P 4 / 8

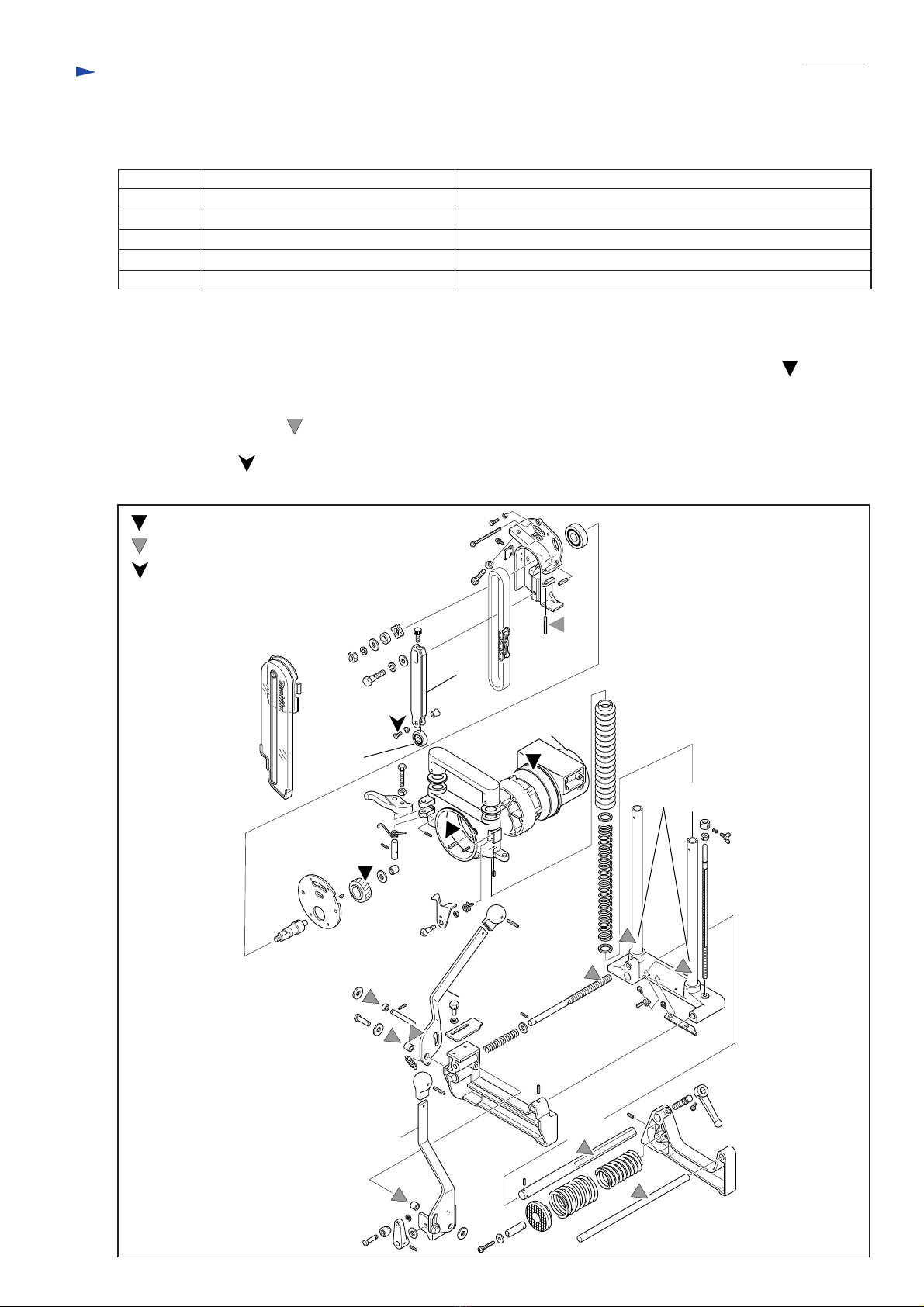

[4] Disassembling Gear Section

[5] Disassembling Vice Element

Note: Gear section can be replaced without disassembling Motor section.

Vice element can be pulled out only by loosening Lever 98 ass'y as illustrated in Fig. 7. If chips attach in the Compression

spring 48 and Compression spring 36, the chips make the clamp operation worse. Therefore, disassemble and clean them.

Loosen M6x35 Pan head screw to remove the Compression springs using cordless impact driver with phillips bit No.3 as

mentioned in Fig. 8 while holding Vice shoe so as not to jump by the reaction force of the Compression springs.

[6] Disassembling Front Vice

Main body including Base complete on vice section can be removed backward from

the Vice section in the following steps.

1) Disassemble Vice element in accordance with the above procedure.

