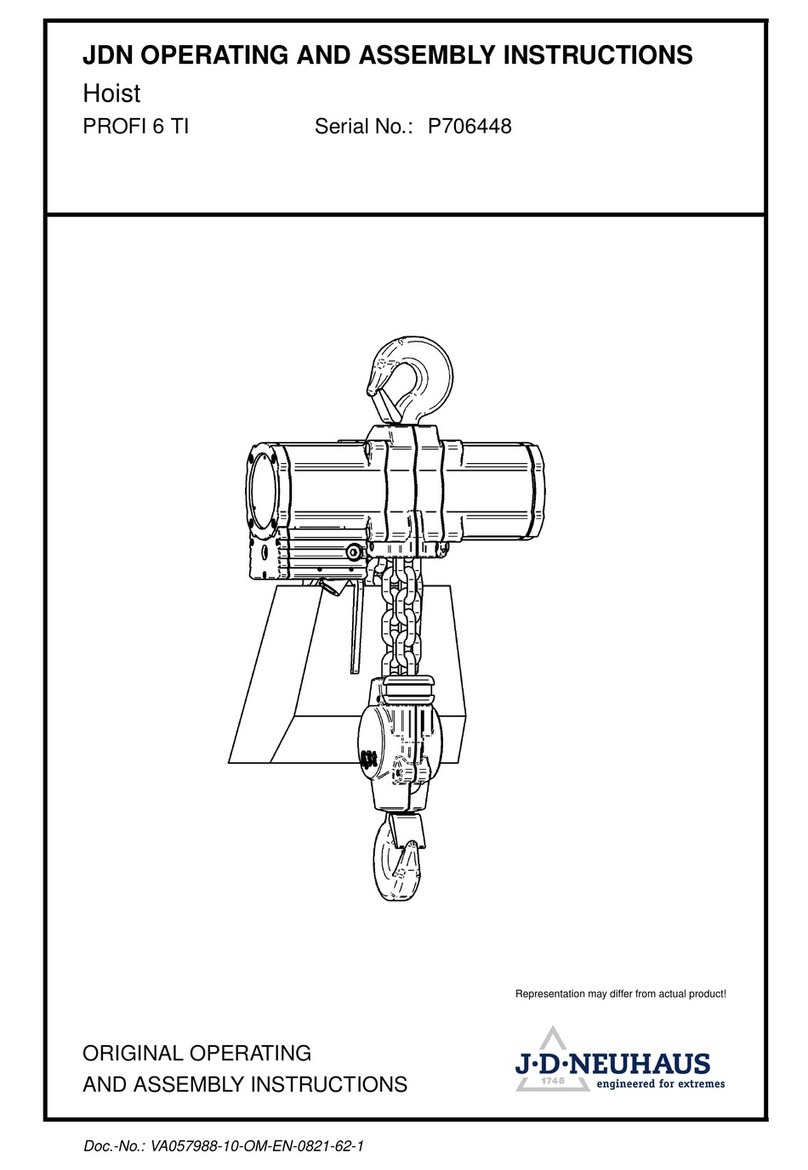

J. D. NEUHAUS PROFI 3 Ti User manual

JDN OPERATION MANUAL

AIR HOISTS

,, ,

16

10

6

3

Page 2

This manual edition 07/2003, covers the following

JDN Air Hoists:

Before operating any hoist, carefully read the entire

manual. For hoists mounted in trolleys, refer also to the

JDN Trolleys Operation Manual.

Please enter the Fabr. No. of your JDN Air Hoist here.

Fabr. No. Fabr. No.

Fabr. No. Fabr. No.

3

6

10

16

Page 3

TABLE OF CONTENTS

Organisational measures . . . . . . . . . . . . . . . . . . 5

Personnel safety . . . . . . . . . . . . . . . . . . . . . . . 5

Preventing property damage . . . . . . . . . . . . . . . 5

The operation manual . . . . . . . . . . . . . . . . . . . . 6

Warnings and symbols . . . . . . . . . . . . . . . . . . . 6

Designation . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assembly overview . . . . . . . . . . . . . . . . . . . . . . 8

Product description . . . . . . . . . . . . . . . . . . . . . . 8

Explosion protection . . . . . . . . . . . . . . . . . . . . . 8

Intended use . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating conditions . . . . . . . . . . . . . . . . . . . . 14

