Jeio tech Lab Companion SK-300 User manual

Page 1

OPERATING MANUAL

[SHAKER]

Model: SK-300 / SK-600/ SK-71

Manual No: 00HAA0001149 (Version :5.0)

This operating manual describes the important subjects to maintain the product¡s

functions and to use it safely. Especially, be sure to read <Safety Precaution> carefully

before you use this equipment. Please keep this operating manual close to the equipment to

use it after reading through it once. Please place it where the new user can find it

easily for the safety use when you hand over or lend the equipment to others.

.

Page 2

Table of Contents

Chapter. 1: Introduction

Caution about the operating instruction----------------- 5

Warning mark of the product----------------------------- 5

Caution for safe operation and reorganization

of the product ------------------------------- 6

Disclaimer --------------------------------------------- 6

Introduction of shaking system ------------------------- 7

Chapter. 2: Transportation Confirmation

and Installation

Unpacking and Transportation Confirmation-------------- 10

Shaker Components ------------------------------------- 11

Installation ------------------------------------------ 12

Chapter. 3: Safety Alert and Caution

Safety Alert ------------------------------------------ 15

Safety Caution ---------------------------------------- 16

Chapter. 4: Part names and Controller Instructions

Part names and functions------------------------------- 18

Operating and functional element ---------------------- 19

How to operate

Input shaking speed ------------------------------- 20

Timer programming --------------------------------- 20

Time programming -------------------------------- 20

Examples of Timer programming ------------------- 23

Shaker movement indication ------------------------ 24

Chapter. 5: Switching Orbital/ Reciprocation Motion

and Stroke width adjustment

How to switching orbital/ reciprocation motion

Switching motion orbital to reciprocal in SK-300 ------ 26

Switching motion orbital to reciprocal in SK-600 ------ 27

Switching motion orbital to reciprocal in SK-71 ------- 28

How to change the stroke width adjustment

How to change shaking stroke on SK-300, 600 ----------- 29

How to change shaking stroke on SK-71 ----------------- 32

Page 3

Chapter. 6: Maintenance and Troubleshooting

Maintenance ------------------------------------------- 36

Safekeeping and Cleaning ------------------------------ 37

Troubleshooting---------------------------------------- 38

Chapter. 7: Specification

Specification ----------------------------------------- 41

Chapter. 8: Warranty and Service

Warranty standard-------------------------------------- 43

Page 4

Chapter. 1

Introduction

Thank you for purchasing the Lab Companion Shaker.

Lab Companion shaker is for cultivating animal or plant cells as

well as microorganism cultivation. The system is integrated with

shaking table and motor. Excellent shaking for smooth oxygen

supply, ph uniformity, culture fluid in growth environment.

Lab Companion shakers are realized perfectly the control and

shaking circumstance related to the operator¡s experimental

condition. Before using the shaker, please comprehend the manual

in detail.

Chapter. 1 - Introduction is composed as follows.

Caution about the operating instruction

Warning mark of the product

Caution for safe operation and reorganization of the product

Disclaimer

Introduction of shaking system

Page 5

Caution about the operating instruction

1. Always keep this instruction near to the instrument.

2. Copying and distributing part or the whole of this the operating instruction with

no permission are prohibited with the law.

3. The operating instruction promised perfection but please ask an agent or us if you

have any question about insufficient points, error and omission on the operating

instruction.

Warning mark of the product

1. This operating instruction uses the warning Signal Word for safe operation to

prevent the users from accidents or damage beforehand.

2. Defined by the Symbol Mark about the safety caution.

¡Warning¡ means that the user may have serious

damage and even die by improper handling on this

unit.

¡ Cauti on¡ means that the user may have mi nor

damage and uni t may have physi cal damage by

i mproper handl i ng on thi s uni t.

Protective Ground Terminal

It marks the terminal must be connected Ground

prior to operating the product.

It marks addi tional i nformati on on the operation and

features of the product

3. Be fully aware of the warning contents during operation.

4. Please exchange original label to the new warning label when it is unreadable from

warning out.

