Das gesetzliche Mindestalter ist einzuhalten.

Neben den in der Gebrauchsanleitung enthaltenen

Sicherheitshinweisen und den besonderen Vorschriften Ihres

Landes sind die für den Betrieb von

Holzbearbeitungsmaschinen allgemein anerkannten

fachtechnischen Regeln zu beachten.

Jeder darüber hinaus gehende Gebrauch gilt als nicht

bestimmungsgemäß und für daraus resultierende Schäden

haftet der Hersteller nicht. Das Risiko trägt allein der

Benutzer.

3.2 Allgemeine Sicherheitshinweise

Holzbearbeitungsmaschinen können bei unsachgemäßem

Gebrauch gefährlich sein. Deshalb ist zum sicheren

Betreiben die Beachtung der zutreffenden Unfallverhütungs-

Vorschriften und der nachfolgenden Hinweise erforderlich.

Lesen und verstehen Sie die komplette Gebrauchsanleitung

bevor Sie mit Montage oder Betrieb der Maschine beginnen.

Bewahren Sie die Bedienungsanleitung, geschützt vor

Schmutz und Feuchtigkeit, bei der Maschine auf, und geben

Sie sie an einen neuen Eigentümer weiter.

An der Maschine dürfen keine Veränderungen, An- und

Umbauten vorgenommen werden.

Überprüfen Sie täglich vor dem Einschalten der Maschine die

einwandfreie Funktion und das Vorhandensein der

erforderlichen Schutzeinrichtungen.

Festgestellte Mängel an der Maschine oder den

Sicherheitseinrichtungen sind zu melden und von den

beauftragten Personen zu beheben.

Nehmen Sie die Maschine in solchen Fällen nicht in Betrieb,

sichern Sie die Maschine gegen Einschalten durch Ziehen

des Netzsteckers.

Zum Schutz von langem Kopfhaar Mütze oder Haarnetz

aufsetzen.

Enganliegende Kleidung tragen, Schmuck, Ringe und

Armbanduhren ablegen.

Tragen Sie Schutzschuhe, keinesfalls Freizeitschuhe oder

Sandalen.

