Jeio tech Lab companion SI-300 User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Find the Lab Companion SI-300R at our website: Click HERE

Page 1

OPERATING INSTRUCTION

[SHAKING INCUBATOR]

Model : SI-300/300R/600/600R

Manual No: 00HAA0001134 ( Version : 5.0 )

This operating instruction describes the important subjects to maintain the product’s

functions and to use it safely. Especially, be sure to read <Safety Precaution> carefully

before you use this equipment. Please keep this instruction close to the equipment to use

it after reading through it once. Please place it where the new user can find it easily

for the safety use when you hand over or lend the equipment to others.

Page 2

■Introduction

Thank you for purchasing Jeio Tech’s product.

This operating instruction forms a definition of warning marks according to the

level of importance and danger in order to use the product safely and correctly and

prevent the users from accidents or injuries. Hence, please use the product in

accordance with the instructions.

Caution about the operating instruction

1. Always keep this instruction near to the instrument.

2. All users must read this operating instruction carefully to operate the product

properly.

3. This operation describes the detailed function of the product so the above

exclusions may not apply to you.

4. Copying and distributing part or the whole of this the operating instruction with

no permission are prohibited with the law.

5. The operating instruction promised perfection but please ask an agent or us if you

have any question about insufficient points, error and omission on the operating

instruction.

Warning mark of the product

1. This operating instruction uses the warning Signal Word for safe operation to

prevent the users from accidents or damage beforehand.

2. It defines warning marks according to the level of importance and danger in order

to use the product safely and correctly.

3.

“Warning” means that the user may have serious

damage and even die by improper handling on this

unit.

“Caution” means that the user may have minor

damage and unit may have physical damage by improper

handling on this unit.

Protective Ground Terminal

It marks the terminal must be connected Ground prior

to operating the product.

It marks additional information on the operation and

features of the product.

4. Be fully aware of the warning contents during operation.

5. The most important thing of warning is a warning label attached to the product. It

is located in front of the door.

6. Please exchange original label to the new warning label when it is unreadable from

warning out. ☞ Please request the new label to an agent or us.

Page 3

Caution for safe operation and reorganization of the product

1. In order to protect the product and system, please use the product in accordance

with the instructions.

2. We shall not be responsible for any incidental or abnormal operation for breach of

any express or implied warranty on this product or any part thereof.

3. It forbids reorganization of Inside of the product or adds.

4. Do not assemble, repair, modify by entities than Jeio Tech’s representatives. It

becomes the cause of electric shocks, fires and improper operations.

5. Please contact the agent or us in case of the component and the consumable parts

of the product will be replaced.

6. Do not give a strong shock to the product. It becomes the cause of product damage

and wrong operations.

Disclaimer

1. In no event will Jeio Tech industries be liable for any incidental or

consequential damages for breach of any implied warranty relating to the product.

2. Any special indirect or consequential property or commercial damage of any nature

whatsoever. Some cases do not allow the exclusion of incidental or consequential

damages, so the above limitation may apply to you.

Page 4

■Confirmation of transport

Please follow the direction to handle the unit.

1. Confirmation of a unit

1. Check the front and rear sides of the unit under packed condition.

2. Carefully unpack the package.

3. Check with care any damage during the transportation of the unit

4. Check the parts (i.e. accessories) of the unit.

2. Dealing with a damaged unit

1. If the unit is damaged, contact the delivery service company immediately.

2. Keep the condition as it delivered and wait for the confirmation by the

carrier.

3. Within 15 days, submit an application be made in writing to the delivery

service company.

3. Compensation regulation of transport

1. Any damage that is occurred during the transport is responsible to the

delivery service company.

2. Except for all damage from the transport, we Jeio Tech will service or refund.

3. If Jeio Tech or our authorized dealers do not deliver the unit, Jeio Tech

disclaims all the responsibility for the damage.

