Jeio tech TC-ME-025 User manual

OPERATING MANUAL

TEMPERATURE CHAMBER (TABLE TOP MODEL)

TC-ME-025/065/100

MANUAL NO.: 00HAA0001203 (Rev 1.0)

0DQXDO1R00HAA0001203 (Rev 1.0)

Before using this product, read this entire Operator's Manual carefully. Users should

follow all of the Operational Guidelines contained in this Manual and take all necessary

safety precautions while using this product. Failure to follow these guidelines could result

in potentially irreparable bodily harm and/or property damage.

Thank you for purchasing Jeio Tech’s products.

Jeio Tech Co., Ltd. is committed to customer service both during and after the sale. If you have questions concerning

the operation of your unit or the information in this manual, contact our Sales Department. If your unit fails to operate

properly, or if you have questions concerning spare parts or Service Contracts, contact our Service Department.

)LJXUH$.

Please locate the identification label on the right side of the instrument. Fill in the information found on the

identification label in the spaces provided above in Figure A. Refer to this identification label information

when calling, if your unit fails to operate properly, or if you have questions concerning spare parts or

service contracts. Additionally, use this information at www.jeiotech.com when you register your

instruments when you fill out the enclosed registration card.

,GHQWLILFDWLRQODEHO6GORGTCVWTG%JCODGT

Ý$OO5LJKWV5HVHUYHG-HLR7HFK&R/WGQuality Management System

Jeio Tech Co, Ltd. is dedicated to providing world-best product quality

and customer satisfaction. To ensure we maintain this commitment we

have developed and implemented a total quality program, which

conforms to the requirements according to DIN EN ISO 9001:2000 for the

design, development, production, sales and servicing of biotechnology,

environmental chemical engineering related products, and reliable

measuring equipment for electric and electronics (ovens, incubators,

constant temperature chambers, constant temperature baths,

refrigerating bath circulators, heat exchangers and shakers).

Visit our Web site at www.jeiotech.com/eng/images/ISO-Jeiotech-1.jpg to view a copy of our certificate.

Disclaimer

Jeio Tech Co., Ltd. is committed to a continuing program of product development and improvement, and

reserves the right to change information, such as specifications, appearance, and dimensions, described in

this document without notice.

Copyright

No part of this manual may be reproduced or transmitted in any form or by any means, including

photocopying, recording, or using information storage and retrieval systems, for any purpose other than the

purchaser's own use, without the express written permission of Jeio Tech Co., Ltd.

©2008. All Rights Reserved. Jeio Tech Co., Ltd.

Any other product names and services identified in this manual are trademarks or registered trademarks of

their respective owners. No such use, or the use of any trade name, is intended to convey endorsement or