Energy requirements . . . . . . . . . . . . . . . . . . . . 15

Principle of operation of

JDN air vane motors . . . . . . . . . . . . . . . . . . . . 16

Operation without chain box . . . . . . . . . . . . . . 17

Operation with service unit . . . . . . . . . . . . . . . 17

CE designation . . . . . . . . . . . . . . . . . . . . . . . . 17

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Safe transportation . . . . . . . . . . . . . . . . . . . . . 18

Storage conditions . . . . . . . . . . . . . . . . . . . . . 18

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installing the hoist . . . . . . . . . . . . . . . . . . . . . 19

Connecting the controls . . . . . . . . . . . . . . . . . . 20

Replacing controls . . . . . . . . . . . . . . . . . . . . . . 23

Connecting to the main air supply . . . . . . . . . . 25

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Checking prior to initial operation . . . . . . . . . . 26

Rules for safe operation of hoists . . . . . . . . . . . 27

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Emergency stop device . . . . . . . . . . . . . . . . . . 31

Overload protection . . . . . . . . . . . . . . . . . . . . . 31

Attaching the load . . . . . . . . . . . . . . . . . . . . . 31

Lifting the load . . . . . . . . . . . . . . . . . . . . . . . 32

Lowering the load . . . . . . . . . . . . . . . . . . . . . . 32

Detaching the load . . . . . . . . . . . . . . . . . . . . . 32

Interrupting working . . . . . . . . . . . . . . . . . . . 32

Shutting down . . . . . . . . . . . . . . . . . . . . . . . . 33

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Maintenance and inspection intervals . . . . . . . . 34

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . 34

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Lubricants . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Inspection and repairs . . . . . . . . . . . . . . . . . . . 34

Checking braking function . . . . . . . . . . . . . . . . 37

Checking direction of movement . . . . . . . . . . . 37

Checking lifting and lowering limiters . . . . . . . 37

Checking emergency stop function . . . . . . . . . . 37

Lubricating the chain . . . . . . . . . . . . . . . . . . . 38

Checking controls . . . . . . . . . . . . . . . . . . . . . . 38

Checking the silencer for permeability . . . . . . . 38

Service unit . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Replacing brake disc and brake piston . . . . . . . 42

Replacing vanes . . . . . . . . . . . . . . . . . . . . . . . 42

Motor installation, motor lubrication . . . . . . . . 42

Removing and installing load sleeve,

bottom block, clamp and buffer . . . . . . . . . . . . 44

Checking chain, chain sprocket and chain guides 46

Check dimensions . . . . . . . . . . . . . . . . . . . . . . 47

Checking axial play . . . . . . . . . . . . . . . . . . . . . 48

Removing and installing chain . . . . . . . . . . . . . 50

Replacing chain and chain sprocket . . . . . . . . . 51

Overload protection . . . . . . . . . . . . . . . . . . . . . 52

Fault table . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Filter silencer . . . . . . . . . . . . . . . . . . . . . . . . . 54

Booster unit . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chain box . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . 56

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . 57

APPENDIX

ACCESSORIES

FAULTS, CAUSE AND REMEDY

MAINTENANCE

TAKING OUT OF OPERATION

OPERATION

INITIAL OPERATION

TRANSPORT AND STORAGE

PRODUCT INFORMATION

SAFETY INSTRUCTIONS

Please note!

Within the Federal Republic of Germany operators of

air hoists must comply with

UVV Winches, Lifting and pulling Devices (BGV D8)

and UVV Load-carrying Devices used with Lifting

Equipment (VBG 9a)

and, for air hoists installed in trolleys, additionally with

UVV Cranes (BGV D6)

in the respective currently applicable version. Operators

must also initiate the prescribed tests (see also

"Principles for the Testing of Cranes" BGG 905 (ZH1/27).

In all other countries, the operator shall comply with

local regulations as applicable.

Special regulations may apply when incorporating air

hoists into other installations or using air hoists under

unusual conditions.

Page 4

JDN Air Hoists are designed in accordance with current

technological standards and accepted safety practice.

Nonetheless, the use of an air hoist may be associated

with risk of injury or fatality to the user or to third

parties or with the risk of damage to the hoist or to

other items.

All personnel charged with operating air hoists, must

have read and understood the operation manual, especi-

ally the section concerning safety instructions, before

commencing work. This is particularly important for

personnel who only occasionally operate the hoist,

e.g. for maintenance or retrofitting work.

Operators of JDN Air Hoists are also under obligation

to ensure safe and hazard-free operation. This can be

achieved through the following measures:

the operation manual must always be kept available

at the hoist operating site,

performing regular training,

implement an inspection log and make regular entries,

and regularly check personnel for safety and hazard

awareness during work.