☞ Please request the new label to an agent or us.

Page 6

Caution for safe operation and reorganization of the product

1. In order to protect the product and system, please use the product in accordance

with the instructions.

2. We shall not be responsible for any incidental or abnormal operation for breach of

any express or implied warranty on this product or any part thereof.

3. It forbids reorganization of Inside of the product or adds.

4. Please contact the agent or us in case of the component and the consumable parts

of the product will be replaced.

5. Do not give a strong shock to the product. It becomes the cause of product damage

and wrong operations.

Disclaimer

1. In no event will Jeio Tech industries be liable for any incidental or

consequential damages for breach of any implied warranty relating to the product.

2. Any special indirect or consequential property or commercial damage of any nature

whatsoever. Some cases do not allow the exclusion of incidental or consequential

damages, so the above limitation may apply to you.

Page 7

Introduction of shaking system

Shaker is for cultivating animal or plant cells as well as microorganism cultivation. The

system is integrated with shaking table and motor. Excellent shaking for smooth oxygen supply,

ph uniformity, culture fluid in growth environment.

Shaking System Feature

Brushless DC Motor

Enables the user to control the motor speed in a circuit diagram and the motor rev up by a

controller.

Fly Wheel System

Excellent in energy efficiency by fixed low level.

Quiet and low vibration with Anti-Weight Fly Wheel System.

Bracket

Double formation between Motor and Bracket.

Possible to adjust the fixing location of the belt.

Photo Sensor

Photo Sensor can perceive a reciprocating motion. As soon as motion is perceived by the

sensor, the shaking system stops at the position exactly. Photo sensor can control the

stop function at exact position.

Shaking Control Function

Stop function at the exact position.

When stopping the shaking system, the function operates on stopping at the exact position.

This function contains the Brake Function for the automatic system in Shaker.

Forward/ Backward Function

Shaking controller contains Auto Reserve Function which can operate Forward/Backward and

Time set Function which can be programmable to set Forward/Backward Function.

Velocity compensation Function

While rotating the motor, the velocity compensation function checks the set RPM and then

memorize. This function can control changeable velocity as set value.

Page 8

Auto Control Function

Operate stable RPM from 10RPM to 300RPM. The rotati on RPM can be programmabl e rel ated

to the experi mental condi ti on.

Rapid Acceleration and Retardation

Actualize rapid Acceleration and Retardation using of Velocity Compensation Function and

Brake Function.

At the same time, minimize Over Shoot and Under Shoot.

Page 9

Chapter. 2

Transportation Confirmation

and Installation

Before you install Shaker, inspect it for damage that may have

occurred in transportation. Confirm any damage for compensating

following the Compensation regulations and transportation of Lab

Companion. Be sure to check the electric conditions for electric

safe. All persons expected to carry out operation, installation and

maintenance of the unit, read and understand the safety information

and operating instructions.

Chapter. 2 - Transportati on Confi rmati on & I nstal l ati on are composed

as fol l ows.

Unpacking and Transportation Confirmation

Shaker Components

Installation

Select a proper place

Level off the machine

Power connection

Page 10

Unpacking and Transportation Confirmation

Protection from any damage occurring in transit, Lab Companion administers excellent

packing and radical transportation.

Any damage or loss during transit, all responsibility is filled with the delivery carrier.

After receiving the unit, carefully unpack and inspect it for damage.

If the unit is damaged or loss during transit, Make sure as follows to be protected from

the ¡Lab Companion Regulations¡

Confirmation a damaged unit

1. Check the front and rear sides of the unit under packed condition.

2. Carefully unpack the package.

3. Check with care any damage during the transportation of the unit

4. Check the parts (i.e. accessories- Page 11) of the unit.

Compensation regulation of damaged unit

If the unit is damaged, contact the delivery service company immediately.

1. Keep the condition as it delivered and wait for the confirmation by the carrier.

2. Within 15 days, submit an application be made in writing to the delivery service

company.

