If the power supply is not sized

appropriately for the number of

cards/rollers it provides power to,

then a low voltage condition may

occur.

If the voltage drops below 15V DC and remains low

for 1s, then the low voltage error will appear.

If the voltage drops below 15V DC five times in 0.5s,

then the low voltage error will appear.

If the voltage drops below 15V DC less than five

times in 0.5s or does not remain low for 1s, the

roller may stutter – quickly turning off then on.

0V line of all power supplies on the

same conveyor line (powering the

card/rollers, & controls) need to be

physically linked together

This completes the signal path from one section of the

conveyor (powered by a power supply) to the adjacent

section of conveyor (powered by another power

supply) and allows for proper communication through

the cable and external interfaces.

Voltage drop

across the

power bus

Use suitable gauge wire in relation to

distance and current draw to prevent

voltage drop.

Operating DC voltage is 24V ±10%

When running long distances from a DC power supply,

the voltage drop during motor operation across the

power bus may be significant (may drop below 15V). If

there is a large enough drop in voltage, the roller(s)

may behave in a strange manner. In order to prevent

this, a larger gauge wire must be used.

Ensure the control card is securely

grounded to the conveyor frame. The

conveyor frame should also be at the

same potential reference as earth

ground. Standard grounding practices

should be followed.

Static discharge may interfere and damage internal

components.

24V DC ±10%

4A maximum current limiter (motor

lock is 4A)

Diode protection for miswiring

Sensor power short circuit protection

5A fuse for power supply protection

Improper power will damage the card. The motor/ card

should not be subject to locked conditions repeatedly.

Internal fuse is not replaceable. If the fuse has blown,

more serious damage has occurred within the

card/motor

Ambient temperature is 32~104°F

Ambient humidity is < 90% RH

Atmosphere has no corrosive gas

Vibration is < 0.5G - Indoor use only

Extreme environmental variables may cause poor or no

performance and damage the card.

Over-speeding of the roller’s no-load

speed by more than 50% may cause

damage.

Back EMF will be generated.

2 Great Valley Blvd., Wilkes-Barre, PA 18706

Office Ph: 570-820-8811

Fax: 570-820-8838

www.itohdenki.com

Specifications subject to change without notice

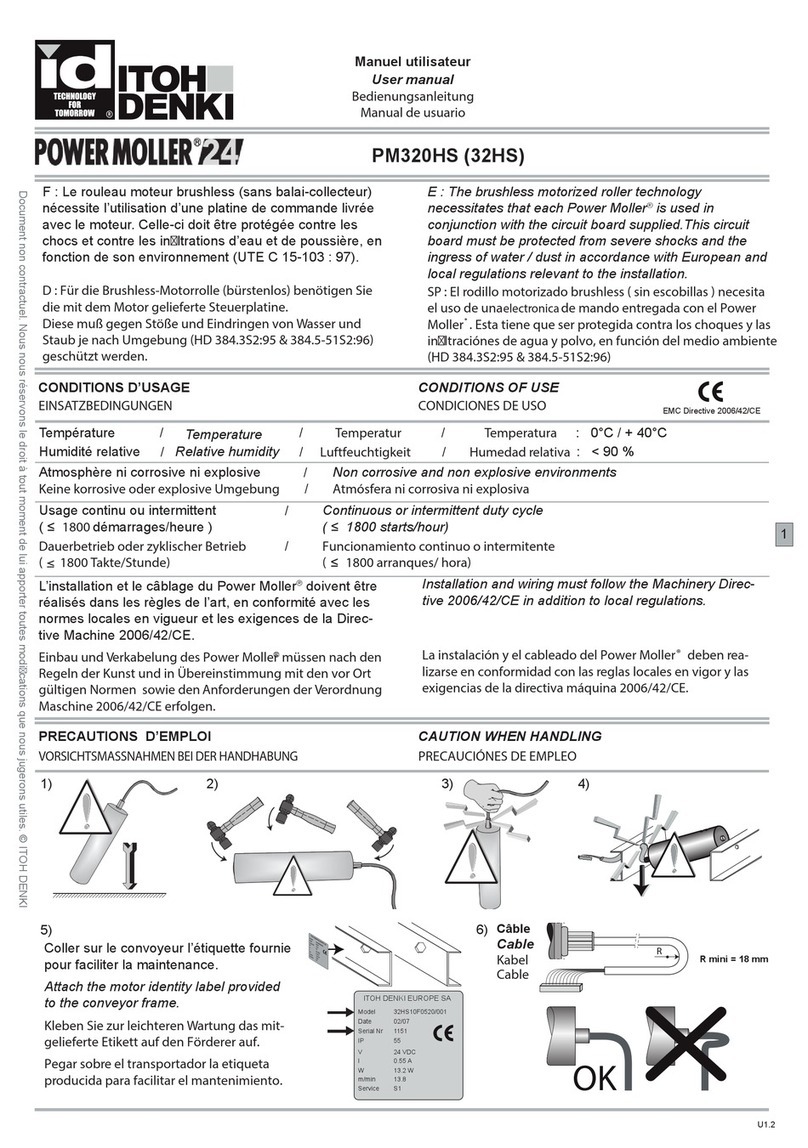

Installation Precautions IMPORTANT: PLEASE READ

BEFORE ISNTALLATION