Summary

1 General safety rules .................................................................................................... 4

1.1 Recommendations for workers ............................................................................ 4

1.2 Typical applications ........................................................................................... 4

1.3 Safety rules ...................................................................................................... 4

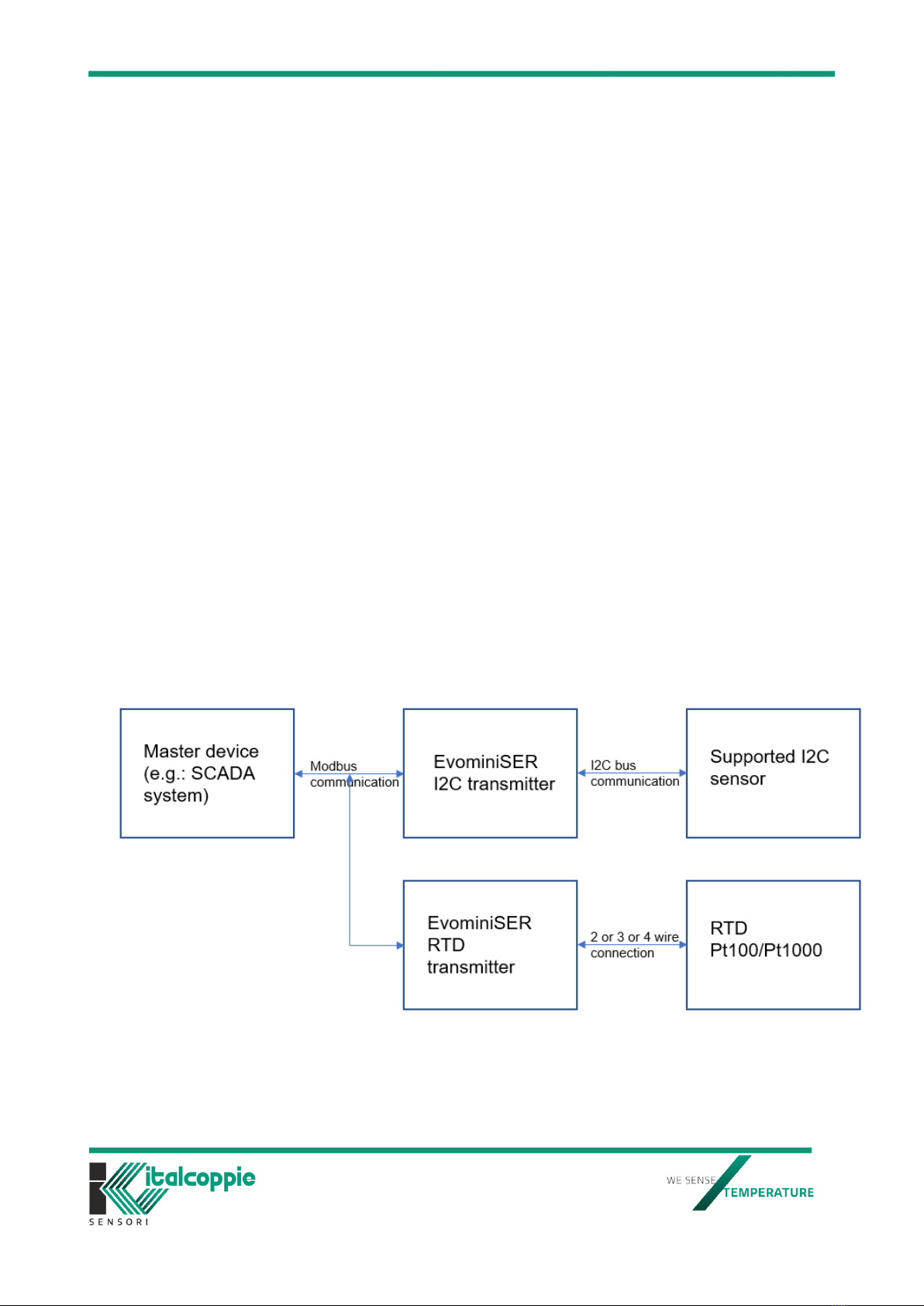

2Introduction ........................................................................................................... 5

2.1 Working principle .............................................................................................. 5

3Installation ............................................................................................................ 6

