SHORT FOREWORD.......................................................................................................5

INTRODUCTION................................................................................................................6

1 TEST SET DESCRIPTION AND USE...................................................................9

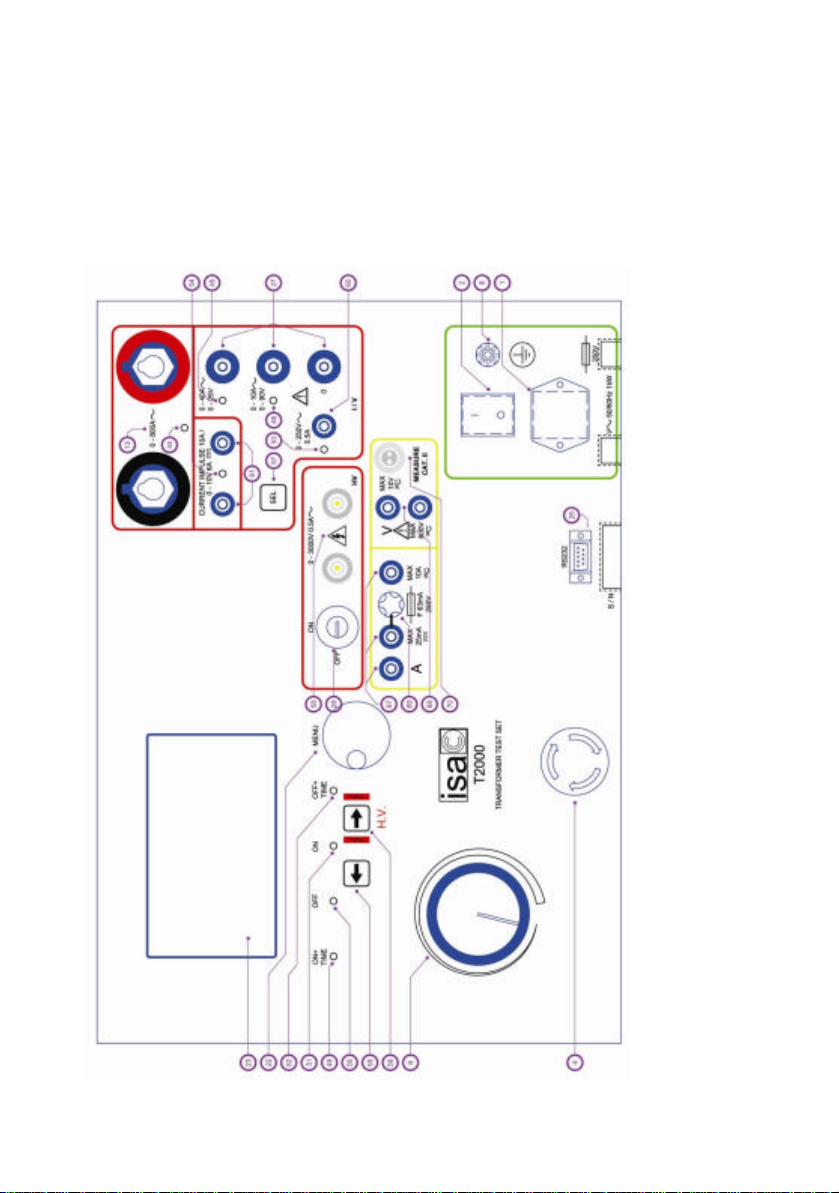

1.1 THE FRONT PANEL....................................................................................................9

1.2 THE POP-UP MENU.................................................................................................12

1.2.1 Transformers selection....................................................................13

1.3 POWER-ON...............................................................................................................18

1.4 OUTPUTS DESCRIPTION AND HAZARDOUS SITUATIONS .........................20

1.4.1 Main current and voltage outputs............................................20

1.4.2 HV voltage output................................................................................22

1.4.3 Hazardous situation summary...................................................23

1.5 CURRENT GENERATION.........................................................................................24

1.6 OPTIONAL THERMAL PRINTER.............................................................................26

1.7 PROTECTIONS .........................................................................................................26

2 TRANSFORMERS TESTING FUNDAMENTALS...........................................30

2.1 CURRENT TRANSFORMERS...................................................................................30

2.2 REMANENCE..............................................................................................................31

2.3 HIGH CURRENT TESTS..........................................................................................31

2.4WINDING RESISTANCE TEST.............................................................................31

3 WHAT’S INSIDE?.......................................................................................................33

3.1 PHYSICAL DESCRIPTION.....................................................................................33

3.2 DETAILED FUNCTION DESCRIPTION................................................................37

3.2.1 Main output transformer, XTF10350 (5).............................37

3.2.2 Main front board PWA11411 (17).............................................38

3.2.3 TRANSFORMERS board PWA21412 (83)...............................38

3.2.4 CONV-T 3000 board PWA21401 (16).....................................39

3.2.5 INTE ON-OFF T 3000 board PWA11410 (7)........................40

3.2.6 MICR T1000 board PWA41300 (15)........................................40

4 THE HELL, IT DOESN’T WORK..........................................................................42

4.1 INTRODUCTION.......................................................................................................42

4.2 ERROR MESSAGES.................................................................................................42

4.3 TROUBLE SHOOTING.............................................................................................46

4.4 AT POWER-ON DOES NOT TURN ON.................................................................47

4.5 NO OUTPUT FROM THE MAIN CURRENT AND VOLTAGE..............................48

4.6 THE AC VOLTAGE MEASUREMENT IS NOT STABLE......................................48

4.7 PROBLEMS DURING UPGRADE............................................................................48

4.8 FALSE ALARM OF MISSING GROUND CONNECTION....................................49