Do not discard the carton or packing material

for the unit until you have checked all of the

damaged parts.

Compensation regulation of transport

1. Any damage that is occurred during the transport is responsible to the delivery

service company.

2. Except for all damage from the transport, we Jeio Tech will service or return.

3. If Jeio Tech or our authorized dealers do not deliver the unit, Jeio Tech disclaims

all the responsibility for the damage.

Page 11

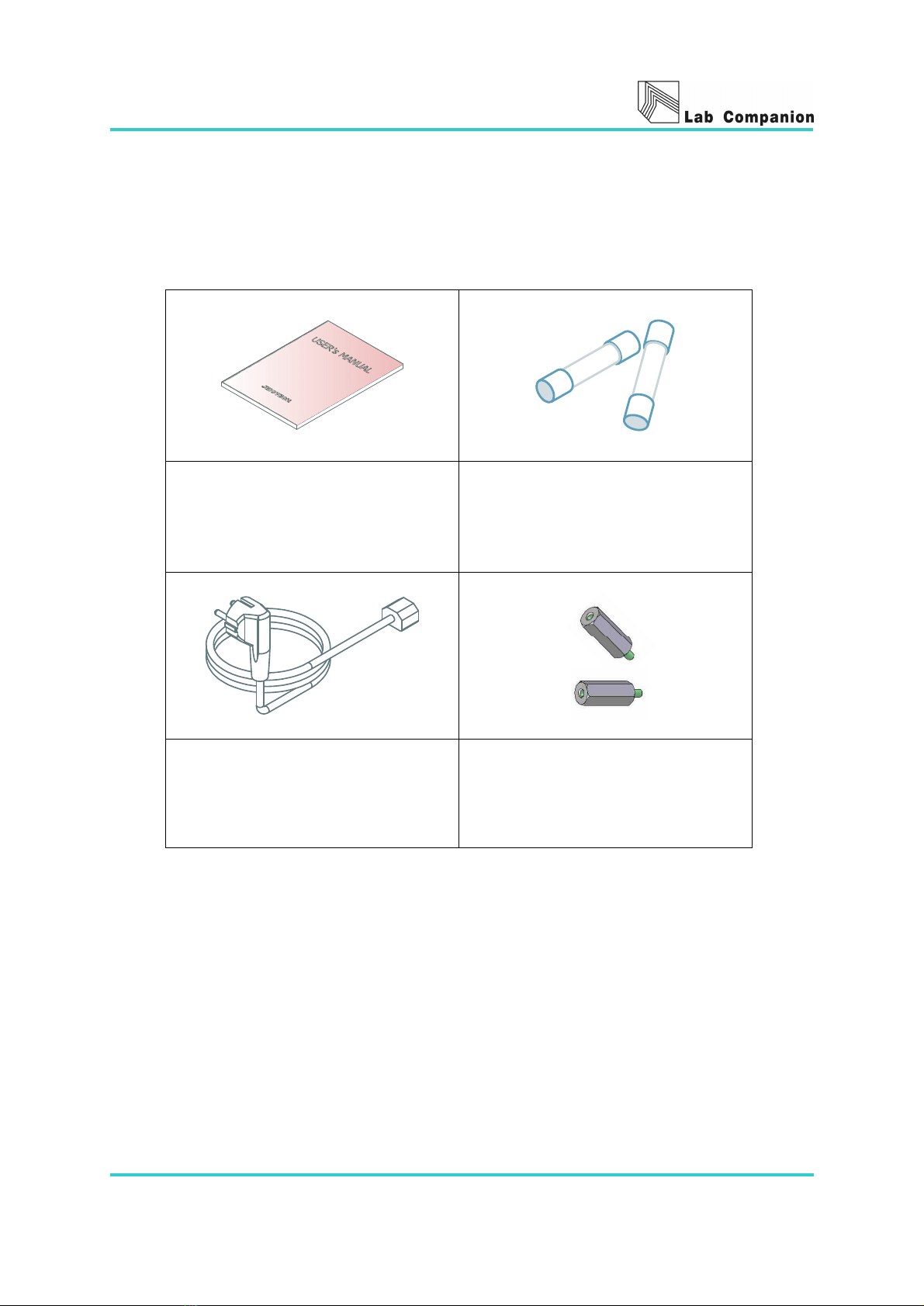

Shaker Components

After unpacking, Please check listed shaker component description as follows.