3.1 Mounting instructions ........................................................................................ 6

3.2 Operating conditions.......................................................................................... 6

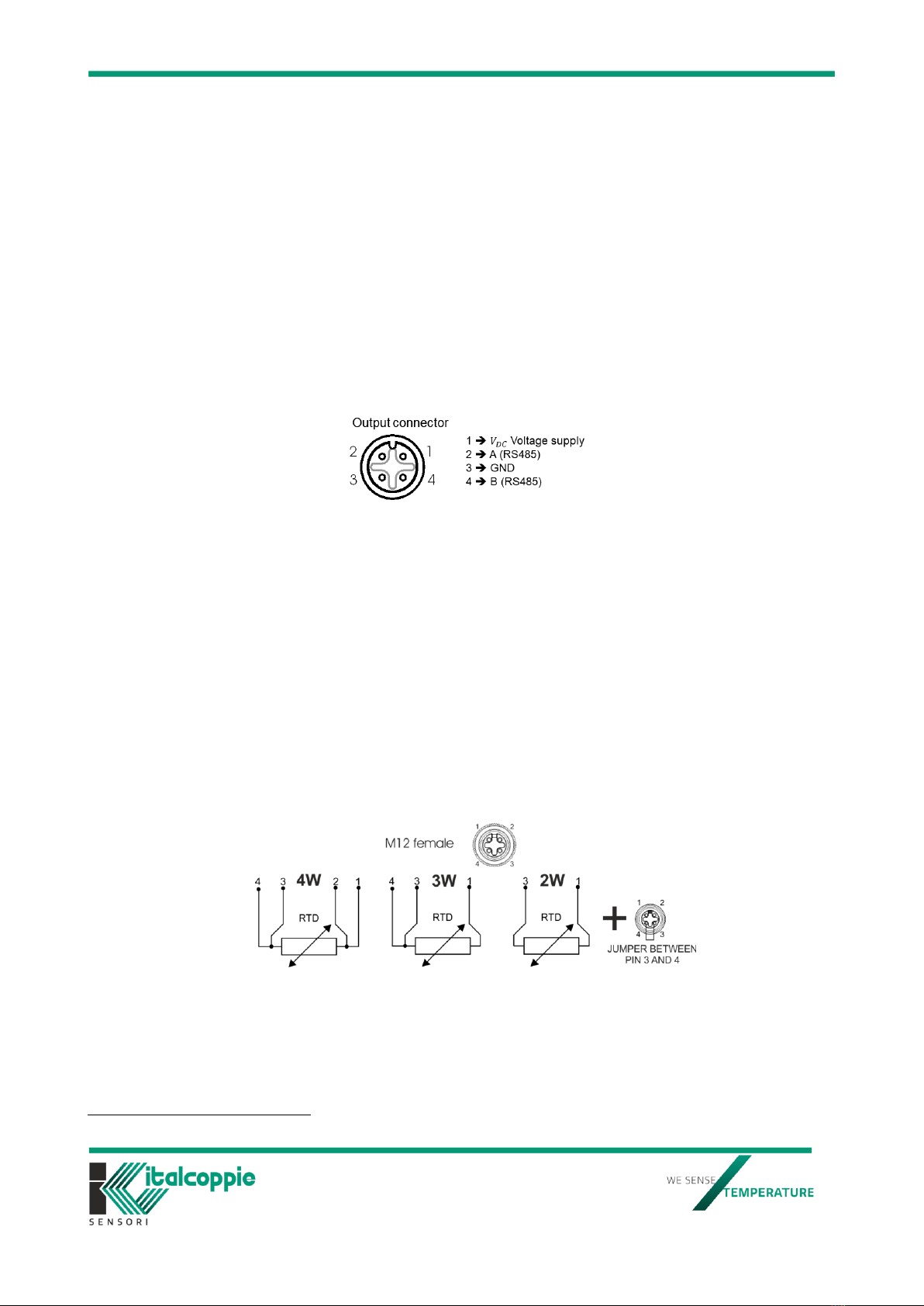

3.3 Electric connections ........................................................................................... 6

3.3.1 Power supply requirements.............................................................................. 7

