parts tables

page 10 of 16

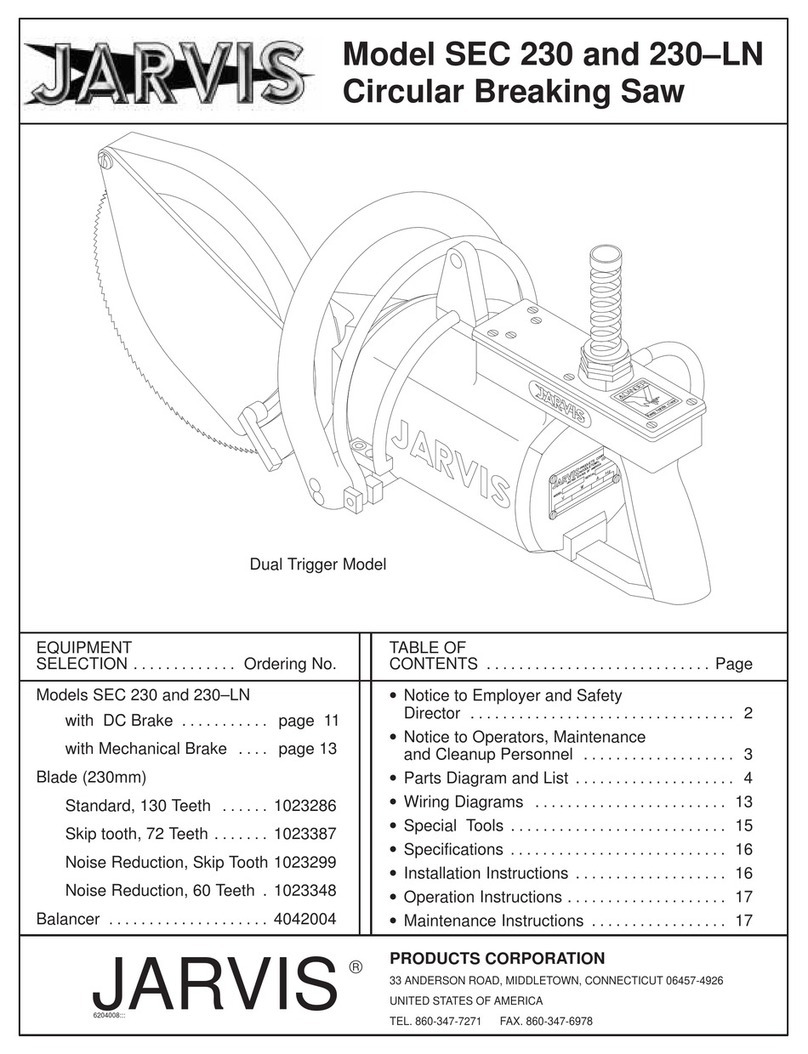

Models SEC 230--4 and 230--4LN

PRODUCTS CORPORATION

33 ANDERSON ROAD, MIDDLETOWN, CONNECTICUT 06457-4926

UNITED STATES OF AMERICA E--MAIL.

TEL. 860-347-7271 FAX. 860-347-6978 WWW.

jarvisproducts.com

JARVIS

6204016.

®

TABLE 1 -- COMPLETE TOOL PART NUMBERS

Saw Voltage/Hz 42v/50 115v/50 208v/60 230v/50 240v/60 380v/50 400v/50 415v/50 480v/60 575v/60

SEC 230--4, 2 Triggers, DC Brake 4004218 4004217 4004216

SEC 230--4LN, 2 Triggers, DC Brake 4004221 4004220 4004219

SEC 230--4, 1 Trigger, Mech Brake 4004206 4004246 4004207 4004215 4004205 4004214

SEC 230--4LN 1Trigger, Mech Brake 4004224 4004223 4004222

TABLE 2 -- DC BRAKE (See Figure E)

Item Name Part Numbers

Control Box, 2 Triggers, DC Brake 3063260 3063261 3063262 3063263 3063263 3063206 3063206 3063264 3063265 3063266

1Auxiliary Contacts 1063528 1063528 1063528 1063528 1063528

2Magnetic Starter 1063557 1063527 1063527 1063527 1063544

3Heater Pack 1063659 1063657 1063657 1063656 1063655

4Suppressor 3 1063709 1063703 1063703 1063703 1063709

5Connector Base with Cover 1063810 1063810 1063810 1063810 1063810

6Connector Insert, Female 1063808 1063808 1063808 1063808 1063808

7Washer 1004226 1004226 1004226 1004226 1004320

8Pan Head Screw 1055970 1055970 1055970 1055970 1055484

9Internal Lock Washer 1004227 1004227 1004227 1004227 1004006

10 Hex Nut 1007318 1007318 1007318 1007318 1007192

11 Cord Connector N/A N/A N/A N/A 1011248

12 Locking Nut N/A N/A N/A N/A 1007249

13 Cord Connector 1011249 1011249 1011249 1011249 1011249

14 Fuse Terminal Block 1063390 1063390 1063390 1063390 1063455

15 Fuse 1063781 1063537 1063537 1063559 1063348

16 Locking Nut 1007256 1007256 1007256 1007256 1007256

17 Electrical Enclosure 1016512 1016512 1016512 1016512 1016573

18 Mounting Plate 1032371 1032371 1032371 1032371 1032474

19 Terminal End Clamp 1063362 1063362 1063362 1063362 1063362

20 Terminal Marker 1063363 1063363 1063363 1063363 1063363

21 Grey Terminal Block 1063494 1063494 1063464 1063494 1063494

22 Terminal Rail 1063393 1063393 1063393 1063393 1063393

23 Female Disconnect Term 1063533 1063533 1063533 1063533 1063533

24 Male/Fem Piggyback Term 1063402 1063402 1063402 1063402 1063402

25 Yellow/Green Terminal Block 1063496 1063496 1063496 1063496 1063496

26 Suppressor 4 1063708 1063708 1063708 1063708 1063708

27 Transformer 1063598 1063598 1063598 1063598 1063598

28 Pan Head Screw 1055803 1055803 1055803 1055803 1055010

29 External Lock Washer 1004247 1004247 1004247 1004247 1004022

30 Terminal Marker N/A N/A N/A N/A 1063456

31 Hex Head Screw 1055754 1055754 1055754 1055754 1055477

32 Internal Lock Washer 1004227 1004227 1004227 1004227 1004244

33 Pan Head Screw 1055910 1055910 1055910 1055910 1055490

34 Fuse F2 1072310 1072310 1072310 1072310 1072310

35 Fuse F1 1072091 1063862 1063862 1063862 1072091

36 Suppressor 2 1063702 1063702 1063702 1063702 1063702

37 Suppressor 1 1063709 N/A N/A 1063701 1063709

38 Circuit Board 1063556 1063530 1063530 1063530 1063556

39 Terminal Fork 1063502 1063502 1063502 1063502 1063502

40 Internal Lock Washer 1002244 1002244 1004244 1004244 1004244

41 Hex Spacer 1029445 1029445 1029445 1029445 1029445

42 Plastic Screw 1073072 1073072 1073072 1073072 1073072

43 Danger Label 1017085 1017085 1017085 1017085 1017085

44 Wiring Diagram Label 1017340 1017342 1017342 1017294 1017344