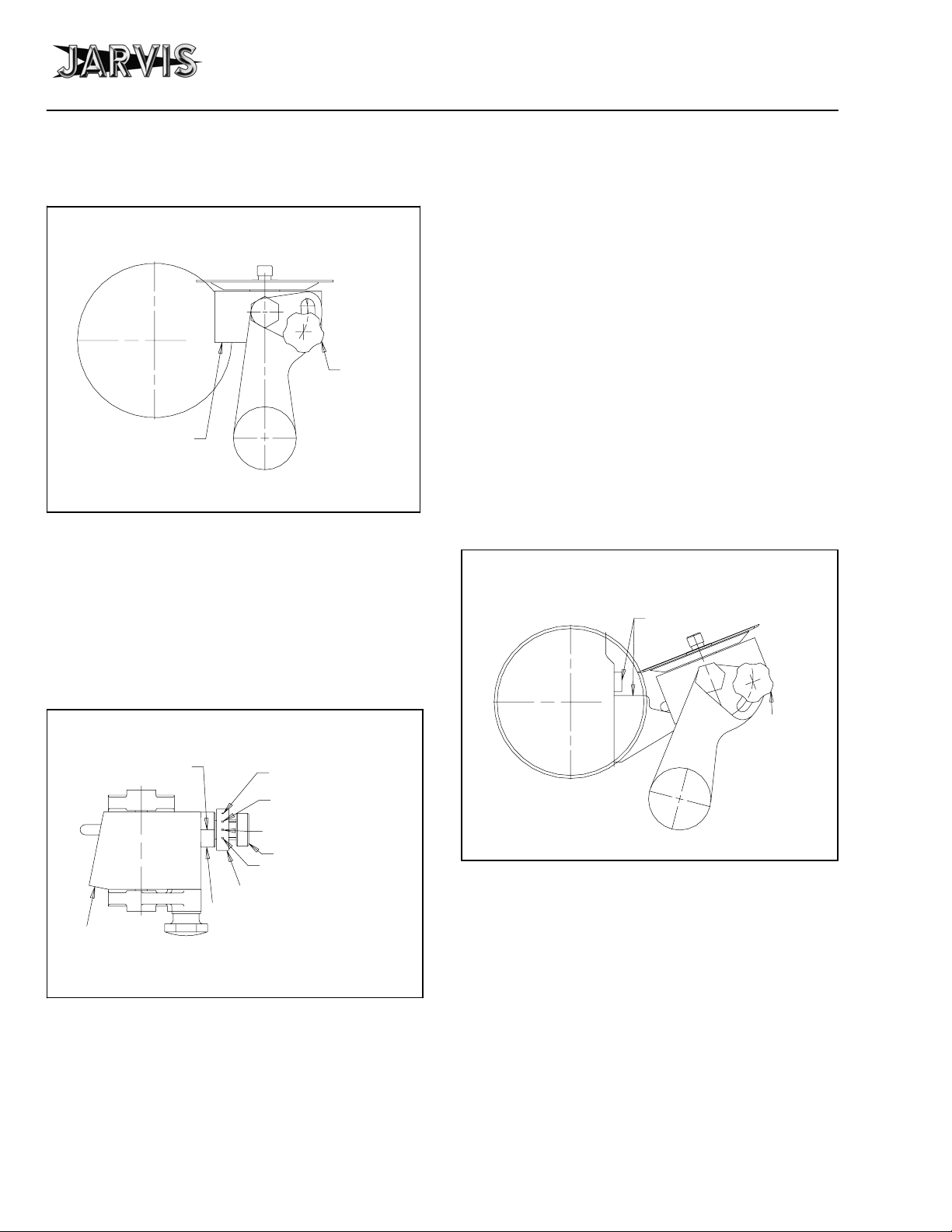

parts list

page 5 of 12 Model BR--5 / 5A / 5B / 5D

®

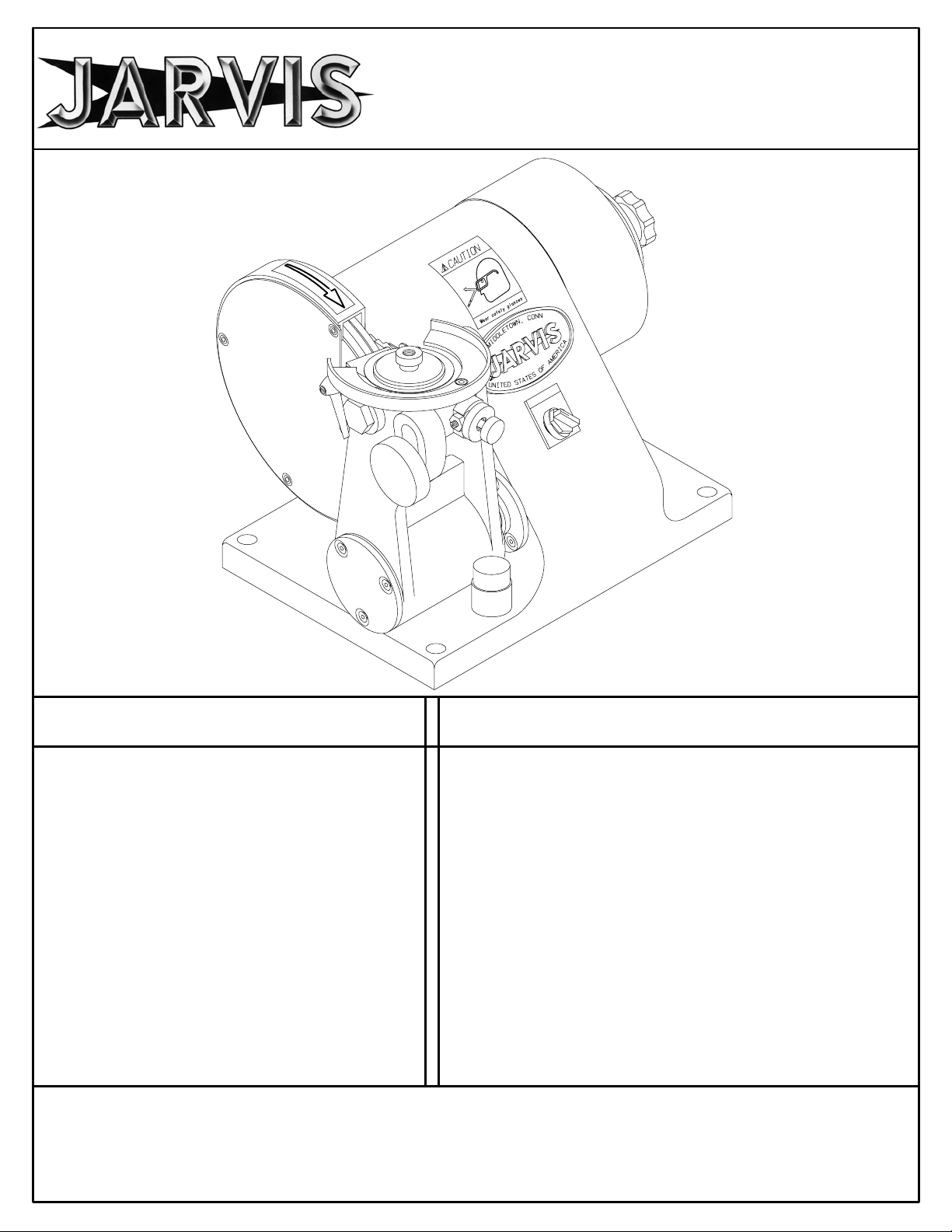

JARVIS

6211003;

