GB - ENGLISH

Operating Instructions

Dear Customer,

Many thanks for the confidence you have shown in us with the purchase of your new JET-machine. This manual has been

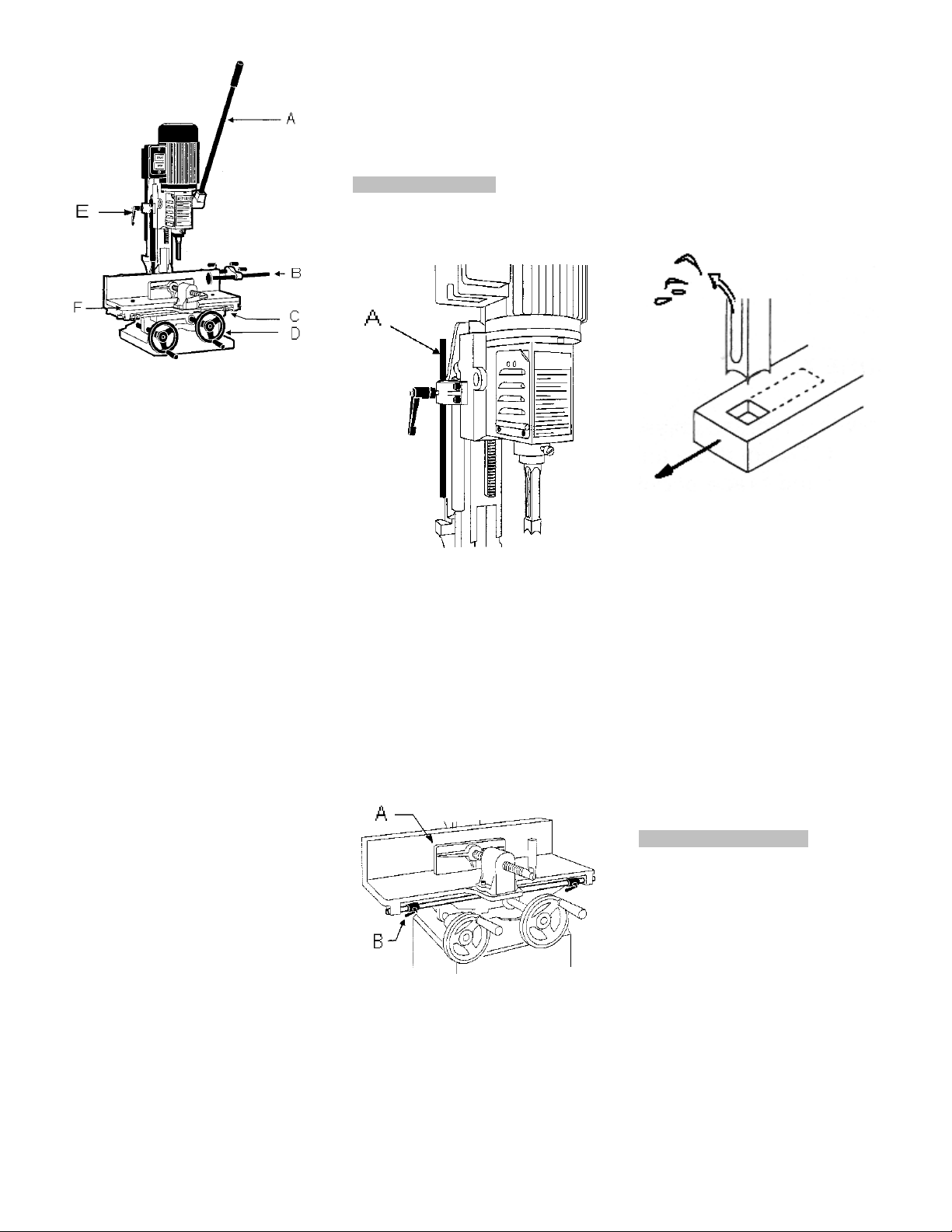

prepared for the owner and operators of a JET 719-A mortiser to promote safety during installation, operation and maintenance

procedures. Please read and understand the information contained in these operating instructions and the accompanying

documents. To obtain maximum life and efficiency from your machine, and to use the machine safely, read this manual thoroughly

and follow instructions carefully.

