10

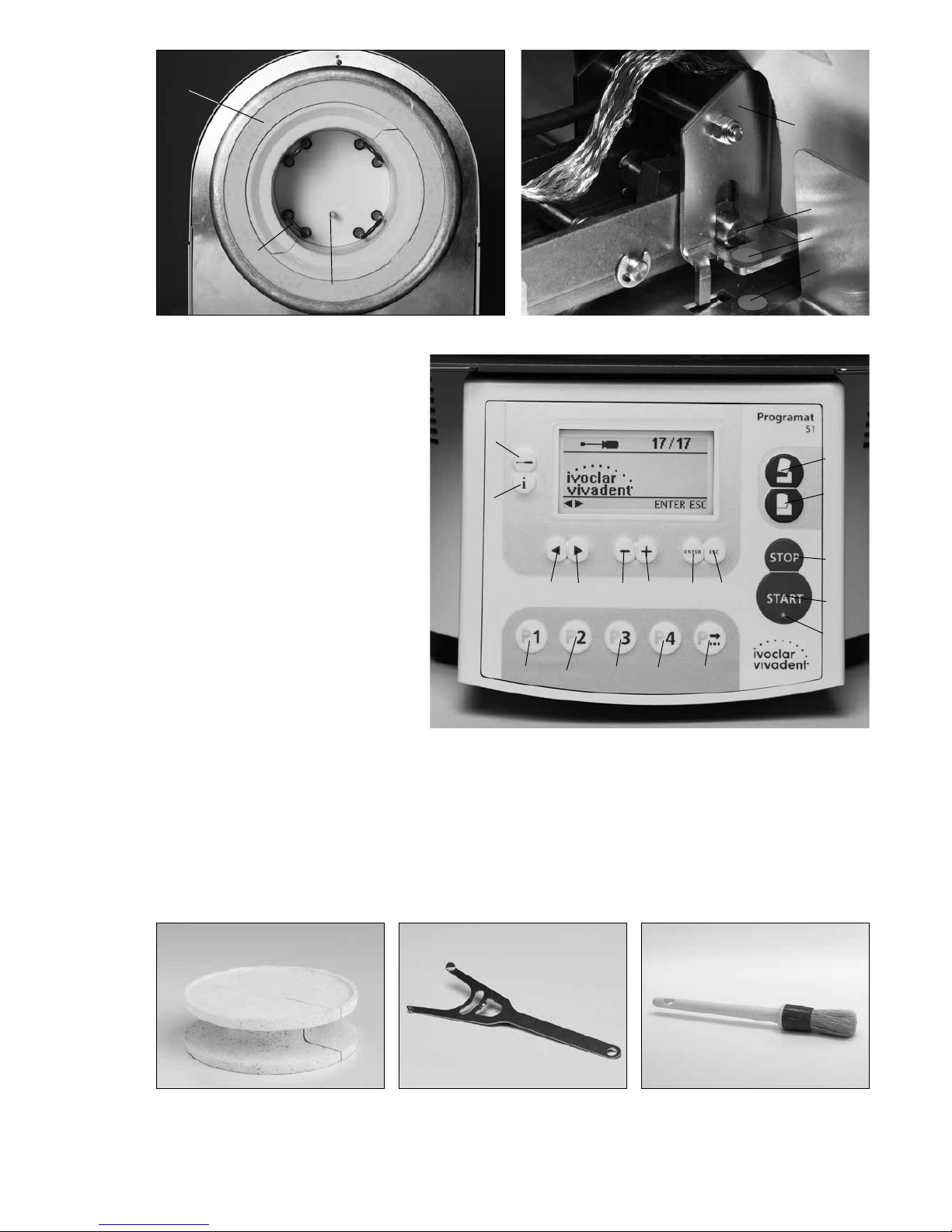

2.1.6

Contraindication

Never use the furnace without the

sinter tray. Use only the original S1

sinter tray. Do not use the firing trays

or honey-combed trays from conven-

tional ceramic furnaces. Furthermore,

check the sinter tray for damage, cracks

or contamination before every sintering

cycle. If the table is damaged, it must no

longer be used. A maximum of one

sinter tray is to be placed in the

sintering chamber. Do not stack the

sinter trays.