3.3.2 Pinout and connections ................................................................................... 7

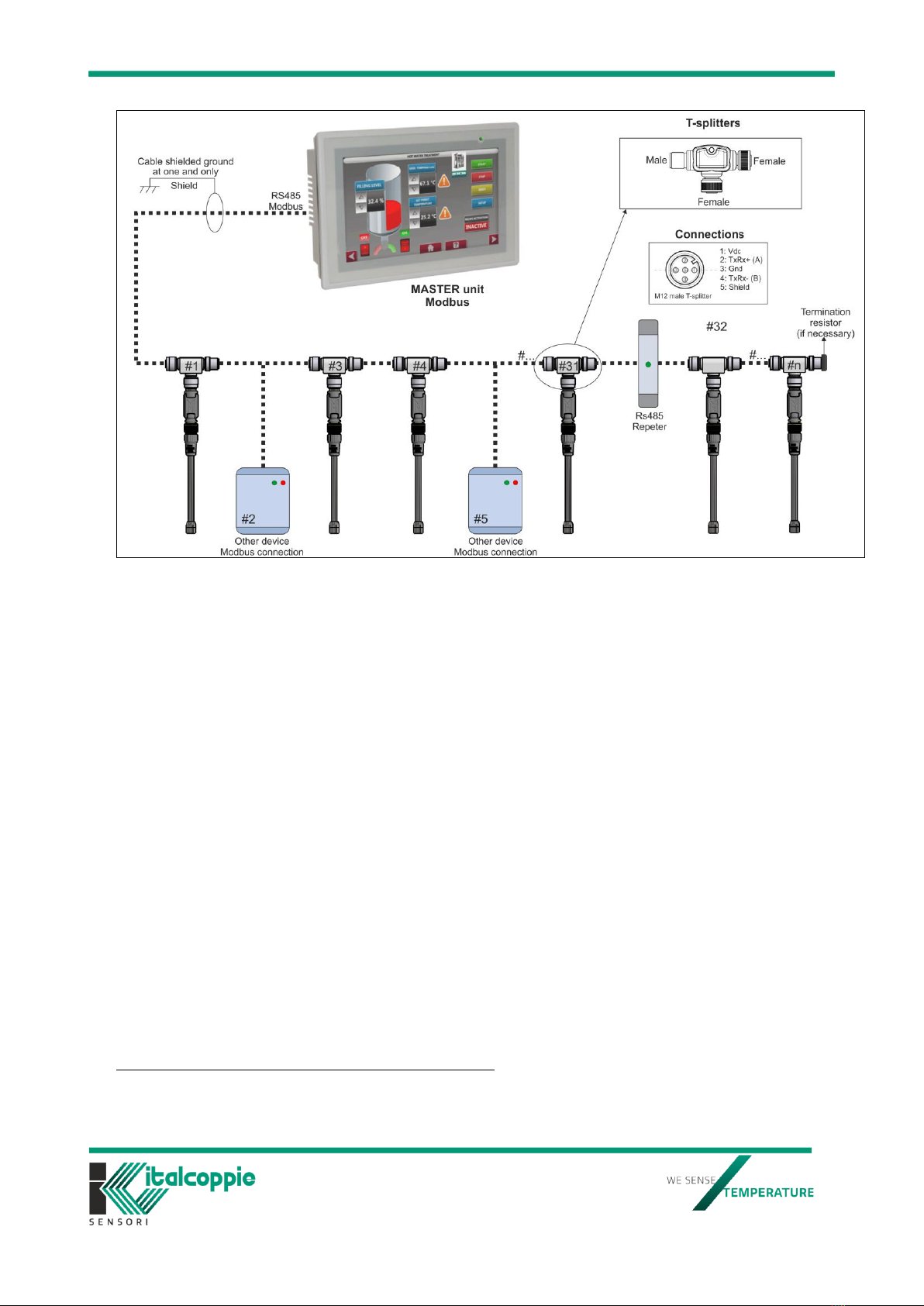

3.3.3 Cabling good practices .................................................................................... 8

3.3.4 Polarity ......................................................................................................... 9