Verwenden Sie die durch Vorschriften geforderte persönliche

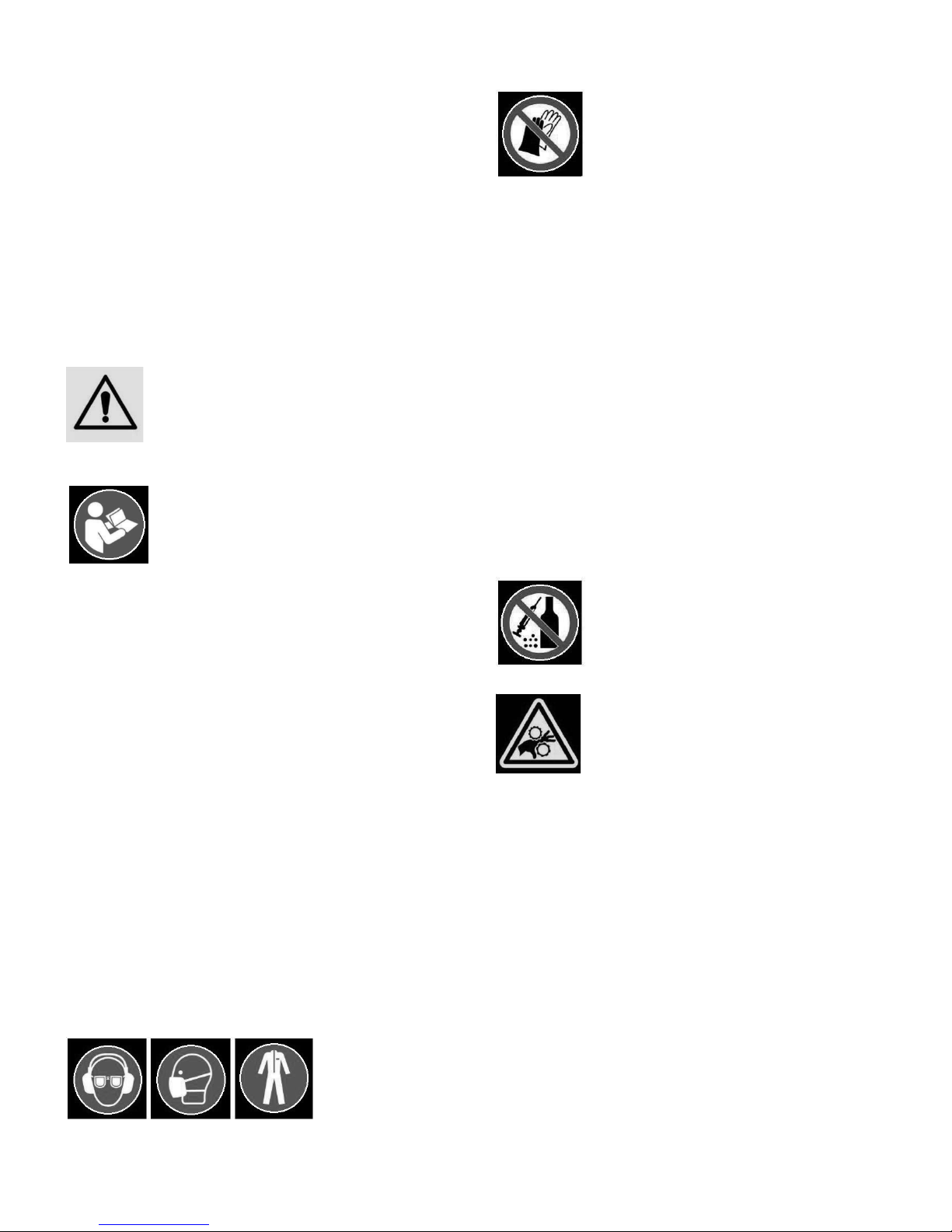

Schutzausrüstung.

- Augenschutz

- Ohrenschutz

- Staubschutz

Beim Arbeiten an der Maschine keine Handschuhe tragen.

Die Maschine so aufstellen, dass genügend Platz zum

Bedienen und zum Führen der Werkstücke gegeben ist.

Sorgen Sie für gute Beleuchtung.