…Table of Contents

1. Declaration of conformity

2. JET Warranty

3. Safety

Authorized use

General safety notes

Remaining hazards

4. Machine specifications

Technical data

Noise emission

Contents of delivery

5. Transport and start up

Transport and installation

Assembly

Mains connection

Dust collection

Starting operation

6. Machine operation

7. Setup and adjustments

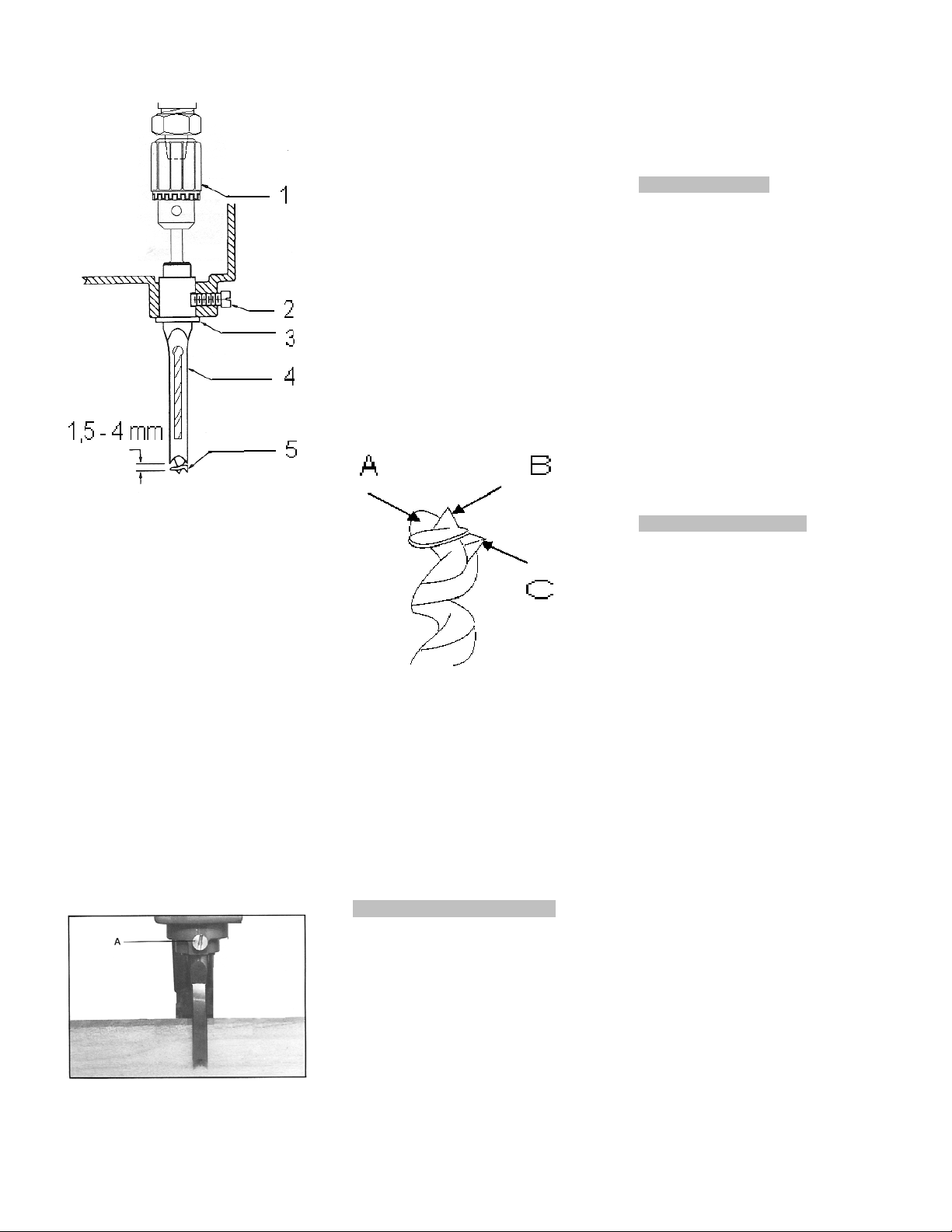

Installing chisel and bit

Sharpening chisel and bit

8. Maintenance and inspection

9. Trouble shooting

10. Available accessories

1. Declaration of conformity

On our own responsibility we hereby

declare that this product complies with

the regulations* listed on page 2.

Designed in consideration with the

standards**.

2. JET Group Warranty

The JET Group makes every effort to

assure that its products meet high

quality and durability standards and

warrants to the original retail

consumer/purchaser of our products

that each product be free from defects

in materials and workmanship as

follows:

2 YEAR LIMITED WARRANTY ON

ALL PRODUCTS UNLESS

SPECIFIED OTHERWISE.

This Warranty does not apply to

defects due to directly or indirectly

misuse, abuse, negligence or

accidents, normal wear-and-tear,

repair or alterations outside our

facilities, or to a lack of maintenance.

The Jet group limits all implied

warranties to the period specified

above, from the date the product was

purchased at retail.

To take advantage of this warranty, the

product or part must be returned for

examination, postage prepaid, to an

authorized repair station designated by

our office.

Proof of purchase date and an

explanation of the complaint must

accompany the merchandise.

If our inspection discloses a defect, we

will either repair or replace the product,

or refund the purchase price if we

cannot readily and quickly provide a

repair or replacement, if you are willing

to accept a refund.

We will return repaired product or

replacement at JET’S expense, but if it

is determined there is no defect, or that

the defect resulted from causes not

within the scope of JET’S warranty,

then the user must bear the cost of

storing and returning the product.

The JET Group reserves the right to

make alterations to parts, fittings, and

accessory equipment which they may

deem necessary for any reason

whatsoever.

3. Safety

3.1 Authorized use

This mortiser is designed for mortising

wood and similar materials only.

Machining of other materials is not

permitted and may be carried out in

specific cases only after consulting

with the manufacturer.

The proper use also includes

compliance with the operating and

maintenance instructions given in this

manual.

The machine must be operated only by

persons familiar with its operation and

maintenance and who are familiar with

its hazards.

The required minimum age must be

observed.

The machine must only be used in a

technically perfect condition.

When working on the machine, all

safety mechanisms and covers must

be mounted.

In addition to the safety requirements

contained in these operating

instructions and your country’s

applicable regulations, you should

observe the generally recognized

technical rules concerning the

operation of woodworking machines.

Any other use exceeds authorization.

In the event of unauthorized use of the

machine, the manufacturer renounces

all liability and the responsibility is

transferred exclusively to the operator.

3.2 General safety notes

Woodworking machines can be

dangerous if not used properly.

Therefore the appropriate general

technical rules as well as the following

notes must be observed.

Read and understand the entire

instruction manual before attempting

assembly or operation.

Keep this operating instruction close

by the machine, protected from dirt

and humidity, and pass it over to the

new owner if you part with the tool.

No changes to the machine may be

made.

Daily inspect the function and

existence of the safety appliances

before you start the machine.

Do not attempt operation in this case,

protect the machine by unplugging the

power cord.