JABSCO 51510 Series User manual

Other JABSCO Water Pump manuals

JABSCO

JABSCO 59520 Series User manual

JABSCO

JABSCO 50840 Series User manual

JABSCO

JABSCO ITT 36600 Series User manual

JABSCO

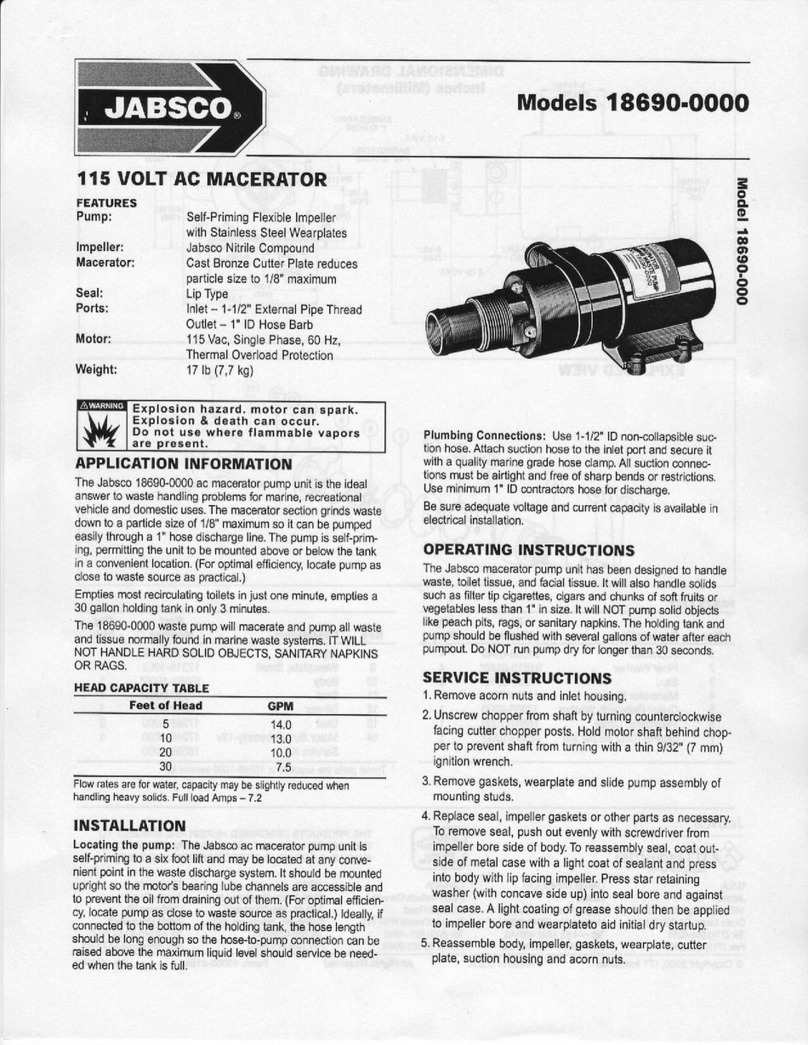

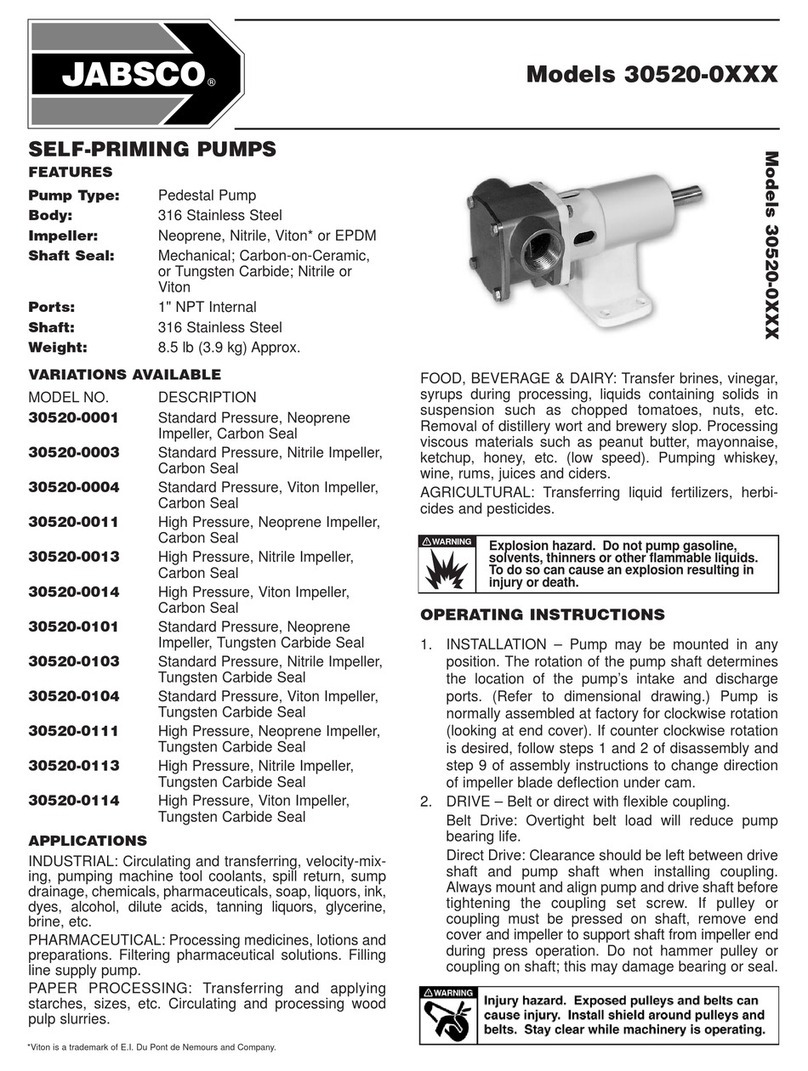

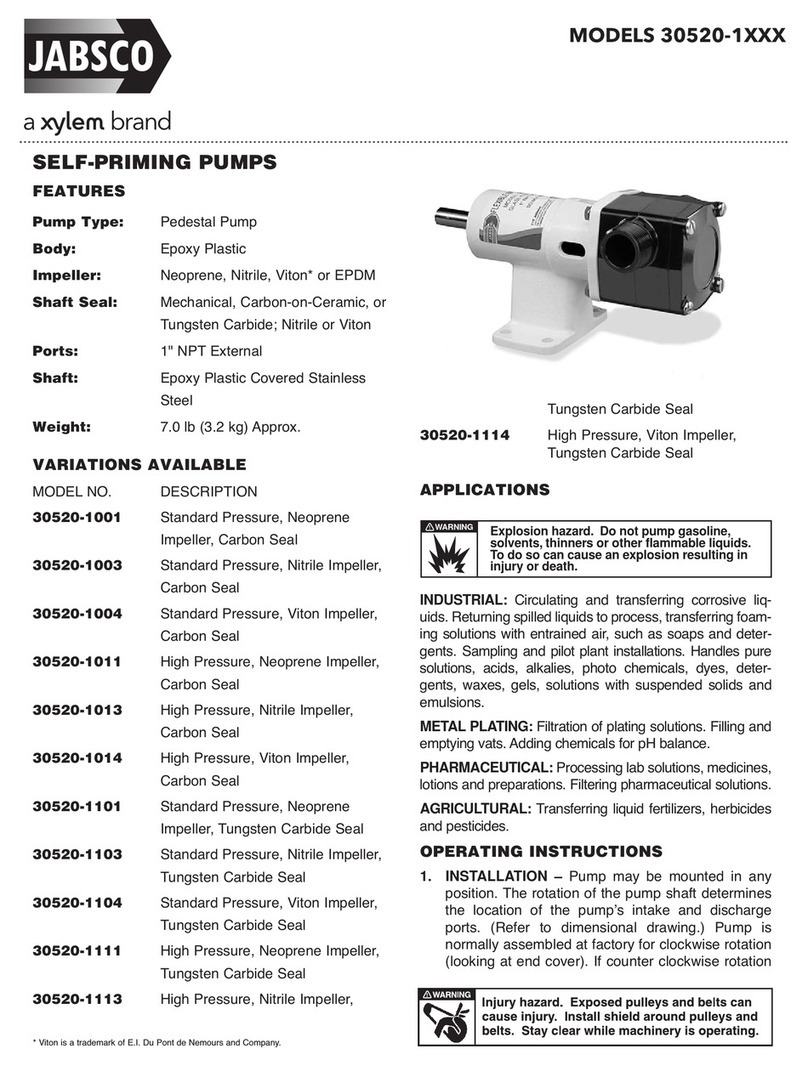

JABSCO 30520-0001 User manual

JABSCO

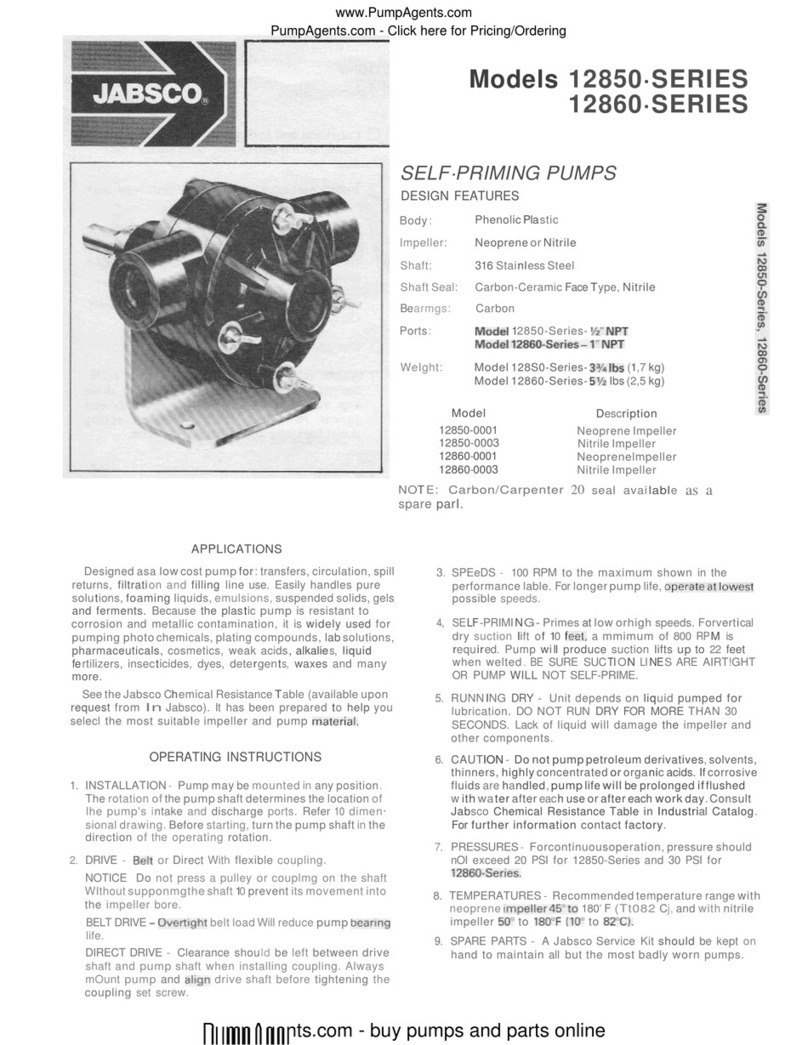

JABSCO 1285O SERIES User manual