other affiliation with Jeio Tech Co., Ltd

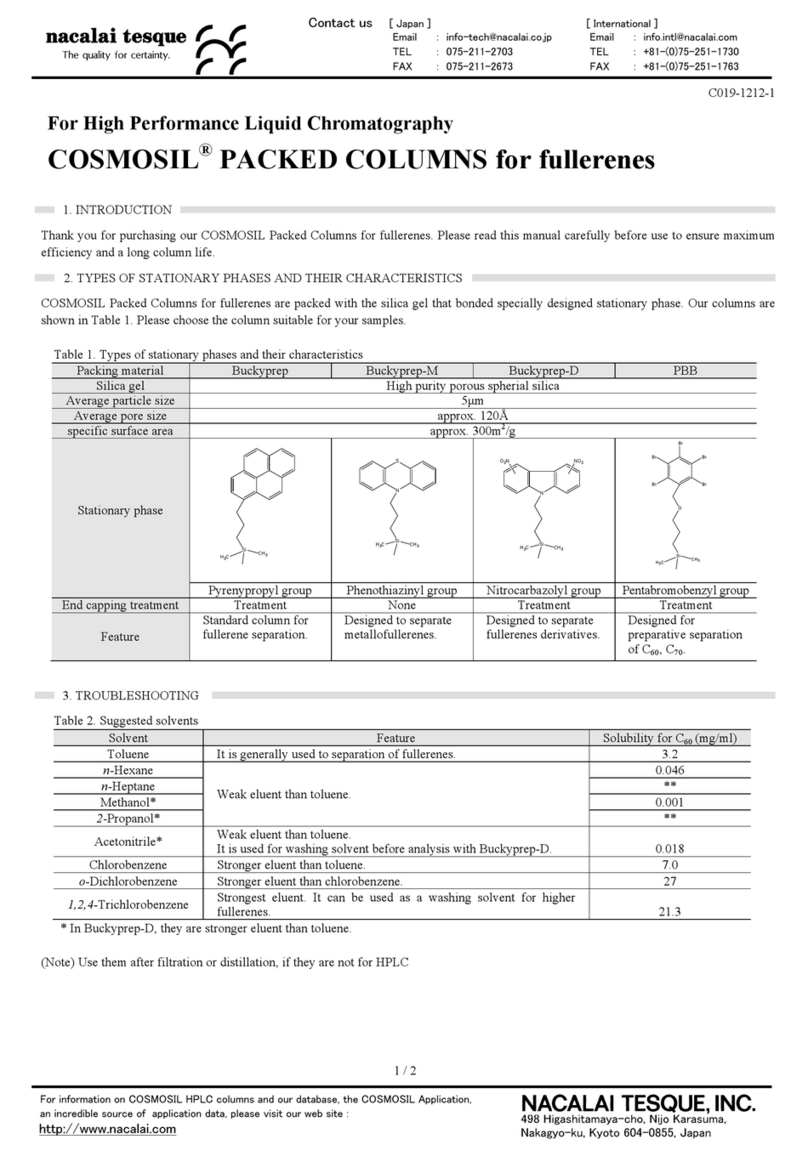

0DQXDO1R00HAA0001203 (Rev 1.0)L6CDNGQH%QPVGPVU5CHGV[1.1 How to use the Manual 1.1.1 Introduction1.1.2 Chapter summary1.1.3 Model number nomenclature1.2 Safety Notice 1.3 Symbols used in this Manual1.3.1 Signal word panels 1.3.2 Safety symbols1.3.3 Miscellaneous none safety symbols used in manual 1.4 Where to Locate Safety Labels on the Temperature chamber 1.4.1 TC-ME/PE-025/065/100 1.5 Precautions for Temperature chamber 1.5.1 Warning statements1.5.2 Caution statements1.6 Responsibility1.6.1 General responsibility1.6.2 Operator responsibility 1.6.3 Maintenance responsibility 1.6.4 Reporting a safety defect

LLÝ$OO5LJKWV5HVHUYHG-HLR7HFK&R/WG2.0 Functional Description2.1 Introduction 2.1.1 Field of Application2.1.2 Applications 2.2 Features 2.2.1 Control range of Temperature & Humidity 2.2.2 Elegant design 2.2.3. Uniformed distribution of temp. & humid.(Up-down flow type)2.2.4. Designed for enhanced user’s convenience---------------------------------------------- 17

2.2.5. Safety functions ------------------------------------------------------------------------------------------ 17

2.3 Construction ----------------------------------------------------------------------------- 18

2.3.1. Unit other components------------------------------------------------------------------------- 21

2.3.2. STAND (OPTION)----------------------------------------------------------------------------------- 22

2.3.3 Max. Number of the mountable shelves/distance between shelves-- 22

2.3.4 How to use water tank --------------------------------------------------------------------------- 23

2.3.5 Main Switch Panel---------------------------------------------------------------------------------- 23

3.0 Installation----------------------------------------------- 25

3.1 Uncrating and inspecting the unit-------------------------------------------- 26

3.1.1 Inspecting before removing outer container--------------------------------------- 26

3.1.2 Removing the unit from shipping container--------------------------------------- 26

3.1.2.1 Phase 1: Removing the outer container ------------------------------------------- 27

3.1.2.2 Phase 2: Removing the unit from wooden crate------------------------------ 30

3.2 Unit components ---------------------------------------------------------------------- 31

3.3 Preparing the installation --------------------------------------------------------- 32

3.3.1 Space requirements------------------------------------------------------------------------------- 32

3.3.2 Environmental setting --------------------------------------------------------------------------- 34

3.4 Locking/Unlocking Casters & Leveling the unit ---------------------- 35

3.5 Connecting Drain hose------------------------------------------------------------- 36

3.6 Pre start-up checks------------------------------------------------------------------- 36

4.0 OPERATION --------------------------------------------- 37

0DQXDO1R00HAA0001203 (Rev 1.0)LLL4.1 Controller---------------------------------------------------------------------------------- 38