3.3.5 Terminating impedance ................................................................................... 9

3.3.6 Allowed maximum number for series connected transmitters ............................... 9

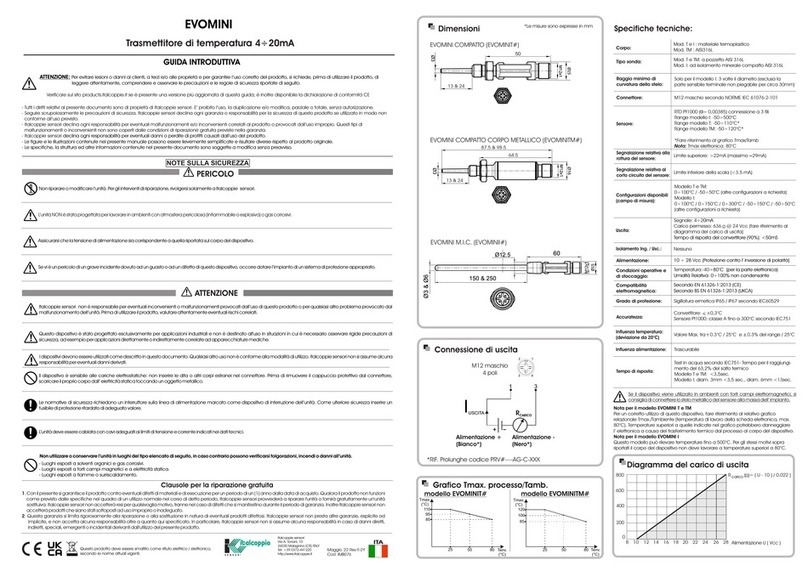

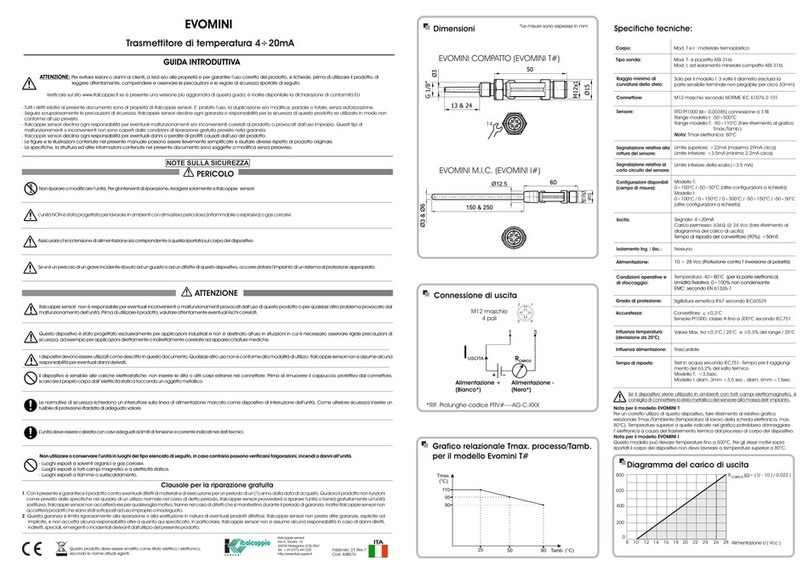

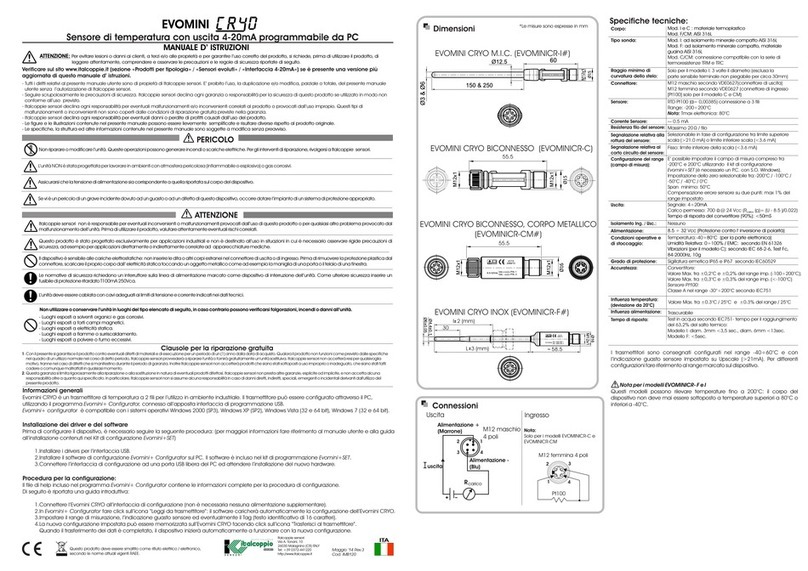

4 Mechanical dimensions .......................................................................................... 10

5 Technical data ...................................................................................................... 11

5.1 LED indicators .................................................................................................... 12

6 Certifications ........................................................................................................ 12

7 Options ............................................................................................................... 13

