3

Table of contents

1. Safety

1.1 Safety warnings (warning notes

) ………………………………………………………………………………

6

1.1.1 Classification of hazards

……………………………………………………………………………......

6

1.1.2 Other pictograms

…………………………………………………………………………………………

7

1.2 Proper

use

……………………………………………………………………………………………………….

8

1.3 Possible dangers caused by the machine…………………………………………………………………..8

1.4 Qualification of personnel

………………………………………………………………………………….......

9

1.4.1 Target group……………………………………………………………………………………………..9

1.4.2 Authorised personnel………………………………………………………………………………….10

1.4.3 Obligations of the operator……………………………………………………………………….......10

1.4.4 Obligations of the user

…………………………………………………………………………...........

10

1.4.5 Additional qualification requirements………………………………………………………………..10

1.5 User positions

……………………………………………………………………………………………….......

10

1.6 Safety devices

………………………………………………………………………………………………......

10

1.6.1 EMERGENCY STOP button

……………………………………………………………………………

11

1.6.2 Protective cover………………………………………………………………………………………… 11

1.6.3 Lathe chuck key

………………………………………………………………………………………….

11

1.6.4 Prohibition, warning and mandatory labels

…………………………………………………………...

12

1.7 Safety check

…………………………………………………………………………………………………….

12

1.8 Individual protection gear

……………………………………………………………………………………....

12

1.9 Safety during operation

……………………………………………………………………………………......

13

1.10 Safety during maintenance

…………………………………………………………………………………….

13

1.10.1 Disconnecting the lathe and making it safe…………………………………………………………13

1.10.2 Using lifting equipment………………………………………………………………………………..14

1.10.3 Mechanical maintenance work

……………………………………………………………….............

14

1.11 Accident report

………………………………………………………………………………………………….

14

1.12 Electrical system

………………………………………………………………………………………………..

14

2. Technical data

Power connection

………………………………………………………………………………………………….

15

Machine data

……………………………………………………………………………………………………….

15

Dimensions

…………………………………………………………………………………………………………

15

Work area

…………………………………………………………………………………………………….........

15

Environmental conditions

…………………………………………………………………………………………

15

Operating material

…………………………………………………………………………………………………

15

2.1 Emissions

………………………………………………………………………………………………………

16

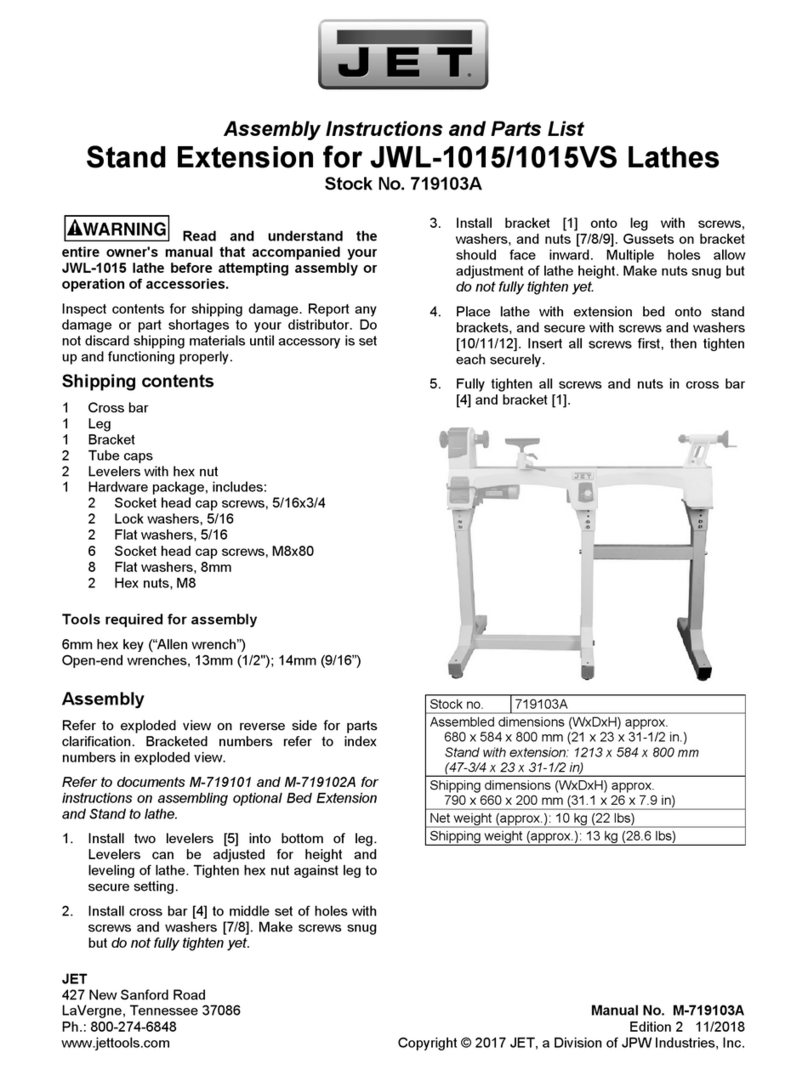

3Assembly

3.1 Extent of

supply………………………………………………………………………………………….........

16

3.2 Transport

……………………………………………………………………………………………………….

16

3.3 Storage

…………………………………………………………………………………………………….......

16

3.4 Installation and assembly

…………………………………………………………………………………….

17

3.4.1 Requirements of the installation site

…………………………………………………………….......

17

3.4.2 Load suspension point

……………………………………………………………………………...…

17

3.4.3 Installation

……………………………………………………………………………………………....

17

3.4.4 Installation drawing

…………………………………....................................................................

18

3.5 First

use……………………………………………………………………………………………………......

18

3.5.1 Cleaning and greasing

………………………………………………………………………………...

19

3.2.2 Visual inspection……………………………………………………………………………………...19