4.1.1 Name and Function ------------------------------------------------------------------------------- 38

4.2 Controller Operation----------------------------------------------------------------- 40

4.2.1. FIX Run -------------------------------------------------------------------------------------------------- 40

4.2.1.1. FIX Control-------------------------------------------------------------------------------------------- 40

4.2.1.2. FIX Display -------------------------------------------------------------------------------------------- 41

4.2.2 PROG Mode-------------------------------------------------------------------------------------------- 42

4.2.2.1. PROG Control --------------------------------------------------------------------------------------- 42

4.2.2.2 PROG Display ---------------------------------------------------------------------------------------- 44

4.2.3. MAIN Screen set and control --------------------------------------------------------------- 45

4.2.3.1. COMM SET -------------------------------------------------------------------------------------------- 45

4.2.3.2 RESERVE----------------------------------------------------------------------------------------------- 46

4.2.3.3 Graph----------------------------------------------------------------------------------------------------- 46

4.2.4. SETUP Screen--------------------------------------------------------------------------------------- 47

4.2.4.1. Password ---------------------------------------------------------------------------------------------- 47

4.2.4.2. TROUBLE Shoot------------------------------------------------------------------------------------ 47

5.0 How to use Software----------------------------------49

5.1. Initial display --------------------------------------------------------------------------- 50

5.2. Separate operating display ----------------------------------------------------- 51

5.3. Program setting display ---------------------------------------------------------- 53

5.4. Graph display -------------------------------------------------------------------------- 58

6.0 Accessories ---------------------------------------------61

6.1 Accessories and Options List -------------------------------------------------- 62

7.0 Appendix -------------------------------------------------63

7.1 Technical Specification------------------------------------------------------------------- 64

7.2 Warranty -------------------------------------------------------------------------------------- 65

7.2.1 Service under Warranty period------------------------------------------------------------- 65

7.2.2 Exceptional cases even during under warranty period ------------------------------ 65

7.3 Technical assistance---------------------------------------------------------------------- 66

7.3.1. Oversea ------------------------------------------------------------------------------------------------- 66

LYÝ$OO5LJKWV5HVHUYHG-HLR7HFK&R/WG

0DQXDO1R00HAA0001203 (Rev 1.0)

1.0 Safety

Ý$OO5LJKWV5HVHUYHG-HLR7HFK&R/WG1.1 How to use the Manual

1.1.1 Introduction

This manual is intended for individuals requiring information about the use Temperature chamber. Use this

manual as a guide and reference for installing, operating, and maintaining your Jeio Tech Temperature

chamber. The purpose is to assist you in applying efficient, proven techniques that enhance equipment

productivity

This manual covers only light corrective maintenance. No installation, service procedure or other

maintenance should be undertaken without first contacting a service technician, nor should be carried out

by someone other than a service technician with specific experience with laboratory equipment and

electricity.

1.1.2Chapter summary

The Functional Description chapter outlines models covered, standard features, and safety features.

Additional sections within the manual provide instructions for installation, pre-operational procedures,

operation, preventive maintenance, and corrective maintenance.

The Installation chapter includes required data for receiving, unpacking, inspecting, and setup of the unit.

We can also provide the assistance of a factory-trained technician to help train your operator(s) for a

nominal charge. This section includes instructions, checks, and adjustments that should be followed before

commencing with operation of the Temperature chamber. These instructions are intended to supplement

standard laboratory procedures performed at daily and weekly intervals.

The Operation chapter includes a description of controller features along with temperature and agitation

parameter setting instructions, multi-segment program setting instructions and instructions for changing the

type of agitation and agitation amplitude.

The Accessories and Option chapter is your source for information on available accessories and option

with brief information.

The Appendix contains technical specifications, warranty and Jeio Tech technical support contact

information.

1.1.3 Model number nomenclature

This manual covers all five models of the Temperature chambers series. The following describes the model

number nomenclature used in throughout the manual.