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926

TEL. 860--347--7271 FAX. 860--347--6978 WWW. jarvisproducts.com

1 1055774 Flat Head Socket Screw 4

2 1002305 Left Guard Cover 1

3 1055727 Socket Head Cap Screw 1

4 1004223 Special Washer 1

5 1057047 Grinding Wheel (BR--5, 5B &5D) 1

1057075 Grinding Wheel (BR--5A)

1057067 Grinding Wheel (Round Tooth)

6 1055775 Flat Head Socket Screw 4

7 1024120 Left Guard (includes item 8) 1

8 1017021 Rotation Label 1

9 1055732 Flat Head Socket Screw 3

10 1035391 Dust Seal 1

11 1029330 Spacer 1

12 1007243 Hex Nut 6

13 1011240 Strain Relief Connector 1

14 3001008 Electric Cord Assembly 1

15 1016380 Grinder Base 1

16 1017159 Safety Label, Glasses 1

17 1017158 Nameplate Label 1

1017402 Nameplate Label, CE

18 1055735 Cheese Head Screw 8

19 1021331 Bearing 1

20 1013196 Retaining Ring 1

21 3020037 Motor Shaft Assembly 1

22 1063427 Stator (115/230V -- 60Hz.) 1

1063435 Stator (115/220V -- 50Hz.) 1

23 1021335 Ball Bearing 1

24 1014109 Wave Spring 1

25 1002303 Rear Motor Cover 1

26 1035393 Seal 1

27 1057046 Hollow Grind Wheel (BR--5A) 1

1057049 Hollow Grind Wheel (BR--5)

1057070 Hollow Grind Wheel (BR--5B)

1057078 Hollow Grind Wheel (BR--5D)

28 1020213 Hollow Grind Shaft 1

29 1021326 Bearing 1

30 1055645 Flat Head Socket Screw 13

31 3019126 Hollow Grind Handle Assembly 1

(includes items 29 and 30)

32 1004005 Split Lock Washer 2

33 1004206 Flat Washer 2

34 1029293 Top Spacer 2

35 1027058 Threaded Rod 2

36 1029294 Bottom Spacer 2

37 1005077 Electric Switch 1

38 1005087 Switch Contact Block 2

39 1017156 Legend Plate 1

40 1024122 Bumper Guard 1

41 1055776 Socket Head Cap Screw 3

42 1036186 Stop Bushing 1

43 1055773 Button Head Screw 3

44 1032318 Stop Plate 1

45 1032332 Stop Grind Plate 1

46 1010177 Dowel Pin 1

47 1030050 Key 1

48 1002302 Arm Shaft Cover 1

49 1014151 Spring Washer 2

50 1021322 Ball Bearing (BR--5, 5A & 5D) 4

1021322 Ball Bearing (BR--5B) 2

1021389** Ball Bearing (BR--5B) 2

51 1029296 Outer Spacer 1

52 see pg. 6 Indexing Arm Assembly 1

53 1029295 Inner Spacer 1

54 1013122 Retaining Ring 1

55 1020211 Arm Shaft 1

56 1007248 Hex Jam Nut 1

57 1036187 Arm Shaft Bushing 1

58 1063083 Ring Terminal 1

59 1055641 Socket Head Cap Screw 7

60 1004227 Lock Washer 1

61 1055733 Socket Head Cap Screw 2

62 1063403 Strip Terminal 1

63 1004225 Flat Washer 2

64 1007253 Hex Lock Nut 2

65 1063074 “F” Disconnect Terminal 6

66 1063304 Capacitor 1

67 1007254 Hex Lock Nut 4

68 1004226 Flat Washer 4

69 1012073 Cable Strap Clamp 2

70 1063402 Piggyback Terminal 2

71 1063305 Electric Switch 1

72 1002304 Wiring Cover with item 74 1

73 1055837 Socket Head Cap Screw 4

74 1055734 Socket Head Cap Screw 2

75 1017085 Safety Label, Electrical 1

1061512 Ferrules (not shown)

3028035 Indexing Arm Assy (BR--5A)

3028036 Indexing Arm Assy (BR--5)

(includes items 30, 43, 48--56,

77, 79--105, 108, 109 and 112)

3028047 Indexing Arm Assy (BR--5B)

(includes items 30, 43, 48--56,

77, 79--105, 108, 110 and 112)

3028050 Indexing Arm Assy (BR--5D)

(includes items 30, 43, 48--56,

77, 79--109, 111 and 112)

ITEM PART NO. PART NAME QTY ITEM PART NO. PART NAME QTY

** BR--5B (90 mm) item different from BR--5 (100 mm),

BR--A (110 mm) and BR--5D (100 and110 mm).