Personnel who operate, maintain, inspect and perform

setting-up work on the hoist must be properly trained

or must receive an introduction from properly trained

personnel, before commencing work.

Due to their technical training and experience, properly

trained personnel have adequate knowledge of hoists.

They are sufficiently familiar with the relevant occupa-

tional safety and accident prevention regulations, that

they are able to assess the condition of hoists, with

regard to working safety.

Follow the operating instructions for your workplace.

Observe the accident prevention regulations,

especially BGV D8 (Winches, Lifting and Pulling

Devices) and VBG 9a (Load-carrying Devices used with

Lifting Equipment).

Ensure that you are properly informed regarding

working with hazardous materials.

Follow the safety instructions set out in this

operation manual.

Operators of JDN Air Hoists are under obligation to

ensure that entries in the accompanying inspection log

are made properly and regularly.

Comply with the prescribed maintenance intervals.

Only use JDN Air Hoists for work which is described

as intended use.

Observe the operating conditions for hoists as

described in this manual.

PREVENTING PROPERTY DAMAGE

PERSONNEL SAFETYORGANISATIONAL MEASURES

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

Page 5

This operation manual is intended to help the operator

familiarise himself with JDN Air Hoists and to take full

advantage of their designated areas of application.

This operation manual contains important information

for the safe, proper and economic operation of JDN Air

Hoists. Observance of the manual helps to avoid hazar-

dous situations, to reduce repair costs and downtimes

and to extend the service life of the JDN Air Hoists.

Safety warnings in this operation manual are classified

in three categories.

DANGER!

Safety warning, which if not followed can

result in a hazard to life and limb, are indi-

cated by this symbol.

The symbol indicates an immediate danger.

The possible consequences of non-observance

may be severe or even fatal injuries.

CAUTION!

This symbol indicates situations, which

may become hazardous. Failure to observe

may result in light injuries.

ATTENTION!

This symbol indicates that failure to follow

instructions may result in damage to the

device or other equipment.

WARNINGS AND SYMBOLSTHE OPERATION MANUAL

PRODUCT INFORMATION

PRODUCT INFORMATION

Page 6

The nameplate mounted on the housing cover identifies

the type of JDN Air Hoist and contains all important

rating data.

If you have any questions concerning operation of JDN

Air Hoists, which are not addressed in this operation

manual, please contact us at the following address:

J.D. NEUHAUS GMBH & CO. KG

Windenstra§e

D - 58449 Witten-Heven

Phone + 49 - 23 02 - 20 80

Fax + 49 - 23 02 - 20 82 86

http://www.jdn.de

e-mail: info@jdn.de

Example of nameplate on housing cover

DESIGNATION

PRODUCT INFORMATION

Page 7

series air hoists consist of the following

assemblies:

1Gearbox with chain sprocket and overload protection

2Centre section

3Motor with integral brake function

4Controls with main air EMERGENCY STOP

5Chain

6Load hook with load sleeve or bottom block and buffer

The series JDN Air Hoists described here are

designed for load-carrying capacities from 3.2 t

()

to 16 t ()

. Various control

devices are available for the different requirements.

The air vane motor of the hoist, together with the

appropriate controls, is capable of sensitive movement.

This enables precise positioning of the load.

series JDN Air Hoists conform to driving

mechanism classification M3/1Bm, ISO 4301/FEM 9.511.

JDN Air Hoist motors feature rotors with

grease chambers. This contains JDN high-performance

grease, which enables operation with oil-free compressed

air. It remains effective for an operating period of

approx. 250 hours and should be renewed after five

years, at the latest (see Motor lubrication, page 43).

Additional lubrication with oil-bearing compressed air

by means of a service unit with oiler is possible.

The basis for the following information is an expert

statement by the DMT Gas & Fire Division on the use

of JDN Hoists, Trolleys and Crane Systems in explosion-

hazardous areas, based upon European Guideline

94/9/EC1("ATEX 100a"). DMT is accredited with the

testing of devices and protection systems for intended

use in explosion-hazardous areas.

series JDN Air Hoists

BASIC EXPLOSION PROTECTION

OF THE STANDARD VERSIONS

Standard version JDN Air Hoists are category 2 devices

(Guideline 94/9/EC, DIN EN 1127-12), for use in zone 1

and 2 for gases of explosion group IIA. (see also IEC

60079-123and IEC 60079-204). These devices are also

suitable for use in zone 2, in the presence of gases of

explosion group IIB, provided that the substances

hydrogen sulphide and ethylene oxide can be excluded

and additionally in zones 21 and 22 for dusts with glow

temperatures above 210¡C and ignition temperatures

above 202¡C, provided that no light metal or other

impact-sensitive dusts are present. In zones 1 and 21,

friction and impacts in the working area of the chain

must be excluded.