àTC-ME-025 chamber capacity (25L)

àTC-ME-065 chamber capacity (65L)

àTC-ME-100 chamber capacity (100L)

0DQXDO1R00HAA0001203 (Rev 1.0)1.2 Safety Notice

Be sure that you are completely familiar with the safe operation of this Temperature chamber. This unit

may be connected to other machinery, such as a temperature control unit. Improper use can cause serious

or fatal injury.

Installation and repair procedures require specialized skills with laboratory equipment and electricity. Any

person that installs or repairs this unit must have these specialized skills to ensure that this unit is safe to

operate. Contact Jeio Tech or their local authorized distributor for repairs or any questions you many have

about the safe installation and operation of this unit.

The precaution statements are general guidelines for the safe use and operation of this equipment. It is

not practical to list all unsafe conditions. Therefore, if you use a procedure that is not recommended in this

manual you must determine if it is safe for the operator and all personnel in the proximity to the equipment.

If there is any question of the safety of a procedure please contact Jeio Tech before starting or stopping the

equipment.

This equipment contains high voltages. Electrical shock can cause serious or fatal injury. Only qualified

personnel should attempt the startup procedure or troubleshoot this unit.

lDocumentation must be available to anyone that operates this equipment at all times.

lKeep non-qualified personnel at a safe distance from this unit.

lOnly qualified personnel familiar with the safe installation, operation and maintenance of this unit

should attempt start-up or operating procedures.

lAlways stop the incubated shaker before making or removing any connections.

Ý$OO5LJKWV5HVHUYHG-HLR7HFK&R/WG1.3 Symbols used in this Manual

The following signal word panels, safety symbols and non safety symbols are used to alert you to

potential personal injury hazards or information of importance. Obey all safety messages that follow these

symbols to avoid possible personal injury or death.

1.3.1 Signal word panels

Signal word panels are a method for calling attention to a safety messages or property damage

messages and designate a degree or level of hazard seriousness. It consists of three elements: a safety

alert symbol, a signal word and a contrasting rectangular background.

The following signal word panels are in accordance with ANSI Z535.4-2007 and ISO 3864 standards.

Indicates a hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a hazardous situation which, if not avoided,

may result in minor or moderate injury.

Indicates a property damage message.

0DQXDO1R00HAA0001203 (Rev 1.0)1.3.2 Safety symbols

Safety symbols are graphic representations—of a hazard, a hazardous situation, a precaution to avoid a

hazard, a result of not avoiding a hazard, or any combination of these messages—intended to convey a

message without the use of words. The following safety symbols are used in this manual.

Mandatory Prohibition

Read manual

No direct sunlight

Wear a face mask

No high frequency

noise

Wear gloves

No corrosive

fluid or cleaners

Wear goggles

No water

WARNING

Safety Alert Symbol.

General caution.

Hand crush or pinch

Electrical shock

Foot crush

Flammable or fire

could be caused.

Lifting hazard

Sharp points

Ý$OO5LJKWV5HVHUYHG-HLR7HFK&R/WG1.3.3 Miscellaneous none safety symbols used in manual

The following graphic representations are intended to convey a message without words or to bring

your attention to important information about the use of the incubated shaker or a feature.

European Union

electrical directive

compliance

Earth ground

Relative humidity

Note

Altitude

Good Design

designated by

Korean government

0DQXDO1R00HAA0001203 (Rev 1.0)1.4 Where to Locate Safety Labels on the Temperature chamber

The safety labels are attached to the temperature chamber to provide important information about

potential hazards and how to avoid them. All users must read this operating instruction carefully to operate

the product properly.

The following illustrations show where the safety labels should be attached to the Temperature chamber

until service of the product is discontinued. If the safety labels are damaged, please contact your local Jeio

Tech office or distributor to request new labels.

1.4.1 TC-ME/PE-025/065/100

Fig. 1.1

Ý$OO5LJKWV5HVHUYHG-HLR7HFK&R/WG1.5 Precautions for Temperature chamber

Our Chamber is designed to provide safe and reliable operation when installed and operated within

design specifications. Make sure you read and understand all instructions and safety precautions listed in

this manual before installing or operating your unit. If you have any questions concerning the operation of

your unit or the information in this manual, contact our Sales Department.