2) Forward the main body to the edge of Screw M4 by turning Knob 20 as shown in

Fig. 9 .

Loosen two Levers in the direction of arrows as illustrated in Fig. 10.

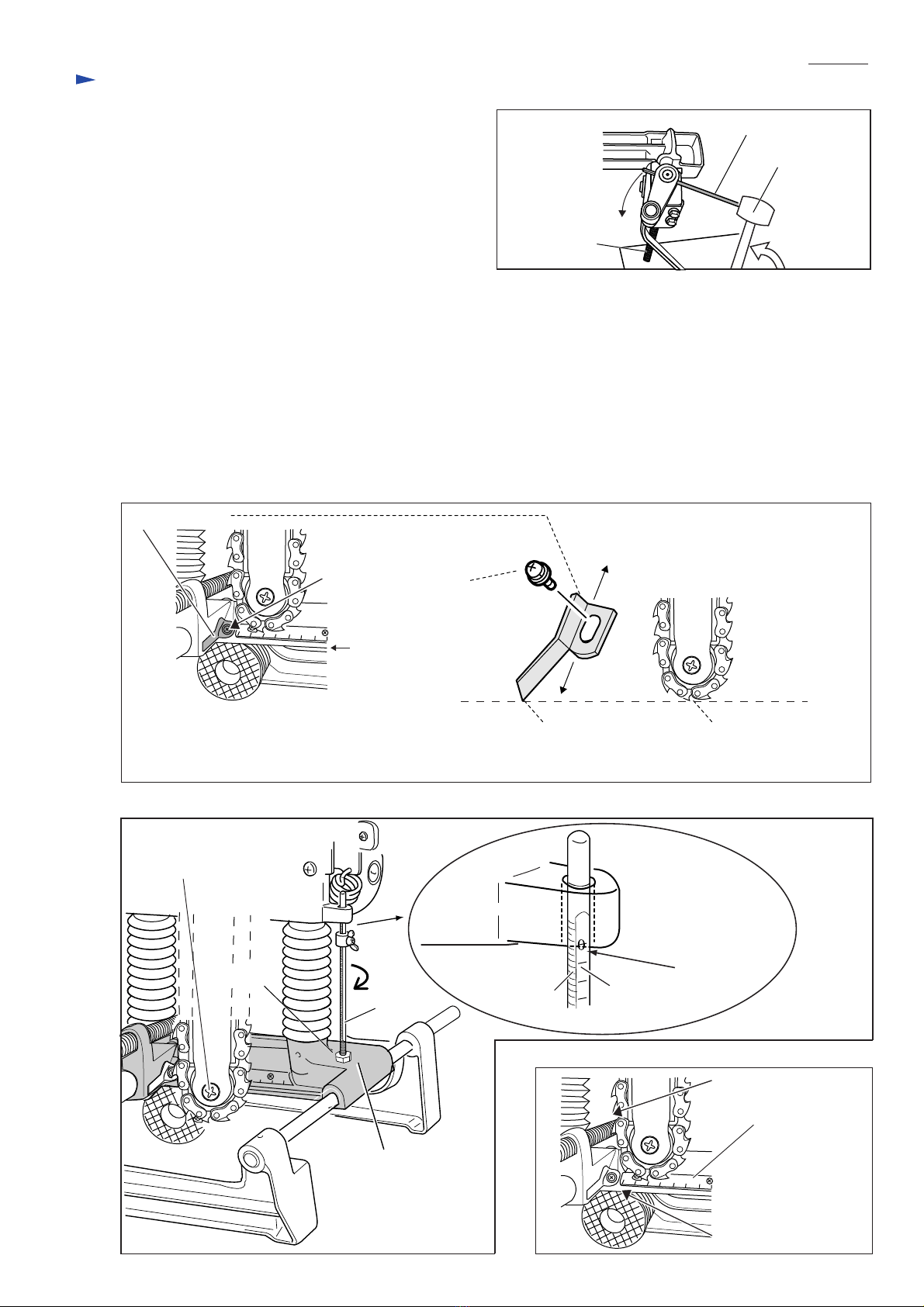

Push one end of Spring pin at the right side of Lever B complete using Spring pin

extractor 4.0 (Makita part No. 1R308) and plastic hammer.

Consequently, Pin 9 and some components can be separated as described in Fig. 11.

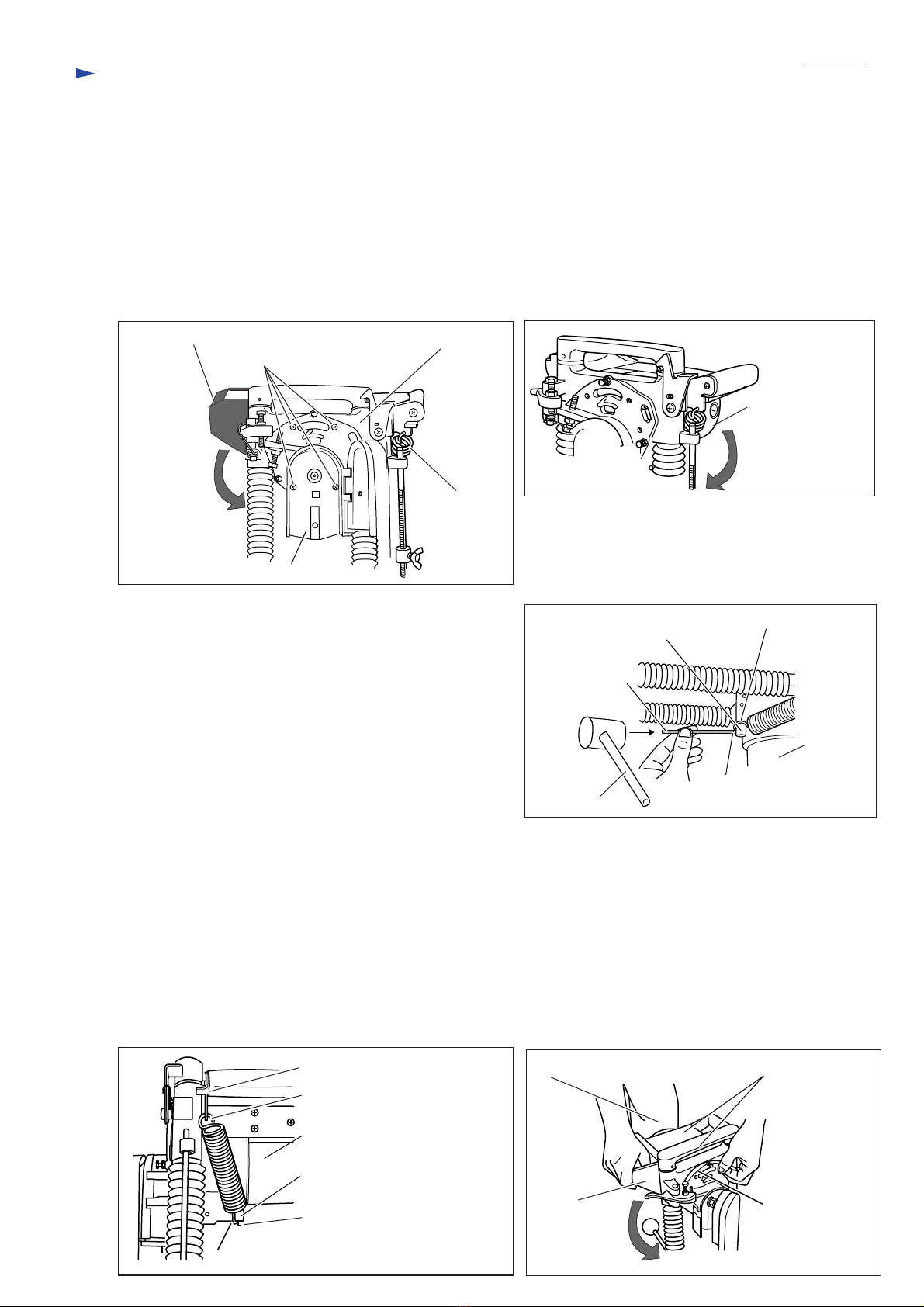

Fig. 6

Fig. 9

Fig. 8Fig. 7

Fig. 10 Fig. 11

Remove Spring washer 10, Flat washer 10 and Ring 15 from Spindle by hand.

Remove Sprocket 4 from tool by hand. If it is stuck on the spindle firmly, use Gear extractor Large (Makita part No. 1R045).

Strike the reverse side of Chain bar holder using plastic hammer, so Gear housing can be separated from Chain bar holder.

The connecting parts of Chain bar holder and Gear housing are three Spring pins 6-24 only.

Remove gear section from Gear housing, and then tap the gear section on the table to separate Helical gear 47 from the

other components of the gear section.

Loosen M10 Hex. nut using Box

wrench 17.

Type 94 Field insert jig

Sprocket 4 Wall of Chain

bar holder

Compression spring 48 and

Compression spring 36 (inside)

Cordless impact drive with phillips

bit No.3

Vice shoe

Vice element Vice element

Lever 98 assembly

Lever

(Lever B complete)

Lever (Clamp)

Spring pin 4-20

(left side)

Pin 9Flat washer 9

Spring pin 4-20 (right side)

Flat washer 9

Sleeve 9 (inside)

Plastic hammer

Sleeve 9

Lever B complete

Spring pin extractor 4.0

Lever B complete

Screw M14

Vice section

Knob 20

Repair

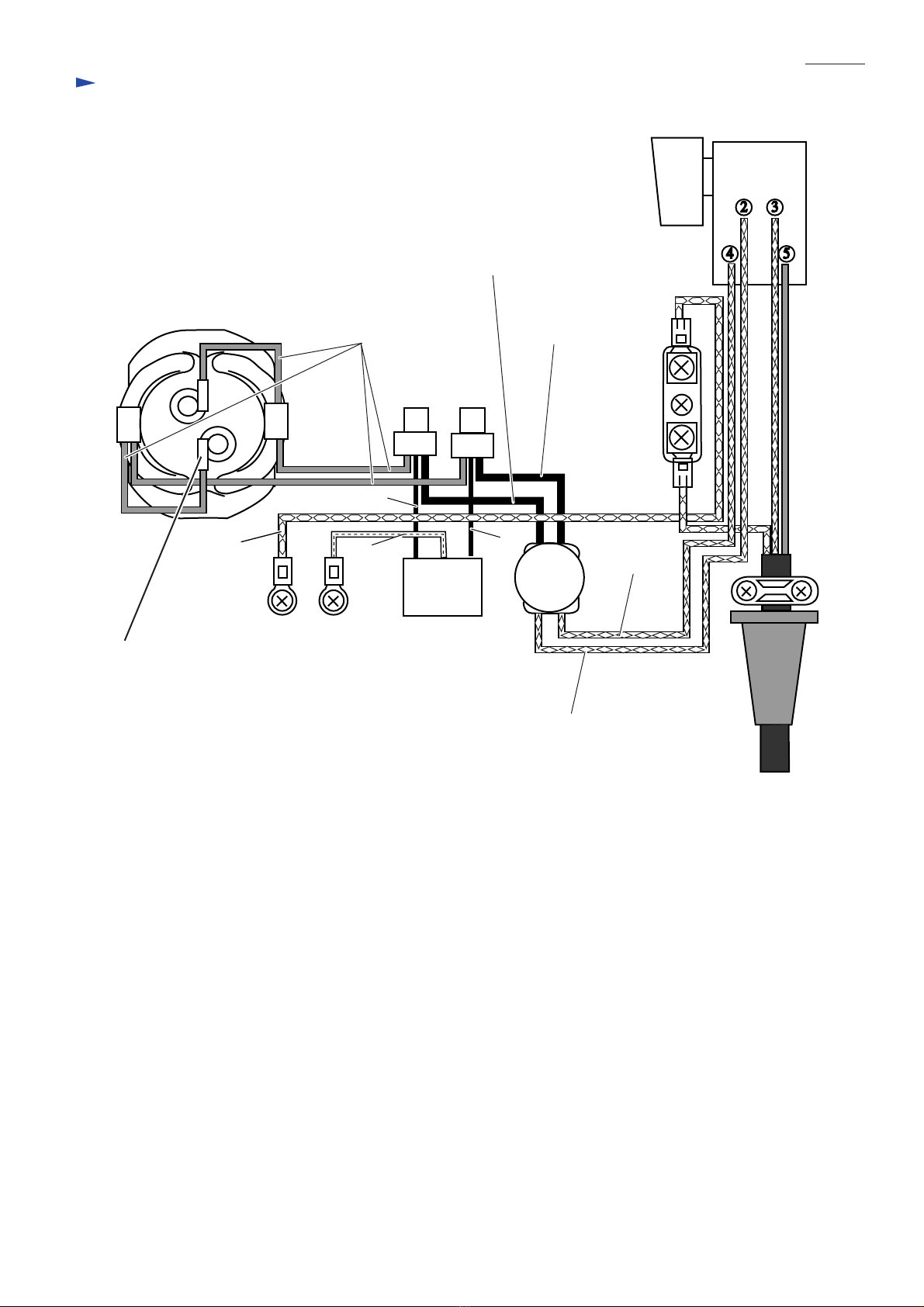

Remove four M5x80 pan head screws in the front of the tool in the same manner

described in Repairing Motor Section.

To release the tensile force of Tension spring 20, Turn the Motor housing clockwise.

The tension spring 20 will return to the original size. Consequently, Motor housing

complete can be easily removed.

Pull out Chain bar holder to your side from the front of tool while turning it.

Insert Type 94 Field insert jig (Makita part No. 1R275) between Sprocket 4 and the

wall of Chain bar holder in order not to revolve Spindle fixed with the Sprocket 4

as shown in Fig.6. Loosen M10 Hex. nut using Box wrench 17 or Wrench 13-17.