These devices are designated by:

.

32

4

6

5

1

2

3

EXPLOSION PROTECTION

16

3

PRODUCT DESCRIPTION

ASSEMBLY OVERVIEW

PRODUCT INFORMATION

Page 8

ADDITIONAL MARKING "X"

or

: This designation does not permit

use in the presence of the extremely flammable sub-

stances hydrogen sulphide and ethylene oxide or in the

presence of light metal or other impact-sensitive dusts,

or in the presence of dusts with glow temperatures

below 210°C and ignition temperatures below 202°C.

: This designation permits use in the

presence of carbon disulphide or other temperature

class T6 substances only under special conditions, which

have been agreed with the manufacturer and which are

described in the crane documentation (Europe: in the

inspection log) and which stipulate the maximum surface

temperatures for the device.

GENERAL NOTE ON DESIGNATION

The highest possible respective designations for lifting

equipment and running gear are usually replaced by a

designation, which corresponds to the normal assembly

of a compact complete device (trolley or crane system).

JDN HOISTS

"WITH INCREASED SPARK PROTECTION"

JDN Hoists in the "with increased spark protection"

version (SP), fulfil further explosion protection require-

ments. With the exception of carbon disulphide, they

can be used in the presence of all gases in zones 1 and

2 and dusts with glow temperatures above 210°C and

ignition temperatures above 202°C and can be designated

with for installation in a trolley,

depending upon trolley version (see below), but also

with . For further operating conditions,

see Instructions for safe operation (Notes and ).

JDN HOISTS FOR USE IN THE PRESENCE OF

TEMPERATURE CLASS T6 GASES OR EXTREMELY

EXPLOSIVE DUSTS

Following separate tests, especially with regard to

ambient temperatures and type of operation, use in the

presence of carbon disulphide or dusts with particularly

low glow or ignition temperatures may be possible with

designation , which includes the

additional marking "X" for special conditions

(see Additional marking "X").

Please contact us with regard to these requirements.

MATERIALS FOR FRICTION AND IMPACT HAZARDS

The combination of particular material pairs results in

an increased ignition hazard. This does not apply to

corrosion-resistant steel or cast iron against aluminium,

magnesium or corresponding alloys.

It applies in particular to the presence of rust or of rust

film. Rust (also rust film) formation is possible, especi-

ally on the chain and on the load hook, at the friction

points. In zones 1 and 21, but also in zone 2 for gases

of explosion group IIC, hydrogen sulphide and ethylene

oxide, as well as in zone 22 for light metal and other

impact-sensitive dusts, the following generally applies:

For the intended use of hoists it must be ensured, that

no rust is present at the above-mentioned friction

points and that material combinations of the above-

named light metals with steel (exception: stainless

steel) are not used in the working area of the hoists, at

potential friction, impact or sliding points. It is thus

possible to exclude sparking due to mechanical influen-

ces with these material combinations.

COMPRESSED AIR HOSES

In zone 1, compressed air hoses must have a sufficiently

low surface resistance of less than 109Ω, in order to

prevent electrostatic ignition hazards. Otherwise

(resistance >109Ω), for explosion groups IIA and IIB

the hoses must be ∅≤30 mm and for explosion group

iic ∅≤20 mm, or proof must be provided that they

cannot become dangerously charged.

ED

... IIC T6(X)

II 3 GD IIA T4(X)

PRODUCT INFORMATION

Page 9

ACETYLENE AND COPPER

When operating JDN products in explosion-hazardous

areas, in which an acetylene-containing atmosphere can

occur, it must be ensured that copper-plated parts are

kept dry, in order to exclude the possibility of oxidation

of the metallic copper and the formation of a watery

phase, which is capable of reacting with acetylene and

which can result in an explosion hazard.

EARTHING

Electrostatic ignition hazards can be prevented by

means of safe earthing. In zones 1 and 21, earthing of

the hoists is required. This must be achieved via the

load hook or the load eyes, if the lifting equipment is

connected to correspondingly earthed parts (earth lea-

kage resistance less than 106Ω). This also applies to

operation with trolleys or cranes. Their tracks must be

earthed on site. Running wheels and rail surfaces must

never be painted, as this can result in unacceptably

high earth leakage resistance values.