To avoid possible personal injury or equipment damage when installing, operating, or maintaining this

chamber, use good judgment and follow these safe practices:

1.5.1 Warning statements

Observe all warning labels.

Do not remove warning labels.

Check the voltage, phase, and capacity of the power supply and connect properly.

Do not ground the chamber to gas pipes or water pipes.

Do not insert multiple plugs into the outlet at the same time.

Do not operate equipment with damaged line cords.

Do not handle or touch electrical cord and electrical parts with wet hands.

Do not move equipment while it is plugged into the power source.

Do not use or keep flammable gases near the chamber.

Do not install the chamber near environments where flammable gas may leak.

Do not use the chamber near environments where explosion can occur due to organic evaporating

gases.

Do not put explosive and flammable chemicals (Alcohol, Benzene, and etc) into the chamber.

Do not let moisture, organic solvents, dust, and corrosive gas enter the control panel.

Do not expose the chamber to direct sunlight.

Do not expose the chamber to direct heat sources.

Do not use the chamber in places where moisture is high and flooding can occur.

Do not install the chamber near machinery generating high frequency noise.

Do not use the chamber in environments that contain industrial oil smoke and metallic dust.

Do not operate damaged or leaking unit.

Do not operate the chamber when there is strange sound, smell and smoke coming from the unit.

Do not disassemble, fix or change the chamber other than for those items described in this

operating manual.

0DQXDO1R00HAA0001203 (Rev 1.0)1.5.2 Caution statements

Do not use doors, handles or knobs to lift or stabilize the unit.

Do not place heavy objects on the power cord.

Do not put the chamber on the power cord.

Do not make the machine wet while cleaning.

Do not pour water or put liquid on the chamber when cleaning the unit.

Do not operate chamber and immediately disconnect the main power supply and request service

when water may be in the unit.

Do not sprinkle insecticide or flammable spray on the chamber.

Do not clean the chamber with a strong cleanser (e.g., solvent type) and use a soft cloth.

In addition to the safety warnings listed above, safety messages are posted throughout the manual.

These safety messages are designated by the use of a signal word panel followed by text and a safety

symbol where applicable. Read and follow these important instructions. Failure to observe these

instructions can result in permanent damage to the unit, significant property damage, personal injury or

death.

Ý$OO5LJKWV5HVHUYHG-HLR7HFK&R/WG1.6 Responsibility

Our chambers are constructed for maximum operator safety when used under standard operating

conditions and when recommended instructions are followed in the maintenance and operation of the

machine.

All personnel engaged in the use of the machine should become familiar with its operation as described

in this manual.

Proper operation of the unit promotes safety for the operator and all workers in its vicinity.

Each individual must take responsibility for observing the prescribed safety rules as outlined. All caution,

warning and danger labels must be observed and obeyed. All actual or potential danger areas must be

reported to your immediate supervisor.

1.6.1 General responsibility

No matter who you are, safety is important. Owners, operators and maintenance personnel must realize

that every day, safety is a vital part of their jobs.

If your main concern is loss of productivity, remember that production is always affected in a negative

way following an accident. The following are some of the ways that accidents can affect your production:

lLoss of a skilled operator (temporarily or permanently)

lBreakdown of shop morale

lCostly damage to equipment and laboratory samples

lDowntime

An effective safety program is responsible and economically sound.

Organize a safety committee or group, and hold regular meetings. Promote this group from the

management level. Through this group, the safety program can be continually reviewed, maintained, and

improved. Keep minutes or a record of the meetings.

Hold daily equipment inspections in addition to regular maintenance checks. You will keep your

equipment safe for production and exhibit your commitment to safety.

Please read and use this manual as a guide to equipment safety. This manual contains safety warnings

throughout, specific to each function and point of operation.

0DQXDO1R00HAA0001203 (Rev 1.0)1.6.2 Operator responsibility

The operator’s responsibility does not end with efficient experimentation and production. The operator

usually has the most daily contact with the equipment and intimately knows its capabilities and limitations.

Plant and personnel safety is sometimes forgotten in the desire to meet incentive rates, or through a

casual attitude toward laboratory equipment formed over a period of months or years. Your employer

probably has established a set of safety rules in your workplace. Those rules, this manual, or any other

safety information will not keep you from being injured while operating your equipment.