Page 5

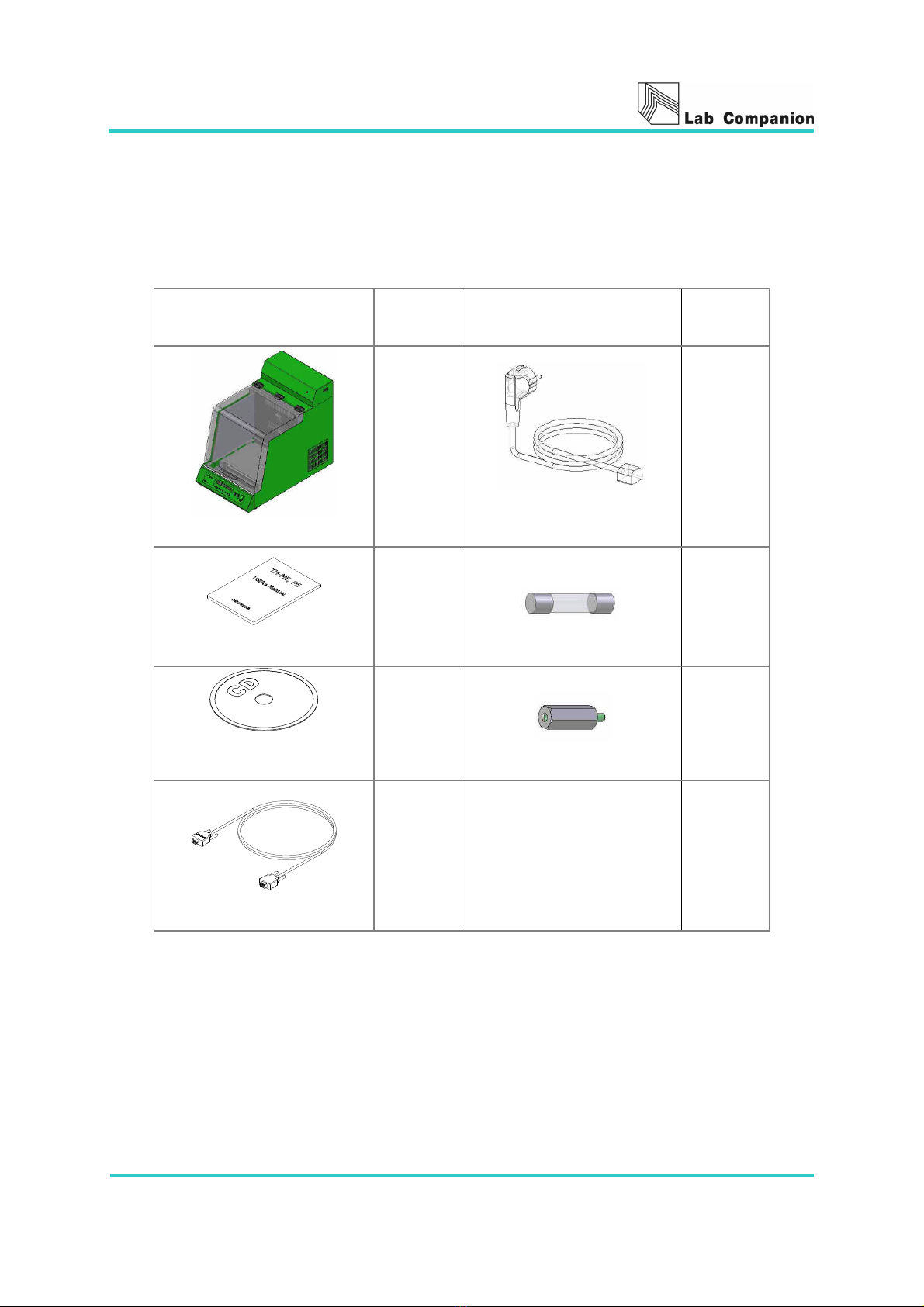

■Components of SI-300/300R/600/600R

After unpacking the unit, check the following components.

