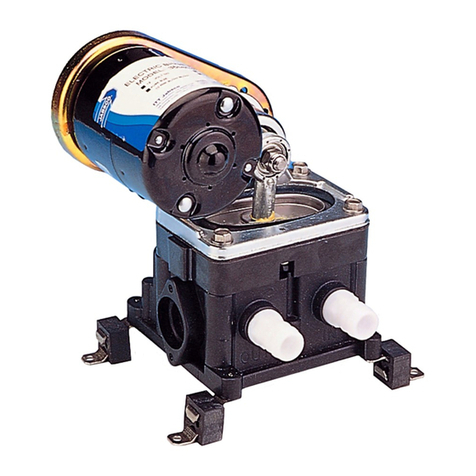

Models18690.0000

115VOLT

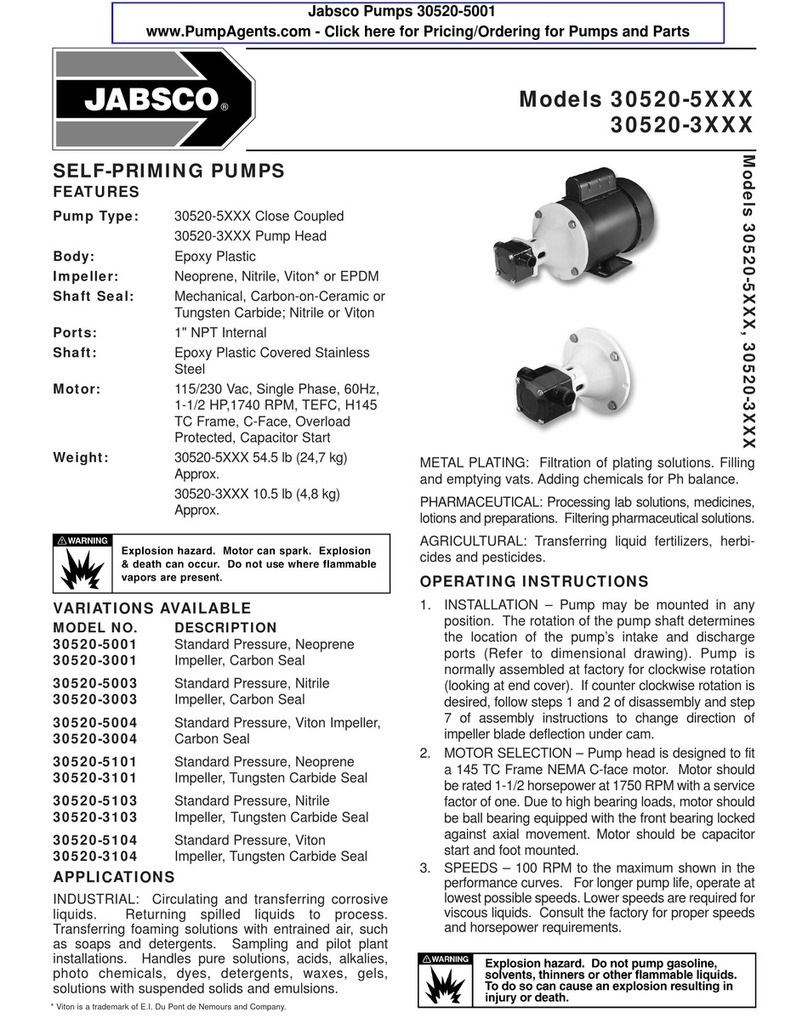

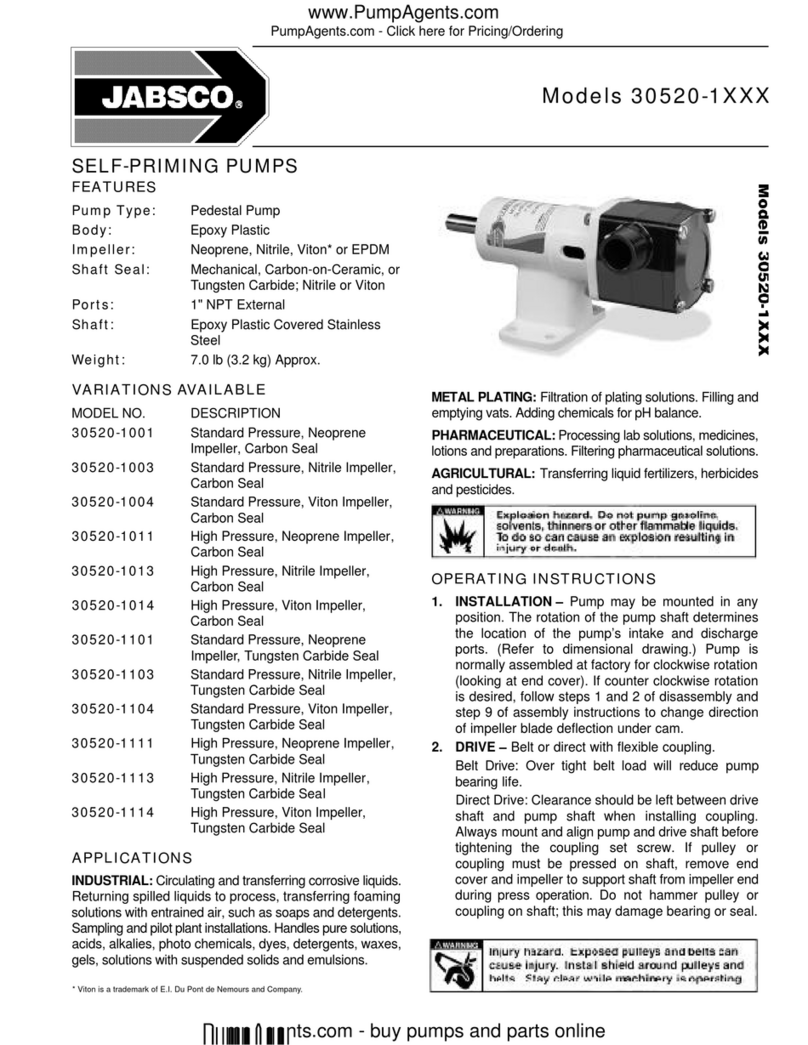

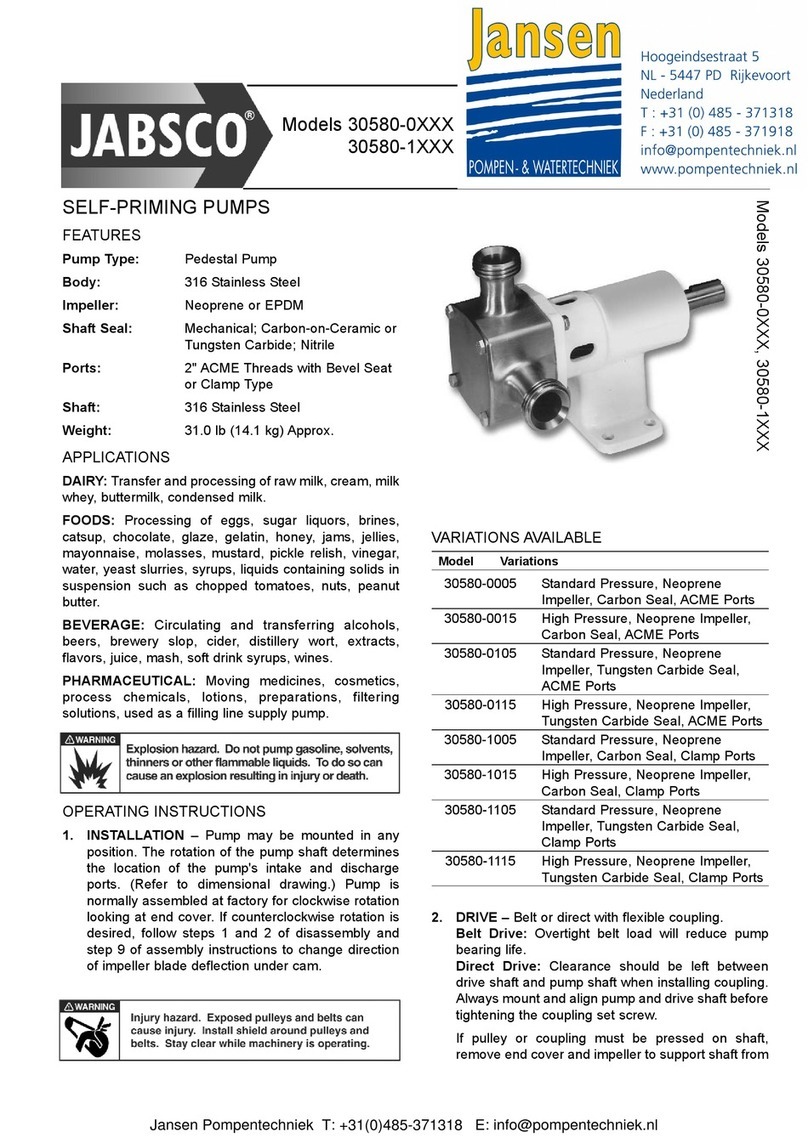

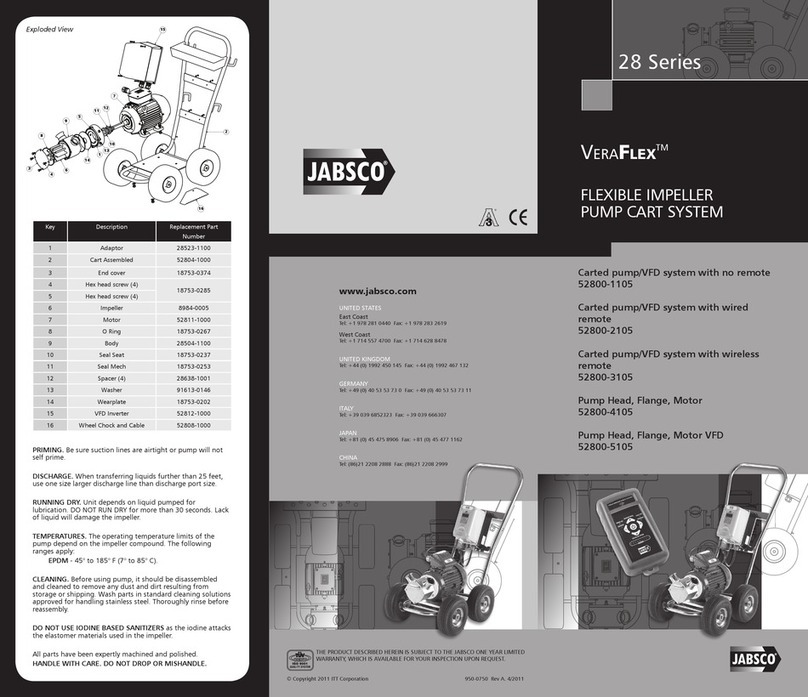

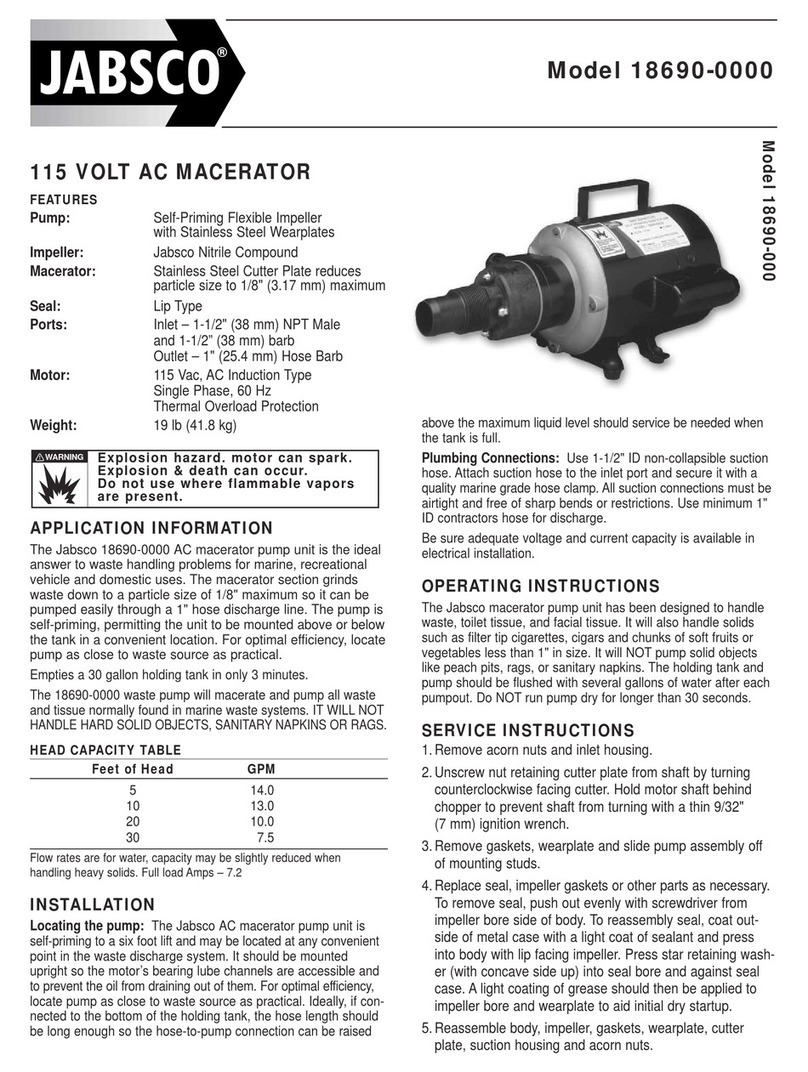

