U.S.A.

Jabsco

20 Icon

Foothill Ranch, CA 92610-3000

Tel: 949.609.5106

Fax: 949.859.1254

UNITED KINGDOM

Jabsco

Bingley Road, Hoddesdon

Hertfordshire EN11 OBU

Tel: +44 (0) 1992 450145

Fax: +44 (0) 1992 467132

CANADA

Fluid Products Canada

55 Royal Road

Guelph, Ontario N1H 1T1

Tel: (519) 821.1900

Fax: (519) 821.2569

JAPAN

NHK Jabsco Company Ltd.

3-21-10, Shin-Yokohama

Kohoku-Ku, Yokohama, 222

Tel: 045.475.8906

Fax: 045.475.8908

GERMANY

Jabsco GmbH

Oststrasse 28

22840 Norderstedt

Tel: +49-40-53 53 73 -0

Fax: +49-40-53 53 73 -11

THE PRODUCTS DESCRIBED HEREIN ARE

SUBJECT TO THE JABSCO ONE YEAR LIMITED

WARRANTY, WHICH IS AVAILABLE FOR YOUR

INSPECTION UPON REQUEST.

© Copyright 2002, ITT Industries Printed in U.S.A. All Rights Reserved Form: 43000-0704 M-1354 Rev. A 8/2002

5-1/8"

(130 mm)

9-3/8" (238 mm) 11-1/4" (286 mm)

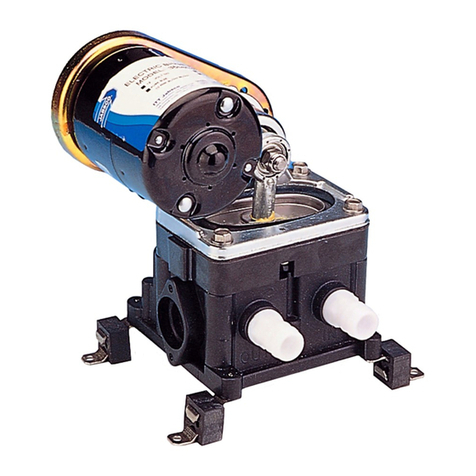

DIMENSIONAL DRAWING

Inches (Millimetres)

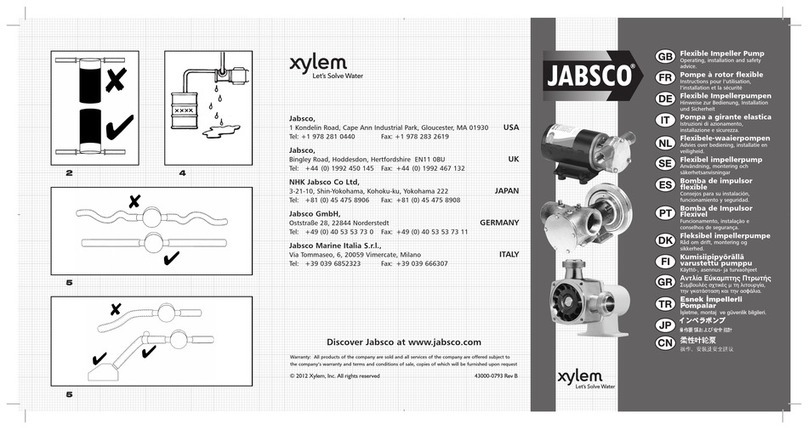

INSTALLATION & PLUMBING

Select a location for the Shower Sump Pump that is

lower than the drain connection at the shower pan and is

easily accessible for periodic inspections of the inlet

strainer. It is best to have a minimum drop of 1" for each

6 feet (2-1/2cm per 1M) of run of the drain hose from the

shower. The drain hose should drop continuously from

the shower pan to the Shower Sump Pump with no dips

in the plumbing that would trap water. Before installing

the reservoir, determine which inlet port fitting(s) will be

used and is(are) the correct size for the shower drain

hose(s), then cut off the closed end of the selected port

fitting(s) with a hack saw. Do not cut off the ends of

port fittings that are not intended to be used.

The shower sump reservoir should be secured to a solid

flat mounting surface with either short stainless steel

screws or affixed with a quality marine sealant with good

adhesive characteristics (such as Rule* Elastomeric

Marine Sealer) used as an adhesive. If securing the

reservoir with screws to the bottom of the vessel, ensure

the penetration of the screw is significantly less than the

thickness of the hull. Mark the location of at least four of

the reservoir’s mounting holes and then very carefully

drill pilot holes for the screws. It is helpful to wrap the drill

bit with a piece of tape so the tape’s edge indicates the

maximum depth of the hole to serve as a stop indicator.

If securing the reservoir with a sealant, apply a liberal

bead of the sealant along the line of the mounting holes

on the underside of the mounting tabs. Press the

reservoir into place and leave it undisturbed until the

sealant has cured (check the manufacturer’s

recommended cure time).