Learn and always use safe operation. Cooperate with co-workers to promote safe practices. Immediately

report any potentially dangerous situation to your supervisor or appropriate person.

REMEMBER:

lNEVER place your hands or any part of your body in any dangerous location.

lNEVER operate, service, or adjust the equipment without appropriate training and first reading and

understanding this manual.

lBefore you start the portable drying/conveying system check the following:

nRemove all tools from the machine.

nBe sure no objects, samples or chemicals are laying on the chamber.

lIf your chamber has been inoperative or unattended, check all settings before starting the unit.

lAt the beginning of your shift and after breaks, verify that the chamber is functioning properly.

lReport the following occurrences IMMEDIATELY:

nunsafe operation or condition

nunusual incubated shaker action

nleakage

nimproper maintenance

DO NOT wear loose clothing or jewelry, which can be caught while working on the equipment. In addition,

cover or tie back long hair.

Clean the equipment and surrounding area DAILY, and inspect the machine for loose, missing or broken

parts.

Shut off power to the chamber when it is not in use. Turn the power switch to the OFF position, or unplug it

from the power source.

Ý$OO5LJKWV5HVHUYHG-HLR7HFK&R/WG1.6.3 Maintenance responsibility

Proper maintenance is essential to safety. If you are a maintenance worker, you must make safety a

priority to effectively repair and maintain equipment.

Before removing, adjusting, or replacing parts on this chamber, remember to turn off all electric supplies

and all accessory equipment at the machine, and disconnect and lockout electrical power. Attach warning

tags where possible.

Be sure that the chamber is correctly connected to earth grounded electrical outlet that complies with

current codes.

When you have completed the repair or maintenance procedure, check your work and remove your tools.

DO NOT restore power to the chamber until all persons are clear of the area. BEFORE you turn the

chamber over to the operator for production, verify the unit is functioning properly.

1.6.4 Reporting a safety defect

If you believe that your chamber has a defect that could cause injury, you should immediately

discontinue its use and inform Jeio Tech or local authorized distributor.

The principle factors that can result in injury are failure to follow proper operating procedures (i.e.

lockout/tag out), or failure to maintain a clean and safe working environment.

This manual suits for next models

2

Table of contents

Other Jeio tech Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Endress+Hauser

Endress+Hauser Liquistation CSF33 operating instructions

Thermo Scientific

Thermo Scientific UNITY LAB SERVICES Eurotherm 3216 Calibration guide

Sartorius

Sartorius Biotrate user manual

Labnet

Labnet 25 operating instructions

Thermo Scientific

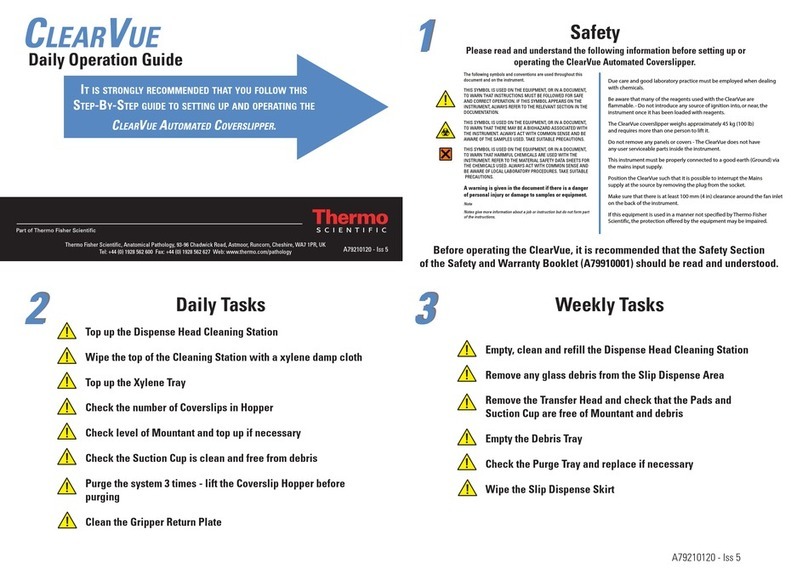

Thermo Scientific CLEARVUE AUTOMATED COVERSLIPPER Daily Operation Guide

Savewo

Savewo FreshQ user manual