In addition, check the features and electric condition.

Components EA Components EA

unit

1

Power Cord

1

Operating instruction

1

Fuse

2

Software CD for

communication

1

Spacer

4

Cable for communication

1

Page 6

Table of Contents

◆ Introduction 2

◆ Confirmation of transport 4

OPERATING MANUAL

1. Warning for safe operation 7

2. Caution for safe operation 9

3. Safety alert definitions 10

4. System composition of SI-300R,600R 11

5. Introduction 13

6. Controller instruction 16

7. How to change the orbital motion and reciprocation motion 38

8. Accessories 39

9. Cause of malfunction and its repairs 46

10. Inspection cycle 49

11. Maintenance and cleaning 50

12. Specification 51

13. Warranty standard 52

14. How to waste 53

15. Warranty 54

16. Setting monitoring program 55

17. Operating monitoring program 56

Page 7

1. Warning for safe operation

Warning means that failure to follow this safety

statement could result in serious personal injury, or

death.

1. Please check the voltage, phase and capacity of power supply and connect properly.

☞ Abnormal connection causes fire or electronic shock.

☞ Power cord must be plugged into a wall outlet with grounded terminal.

2. Do not insert a lot of plug into the outlet at once.

☞ Using of unreasonable electronic power causes electric shock and fire.

☞ Must use a separate electronic wiring for the Temp & Humidity Chamber.

3. Power supply must be properly grounded.

☞ Abnormal grounded connection causes serious damage. Grounded connection must

not be on the water pipe and gas pipe.

4. Please check the power supply and frequency on the ID plate before installation.

☞ The unit requires an independent line (100V, 120V, 230V, single phase), a

grounded and polarized.

(100V, 120V:16AWG,12A,1.25SQ ; 230V:18AWG,10A,0.75SQ)

5. Do not install the product in the place that the gas could leak out.

6. Do not use in the place that has the industrial oil smoke and the metallic dust.

☞ It causes fire or electric shock.

7. Unplug, when there is strange sound, smell and smoke from the product.

☞ Please request the service.

☞ It causes fire or electric shock.

8. Keep out of the direct sunlight.

☞ It may cause fire and abnormal operation.

☞ When use in the direct sunlight, please set up a proper interception to make

shade.

9. Do not use in the place that has the industrial oil smoke and the metallic dust.

Keep in the dry place.

☞ It may cause fire and makes the product does not work well.

☞ Request service, if the product is flooded.

10. Do not assemble, repair, modify on your own.

☞ It may cause fire and electric shock.

☞ The product may not work well and fall off in the efficiency of the product.

☞ Please do not use with the exception of the origin purpose.

Page 8

11. Do not use or keep the inflammables near by the product.

☞ Inflammable gas or dust may cause fire.

☞ It may cause fire or explosion.

☞ Do not operate the product in a dangerous article area.

12. Never put inflammables and explosives in the product.

☞ A sample may explode in the chamber at a high temperature. The explosives are

acetic acid, ester, nitro compounds etc. and the inflammables are peroxides,

inorganic peroxides, acetate, and organic solvent.

☞ This product was not designed to prevent from any explosion.

Page 9

2. Caution for safe operation

Warning means that failure to follow this safety

statement could result in serious personal injury, or

death.

1. Do not pour water or put liquid on the top of the product when cleaning.

☞ It causes abnormal operation or trouble.

☞ Please intercept the main power immediately and request the service when water

may be in the product.

2. Do not let the product take any strong shock or vibration.

☞ It causes abnormal operation or trouble.

☞ It may deteriorate the ability of the product and not obtain correct results.

3. Do not put a heavy object on the main cord or let the cord be pressed down by the

product.

☞ It may take off the wire coating and causes the electric shock.

4. Do not touch it with wet hands and put the main plug correctly.

☞ Abnormal connection may cause fire,

☞ It may cause the electric shock or injuries.