JABSCO

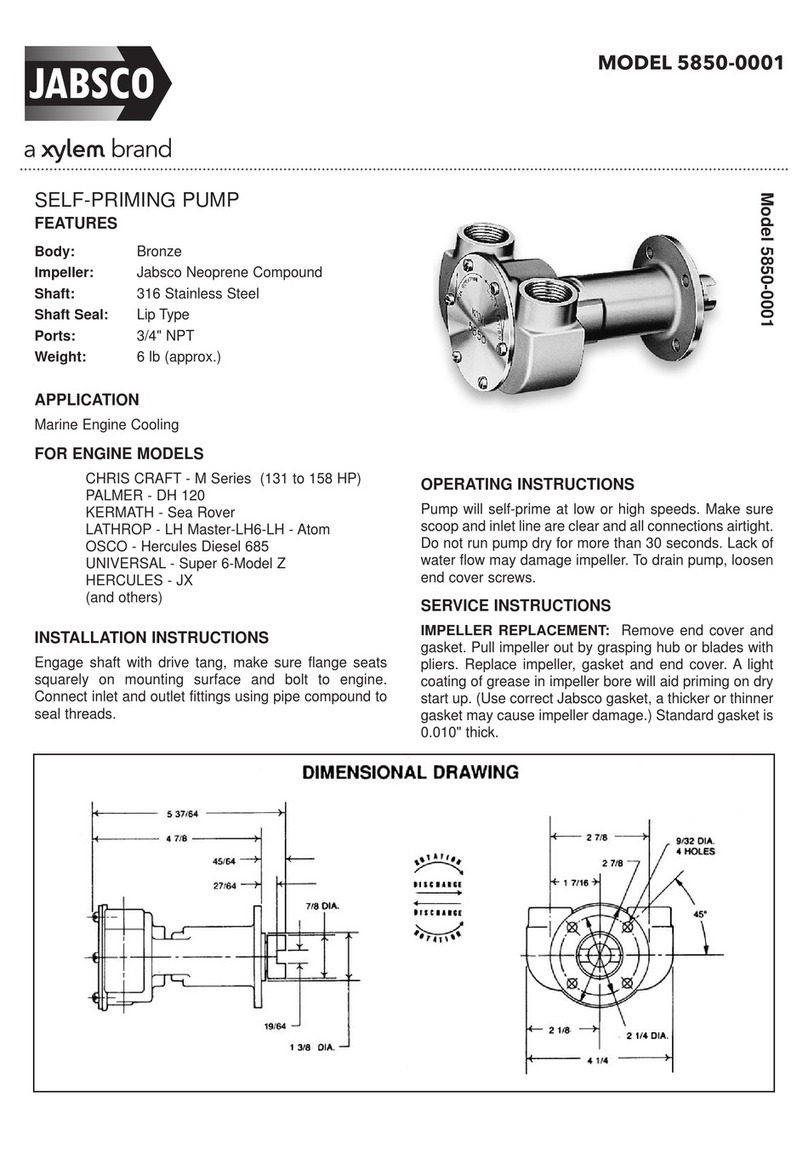

JABSCO 5850-0001 User manual

JABSCO

JABSCO 50870 Series User manual

JABSCO

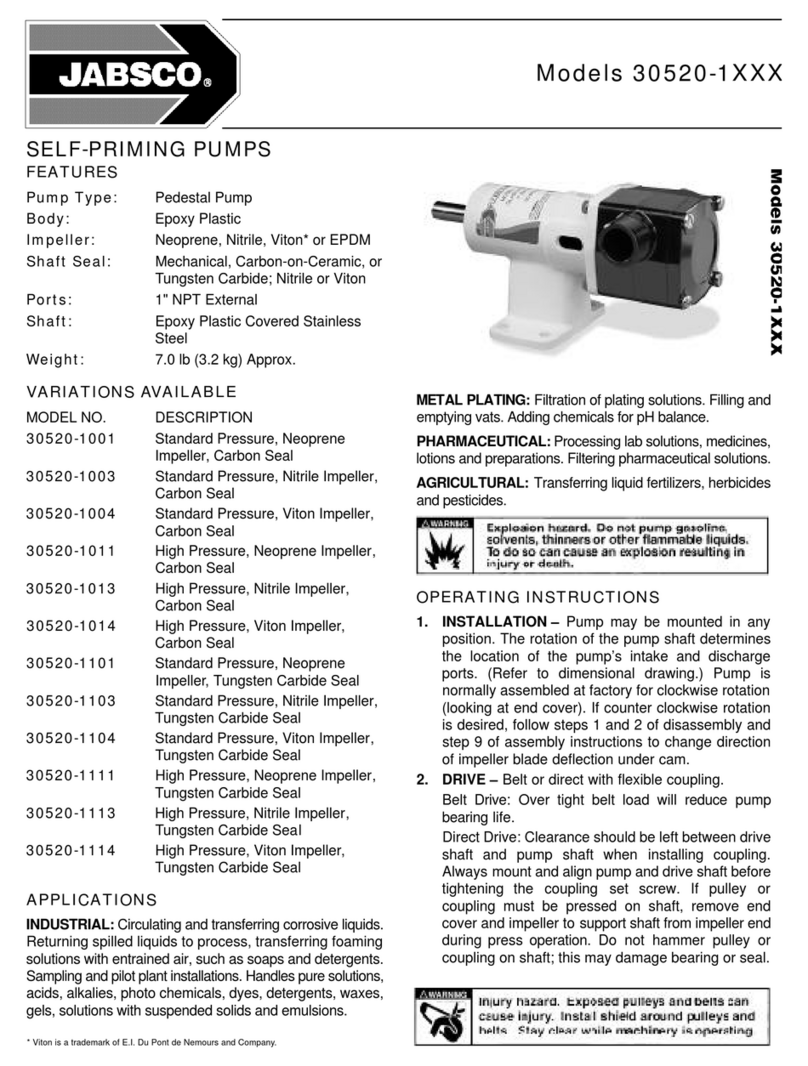

JABSCO 30520-1001 User manual

JABSCO