If you didn¡t receive one or more component as follow, Contact the Jeio Tech Service

center or the distributor where you purchased.

Operating manual

After unpacking, check the operati ng

manual . If you di dn¡ t recei ve the

operati ng manual , Contact the di stri butor

or the Jei o Tech servi ce center.

Fuse

Duri ng bei ng in use, i f you contact

the service center or the distri butor,

you wi l l recei ve the servi ce.

Power Cord

Check the power cord matches the supply

voltage.

Spacer-Option

SK-300: M5*43L(4EA)

SK-600: M5*43L(4EA)

Page 12

Installation

The machine should be installed on a safe and proper environment following to the below.

Check Points

Select a proper place

Level off the machine

Power connection

Select a proper place

1. Operating condition: Class 100 ~ Class 10,000 as Clean environment degree for Bio

Clean room is optimal condition for shakers.

Room condition of temperature and humidity should be normal as 18 ℃~ 25℃, below

80%RH.

2. Environmental condition: Do not expose the machine to direct ray of light.

3. Setting place: The floor should be on flat and leveled ground.

4. Space: The machine should be kept at least 1.5m from any illuminators and 20 cm from

walls.

The machine should be operated at the optimum

condition for cleanness, electricity and

preparation against fire.

Level off the machine

All of the bottom sides should be leveled.

Page 13

Power connection

Check the ID Plate on the back side of the machine to find the electric conditions.

Do not connect the power before checking

how to do correct operation.

1. Check i f the pl ug condi ti on and el ectri c wi res are normal .

2. Check the connection of ground wire.

Check the power plug to find if the

electric conditions are correct. The

voltage fluctuation should be within 10%

Page 14

Chapter. 3

Safety Alert and Caution

¡Alert¡ shows that users can

be dead or seri ousl y wounded by

wrong operati on.

¡Notice¡ shows that users can

be wounded or machi nes broken by

wrong operati on.

¡ Si gnal Word¡ i s used i n the operati on manual for safe and

proper operati on and keeps users from bei ng damaged by

acci dents.

Each ¡ Symbol Mark¡ i s i denti fi ed fol l owi ng to the degree of

i mportance and danger.

Pay attenti on to the ¡ Al ert¡ and ¡ Noti ce¡ i n the manual to

avoi d fromany acci dents.

Page 15

Safety Alert

¡Alert¡ shows that users can be dead or

seriously wounded by wrong operation.

Check the voltage, phase and capacity on the ID plate before installation. Sources

of electricity should be separately wired.

The sources of electricity should be grounded.

The sources of electricity without ground connection can cause serious damage to

users or the machine. Don¡t earth the machine to gas pipes or water pipes.

Do not install the machine near to places where inflammable gas can be leaked.

Do not use the machine near to places where explosion can be happened due to

organic evaporating gases.

Explosive materials: Acid, Esther, Nitro compound

Inflammable materials: salt peroxides, inorganic peroxide, salt acids

Put off the power plug if some sounds and smell, smokes are happened.

Do not expose the machine in direct sunlight.

Do not use the machine at places where moisture is high and flooding can be

happened.

Do not disassemble or fix, change the machine.

Check if there is big vibration while the machine is operated.

Check ¡Troubleshooting¡ on the manual.

At least 2 persons should move the machine when it is necessary.

The weight of the machine is about 24 ~ 50kgs. Please use other devices to move

the machine.

Page 16

Safety Caution

¡Notice¡ shows that users can be wounded

or machines broken by wrong operation.

Do not put heavy things on the power line. Do not put the machine on the line.

