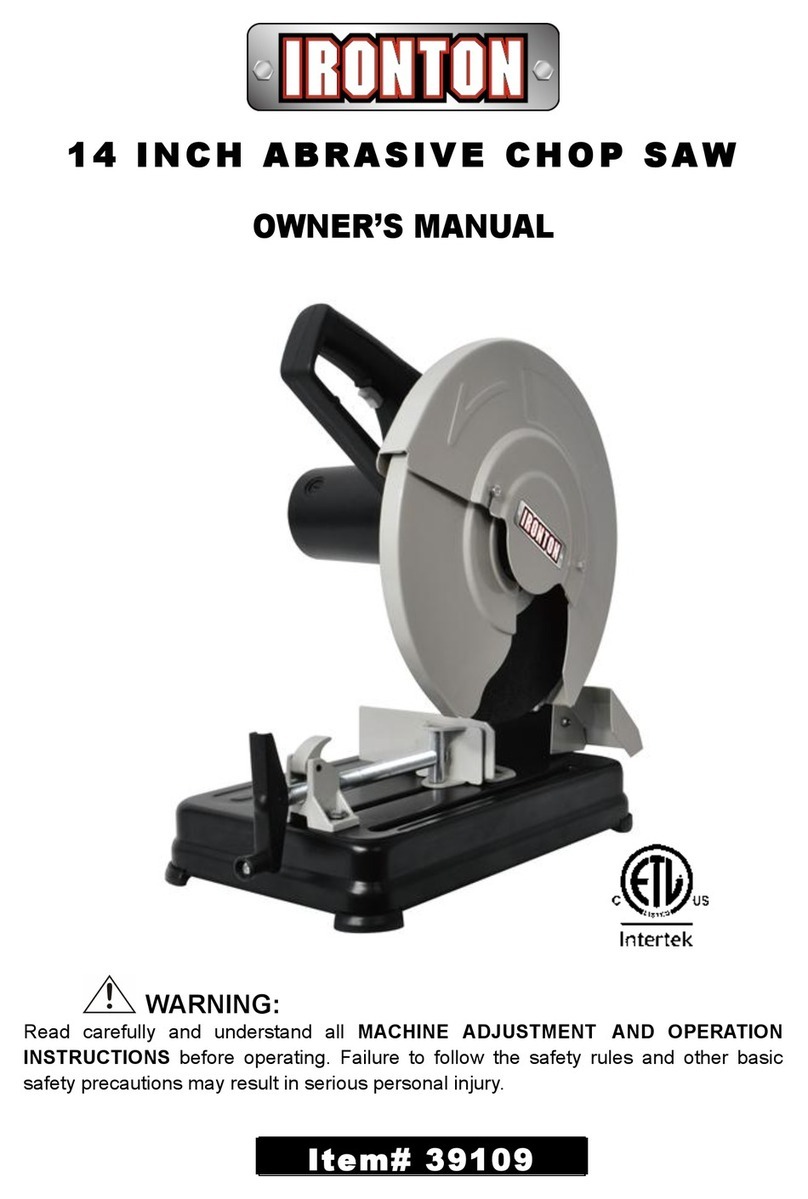

Do not use circular saw blades or any other toothed blades with this tool.

Avoid bouncing the wheel or giving it rough treatment. If this occurs, check the wheel for cracks or

damages.

The outside diameter and the thickness of your accessory must be within the capacity rating of the

saw.

The arbor size of wheels and flanges must properly fit to the spindle of the saw.

Position the cord clear of the spinning accessory.

Never lay the saw down until the accessory has come to a complete stop.

Kickback is a sudden reaction to a pinched or snagged rotating cutting disc. Pinching or snagging

causes rapid stalling of the rotating disc which in turn causes the uncontrolled saw to be forced in

the direction opposite of the accessory’s rotation at the point of the binding.

Maintain a firm grip on the saw and position your body and arm to allow you to resist kickback

forces. Always use auxiliary handle, if provided, for maximum control over kickback or torque

reaction during start-up.

When the cut-off disc is binding or when interrupting a cut for any reason, switch off the power tool

and hold the power tool motionless until the wheel comes to a complete stop. Never attempt to

remove the cut-off wheel from the cut while the wheel is in motion otherwise kickback may occur.

Do not position your body in the area where the saw will move if kickback occurs.

Use only wheel types that are recommended for the saw and the specific guard designed for the

selected wheel.

Always use undamaged wheel flanges that are of correct size and shape for the saw’s wheel.

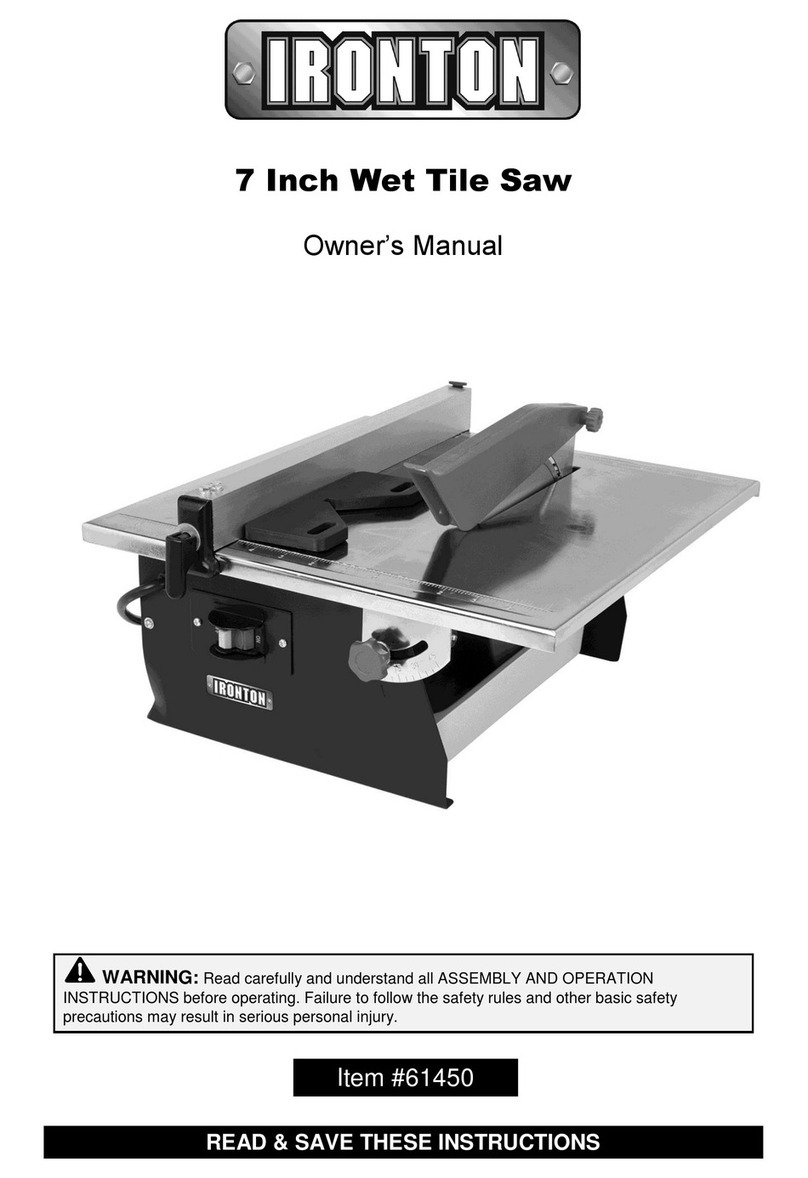

Do not use accessories that require liquid coolants.

Do not ″jam″ the cut-off wheel or apply excessive pressure. Do not attempt to make an excessive

depth of cut.