Earthing of the load hook is via the chain (see also

"Load chain" below).

Loads must be earthed during transportation. A separa-

te earth is required, for example, when using non-con-

ducting sling gear.

LOAD CHAIN

In order to prevent mechanical sparking in zones 1 and

21, but also in zone 2 for gases of explosion group IIC,

hydrogen sulphide and ethylene oxide, as well as in

zone 22 for light metal and other impact-sensitive

dusts, the chain and the load must always be moved in

such a way, that sliding or frictional contact with other

plant and components is excluded.

In order to guarantee the required degree of earthing,

rusty chains must no longer be used in zones 1 and 21.

As, depending upon the degree of corrosion, the leakage

capability of the chain may be impaired to a level that

is no longer adequate.

PRODUCT INFORMATION

Page 10

PRODUCT INFORMATION

Page 11

( ): The measured values for the substances placed in brackets are close to the limit of the next group of class when classified

in the explosion groups or temperature classes. For this reason, they have been included in both.

**: Extremely flammable substances (cf. additional marking "X")

*1 (Methanol = Methyl alcohol)

Ex group Temperature class

T1 T2 T3 T4 T5 T6

Ignition temperature

> 450°C 450-300°C 300-200°C 200-135°C 135-100°C 100-85°C

Maximum permissible surface temperature of operating facilities

450°C 300°C 200°C 135°C 100°C85°C

II A Acetone (Ethyl alcohol) n-Amyl alcohol Acetaldehyde

Ammonia (Ethylene glycol) Benzene

Aniline i-Amyl acetate (petrol)

Benzol n-Butane Diesel

Chlorobenzene n-Butyl alcohol Fuel oil

1,2-Dichlorobenzene 1-Butylene n-Hexane

Acetic acid 1,2-Dichloroethane jet fuels

Ethane Di-i-Propyl ether

Ethyl acetate Natural gas

(Ethyl bromide) Acetic anhydride

Ethyl chloride n-Propyl acetate

(Carbon monoxide) (n-Propyl alcohol)

o-Cresol i-Propyl alcohol

Methane Vinyl chloride

Methyl acetate

Methyl alcohol*1

Methyl bromide

Methyl chloride

Methylene chloride

Naphthaline

(Nitrobenzene)

Phenol

Propane

Toluene

o-Xylene

II B Hydrocyanic acid Butadiene-1,3 Dimethylether Ethyl ether

(Ethyl bromide) Dioxane-1,4 **Hydrogen Ether

(carbon monoxide) Divinyl ether sulfide Anaesthetic ether

(Nitrobenzene) (Ethyl alcohol) Diethyl ether

Town gas Ethylene

(Ethylene glycol)

**Ethylene oxide

Isoprene

(n-Propyl alcohol)

II C **Hydrogen **Acetylene **Carbon

disulphide

EXPLOSION GROUPS AND TEMPERATURE CLASSES OF THE MOST IMPORTANT GASSES AND VAPOURS ( SELECTION )

(according to DIN VDE 01655, Redeker6, Nabert, Schön7, IEC 60079-123and IEC 60079-204)

PRODUCT INFORMATION

Page 12

*1: Features:

A: The chain is made of zinc-plated steel; metal controls are conductively connected to the hoist. This is part of

the standard equipment. For technological reasons, a zinc-plated version of chain size 31.5 x 90 is not available.

This is only used for the extremely slow-running chain drives of large hoists, so that the sliding velocity for

potential friction points between the chain and the surroundings remains well below 1 m/s.

SP: Hoists "with increased spark protection":

Copper-plated load hook and bottom block with brass safety catch.

FSR: Running gear "with increased spark protection":

Running wheels for trolleys and cranes are bronzed or are made of bronze.

*2: Instructions for safe operation:

: Ignition hazards are not to be expected if hoists or cranes are used in the normal manner. Friction and impacts in

the working area of the chain, not resulting from intended use of the hoist or crane and which result in sparking,

must be excluded. This applies in particular to use in conjunction with light metals or light metal alloys.

(exception: stainless steel)

: A gas-free or spark-free environment must be ensured in the working area. This means, for example, that the

chain, the bottom block and the load hook must be prevented from swinging against surrounding objects or that a

gas-free environment must be ensured.

: Ambient temperature and the type of operation must be examined separately. Equipment surface temperatures are

dependent upon the type of operation and the ambient temperature.

Therefore, separate testing is required for materials of the temperature classes T5 and T6.

