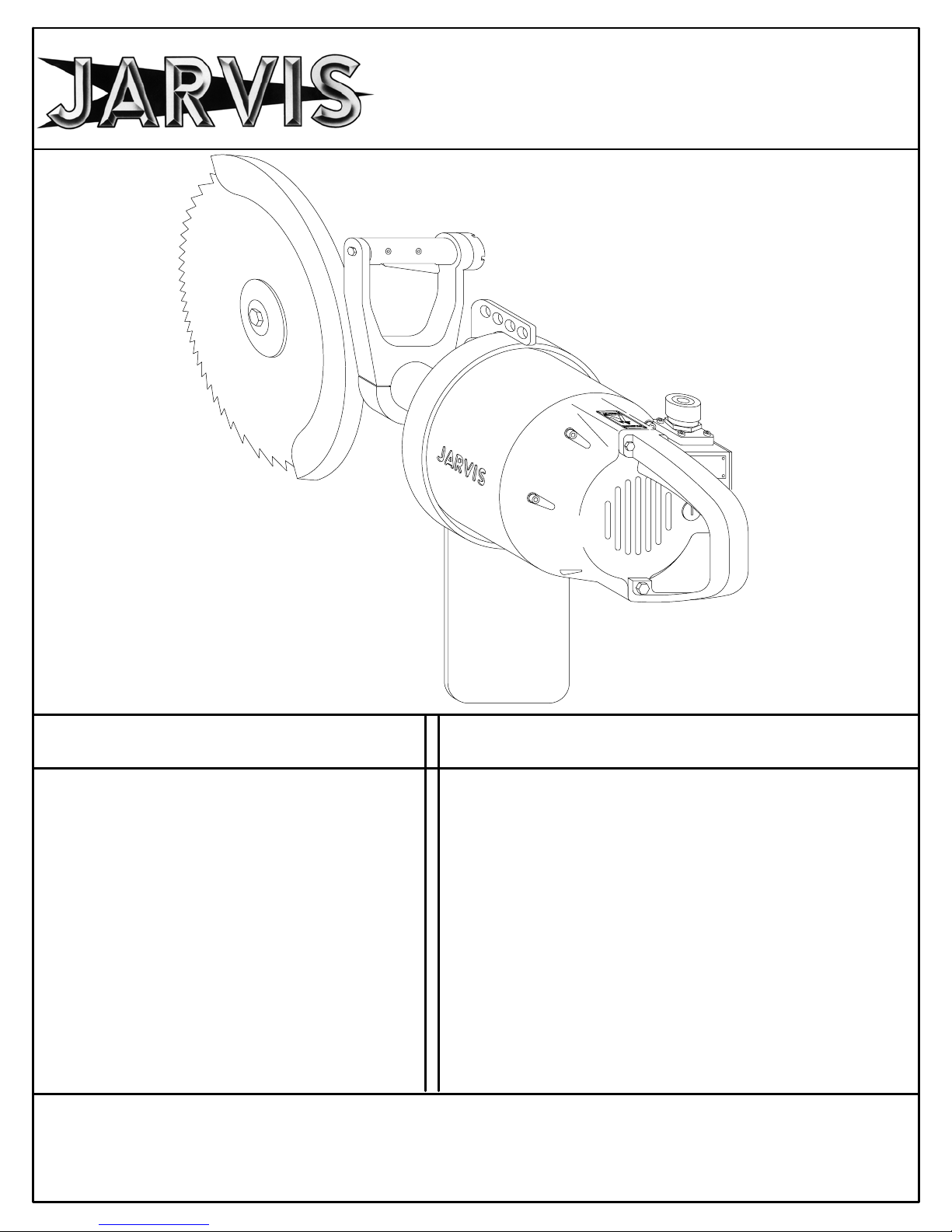

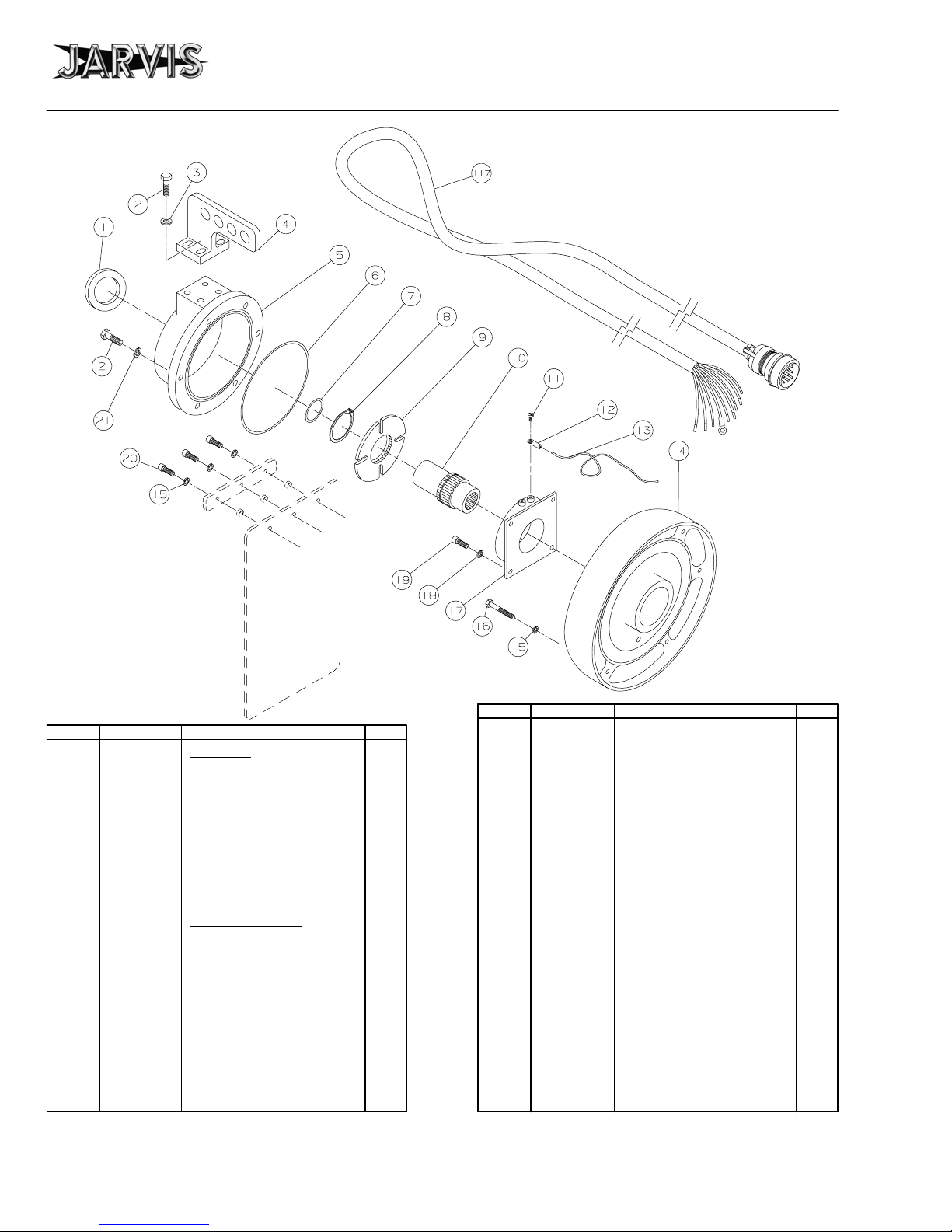

parts diagram and list

Model SEC 400 page 4 of 24

JARVIS PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457--4926

TEL. 860--347--7271 FAX. 860--347--6978 WWW.jarvisproducts.com

6204004;.

®

1 1055749** Hex Head Screw 1

2 1012076 Blade Clamp 1

3 1023297 Standard Blade (16 inch) 1

1023284 Saw Blade (18 inch)

1023290 Saw Blade (21 inch)

4 1010360 Dowel Pin 2

5 1030053 Key 2

6 1020222 Blade Mounting Shaft 1

(includes item 4)

