Auto-Calibration - Sensors

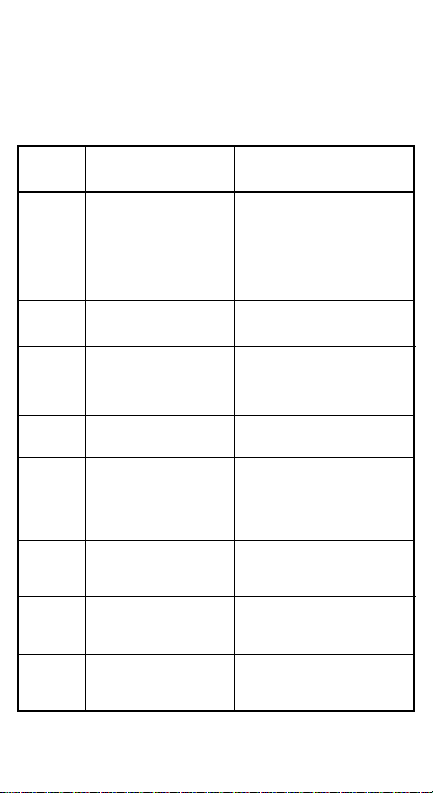

Description

• After the Acceptor’s components have been disassembled

for repair.

• After a sensor board has been replaced.

• Whenever Bill/Note acceptance is degraded.

• During scheduled Preventive Maintenance.

• When upgrading, downloading software.

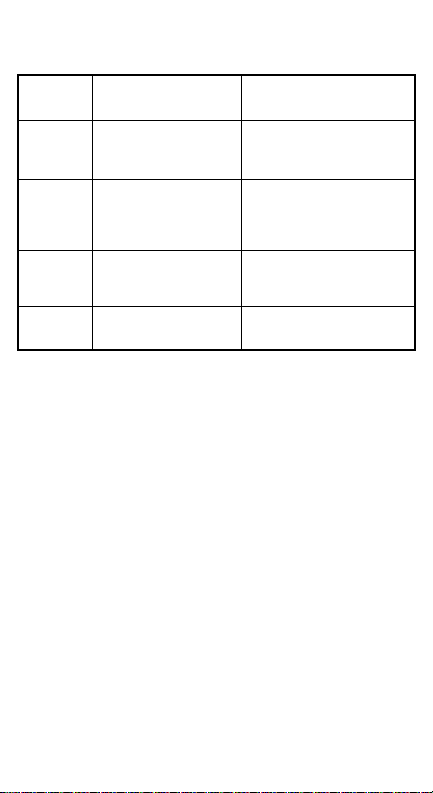

Procedures

1. Remove Transport unit w/head.

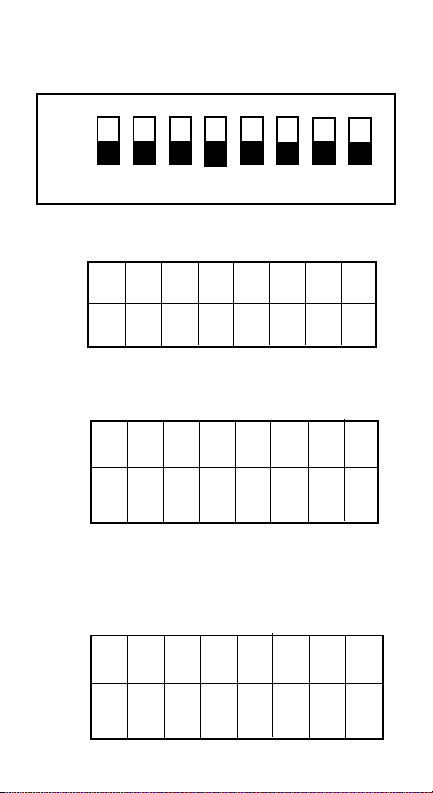

2. Set Dip switches 5, 6, 7, & 8 to the “ON” position, all

others to the “OFF” position.

3. Connect Transport unit w/head to power source -

either host machine, or adaptive power supply.

4. Listen for activation of transport motor - forward and

reverse for up to 2 seconds, then stop - READY.

5. After inserting the calibration paper, black paper first, the

unit will carry the paper forward/

reverse several times. When the

process is complete, the unit will

return the paper.

6. Wait a few moments to allow for

complete transfer of calibration data to be stored in

memory. This is indicated via the LED on the test

harness, or the bezel light on some applications with fast

blinks.

7. Unsuccessful Calibrations - Check the lenses. Re-try

calibration. If necessary, refer to Error Conditions Chart

on the next page. Additional testing/troubleshooting may

be required.

Part #501-000032

Calibration sets a starting reference point for all optical

sensors within the unit. This can be done at the host unit or

at the work bench with just a power source.

When to Calibrate

Note: When installing a new CPU, you must recalibrate.