pg 5 of 8 MODEL 404

JARVIS

6205006;:.

®

blades, blade supports

and accessories

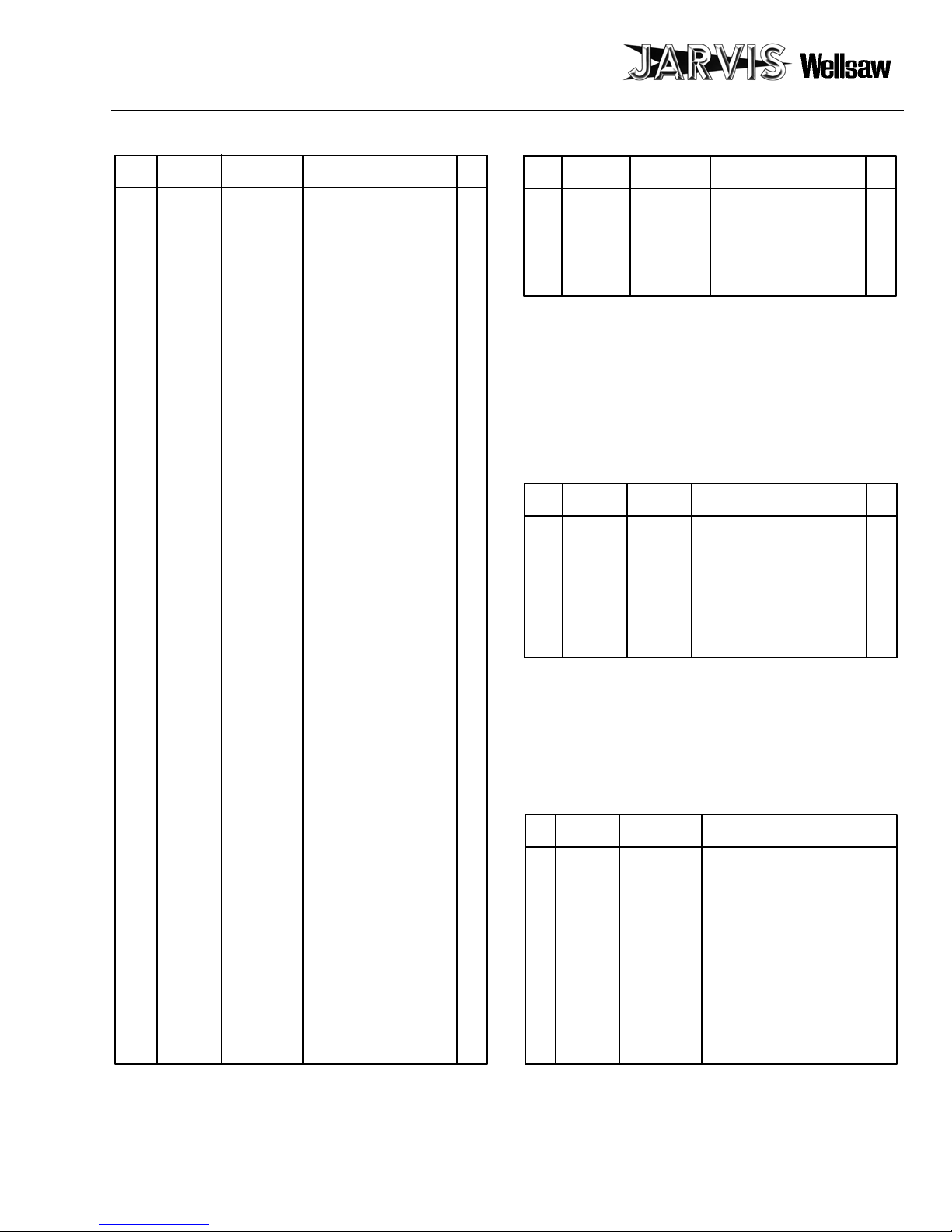

ITEM

OLD

PART NO.