The Shower Sump Pump’s 3/4" (19mm) discharge hose

should climb continuously and be attached to a thru-hull

fitting that remains well above the vessel’s waterline at

all angles of heel and trim. Sailboats normally discharge

through or just below the transom. The discharge

plumbing must not have any dips in it that would create

a water trap that will retain water in the hose. If this

occurs the Shower Sump Pump might airlock. To

maximize pump performance, the discharge plumbing

should be kept as short and straight as possible. Attach

all hoses to their respective hose barbs with stainless

steel band clamps. It is recommended that all plumbing

be secured in place about every 18" to 24" (45cm to

60cm) along the length of its run.

*Rule® is a registered trademark of ITT Industries.

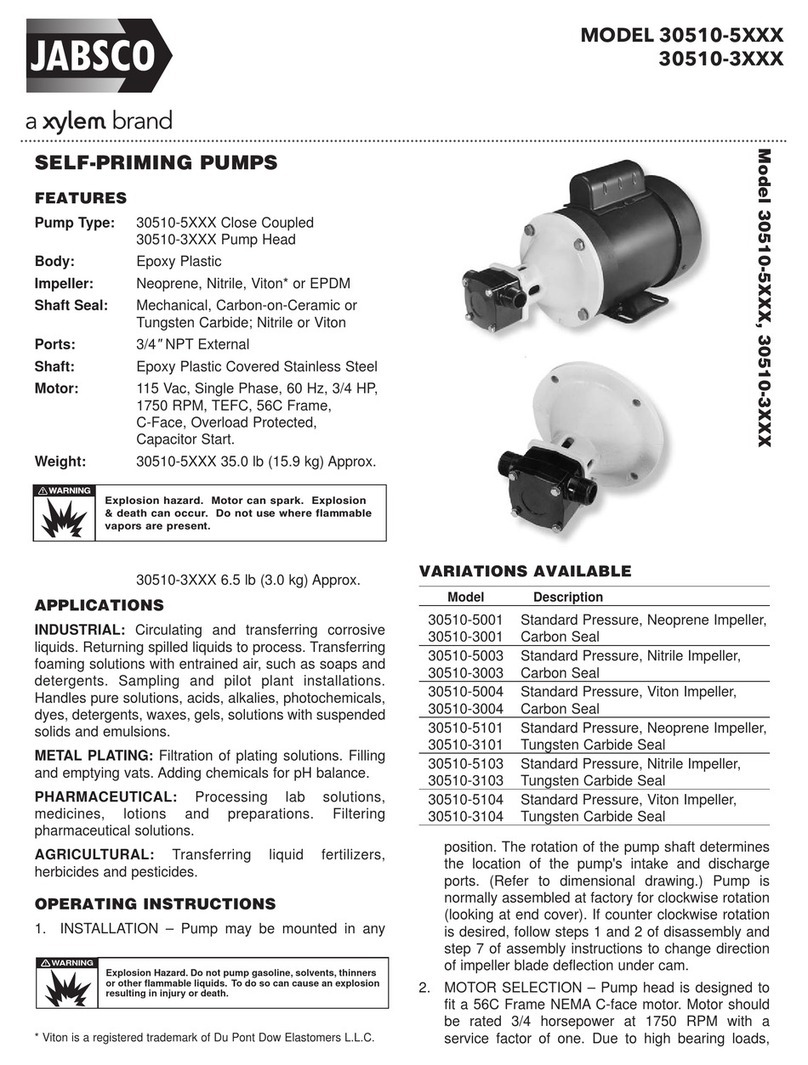

WIRING

All wiring connections must be made with mechanical

locking connectors (crimp type) and secured in a dry

location well above bilge areas where water may collect.

To better protect butt connections made in a humid

marine environment, it is advisable to seal the connections

with a small amount of marine sealant. Connect the gray

wire lead (from the switch) to a positive (+) power source

using a minimum16 gauge (1.5mm2) conductor**. This

conductor should originate from an overload protected

distribution panel where the conductor (and complete

circuit) is protected by a 5 amp fuse or circuit breaker for

12 Volt pumps and a 2-1/2 amp fuse or breaker for 24

Volt pumps. Connect the black lead (from the pump) to

battery negative.

** 16 gauge (1.5mm2) wire is large enough for total 12

Volt circuit lengths (combined positive (+) and negative

(-) conductors) of up to 50 feet (15M). Circuits longer

than this should use larger wire. Between 50 and 90 feet

(15M and 27M) use 14 gauge (2.5mm2) and between 90

and 130 feet (27M and 40M) use 12 gauge (4mm2). 24

Volt circuits can use 16 gauge (1.5mm) wire for total circuit

lengths of up to 100 feet and should use 14 gauge

(2.5mm) if the circuit length is between 100 and 150 feet.

Pump

Switch

Black

Gray

Overload

Protected

Distribution

Panel

Battery

WIRING DIAGRAM