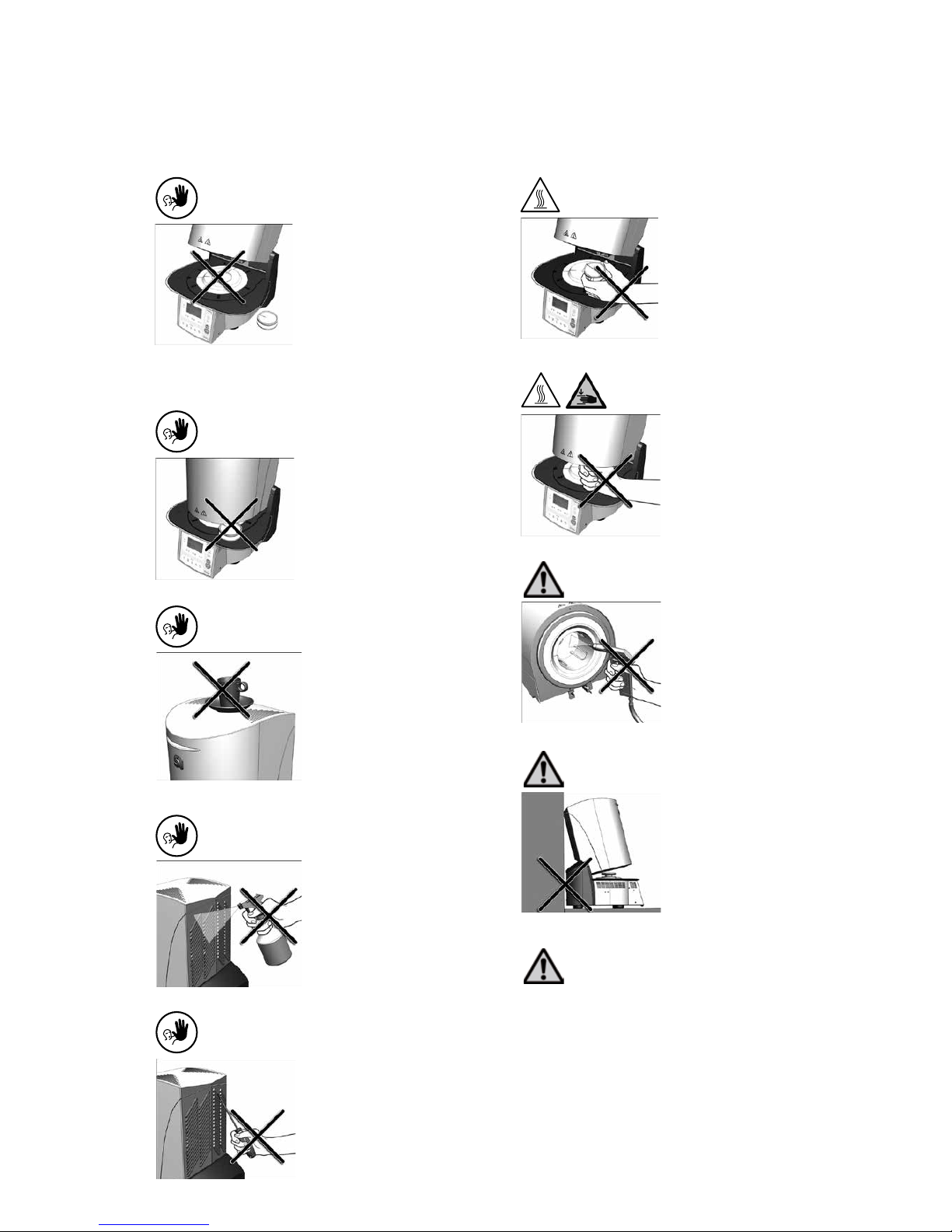

2.1.7

Contraindication

Firing trays must not be placed in the

area surrounding the firing table, since

this will obstruct the closing of the fur-

nace head.

2.1.8

Contraindication

Foreign objects must not be placed on

the furnace head or the air vents.

Make sure that no liquids or other for-

eign objects enter the air vents, since

this may result in an electrical shock.

2.1.9

Contraindication

Make sure that no liquids or other

foreign objects enter the furnace.

2.1.10

Contraindication

Do not insert any foreign objects into

the air vents. There is a risk of

electrical shock.

2.1.11

Burn hazard

Never place objects in the sintering

chamber by hand, since there is a burn

hazard. Always use the sinter tray fork

(accessories) supplied for this purpose.

Never touch the hot surface of the

furnace head, as there is a burn

hazard. Please also refer to the

warnings on the furnace.