5. Do not sprinkle insecticide or flammable spray on the product.

☞ It may cause trouble, the electric shock or fire.

6. Do not clean it with a strong cleanser (like solvent type) and use a soft cloth.

☞ It may cause fire or modification of the product.

☞ Clean it with a soft cloth dipping in neutral detergent.

Warnings and confirmations when operating the product

1. Insure a enough space because the cover is opened up to 70°.

2. Do not pull down the product and give a shock. Operate it on a flat place.

3. Please leave space between lighting fixtures (1.5m), wall (20cm) from the product.

4. Please maintain the horizontality of the product on a flat place to prevent

unusual vibration and sound.

5. Please set the product in a place which maintains the normal temperature and

humidity (less than 30°C, 80%RH), far from a heat source like a heater.

6. Please pay attention in transportation with propel equipment because it is heavy.

Confirmations after operating the product

1. Please check all wires have been operated accurately.

2. Please check the ground wire has been grounded accurately.

3. Please insure a enough space to operate.

4. Connect a hose to the Drain Hose Nipple. ( Refer to Page 18, #20)

5. After considering the safety regulations fully, use the product.

Page 10

3. Safety alert definitions

The safety alerts, attaching on the product, provide information of danger and safety

about it. All users must read this operating instruction carefully to operate the

product properly. The safety alerts should be attached in the same place below until

disusing the product. If the safety alerts are damaged, please request new labels to

an agent or us.

* Caution

It shows the caution when opening and shutting the inner

class door and the out door.

* Warning

It is to forbid putting inflammables and explosives

inside of the product.

* Caution

If the air filter is being stopped up, refrigeration

efficiency would be decreased and correct temperature

controlling would be impossible.

Page 11

4. System composition of SI-300R, 600R

CLS (Custom Logical Safe)-Control System

The CLS-Control system (Patent no.0328729) is our enhanced

safety controller developed by our engineers. Designed to allow

our equipment to be operated in environments that require

perfect thermal safety-including areas where flammable

chemicals are used.

In most cases with other brands of lab equipment, the CPU comprises both control and

safety features together. In the event of the CPU failing, the logic controlling the safety

features will often be compromised.

Jeio Tech has separated these two important elements and now has an independent

safety system running alongside the performance controller.

When any risk factors are sensed (ex: voltage peaks, short circuit, over temperature

etc.) the machine will go into a recoverable safety mode as follows.

The power supply to individual components is isolated by a magnetic switch,

leaving only the earth in circuit.

Details of the fault are displayed (indicator codes)

Audio and visual alarms are set off to alert the user and remain on until attended.

Shaking System

■ Stop the one regular position

The automatic system with Brake function allows the shakers can always stop at

the same position.

■ Turn Right and Left both ways

Our original Auto Reverse function allows it turns right and left both ways, in

addition to control the each turning time period by setting with the timer.

■ Speed recovery

The motor often check the set rpm and memorize the speed value. If there is

any outside interruption, it can recover the set speed.

■ Auto-control

To control speed and stop the one regular position accurately, it can memorize

the settle parameter value automatically.

■ Wide working range

From minimum 10 rpm to maximum 300 rpm, it works very stably.

■ Prompt acceleration and deceleration

It can accelerate/ decelerate promptly with the speed recovery function and the

brake function at once minimizing Over shoot/ Under shoot.

Page 12

Uniform temperature control

■ If the cover is opened, fan and heater will be stopped immediately to keep away

meeting inner air with outer air.

■ We use a cross type fan to make good uniformity.

Prevention against inner air leakage

■ To prevent against inner air leakage, external chamber is treated with heat

insulators and the open cover is stuck to the body unit with Packing.

■ To observe inside of chamber without opening the open cover, we are using a

translucent acrylic cover and setting a lamp up.

Programmed auto-run function

■ Our integrated controller allows controlling the inner circulating fan speed on

three steps. The 9-Step Programmed Control system can make to auto-run on

nine different temperatures and times (Max. 99hr. 59min.) and maximum 200

times for each time.