A maximum ambient temperature of 40°C is a pre-condition for the specification of temperature class

(see also EN 500148).

T

E

D

DECISION CRITERIA FOR SELECTING THE CORRECT JDN HOISTS IN EXPLOSION HAZARDOUS AREAS

Explosion groups of gases and vapours Zone Version*1Operation*2

(cf. Explosion groups and temperature classes of the most important gasses and vapours)

II A 2 A

1A

II B (X) except hydrogen sulphide, ethylene oxide 2A

(particularly flammable) 1AFS

II B 2 A FS

1AFS

II C / T4 2 A FS

1 A FS FSR

II C / T6(X) 2 A FS

1 A FS FSR

Explosion-hazardous dusts Zone Version*1Operation*2

Usual industrial dusts 22 A

21 A

Light-metal or impact-sensitive dusts 22 A FS

21 A FS D

D

D

TED

TED

ED

ED

ED

ED

D

D

PRODUCT INFORMATION

Page 13

TEMPERATURE LIMIT FOR

EXPLOSION HAZARDOUS DUSTS

In areas which are explosion-hazardous due to combu-

stible dusts, the surface temperature must not exceed

two-thirds of the ignition temperature in °C of the

dust/air mixture. The temperatures of surfaces on which

hazardous deposits of combustible dusts can be formed,

must not exceed the glow temperature of the relevant

dust minus 75°K. Greater safety margins are required if

thickness of the dust layer exceeds 5 mm.

The corresponding surface temperatures can be derived

from the lowest values for glow and ignition tempera-

tures of dusts specified in the HVBG/BIA Report 12/979

"Combustion and explosion characteristics of dusts":

Synthetic rubber, soot-containing:

Glow temperature 220°C - 75°C = 145°C

max. permissible

surface temperature

Stearic acid:

Ignition temperature 190°C x 2/3 = 126°C

max. permissible

surface temperature.

PLEASE ALSO OBSERVE YOUR

CORRESPONDING NATIONAL REGULATIONS.

1Guideline 94/9/EC OF the European Parliament and the Council of 23 March 1994 on the approximation of the laws of

the Member States concerning equipment and protective systems intended for use in potentially explosive atmospheres

2DIN EN 1127-1: Explosive atmospheres - Explosion prevention and protection - Part 1: Basic concepts and methodology,

1997-10

3IEC 60079-12: Electrical apparatus for explosive gas atmospheres, Part 12: Classification of mixtures of gases and

vapours with air according to their maximum experimental safe gaps and minimum igniting currents, 1978.

4IEC 60079-20: Electrical apparatus for explosive gas atmospheres, Part 20: Data for flammable gases and vapours,

relating to the use of electric apparatus, 1996-10.

5DIN VDE 0165: Installation of electrical systems and equipment in areas with explosion hazard, 1991

6Nabert, Schön: Sicherheitstechnische Kennzahlen brennbarer Gase und Dämpfe 2nd edition, 1978

7Redeker, Schön: 6. Nachtrag zu Sicherheitstechnische Kennzahlen brennbarer Gase und Dämpfe, 1990

8DIN EN 50014 (VDE 0170/0171 part 1): 2000-02

Electrical apparatus for use in explosion hazardous areas: General provisions

9HVBG/BIA-Report 12/97: Central association of German employer's liability associations/Trade association institute

for industrial safety

PRODUCT INFORMATION

Page 14

JDN Air Hoists are designed for lifting and

lowering loads within the specified load-carrying capa-

cities, with a vertically-arranged chain. They are also

suitable for pulling loads horizontally. Under certain

conditions, the lifting of personnel-carrying equipment

is also permitted.

In combination with trolleys, JDN Air Hoists are also

suitable for the floorless horizontal movement of loads.

Any other use or use outside these stipulations is

deemed to be abnormal. Oblique pulling, see section

Operation, page 27. J.D. NEUHAUS GMBH & CO. KG

cannot be held liable for any resulting damage.

The entire risk is borne by the user (see also section

Rules for safe operation of hoists, page 27).

Intended use also includes observance of the operation

manual and compliance with the inspection and mainte-

nance conditions.

JDN Air Hoists are extremely robust and require little

maintenance. They are suitable for use in explosion-

hazardous areas, as well as in areas with increased

concentrations of soot and dust, high humidity and at

temperatures of -20°C up to approx. +70°C.

The thermal endurance of chains and hooks is +150°C.

CAUTION!

When touching metallic hand controls which

are colder than 0°C, freezing of the skin can

occur within a few seconds and for tempera-

tures above 43°C, burns can occur.