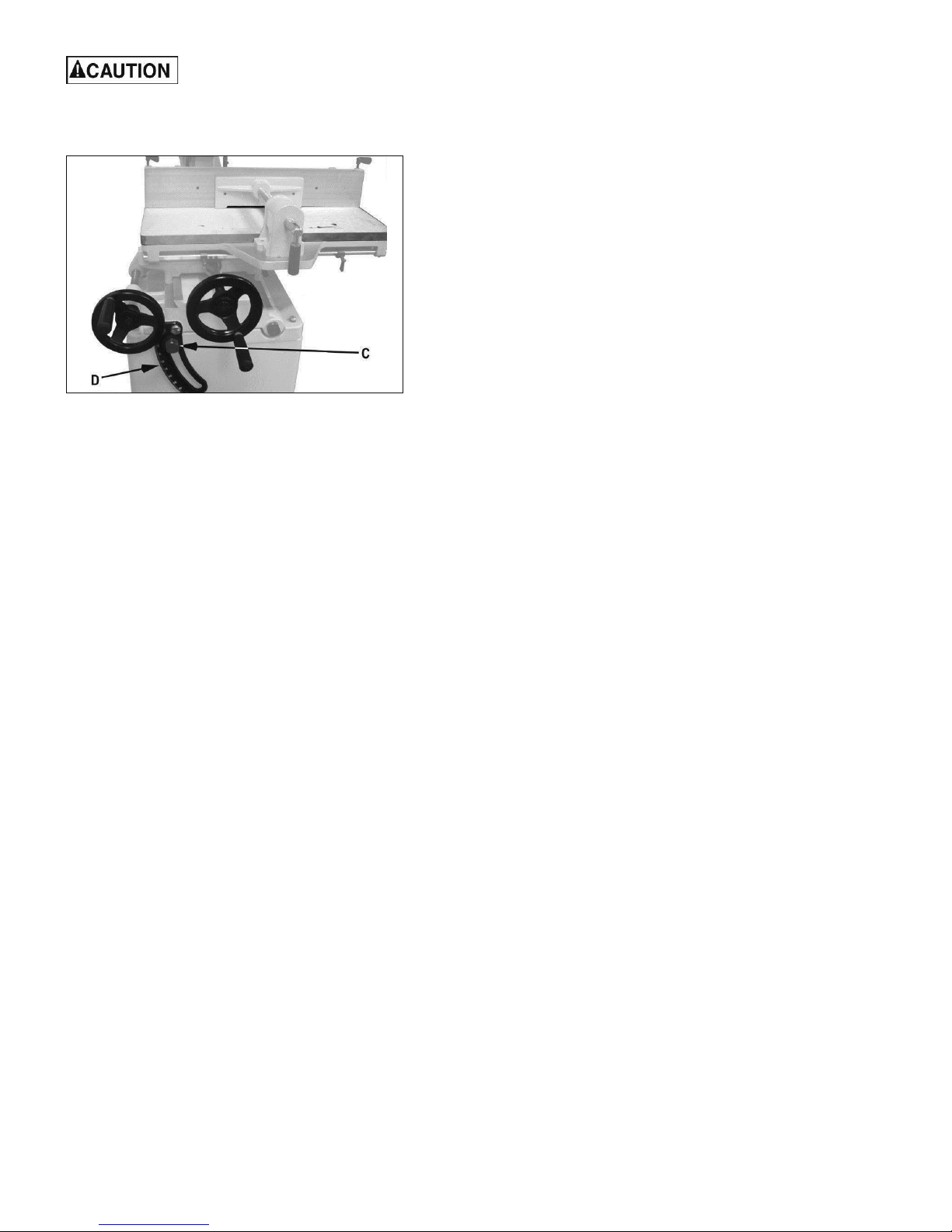

Achten Sie darauf, dass die Maschine standsicher auf fester

und ebener Tischfläche oder auf dem Originalunterschrank

festgeschraubt ist.

Beachten Sie dass die elektrische Zuleitung nicht den

Arbeitsablauf behindert und nicht zur Stolperstelle wird.

Den Arbeitsplatz frei von behindernden Werkstücken, etc.

halten.

Niemals in die laufende Maschine greifen.

Seien Sie aufmerksam und konzentriert. Gehen Sie mit

Vernunft an die Arbeit.

Achten Sie auf ergonomische Körperhaltung.

Sorgen Sie für sicheren Stand und halten Sie jederzeit das

Gleichgewicht.

Arbeiten Sie niemals unter dem Einfluss von Rauschmitteln

wie Alkohol und Drogen an der Maschine. Beachten Sie, dass

auch Medikamente Einfluss auf Ihr Verhalten nehmen

können.

Niemals in die laufende Maschine greifen.

Halten Sie Unbeteiligte, insbesondere Kinder vom

Gefahrenbereich fern.

Die laufende Maschine nie unbeaufsichtigt lassen.

Vor dem Verlassen des Arbeitsplatzes die Maschine

ausschalten.

Benützen Sie die Maschine nicht in der Nähe von brennbaren

Flüssigkeiten oder Gasen.

Beachten Sie die Brandmelde- und

Brandbekämpfungsmöglichkeiten z.B. Standort und

Bedienung von Feuerlöschern.

Benützen Sie die Maschine nicht in feuchter Umgebung und

setzen Sie sie nicht dem Regen aus.

Vor der Bearbeitung Nägel und andere Fremdkörper aus dem

Werkstück entfernen.