Safety device

■ Independent IC logic detects and intercepts electronic interference before the

main control board to give added safety to both user and product.

■ Built in Over Temp. protector warns (beep and LED lighted) and shuts off the

heater in the event of overheating problems.

Page 13

5. Introduction

(1) Cover

Easy to observe the sample through Acrylid.

(2) Over Temp. limit

This the safety device which is independent of the circuit.

The Heater reaches over the setting value, the controller shutdown of the

main power

Completely. the over temp. LED illuminates with audible Beep sound.

When the power is shut down, Please set the Knob over 15% than the setting

value.

Press the Start/Stop switch, and then Check the Temp LED illumination.

(3) Communication Port

The serial interface RS-232 can connect the PC through COM1 or COM2 port.

It’s allow to check the condition of the unit and the setting value.

This interface can restore the data and then print out.

(4) Body

※Back side

※ SI-300/600

※SI-300R/600R

Page 14

(5) Compressor Cover

The cover for the refrigeration System A/S.

(6) Foot

The foot for protected the unit from the dust..

(7) Shaking table

The shaking table relates to the shaking system. This can be installed the Universal

Platform, Spring wire wrack and other accessories.

(8) Main switch

Turn power on / off switch to unit

(9) Shaker I/O Switch

Turn On / Off switch to Shaker

(10) Lamp Switch

Turn on / Off for the inner chamber.

(11) Controller

- Shaking Control

Shaking Control can be set the left, right, pause function and each motion.

- Temp. Control

Temp Control has the Microprocessor(CPU) can be performed Digital PID Auto

tuning.

(12) Chamber Air Out

Inner air is out to go through the heater or Evaporator.

(13) Temperature Sensor

With Thin Film PT-100Ω

(14) Blower(Inner)

Blower for the temperature uniformity.

(15) Gas Spring

Gas spring is for changing the sample conveniently.

(16) Door Switch

There is door limit switch between door and the appliances mainframe upper parts,

and discontinuance gets operation of Shaking unit, Blower and Heater done by the

Logic IC which received an open signal if it opens Door. And Door LED is turned on.

(within five minutes)

Door LED twinkles for warning ventilation of a user after a door opened if a user does

not shut a door so that five minutes pass, and an alarm sound continuously rings.

Page 15

And it blocks off the power to be authorized with a power switch, and Off gets a

power switch done and all blocks off 2 phase of the power supplied with to an each

part of appliances, and configuration does the safe state that only a Ground part is

connected. At this time light is effective on Temp LED if closes a door again and

presses a Button.

(17) Lamp

Lamp is for observing the inside.

(18) Power Code

(19) Fuse

Fuse is for protecting the unit from the momentary overpower.

When exchanging the Fuse, check the main power.

Model Electric requirements Fuse Quantity Remarks

100V, 50/60Hz 2 EA

120V, 60Hz

AC 250V, 10A

Slow-blow 2 EA

SI-300/600

230V, 50Hz AC 250V, 5A

Slow-blow 2 EA

100V, 50/60Hz 2 EA

120V, 60Hz

AC 250V, 12A

Slow-blow 2 EA

SI-300R/600R

230V, 50Hz AC 250V, 8A

Slow-blow 2 EA

(20) Drain Hose Nipple

Drain hose nipple is for draining the moisture in evaporator.

(21) Filter

Filter by outboard is protecting the condenser from the dust.

(22) Hose Coupling(SI-300/600)

Circulating the heating medium in Evaporator when decreasing the inner temperature.

Page 16

6. Controller instruction

Planning for the shaking incubator

This controller is divided into the Temp LED and shaking LED.

Once setting the controller, the operator can use the Temp &

shaking function simultaneously.

Know well the operator to perform functions like temp, shaking,

programmed all on the controller in right process.

1. PV Display

Indicates the present value.