7.1 Isolator / Serial repeater .................................................................................. 13

7.2 Connection cables ........................................................................................... 14

7.3 Extension cables with M12 connectors ............................................................... 15

7.4 T distributor for digital transmission .................................................................. 15

7.4.1 T distributor for digital transmission with integrated extension cable ................... 16

7.5 Wall fixing bracket........................................................................................... 17

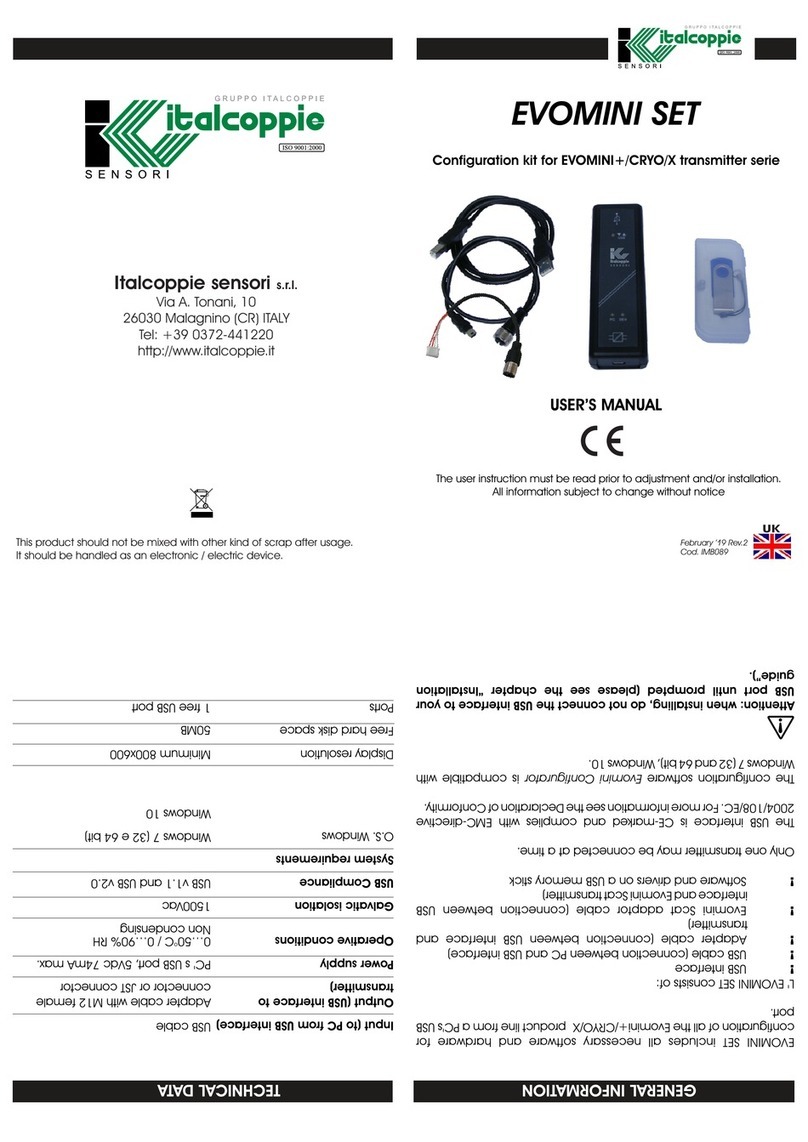

7.6 Configuration kit ............................................................................................. 17

8 Order code........................................................................................................... 18

9. Compatible sensors.................................................................................................. 19

9.1 Temperature and relative humidity sensor.......................................................... 19

9.2 Temperature sensor with magnetic connector ..................................................... 20

9.3 Sensor for ambient ligh.................................................................................... 21

9.4 RTD temperature sensor .................................................................................. 23

10. Modbus registers table............................................................................................ 23

10.1 Modbus communication parameters................................................................ 23

10.1.1 Modbus communication parameters description .............................................. 24

10.2 Device parameters ....................................................................................... 25

10.2.1 Device parameters description...................................................................... 25

10.3 System parameters ...................................................................................... 27

10.3.1 System parameters description .................................................................... 27

10.4 Set sensor type............................................................................................ 29

10.4.1 Set sensor type description .......................................................................... 29

10.5 User data (available only on EvominiSER-RTD item) ......................................... 29

10.5.1 User data description .................................................................................. 30

10.6 Process data ................................................................................................ 32

10.6.1 Process data for temperature and relative humidity sensor .............................. 32

10.6.2 Process data for temperature and relative humidity sensor description .............. 32

10.6.3 Process data for surface temperature sensor .................................................. 33

10.6.4 Process data for surface temperature sensor description.................................. 33

10.6.5 Process data for Lux sensor ......................................................................... 34

10.6.6 Process data for Lux sensor description ......................................................... 34