It causes fire and electric shock.

Connect the plug correctly and do not touch it with wet hands.

It can cause fire if the connection is not fit.

It can cause fire and damage to users.

Do not make the machine wet while cleaning. Do not put liquid on the machine.

If the machine is wet, off the power and contact where you purchase the machine to

check it.

Do not shock the machine or vibrate it.

It can cause damage to the machine.

Do not clean the machine with solvent abstergent. Use smooth cloths.

Cleaning with solvent can cause fire and deformity.

Do not touch the shaking table while the machine is operated

Stop the machine by using Start/Stop button and do necessary works.

Do not put anything near to the turning radius of the machine while operation.

Turning radius of the machine is from 20mm to70mm.

Do not put the sample in a flask installed shaking table.

It can cause damage to the machine.

Be sure to pull out the flask from the shaking table to put the sample in and then,

install the flasks.

Do not put the sample over the max scale shown on the flask.

It can prevent from overflowing the sample When the machine operates in max rpm.

Page 17

Chapter. 4

Part names

and Controller instructions

Users should be familiar with how to control the controller before

operation.

Please do operate the machine after checking chapter 4 for 2~3 times.

Please do trial test of the machine without loading any sample flask on

it.

Please do contact us if you have request while using the controller.

Contents of chapter 4

Parts name and function

Operating and Functional element

How to operate

-Input shaking speed

-Timer programming

-SHAKER Movement indication

Page 18

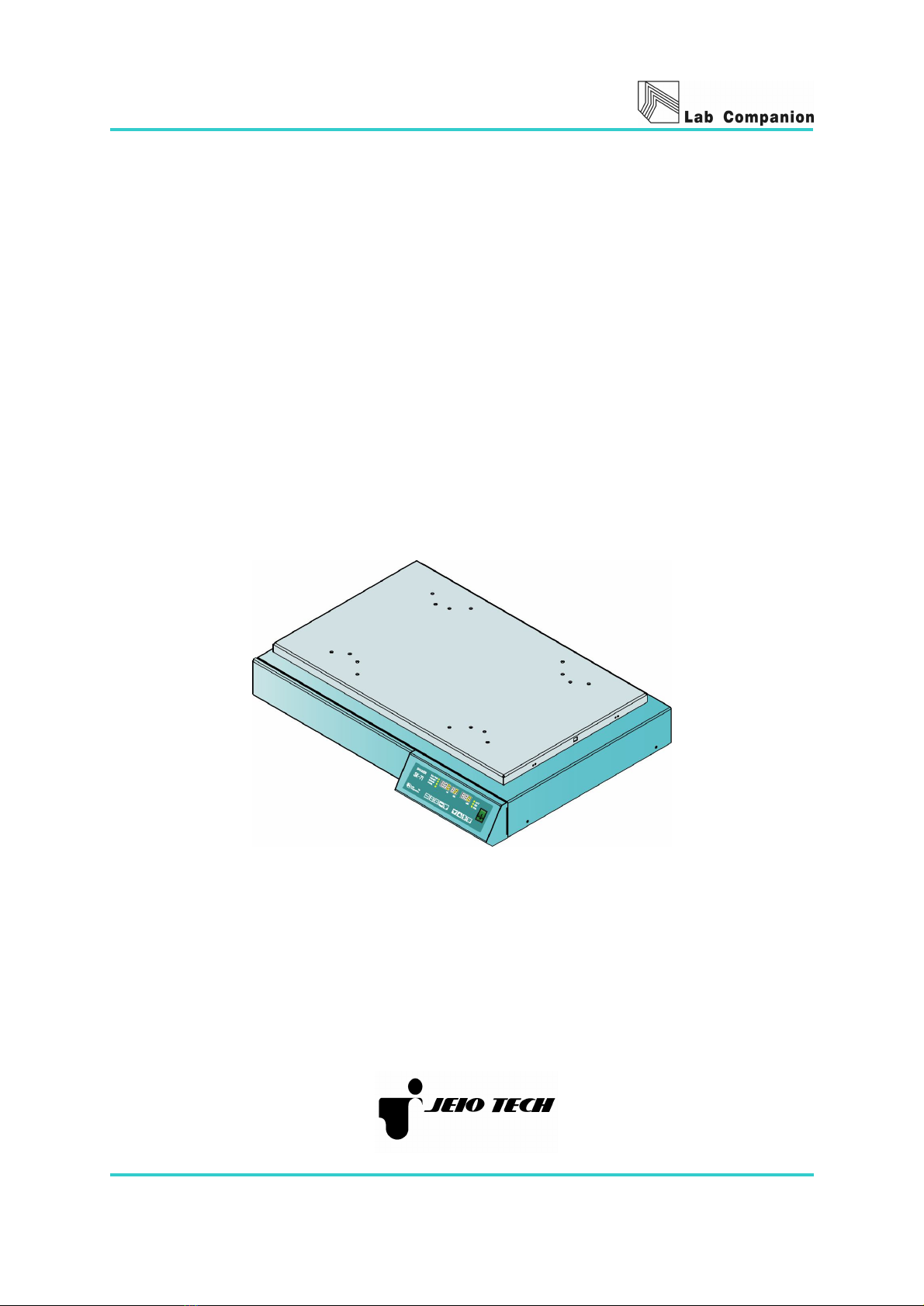

Part names and functions

1. Shaking Table: Orbital and reciprocating motion is performed

2. Receptacle with Fuse: Electric Socket with fuse.

3. Foot: Supporter of the body. The supporter can be adjustable its height.

4. Body:Fly Wheel system is equipped inside the body.

5. Control Panel:Shaking controller, power switch and LED signal lamp are set.

5

4

2

1

3

Page 19

Operating and functional element

1. MODE

Indicates each operating function.

2. SV/TIME

Set time an remaing time display.

3. PV/RPM

Speed of rotation displays.

4. Shaker LED

TIMER LED : In case of Timer mode, it is ON once total run time is set.

F/WARD LED : It is ON, once time for clockwise rotation is set.

B/WARD LED : It is ON, once time for clockwise rotation is set.

PAUSE LED : It is ON, once time for pause is set.

5. Adjust keys

UP key: To increase value. ( value moves faster on pressing and holding.)

DOWN key : To decrease value. ( value moves faster on pressing and holding.)

Enter key : To store value or finish set.

6. SHAKE/SET

To set shaking speed and timer.

7. START/STOP

To start and stop unit.