2. SV Display

Indicates the set value or remaining time

of the timer

3. rpm Display

Indicates the actual rpm or rotation

direction.

1 2 3 4

5 7 8 96

Page 17

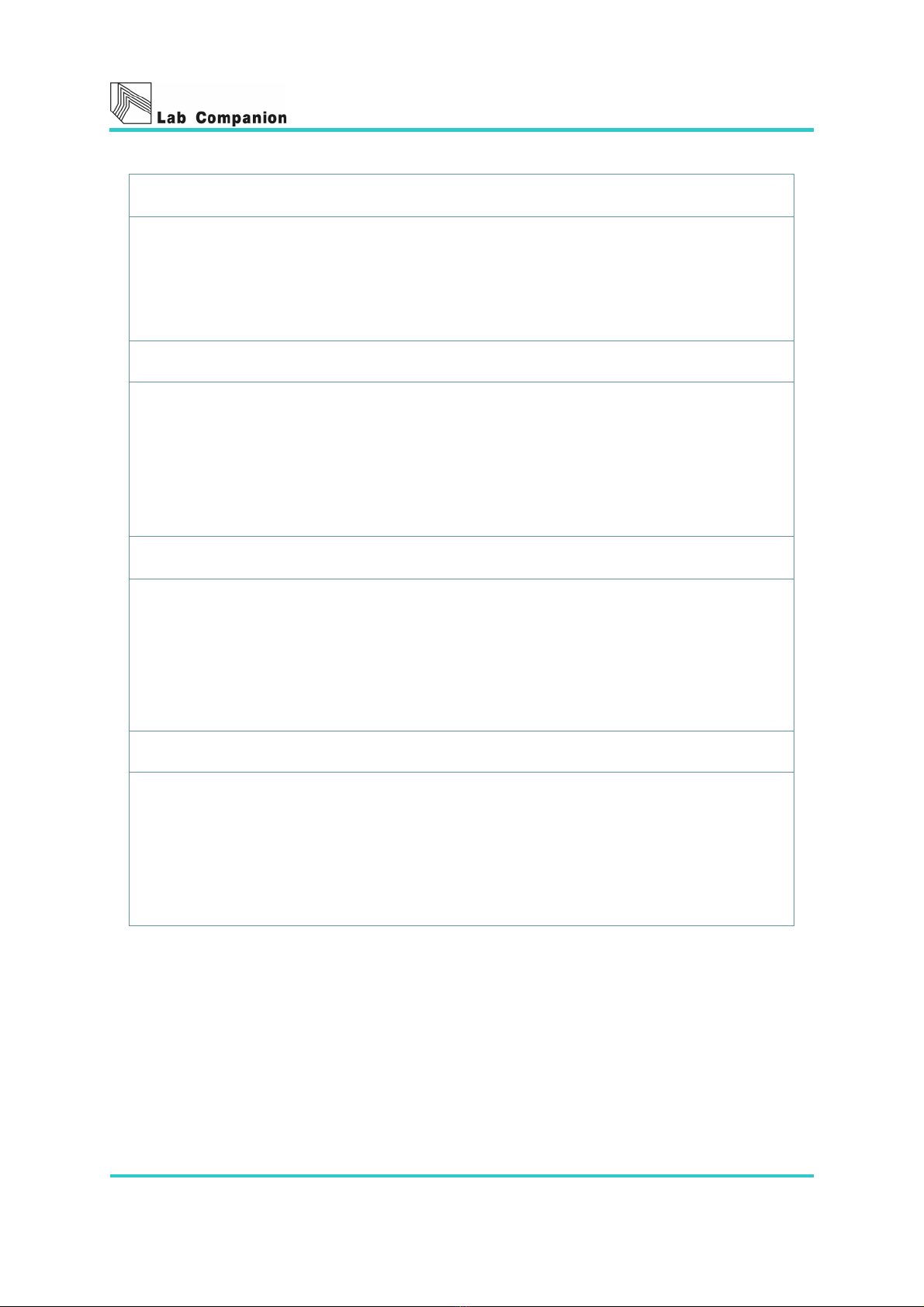

4. Shaker LED

Shake LED

Illuminates When setting the time.

