Read and understand the

entire contents of this manual before attempting

to install and operation. Failure to comply may

cause serious injury.

6.0 Setup

6.1 Unpacking and Cleanup

Inspect the Air Filtration Unit and check for shipping

damage. Report any damage immediately to your

distributor and shipping agent. Do not discard any

shipping material until the Air Filtration Unit is

installed and running properly.

Compare the contents of your container with the

following parts list to make sure all parts are intact.

Missing parts, if any, should be reported to your

distributor.

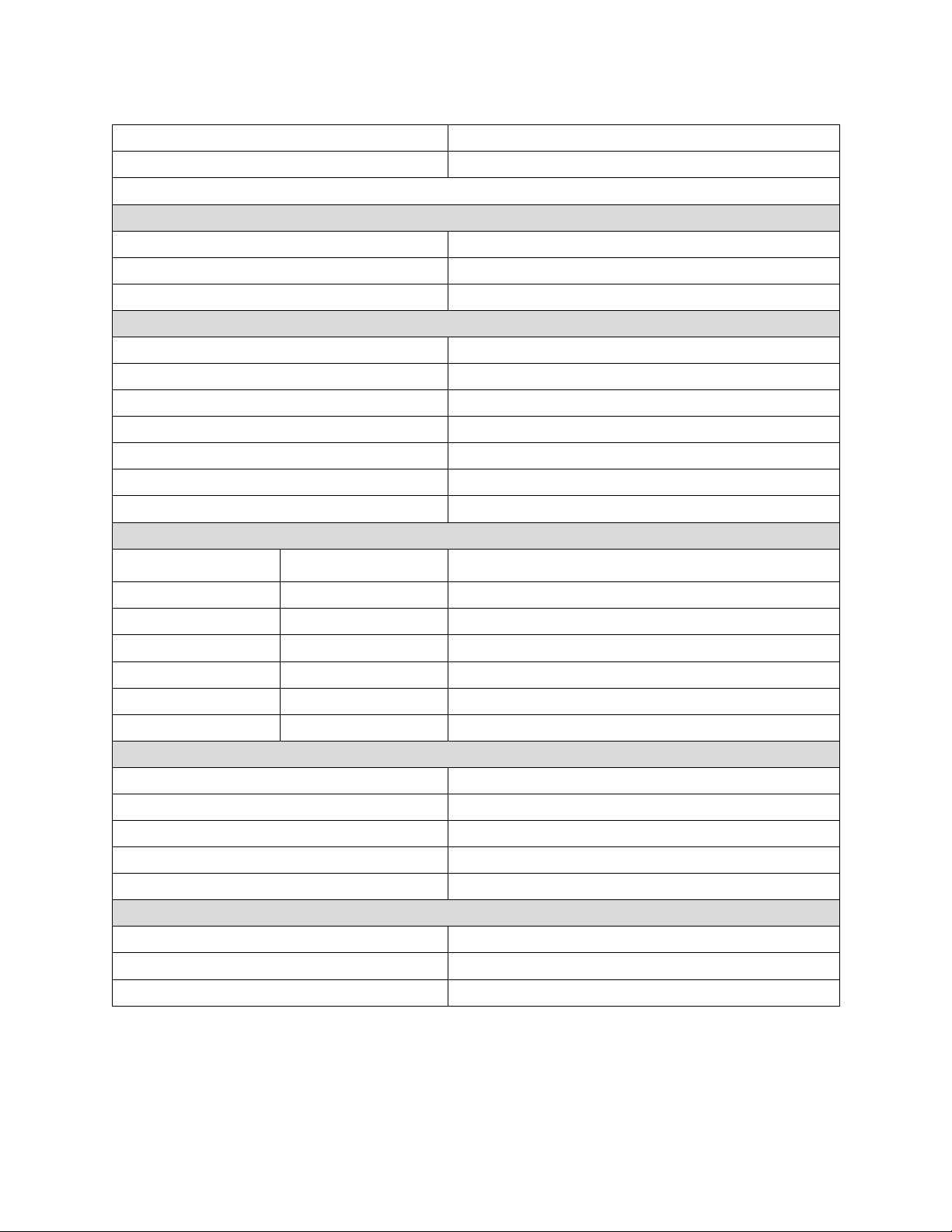

6.2 Shipping Contents

Carton contents

1 Air Filtration Unit

1 Manual and Warranty Card

6.4 Installation

This machine is designed to

operate while it is setting on the floor. Only use

this machine with it setting on a level, stable

floor surface. Never place this machine on a

bench, chair, table, cart, or any other elevated

surface, or where there is a risk of tipping over.

Do not hang this machine from the ceiling or any

other structure.

The AFS-850 has a 15-foot power cord, a wide

base, and a 360° circular handle. Using the handle,

you can slide or move this machine to an area

closest to your dust source.

This unit will work best if located away from corners

and heating/cooling vents.

Installation is quick and easy. Just plug the power

cord into an electrical outlet and the machine is

ready to power on and use.

Follow these power cord safety requirements:

• Route the power cord so that it will not

become entangled in the machine in any

way.

• Route the cord to the power supply in a way

that does not create a trip hazard.

• Do not route cord under carpeting or cover

the cord with throw rugs, runners, or similar

coverings.