For stationary outdoor operation, hoists must be protec-

ted against weathering and the maintenance intervals

must be shortened.

Depending upon the version, JDN Air Hoists must be

operated at a system pressure of 4 bar or 6 bar. If the

system pressure is too low, important functions of the

hoist will be impaired:

The brake will drag and is thus subject to a high

degree of wear.

DANGER!

Warning against excessive system pressures

Operating with excessive system pressures

results in danger due to overloading.

Therefore, the pressure must be limited to

that specified on the nameplate.

JDN Air Hoists must be operated with a sufficiently

clean and dry air supply. The air supply must fulfil the

following quality requirements:

Particle size less than 40 µm

Particle density less than 5 mg/m3

In order to provide adequate compressed air quality,

operation with a service unit is recommended. Usually,

an oiler is not required in the service unit, as the motor

is provided with internal permanent lubrication.

Pressure dew point at least 10°C below the lowest

expected ambient temperature

Do not operate JDN Air Hoists with other gases.

With moist air and ambient temperatures at or below

0°C, there is a danger of icing in the motor.

Icing can be prevented by:

the use of an upstream air dryer or using a service

unit with oiler,

adding anti-icing agent to the lubrication oil

(depending upon moisture content of compressed air)

or using compressed air oil (Art. no. 11900) with

anti-icing agent for relevant temperatures.

In case your JDN Air Hoist is operated in combination

with a trolley, please read also the trolley operation

manual and the relevant accident-prevention regulations

for operation with trolleys.

OPERATING CONDITIONS

INTENDED USE

PRODUCT INFORMATION

Page 15

For air pressure, air quantity and connections, see the

table Technical data, page 56.

AIR PRESSURE CONDITIONS IN OPERATION

The system pressure in the air line must correspond to

the nominal pressure. Higher pressures must be reduced.

After switching on, the nominal pressure p1 drops to

the actual pressure p2.

The value of the actual pressure p2 at which the hoist

is operated, depends upon

the weight of the load and

the direction of movement of the load.

When lifting the nominal load (load-carrying capacity),

the actual pressure p2 must not fall below a value 10%

below the specified nominal pressure of the hoist.

Example:

A hoist with a nominal pressure of 6 bar lifts

its nominal load at the specified lifting speed, at an

actual pressure of 5.4 bar.

... the weight of the load ...

... and the direction of movement of the load.

The value of the actual pressure depends upon ...

ENERGY REQUIREMENTS

The vane motor consists of a cylinder liner 1with two

side bearing plates and an internal rotor 2.

The rotor is mounted eccentrically in the cylinder liner

and is provided with slots 3for installation of the vanes 4.

The vanes can move freely and make contact with the

inner wall 5of the cylinder liner. Each chamber is formed

by two vanes 6.

Due to the incoming compressed air, a greater force is

created at the leading, larger vane surface 4.1 than that

at the trailing, smaller vane surface 4.2. The difference

in force generates the rotor torque.

As the chamber passes the outlet aperture 7, the com-

pressed air can escape.

Lubricant chambers 8 are provided between the vane

slots of the rotor. They ensure continual motor lubri-

cation over a period of 250 - 500 operating hours

(depending upon motor type).

The arrows in the illustration indicate the direction of

rotation of the rotor and the corresponding path of the

compressed air.

4.2 164.1 2 5

3

847

PRINCIPLE OF OPERATION

OF JDN AIR VANE MOTORS

PRODUCT INFORMATION

Page 16

PRODUCT INFORMATION

Page 17

DANGER!

If JDN Air Hoists are operated without a

chain box, it must be ensured that the idle

chain (unloaded chain end) running up or

down at the chain sprocket, does not present

a hazard, e.g. due to catching, impacting or

falling.

Danger due to falling chain can also arise, if

the idle chain is first deposited on a load with

a large surface and then slides off and drops.

JDN Air Hoists are provided with motor lubrication,

which is sufficient for approx. 250 operating hours.

Therefore, the service unit for filtration and pressure-

regulation of the compressed air can be installed without

an oiler. If required, the service unit is also available

with an oiler.

Only hoists which have a designation

may be operated within the EU.

Each JDN Air Hoist is delivered with a factory certificate.

Only use original JDN spare parts. J.D. NEUHAUS

GMBH & CO. KG accepts no liability for the use of

non-original components and/or modifications by

unauthorised persons.