Flashes during the timer mode.

F/Ward

Illuminates when settting the clockwise

timer.

Flashes during the timer mode or anti

clockwise mode.

B/Ward

Illuminates when setting the anti clockwise

timer.

Flashes during the timer or clockwise timer

Pause LED

Illuminates when setting the pause timer.

Flashes

during the timer mode or pause mode.

5. Temperature LED

Temp LED

Set the temperature using of the TEMP Button,

Illuminates when pressing the START/STOP Button.

Heater LED

Indicates the heater output.

Auto-tune LED

Flahses during Auto-tune function.

Wait on timer LED

After setting time,indicates starting point

of the unit. Illuminates while operating.

Wait off timer LED

After setting time, indicates the unit

stops.Flashing the timer LED during

operation. The timer LED is lit, the timer

is standing by.

Door LED

When opening the door, shaking table,

heater,circulation fan stops operation.

After 5minutes, break the mainpower then

Door LED is flashing with audible Beep

sound.

Over temp. LED

When the inner temp is over the over temp.

limit, the unit stops then, flahsing the

Over temp LED with audible Beep sound.

Page 18

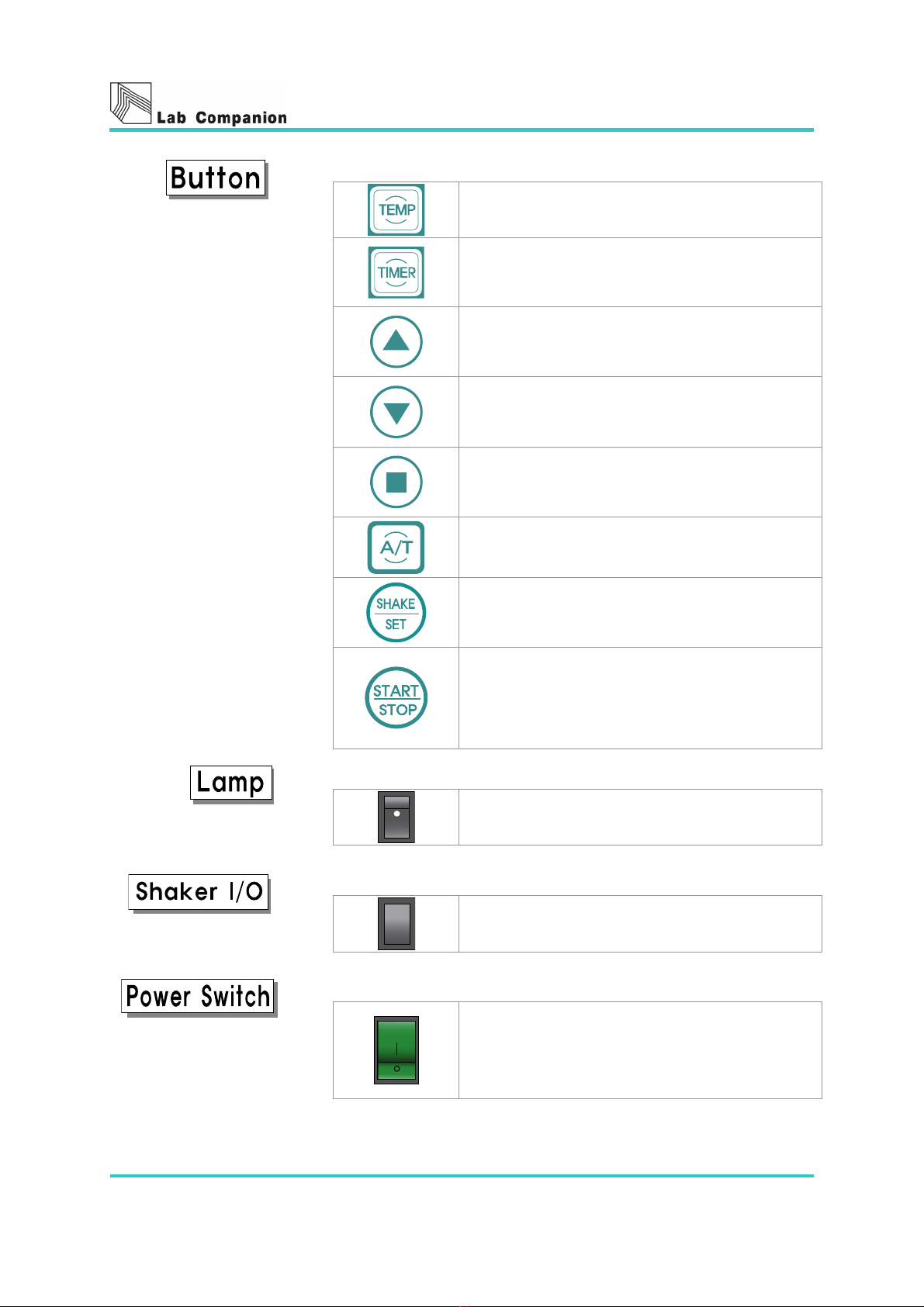

6. Entering button for the setting value

Temp Button

Setlects for the temp

Timer Button

Selects for the timer.

Up Button

Increases the set value.

Down Button

Decreases the set value.

Enter Button

After setting the value, store the set value

using of Enter button.

Auto-tune Button

Auto-tune Fu

nction operates while pressing

the button for a second.

SHAKE/SET Button

For Checkng the setting and present rpm

and entering the new rpm value

START/STOP Button

Starts and Stops the unit.

When the unit stops operating, user can

remove the beep sound and flashing LED with

Start/Stop Button.

7. Lamp Button

Turns On / Off the inner Lamp.

8. Shaker I/O Button

Shaker I/O Buton