7 1055746 Socket Head Cap Screw 4

8 1038011 Grease Fitting 2

9 1002312 Gear Box Cover 1

10 1035371 O--ring 1

11 1035256 Shaft Seal 1

12 1032322 Bearing Plate 1

13 1021328 Ball Bearing 1

14 1026151 Crown Gear, Std 1

1026199 Crown Gear, Low Speed

15 1013212 Retaining Ring 1

16 1021276 Cylindrical Bearing 1

17 1016462 Gear Housing (2.84 dia.) 1

18 1055613 Hex Head Screw 2

19 1004245 Flat Washer 1

20 1042266* Ft Hdl Bkt (2.44 dia Gr Hsg) 1

1042339 Ft Hdl Bkt (2.84 dia Gr Hsg) 1

21 1055743 Set Screw 2

22 1018120 Trigger Lever (with Item 33) 1

23 1019140 Front Handle Grip 1

24 1010334 Threaded Pin 4

25 3005026 Switch Assembly 1

26 1063009 Wire Nut 2

27 1035375 O--ring 1

28 1002314 Front Handle Cover 1

29 1055744 Socket Head Cap Screw 3

30 1011305 Connector 1

31 1001122 Molded Plug and Wire 1

32 1059056* Hose Assembly 1

33 1014150 Compression Spring 1

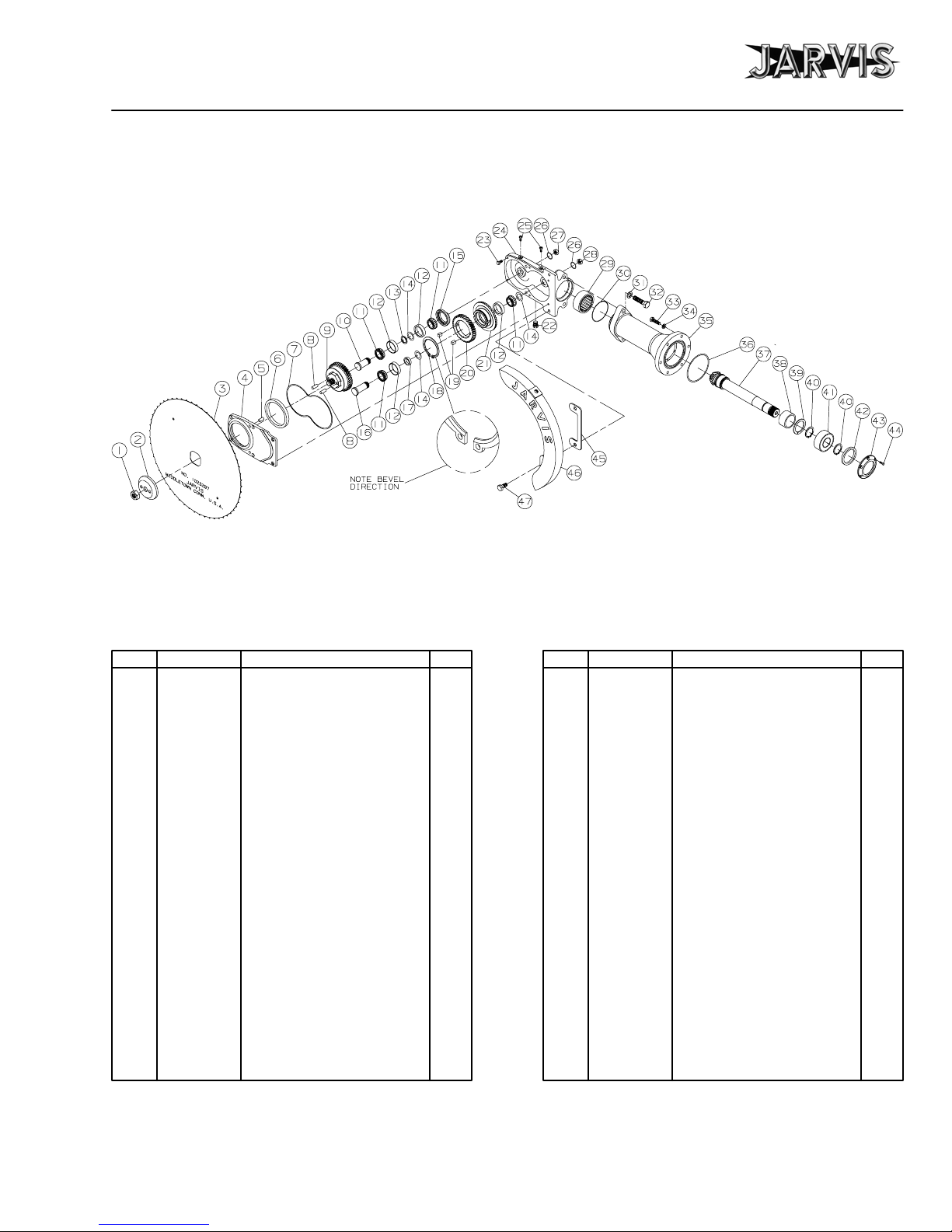

ITEM PART NO. PART NAME QTY

34 1055753 Hex Head Screw 7

35 1004232 Split Lock Washer 7

36 1035372 O--ring 1

37 1021327 Needle Bearing 1

38 1026164 Pinion Gr. Sft (Splined, 15T) 1

1026180* Pinion Gr. Sft (Tang, 15T)

1026198 Pinion Gr. Sft (Splined, 13T)

Low Speed

39 1063220 Connector 1

40 1036190 Inner Ring Bushing 1

41 1013237 Retaining Ring 1

42 1013243 Retaining Ring 2

43 1021329 Ball Bearing 1

44 1035537 Oil Seal 1

45 1013208 Thrust Ring 1

46 1055617 Socket Head Cap Screw 6

47 1011301 Splined Coupling 1

48 1035534 O--ring 1

49 1030052* Key 2

50 1054132* Special Screw 1

51 1035367 Guard Gasket 1

52 1055748 Socket Head Cap Screw 2

53 1038025* Grease Relief Fitting 1

54 1050607 Hex Head Plug 1

55 1024125 Blade Guard (16 inch blade) 1

1024128 Blade Guard (18 inch blade)

1024131 Blade Guard (21 inch blade)

56 1055750 Hex Head Screw 2

3016271 Gear Hsg. Assy (incls. 1, 2,

4--17, 34--38, 40--46 and 54)

3016381 Gear Hsg. Assy, Low Speed

3019143 Front Handle Assy (incls.

items 18--31, 33, 39 and 52)

3011022 Coupling and Seal Assy

(incls. items 47 and 48)

3013005 Thrust Ring Seal Assy

(incls. items 44 and 45)

ITEM PART NO. PART NAME QTY

Figure A

*

*

*

*

*

**

***

* For spare parts only, not in current tools.

** Tighten to 65 lbf--ft.

*** Install open end facing blade.