SPARE PARTS

CERTIFICATION

DESIGNATION

OPERATION WITH SERVICE UNIT

OPERATION WITHOUT CHAIN BOX

TRANSPORT AND STORAGE

Page 18

TRANSPORT AND STORAGE

If you wish to transport your JDN Air Hoist to another

site, please observe the following points:

Set the housing down carefully; do not allow to drop.

Weight of hoist, see Technical data, page 56.

Lay control and supply hoses together in such a way

that they are not kinked.

Secure the chain.

BREAKS IN OPERATION

In the case of longer operational breaks, coat the

chain and hook with a light oil film.

Motor conservation

If the grease packing of the rotor is not renewed after

250 operating hours, the motor must be conserved.

For this purpose, use a non-resinous and non-sticky

conserving oil with conserving protection duration,

which corresponds to the length of the planned ope-

rational break.

STORAGE

Close off the air supply hose connection using

adhesive tape or a suitable cap, in order to prevent

dirt ingress.

Store your JDN Air Hoist in a clean and dry place.

STORAGE CONDITIONS

SAFE TRANSPORTATION

INITIAL OPERATION

Page 19

INITIAL OPERATION

CAUTION!

When unpacking, take account of the weight

of the hoist. See Technical data, page 56.

ATTENTION!

Do not kink the control lines. Kinked

control lines can result in malfunctions.

Keep the accompanying documents in the place

provided, near the operating site.

Lift the hoist carefully out of the packaging.

Dispose of packaging in the local recycling system.

JDN Air Hoists are usually delivered pre-assembled.

If not, first read the following sections:

control connection (page 20)

Removing and installing chain (page 50)

Chain box (page 55)

In the case that the chain is included unattached, a

short auxiliary chain is drawn into the hoist. In order

to draw in the chain, the hoist must be connected to

the main air supply and must be ready for operation.

PRIOR TO INITIAL OPERATION,

THE CHAIN MUST BE LUBRICATED

(SEE PAGE 38).

DANGER!

JDN Air Hoists must only be installed

by qualified persons.

A defective installation can result in

the most serious of accidents.

DANGER!

The attachment points for JDN Air Hoists

must able to safely withstand the expected

forces.

DANGER!

The supporting structure of the air hoist

must form a rigid mounting. Vibration dama-

ges the chain and can lead to chain fracture.

Furthermore, external vibration must on no

account be transmitted to the hoist (lifting

gear). (e.g. from the suspended load).

Provide a suitable working platform.

Attach the hoist at the suspension hook (or suspensi-

on eye) to running gear or stationary fixing.

Ensure that the hook safety catch closes automatically.

Attach the hoist securely at the suspension hook

or suspension eye.

HOIST INSTALLATION

ASSEMBLY

UNPACKING

INITIAL OPERATION

Page 20

CONNECTING THE ROPE CONTROLS

Knot both control ropes at the ends of the

control lever.

Knot the green pin into the rope which activates

"lift" mode, with the pointed end upwards.

(See also illustration Rope control page 31)

Knot the yellow pin into the rope which activates

"lower" mode, with the pointed end downwards.

Knot the handle into the rope so that the arrow

markings correspond to the actual direction of

movement.

E-CONTROL CONNECTION

Pushbutton valve (hand control)

Guide the strain-relief rope through the eye on the

pushbutton valve and secure using the rope clamp.

Push the one-ear clamps onto the hose ends.

Attach the hoses to the hose nipples.

The one-ear hose clamp must lie in the middle of

the hose nipple clamping range. The best clamping

characteristics can be achieved in this range.

Pushbutton valve with nipples and rope with

designation lift and lower

Rope control, motor side

CONNECTING THE CONTROLS

Other manuals for PROFI 3 Ti

1

This manual suits for next models

3

Table of contents

Other J. D. NEUHAUS Chain Hoist manuals

J. D. NEUHAUS

J. D. NEUHAUS PROFI 3 Ti Product guide

J. D. NEUHAUS

J. D. NEUHAUS PROFI 6 Ti Product guide

J. D. NEUHAUS

J. D. NEUHAUS JDN mini 125 User manual

J. D. NEUHAUS

J. D. NEUHAUS PROFI 16 Ti Product guide

J. D. NEUHAUS

J. D. NEUHAUS PROFI 2 TI Product guide

J. D. NEUHAUS

J. D. NEUHAUS PROFI 25 TI Product guide

J. D. NEUHAUS

J. D. NEUHAUS Profi 025Ti User manual

J. D. NEUHAUS

J. D. NEUHAUS PROFI 25TI User manual