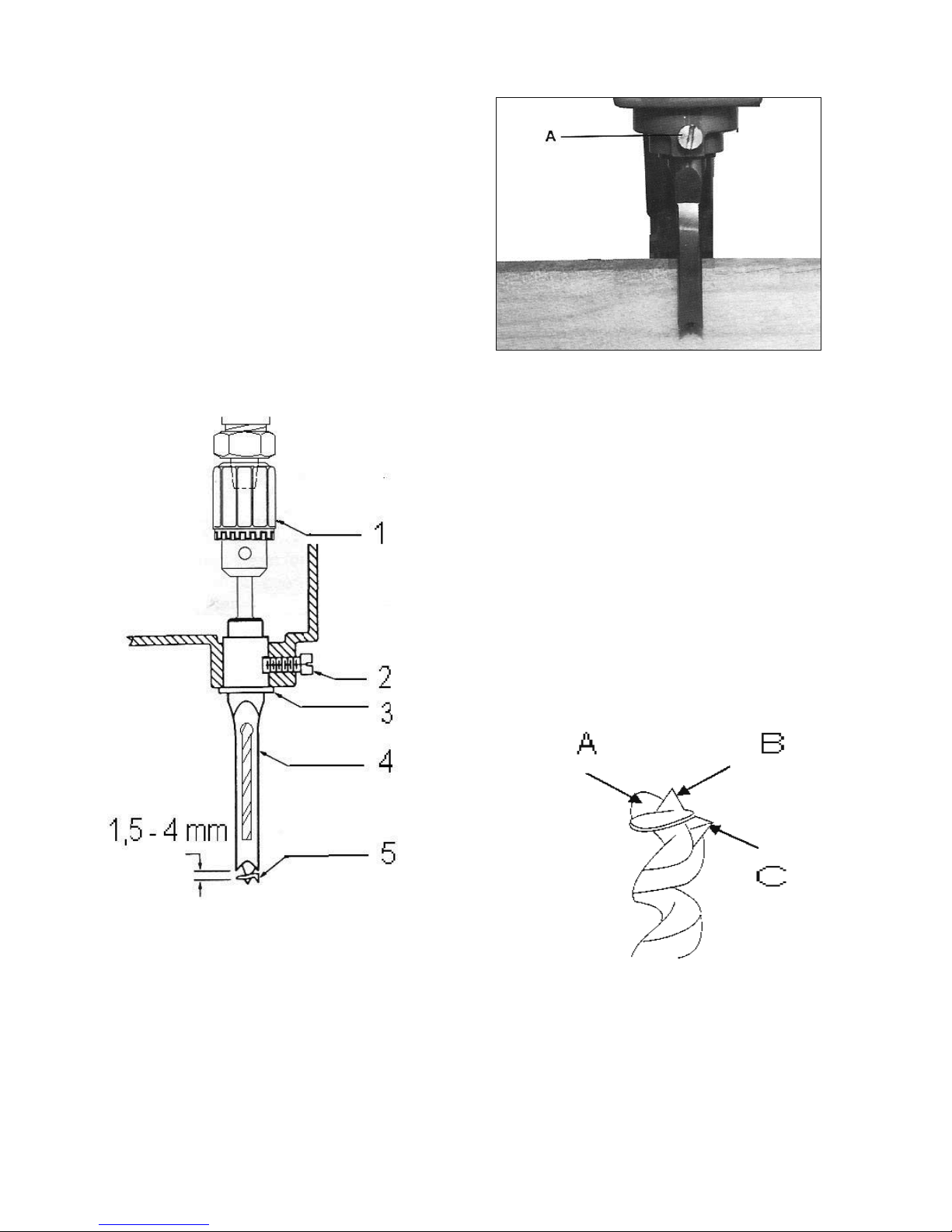

Nur mit gut geschärften Werkzeugen arbeiten.

Bearbeiten Sie nur ein Werkstück, das sicher auf dem Tisch

aufliegt.

Arbeiten Sie nie bei geöffneten Bohrfutterdeckeln.