8. Power Switch

1

2

3

4

5

6

7

8

Page 20

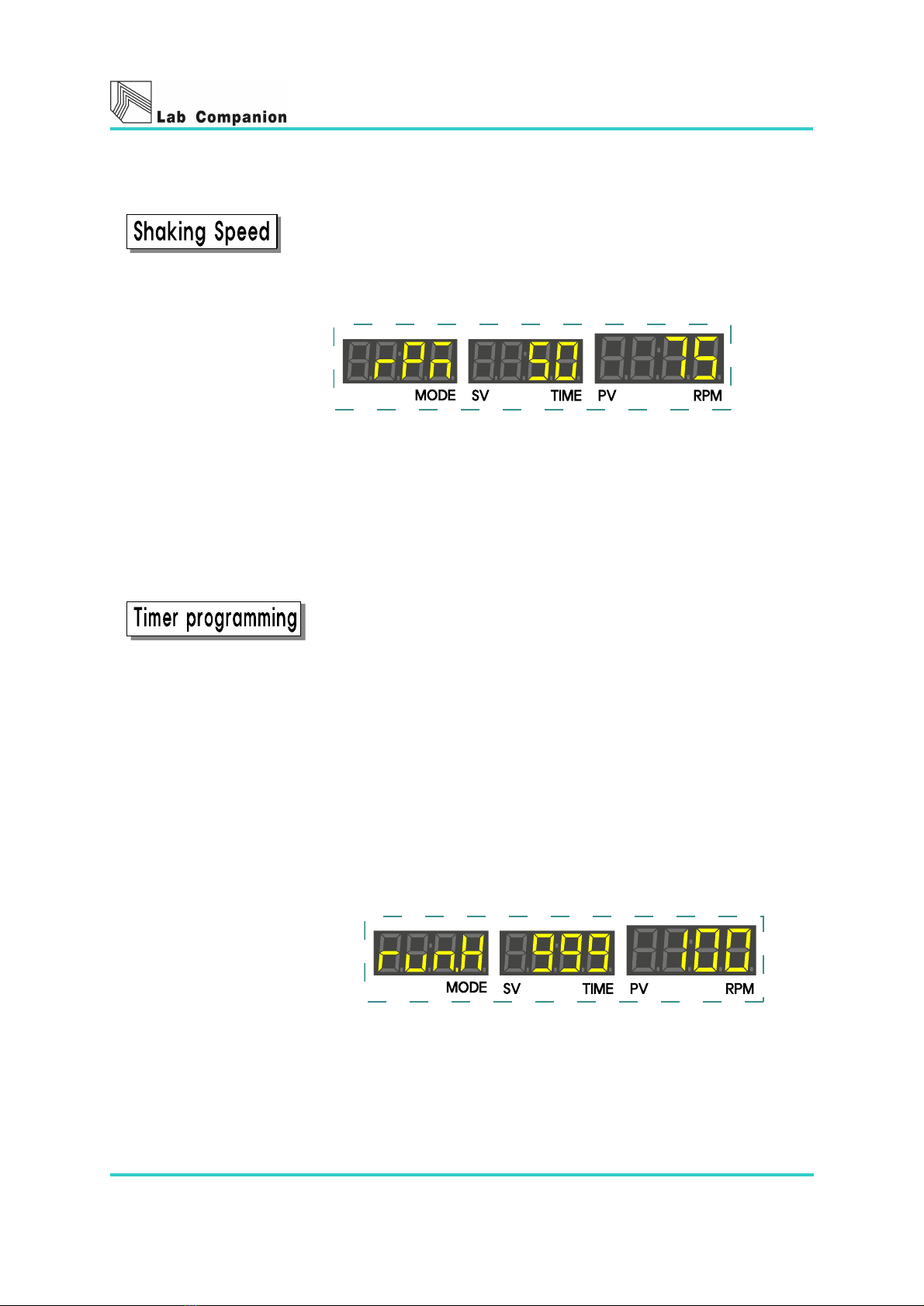

How to operate

Input shaking speed

1. Press SHAKER/SET key.

2. Press UP/DOWN key.

Input RPM.

3. Press Enter Button.

Finish to set value.

4. Press START/STOP key.

Shaking starts in clockwise rotation.

※Recall function of RPM value

- Previous RPM value starts if new RPM is set again.

Timer programming

1. Time Programming

- Programming time can not be done during shaking. So, stop shaking by

pressing START/STOP key and start programming.

1) Input total run time

1. Press SHAKER/SET key Twice.

This section is for setting total run time.

¡run.H¡ shown on MODE display.

2. Press UP/DOWN Button to set Time and then press

ENTER key to store the value. (Max Input Time: 1~999

hours)

After setting the value, TIMER LED is on.

3. Press SHAKER/SET key.

This section is for setting minute and seconds.

¡run.S¡ shown on MODE display

4. Press UP/Down key to set minute and seconds and then

press Enter key to store the value.

(Max Input Time: 10seconds~ 59 minutes 59 seconds)

This manual suits for next models

2

Table of contents

Other Jeio tech Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Turner Designs

Turner Designs TD1000C manual

Qiagen

Qiagen Hybrid Capture System Microplate Heater 1 user manual

Thermo Scientific

Thermo Scientific 1300 Series user manual

KSB

KSB Delta Solo SVP Installation & operating manual

MFJ

MFJ MFJ-5012 owner's manual

Optika Italy

Optika Italy SZP Series instruction manual