Jadever IDS701-CTRUCK User manual

Other Jadever Scale manuals

Jadever

Jadever Jadever SKY User manual

Jadever

Jadever JKH User manual

Jadever

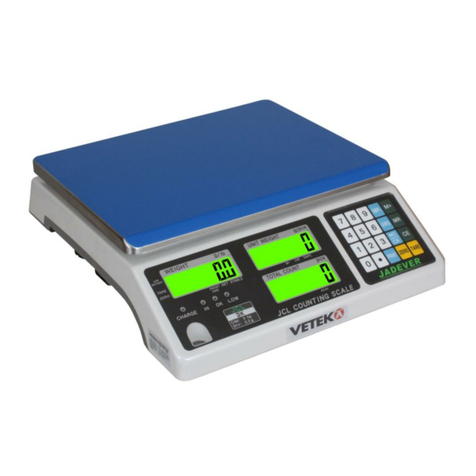

Jadever JCL-3K User manual

Jadever

Jadever JKD 250 User manual

Jadever

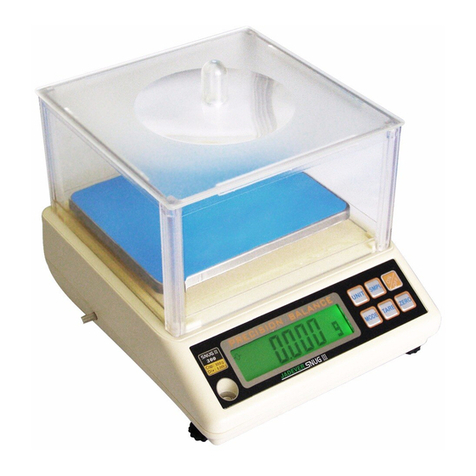

Jadever SNUGIII Series User manual

Jadever

Jadever NWTE User manual

Jadever

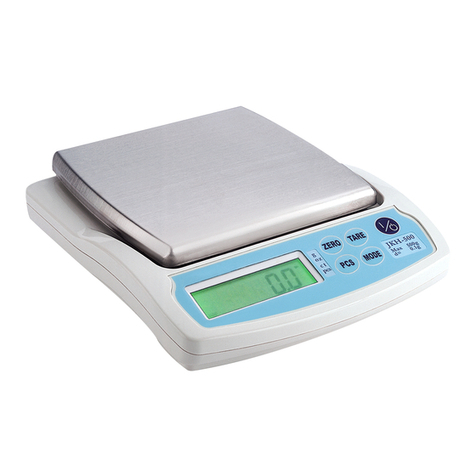

Jadever JC User manual

Jadever

Jadever JWE User manual

Jadever

Jadever JCL User manual

Jadever

Jadever JWE User manual

Jadever

Jadever LGCN-3075 User manual

Jadever

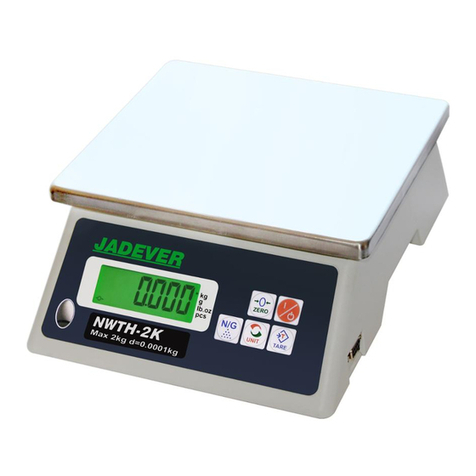

Jadever JWE-3K User manual

Jadever

Jadever LPWN-1530 User manual

Jadever

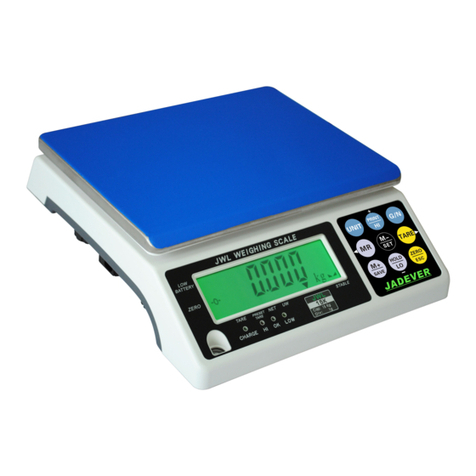

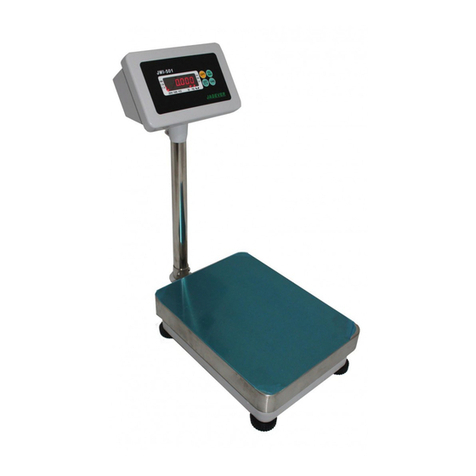

Jadever JWI-501 Series User manual

Jadever

Jadever JCL Series User manual

Jadever

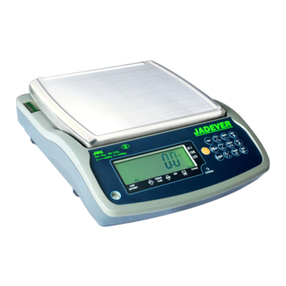

Jadever JWA series User manual

Jadever

Jadever JCN User manual

Jadever

Jadever JCAII User manual

Jadever

Jadever JCAII User manual

Jadever

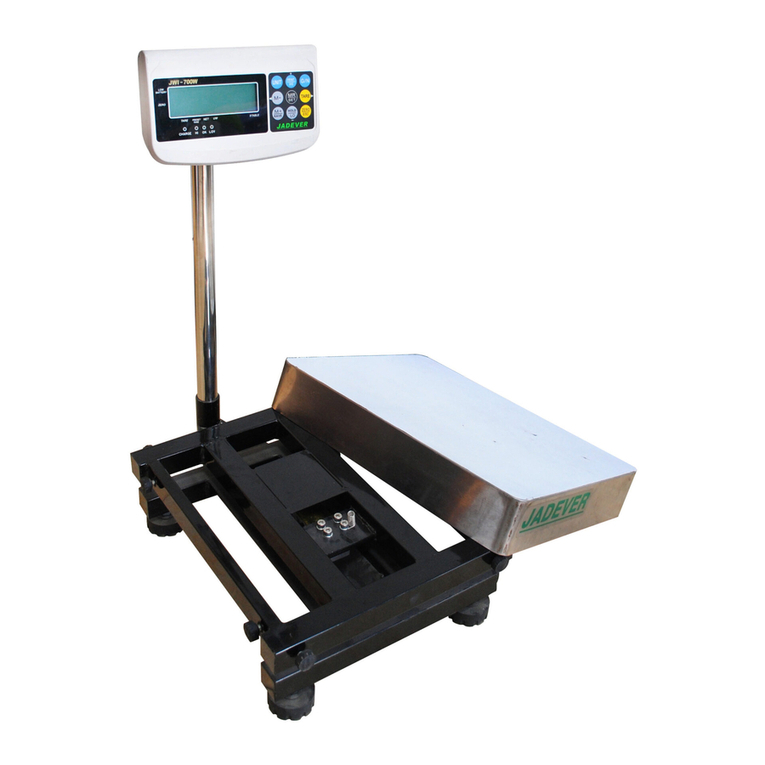

Jadever JWI-700W User manual