JABSCO 30520-4 Series User manual

JABSCO

JABSCO VR050-2022 User manual

JABSCO

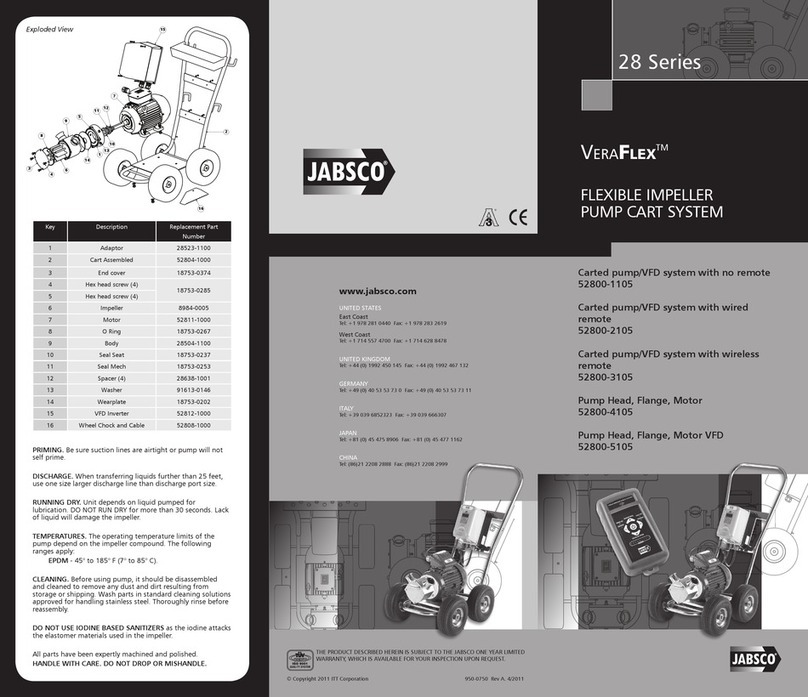

JABSCO 28 Series User manual

JABSCO

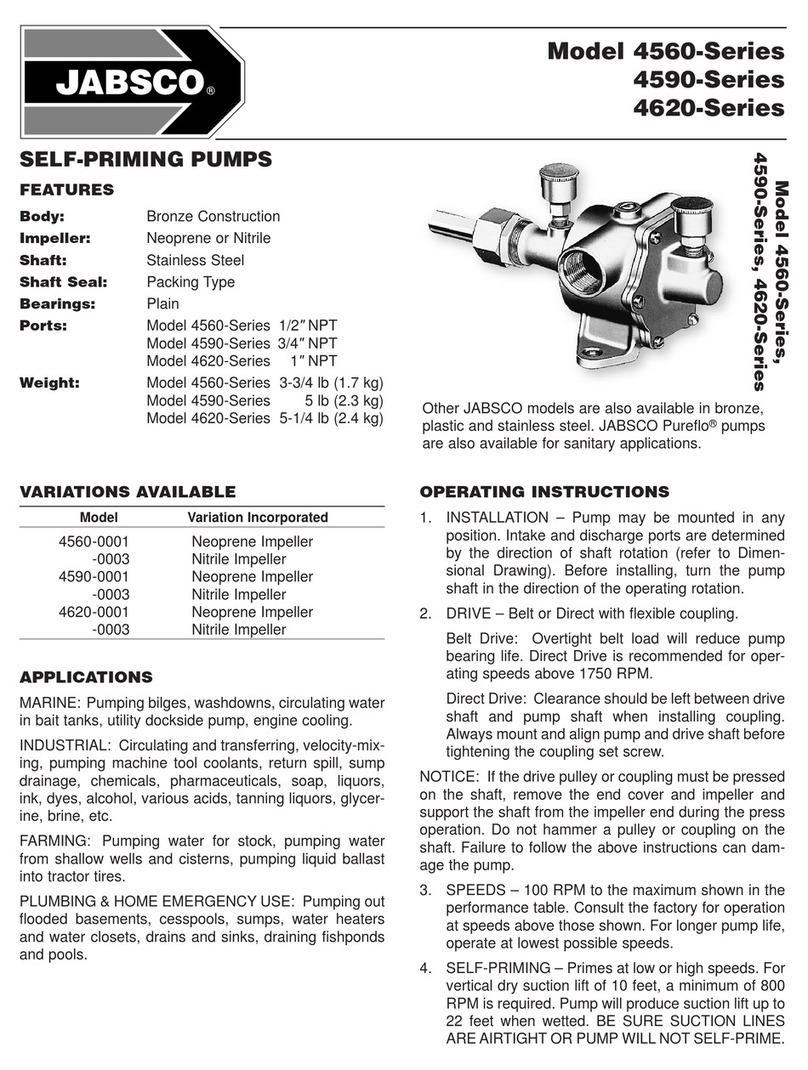