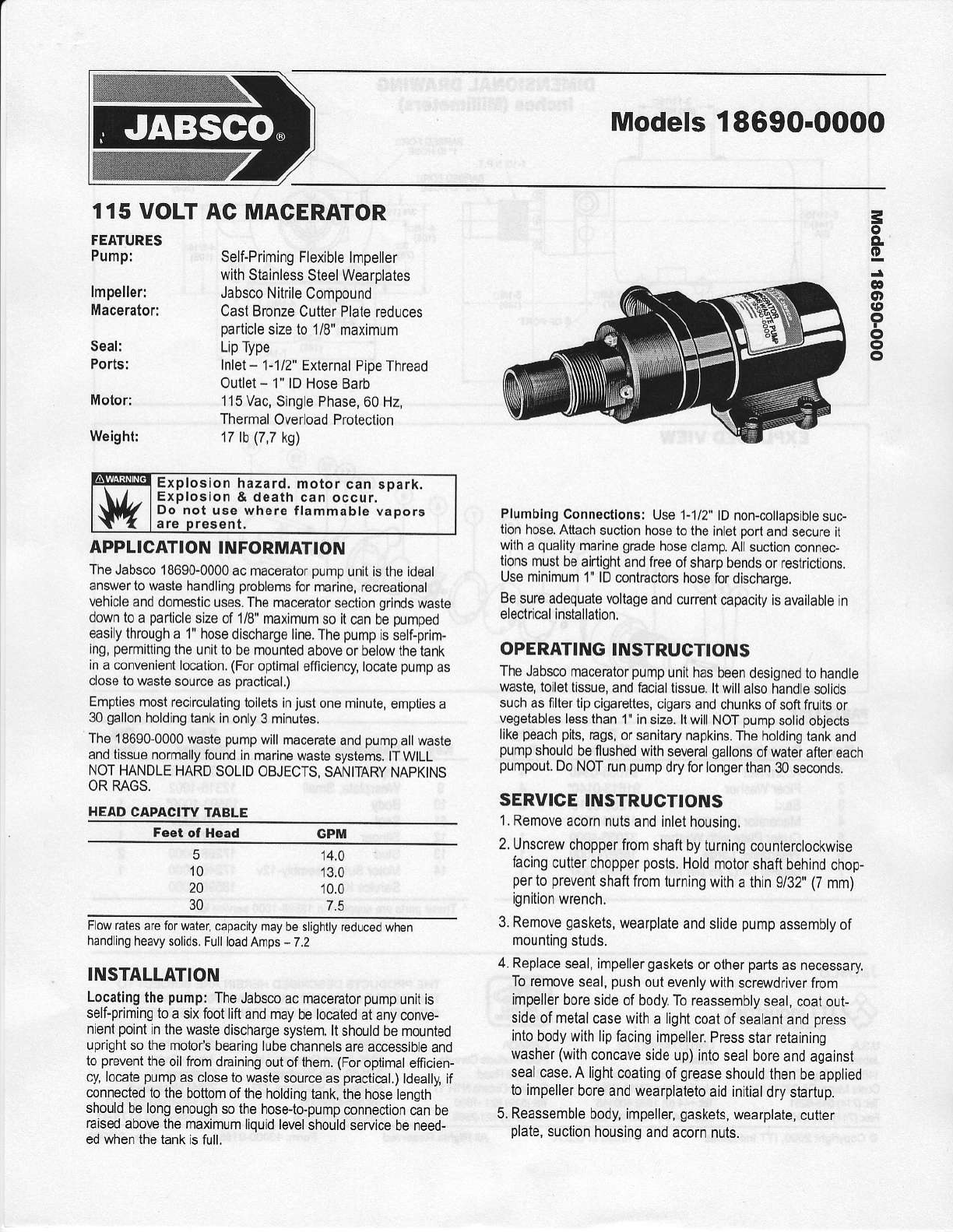

FEATURES

Pump:

lmpellerl

Macelatori

Seal:

Ports:

Motor:

W€ight:

ACMACERATOR

Self-PrimingFlexible

lmpeller

withStainless

SteelWearplates

JabscoNihile

Compound

CaslBrcnzeCullerPlale

reduces

padicle

sizetol/8'maximum

LipType

Inlet-1-1l2"Exlemal

PipeThread

outlet

- 1'lD

HoseBarb

115Vac,

SinglePhase,60Hz,

Thermal

overloadProtection

17lb

(7,7

ks)

3

c

l

Q

o,

@

o

o

o

o

APPLICATION

IiIFORMATIOiI

The

Jabsco1869G0000

acmaceEtor

oumounitistheid6al

answettowastahandllng

prcblemsfor

mane,rccrearcnal

vehicle

anddomestic

us€g.ThemacarBlor

sec:rio^

gnnds

w6ste

downlo

apBdicle

s.z6of

1/8'

m6x,mum

soit

canb6

prinoed

easlly

througha1"hos6

dischargelln€.The

pump

isself-prlm-

hg,

permitting

lhB

lnittobemount€d

aboveorbelowth€lank

inaconvenlenllocation.(Foropilmal

gfficienq/,

loc€tg

purnp

as

cosetowEsle

sourcsas

pracllcal,)

Empliesmostr6ckculating

toll6ls

injuston6minule,

gmpties

a

30

gallon

holdinglankInonly

3minuies.