JARVIS

PART NO. PART NAME QTY

1 1063112 501022--005 Brush Cap 2

2 1063111 501022--004 Brush and Spring 2

3 1063110 501022--003 Brush Holder 2

4 1015006 501174 Deflector 2

5 1002191 501002 Top Cap 1

6 1017083 Danger Label 1

7 1055428 100101--004 Screw, Flat Head 4

8 1021215 100403--003 Ball Bearing 1

9 1063119 501224--003 Stator, 115V 1

1063120 501224--004 Stator, 230V 1

10 1027040 501021 Stator Stud 2

11 1007164 100105--001 Lock Nut 4

12 1063117 501224--001 Armature, 115V 1

1063118 501224--002 Armature, 230V 1

13 1026072 501225 Pinion Gear 1

14 1021227 100422--004 Ball Bearing 1

15 1035193 501120--001 Seal 1

16 1035192 501103 Seal 2

17 1036116 501171 Bushing 1

18 1027041 501046 Rod Stud 1

19 3065010 501172 Push Rod and Stud 1

20 1012050 501350 Clamp Ring 1

21 1055422 100034--038 Set Screw, 1/4 inch 1

22 8030031 100099--001 Hex Key 1

23 1002206 501003--001 Blade Support Cover 1

24 1007162 100022--006 Cap Nut 6

25 1055439 100102--002 Screw, Oval Head Phil 2

26 1054076 501380 Screw, Coated 3

27 1002203 501004 Handle Cover 1

28 1005038 100739--001 Switch 1

29 1073190 Screw, Round Head 2

30 1012046 501042 “S” Clip 1

31 1012047 501043 “U” Clip (rubber) 1

32 1027048 501272 Stud 3

33 1036120 501273 Insert Bushing 3

34 1017033 501187 Info Label 115V, Eng. 1

1017034 501179 Info Label 230V, Eng.

1017054 Info Label 115V, French

1017234 Info Label 230V, French

35 1045013 Label Retaining Rivet 4

36 1004149 100426--001 Thrust Bearing Race 1

37 1021218 100425--001 Needle Thrust Bearing 1

38 1027043 501081 Drive Stud 1

39 3026024 501223 Gear and Stud (32) 1

40 1020133 501377 Gear Shaft 1

41 1021228 Needle Bearing 2

42 1035191 501008 Gasket 1

43 1002193 501005 Bottom Plate 1

44 1055426 100101--001 Screw (set of 12) 4

45 3028030 501053 Connecting Rod & Brg 1

46 1029185 501082 Spacer 1

47 1013310 100069--013 Snap Ring 1

48 1021216 100424--001 Needle Bearing 2

49 1055454 Screw, Round Head 1

50 3001008 501006 Cord, Plug & Molded

Strain Relief, 115V

3001010 501089 Cord, Plug & Molded

Strain Relief, 230V

51 3001011 501337 Cord w/o Strain Relief 1

52 1063125 501294 Strain Relief 1

ITEM

OLD

PART NO.

JARVIS

PART NO. PART NAME QTY

replacement kits

IT. OLD

PART NO.

JARVIS

PART NO. PART NAME

3063010 501351--001 Armature and Bearing

(no pinion gear) 115V

3063011 501351--002 Armature and Bearing

(no pinion gear) 230V

3063007 501235--001 Armature, Bearing

and Pinion Gear, 115V

3063008 501235--002 Armature, Bearing

and Pinion Gear, 230V

3063013 501232 Armature and Pinion,115V

3063014 501233 Armature and Pinion,230V

3026023 501088 Gear & Bearing Assembly

3016119 501169--001 Hsg, Seals & Bushing Assy

3061152 Service Kit (items 11, 13,

27, 33, 38 and 42)

ITEM

OLD

PART NO.

JARVIS

PART NO. PART NAME QTY

53 1013137 501295 Clamp Ring 1

54 1063109 100647 Grommet 1

55 1016199 501001--006 Housing 1

56 1007166 501376 Gear Stud Nut 1

57 1006021 501066 Knob 1

58 1055429 100102--003 Screw, Oval Head Phil 2

59 1027042 501065 Handle Stud 1

60 1058071 501175T Blade Support 8” End Cut 1

1058070 501128T Blade Sup. 16” End Cut

61 1023122 501246 Blade 8” End Cutting 1

1023121 501247 Blade 16” End Cutting

62 1058075 502077T Blade Sup. 8” Heavy Duty 1

1058074 502076T Blade Sup. 16” Heavy Duty

63 1023123 501319 Blade 8” Heavy Duty 1

1023124 501320 Blade 16” Heavy Duty

1062003 Gear Grease, 1 Lb Can 1

parts list

Cutlerymania.com is an authorized online parts distributor supplying

Original Jarvis Products. .

FAX: 973-751-7701 Telf: 973-751-7775 www.cutlerymania.com