2.1.12

Risk of crushing and burn hazard

Never reach under the furnace head

with the hand or other parts of the

body during operation, since there is a

risk of crushing and a burn hazard.

2.1.13

Risks and dangers

This product contains ceramic fibres

and may release fibre dust. Do not use

compressed air, or blow, on the

furnace, thus distributing the dust in

the environment, and observe the

additional notes on page 11.

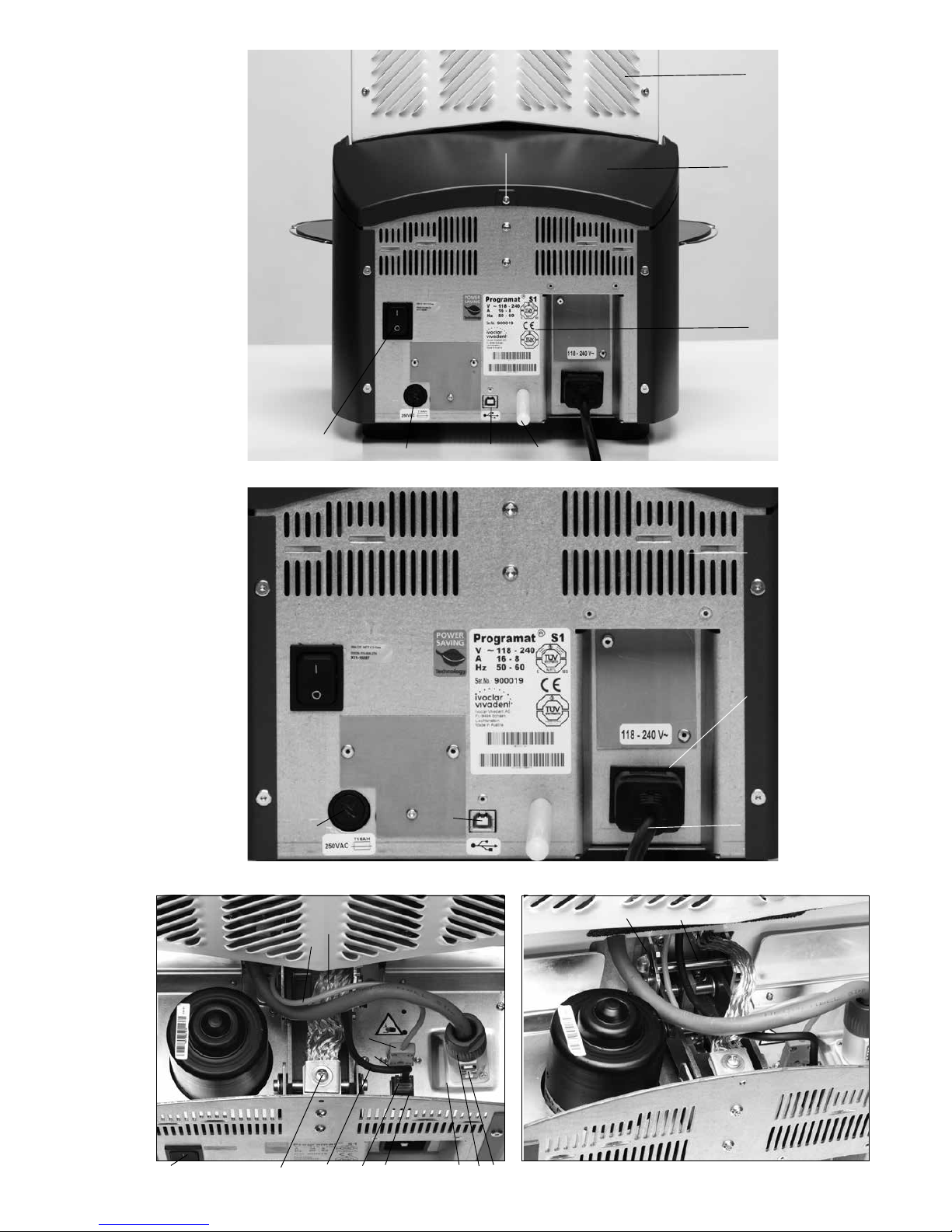

2.1.14

Risks and dangers

Do not use the furnace without

spacer, since the distance to the back

wall has to be kept!

2.1.15

Risks and dangers

The furnace must not be operated if the heating element

in the sintering chamber is damaged. There is a risk of

electric shock upon contact with the heating wire.