Starts/ Stops the shaking table.

9. Power switch

Power switch

Turns On / Off the Power to shaker.

Page 19

The unit Operation

Before using the unit, Make sure the shaking direction to

protect the unit from the dust

Position the appropriate accessaries on the shaking

table and toghten securely.

If using the temp function, the unit should be operated

5minutes before.After maintaining the temp uniformity,

install the vessels and accessarries on the shaker table.

Select the desired value, Starts the operation

Control of the Temperature

This control is for the chamber of the inner temp.

Controlling the temp, other function and programming temp

using of the Temp button.

Method of the setting temp

① Turns on the power switch and wait for the unit

stabilized.

② Press Temp button.

③ Flashing the number activated on the SV display.

④ Set the desired temp with Up button and Down button

⑤ Press Enter button to finish setting.

⑥ After pressing the Start/Stop butoon, the unit operates

following the setting temp.

If not setting the temp for

10seconds, the display

will be back in the main.

This manual suits for next models

3

Table of contents

Other Jeio tech Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Molecular Devices

Molecular Devices StakMax user guide

Sutter Instrument

Sutter Instrument MT-75 Series Assembly instructions

Bibby Sterilin

Bibby Sterilin Stuart SW5 Instructions for use

MMM Group

MMM Group ECOCELL 22 operating instructions

Specac

Specac Gateway ATR user manual

Faro

Faro SK07 Series instruction manual

Tuttnauer

Tuttnauer T-Top 10 Operation and maintenance manual

Endress+Hauser

Endress+Hauser Liquistation CSF48 operating instructions

Monmouth Scientific

Monmouth Scientific Circulaire HLFT1000 operating & maintenance manual

Bullard

Bullard Eclipse LD user manual

Elmi

Elmi CM-50M user manual

CURIOSIS

CURIOSIS Celloger Mini Plus Quick manual