Continuous product development at IV Produkt may give rise to specification changes without notice.

Flexomix 060-950

DU14.F.110907.05.EN

Inspection

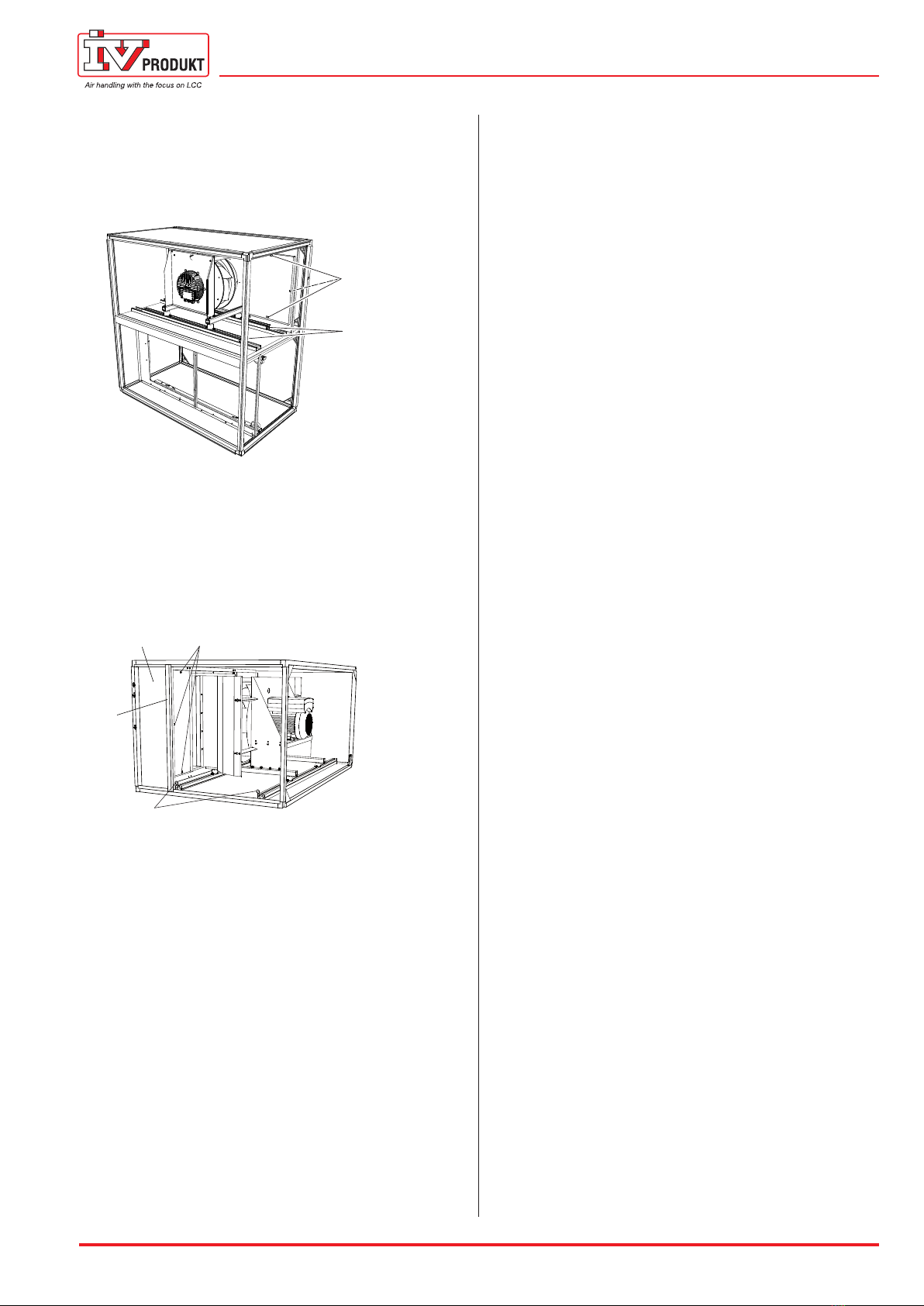

1. Sizes 060–360:

Removethescrews(item1)andthepins/screws

(item 2) and withdraw the fan units (fan and motor

are mounted on slide rails).

2

1

Example fan unit sizes 060–360

Sizes 480–600:

Accesstothefanisnormallyviatheinspection

door.Ifrequired,removethecentreuprightbeam

(item 1) and fixed cover (item 2), remove the screws

(item3)andthepins(item4)andwithdrawthefan

units (fan and motor are mounted on slide rails).

4

1

23

Example fan unit sizes 480–600

Sizes 740-950:

Thefansarerigidlymountedandcanbeaccessed

through the inspection door/doors.

2. Checkthattheimpellerrotateseasily,isinbalance

andisnotvibrating.Checkalsothattheimpeller

iscleanfromanyaccumulationofparticles.Imbal-

ancemaybeduetoacoatingordamagetothe

impellerblades.

3. Listentothesoundfromthemotorbearings.Ifthe

bearingsareingoodconditionyouwillhearaslight

purringsound.Ascrapingorpoundingsoundmay

meanthatthebearingsaredamagedandservicing

is then required.

4. Check that the impellers firmly mounted and that

they have not shifted sideways toward the inlet

cone.

5. Thefanimpellerandmotoraremountedonabase

framefittedwithrubberanti-vibrationmountings.

Checkthattheanti-vibrationmountingsarefirmly

mounted and are intact.

6. Checktheconditionofthemountingscrews,the

suspensiondevicesandthebaseframe.

7. Check that the gaskets on the connection plates

around the connection opening are intact and are

firmly fitted.

8. Checkthatthemeasurementtubesarefirmlyfitted

to their relevant measurement tapping.

9. Reassemblethefanunits.

10.ChecktheairflowsbymeasuringΔp in the connec-

tionsforflowmeasurement.UsetheAHU’sflowla-

belandreadwhichflowcorrespondstomeasured

Δp.

Cleaning

1. Follow item 1-8 under Inspection.

2. Wipethefanimpellerbladestoremoveanycoat-

ings. Use an environment-friendly degreasing

agent.

3. Theexternalsurfacesofthemotorshouldbekept

clean.Removeanydust,dirtandoil.Cleanwith

a dry cloth. If they are severely fouled, use an

environment-friendly degreasing agent. The motor

is likely to overheat if thick layers of dirt prevent air

from entering the motor to cool the stator structure.

4. Vacuum clean inside the air handling unit so that

particleswillnotbeblownoutintotheductsystem.

5. Clean the other parts in the same way as the impel-

ler. Check that the inlet cones are securely mount-

ed.

6. Followitem9underInspection.

To reset the overheating protection

(EC motors)

1. Switchoffthepowersupplytothefanmotor.

2. Wait at least 20 sec. after the impeller has finished

rotating.

3. Switchonthepowersupplytothefanmotor.