JABSCO 4560 Series User manual

JABSCO

JABSCO 30520-1001 User manual

JABSCO

JABSCO 31295 Series User manual

JABSCO

JABSCO 31595-009 User manual

JABSCO

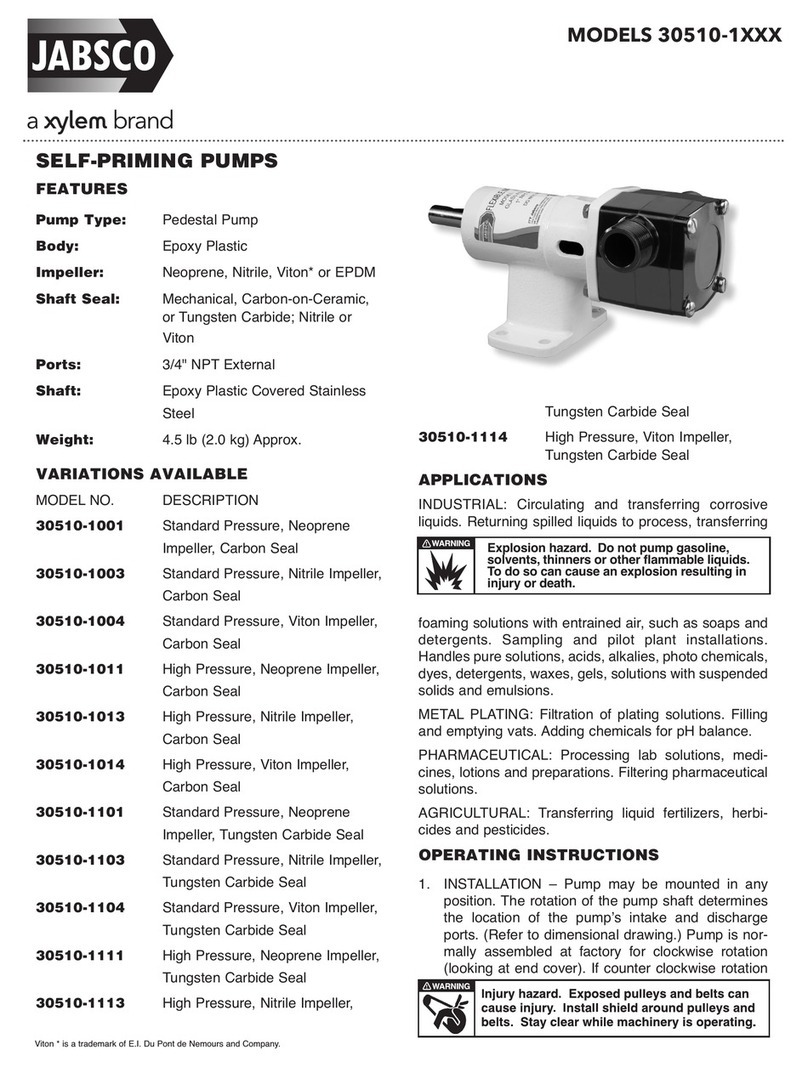

JABSCO 30510-1003 User manual

JABSCO

JABSCO 30570-0 Series User manual

JABSCO

JABSCO 36960-2 Series User manual

JABSCO

JABSCO 36680-2 Series User manual

JABSCO

JABSCO 5850-0001 User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual