JENTNER DIGITAL II User manual

Side 2 –Operating Instructions DIGITAL II Version 2.0

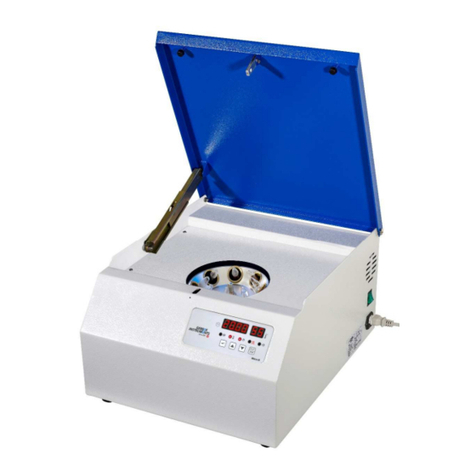

Small-Size Electroplating Unit DIGITAL II Version 2.0

The universally compact electroplating units are applicable for all current plating solutions, such as

Electrolytic Degreasing, Gold-, Silver-, Rhodium-, Palladium and Ruthenium plating baths; as well as

for baths without precious metals like Copper and Nickel.

Dimensions and weight

Digital II: Width 700 mm, depth 320 mm, height 250 mm, weight 18 kg

The DIGITAL II Version 2.0 includes:

• 8 tanks, PP (4 working- and 4 rinsing tanks)

• Dimension: 150 x 100 x 150 mm, Volume 1,5 litre

• 1 safety protection cable

• 1 thermo couple with titanium holder

Available accessories/spare parts (not included)

• Thermo couple / level regulator for a second heater

• Working/rinsing tank, PP

• Tank lid, PP

• Jig for rings

• Jig for chains

• Immersion titanium heater, 200 Watt

• Titanium holder for heater

• Titanium holder for thermo couple

• Anodes of stainless steel, platinized titanium, mixed oxide (MOX), silver, copper and nickel

• Filter pump MINI

• plating pen for multicolour processing

• Copper wire

Side 3 –Operating Instructions DIGITAL II Version 2.0

Operating elements

❶Button „Start/Standby “

❷Button “Motor/Movement “

❸Button „Heizung/Heater 1“

❹Button „Heizung/Heater 2“

❺Control panel / display

❻Button “Temp” – setting temperature

❼Button “Volt” – setting voltage

❽Button “Charge” – setting Amin (charge)

❾Button “Time” – setting of exposure time

❿Button “Basin” – selection of the working tank

⓫Button “OK” – save of the set values

⓬Button “Prog” – selection of the working program

⓭Rotary button for selection of parameters and values

⓮Connection socket “red” for plating pen (anode)

⓯Connection socket “blue” for tweezers/clamp (cathode)

⓰Tanks (8 pieces)

⓱Anode rods (2 x)

⓲Cathode rod

Side 4 –Operating Instructions DIGITAL II Version 2.0

The anode rods ⓱can be pulled out very easily, the cathode rod ⓲in the middle can be screwed

out (clockwise).

Agitation (cathode rod)

The movement is effected by a built-in driving motor. The movement can be started with the button

❷“Motor / Movement”.

Heating of the bath

The heater is fixed with a special holder in the corresponding galvanic bath. The temperature is

controlled continuously by an included temperature sensor (thermo couple / level regulator).

Attention! Heater and temperature sensor must always hang together in a tank. Only for intended

use! The immersion heater is inserted for operation on the case back to a socket. The immersion

heater can be turned on by a button on the control panel. The heating is regulated automatically.

Attention! The level regulator turns off the heater if the volume is too low! Nevertheless, the heater

must be turned on only when the working tank is filled with liquid. If the level is too low, or if the

immersion heater is outside the tank, there is the risk of fire and the destruction of working tank and

immersion heater. The holders of immersion heater and sensor must be fixed to the side of the tank

and not at the anode rod.

Anode materials

The anodes must be fixed on the outer anode rods ⓱. Attention! Pay attention for a good

conductive contact. The required anode material (for example stainless steel, MOX, fine-silver,

platinized titanium) depends on each plating bath. Please note the information in the data sheets of

the chemical producer. Our scope of delivery contains anodes in various dimensions.

Process parameter / course of process

The parts should be put on a jig (for example we deliver a special a jig for rings or for chains) and

fixed on the middle cathode rod ⓲. Pay always attention for a good conductive contact. Please

clean the cathode rod continuously.

The first step in the small-size-electroplating unit must be the electrolytic degreasing bath. Anything

else depends on your needs. Rinse well in distilled water after each step. Always follow the

information on the product data sheets.

Pen-plating

With this machine you have also the opportunity to galvanize partially. Therefore, you need the

galvanizing pen and tweezers. You have to connect both to the allowed ports ⓮and ⓯. These

ports are situated in the left front of the machine. The required voltage is set by the chosen program.

The special chemicals for the pen-plating process (rhodium, silver, gold electrolytes) can be delivered

by us or any other chemical producer.

Covering of the machine

The cover takes care of the sensitive and valuable plating solutions, it protects them against dust and

dirt whenever the machine is not in use. Attention! When working with heated bathes the cover has

to left open. If the cover is closed it is possible that the heat accumulation deforms the cover.

Side 5 –Operating Instructions DIGITAL II Version 2.0

Start up

The delivered power plug which is equipped with protective earth contacts has to be connected with

the power plug port situated on the backside of the machine. Then put the other end of the cable

into an electrical power point 230 V / 50 Hz (120 V / 60 Hz). The unit will be switched on with the

toggle switch at the backside. The power of the rectifier is 15 V / 20 A.

Maintenance

Anode and cathode rods must be regularly cleaned with a Scotch sponge. Experience has shown that

this should be done every 6-8 weeks.

Short-circuit proof / fuse

The unit is short-circuit-proof if there will be short-circuit between cathode and anode.

The fuse is located on the backside of the machine, situated in main connection socket inside fuse

holder. Only micro fuse 4 A (slow blow), 115-250 V ~, 5* 20 mm must be used.

Attention

Make sure there is good ventilation in the work area.

Rinse water and used chemicals must be disposed of properly. Please refer to the legal regulations.

Please observe the instructions of the Safety Data Sheets (MSDS). Your chemical supplier provides

these.

The unit must be turned off after work necessarily!

The heater should never be operated unattended!

Chemicals

The required bath chemicals are available from us or from special producers. Please read the product

information of the manufacturer carefully and follow the instructions.

Side 6 –Operating Instructions DIGITAL II Version 2.0

Example Charge Rhodium bath

Each plating bath uses a theoretical deposition value, eg Rhodium approximately 6 mg / Amin (value

see product description). You can now choose whether a deposition time should be selected, or a

charge is determined.

Side 7 –Operating Instructions DIGITAL II Version 2.0

By setting the charge, the metal weight is determined. For the Rhodiumbath a setting of 10 Amin

would be mathematically a deposition of 60 mg (10 Amin x 6 mg / Amin = 60 mg). Please note, these

are purely theoretical values, which may differ from the actual values.

Functions

• 15 programs can be saved

• Display in 4 different languages (GER, ENG, SP, and F) is possible. For the choice of language

press „OK“ button for 3 sec

• For the standby mode press button “start” for 3 sec

• The programs are flexible installable

15 programs can be used

EF Degreasing

Au Gold

Ag Silver

Rh Rhodium

Ru Ruthenium

Pd Palladium

Pt Platinum

Ni Nickel

Cu Copper

The programs from 1 to 6 are unnamed. For each tank up to 3 programs can be installed.

Approach to programming

1. Turn on main switch

2. Press button „progr“

3. Select with the rotary switch the desired program

4. Confirm with “ok” button

5. Now enter the working parameters. Press the respective button (time, voltage, etc. see below) and

select the value using the rotary switch. The entries in each case confirm with "ok":

„Temp“ Temperature (if the bath must be heated)

„Volt“ Voltage

„Time“ Choose between minute and second (or choose charge see above)

If no time is entered permanent mode is chosen automatically.

6. When all values are entered, press button „progr" for 3 seconds to save the settings. The display

shows the previously entered values

7. Press button „save“

8. Confirm with „OK“ and return to the actual values

9. Start the process with „start“

Side 8 –Operating Instructions DIGITAL II Version 2.0

Control functions

1. Heat protection / level regulator

If the level is too low in a heated bath the heater is switched off by the thermo couple. The display

shows a warning signal over the full area. The signal can be confirmed with “ok” but the heater

remains off. An overheating of heater or tank is avoided. When the bath is refilled the heater will be

automatically turned on.

2. Total charge

For each basin a total charge can be set. So a metal content is determined, which can be deposited.

When this value is exceeded a warning appears and the bath should be regenerated. To set the total

charge press button “Basin” for 3 sec and enter the desired value and (important!) basin. After this

the display shows the signal

If the total charge is matched with a desired program (by setting the number of the basin in that

program) the control is done for this process. Do as following:

1. Press button “basin” 3 seconds

2. Enter the desired value and basin

3. Press “save”

4. Leave with “OK”

5. Press button “progr” and choose the desired one

6. Set the same basin as in point 2

7. Leave with “OK”

8. Press “progr” for 3 seconds and save the process

9. Leave with “OK”

If basin number 0 is selected you can work manually (without control).

Example total charge Rhodiumbath

The deposition rate of the bath is 6 mg / Amin (see data sheet of the chemical supplier). For this the

total charge of 200 Amin can be set. That means that after receiving this value 1200 mg of rhodium

are deposited (6 mg/Amin x 200 Amin = 1200 mg Rh) and the bath can be regenerated accordingly. A

consisted quality is ensured. Rinsing losses are not taken into account!

Heaters

Up to max. two heaters can be connected with the corresponding sensors on the unit. These can be

used in any tank. The tanks where heater and sensor hang will be heated. The heaters can be turned

on at the control panel. The display shows a signal as soon as a heater is active.

Attention: Heaters only for intended use.

Side 9 –Operating Instructions DIGITAL II Version 2.0

Other manuals for DIGITAL II

1

Popular Laboratory Equipment manuals by other brands

Velp Scientifica

Velp Scientifica HSC F20500101 instruction manual

Gerber Instruments

Gerber Instruments Micro 3 operating instructions

INHECO

INHECO ODTC Verification Tool 96 user manual

Miele

Miele PG 8583 operating instructions

Helmer

Helmer QuickThaw DH2 Operation manual

J.P. SELECTA

J.P. SELECTA RS 3001-V manual

Air Vent

Air Vent UV-C FiltAir instruction manual

PerkinElmer

PerkinElmer LS 55 user guide

Thermo Forma

Thermo Forma 3911 Operating and maintenance manual

Isotech

Isotech LIBRA 785 User maintenance manual/handbook

3D Histech

3D Histech Pannoramic 250 user guide

J.P. SELECTA

J.P. SELECTA DE-1626 instruction manual