• Do not route cord under furniture or

appliances.

7.0 Electrical Connections

Electrical connections should

be made by a qualified electrician in compliance

with all relevant codes. Failure to comply may

cause serious injury.

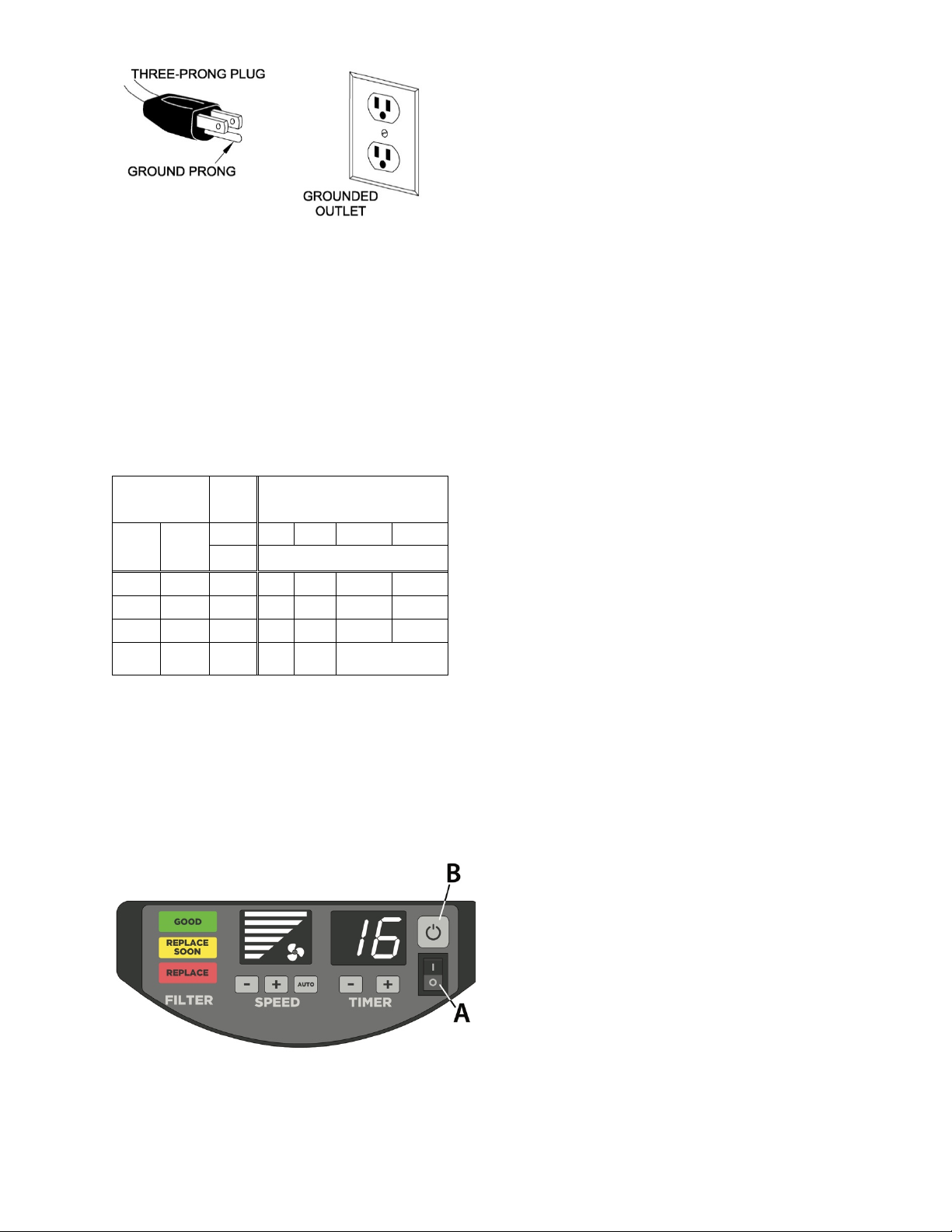

The AFS-850 Air Filtration System is prewired for

single phase, 120V power. It is provided with a plug

designed for use on a circuit with a grounded outlet

that looks like the one pictured in Figure 7-1.

It is recommended that the AFS-850 be connected

to a 15-amp circuit with a circuit breaker or fuse. If

fuses are used, they should be time-delay fuse

marked “D”. Local codes take precedence over

recommendations.

7.1 GROUNDING INSTRUCTIONS

1. All Grounded, Cord-connected Tools:

This machine must be grounded. In the event of a

malfunction or breakdown, grounding provides a

path of least resistance for electric current to reduce

the risk of electric shock. This tool is equipped with

an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be

plugged into a matching outlet that is properly

installed and grounded in accordance with all local

codes and ordinances.

Do not modify the plug provided - if it will not fit the

outlet, have the proper outlet installed by a qualified

electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipment-grounding

conductor to a live terminal.

Check with a qualified

electrician or service person if the grounding

instructions are not completely understood, or if

in doubt as to whether the tool is properly

grounded. Failure to comply may cause serious

or fatal injury.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug.

Repair or replace damaged or worn cord

immediately.

2. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating less than

150 volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in Figure 7-

1.