The18690-0000

waslo

pump

willmacoraio

and

pump

allwasi6

and

ll6suenormallyfound

inmarin€waste

syslems,ITWILL

NOT

HANDLEHARD

SOLIDOBJECTS,

SANITARYNAPKINS

ORRAGS.

HEADCAPACITY

TABLE

Exploslonhazard.

motor

canBDark.

Exploslon

& dsathcanoccur.

Donot usewh€.€flammable

vaoor3 Plumblng

Connoctlonsr

us€1'1l2"

lDnon-cottapsible

suo

Uon

hose,Atlach

suctionhos6lothg

inlet

porl

and

sscufeI

with

a

quallly

mafine

grade

hos€

d6moAllsuctton

oonneo-

llon6

mustb6alrtight

andfre€

ofsharpb€nds

or

restriclions.

Useminifillm

1"lDcontraclorshos€

fordlschaEe,

Bo

sureadequatovoltage

andcurrent

capacityisavaiabte

in

elsclric€liruiallatLon,

OPERATIiIG

INSTRUCTIOITIS

TheJabsco

macerator

pump

unithasb€en

designedtohandtg

wast6,ioll6l

lissu€,andiacial

tissu6.ltwttt

alsohand6soflds

such

ar tilt€riipcigargttos,

cigalsand

chunksofsofitruil6

ol

veg6lab€sl6ss

tnan1'rn

EJz6.

lt

wlltNOT

pLTp

sottd

obj€cts

lik€

peach

pils,

rags,

or

63nrtarynapkin6.Th€ho.ding

l€nk

and

pump

shouldb6flushed

wilhs6v6ral

gallons

ofwat€a

aftereach

pumpout.

DoNOT

run

pump

dryfor

longerthan30s6conds.

SERVICE I STRUCTIO S

i.Remove

acornnutsandinlel

housing,

2.lJnscrew

chopperfrom

shaftbytuming

counterctockwlse

facing

cuttefchopper

posts,

Hold

moiorshafrbehind

chop-

pertopr€vent

shaftfromturning

withathin

9/32'(7mm)

ignllion

wrench.

3.Remove

gaskets,

wearplateand

slide

pump

assembly

of

mouniing

studs.

4.Replace

seal,impellergaskets

ofolher

parts

asnecessary

Toremove

seal,

push

oulevenlywilh

screwdriverfrom

impellerbore

sideofbody.

Toreassembly

seal,coarour-

side

ofmelaicasewith

alightcoat

ofsealantand

press

into

bodywlthlip

facingimpeller

Pressslarretaining

washer

(wilh

concaveside

up)intoseal

borcandagainst

sealcase.

Alighlcoating

ofgrease

shouldlhenbeapplied

loimpeller

boreandwearplateto

ajdinitial

drystarlup.

5.Reassemble

body,impeller,

gaskels,

wearplate,

cuner

plate,

suclion

housingand

acornnuts.

Feet ol Hoad 14.0

13.0

10.0

7.5

Flowmles

arcfo.water,capaciiy

maybesiehlty

rcducedwhen

handling

heavysolids.

FullloadAnps

- 7.2

INSTALLATION

Locating

the

pump:

TheJabscoacmaceraor

pump

un,ris

self-pningloasixfoolliflanornay

belocal€datanyconv+

nient

poinl

in1fuwaste

dischae€

6ystem,llshouldbomoufieo

upfighlsothemoto/s

bearinglube

channetsaroaccessible

and

topre!€nl

lhe

oilfromd|aining

outoflhem.

(For

opiirnatemci€n-

cy,locaie

pump

asclosetowastesourceas

practic€t.)

ldeattyif

connecled

tothebotlom

of

the

holdinglank,ihehose

tength

shouldbelong

enoughsothehose-tilpump

conneclioncanbe

€isedabovethemaximum

liquidlevel

shouldservice

oeneeo,

edwhenthelankis

full.

5

10

20

30