3

2.0 Table of Contents

Section Page

1.0 Warranty and Service.....................................................................................................................................2

2.0 Table of Contents...........................................................................................................................................3

3.0 Safety Warnings.............................................................................................................................................4

4.0 Specifications.................................................................................................................................................6

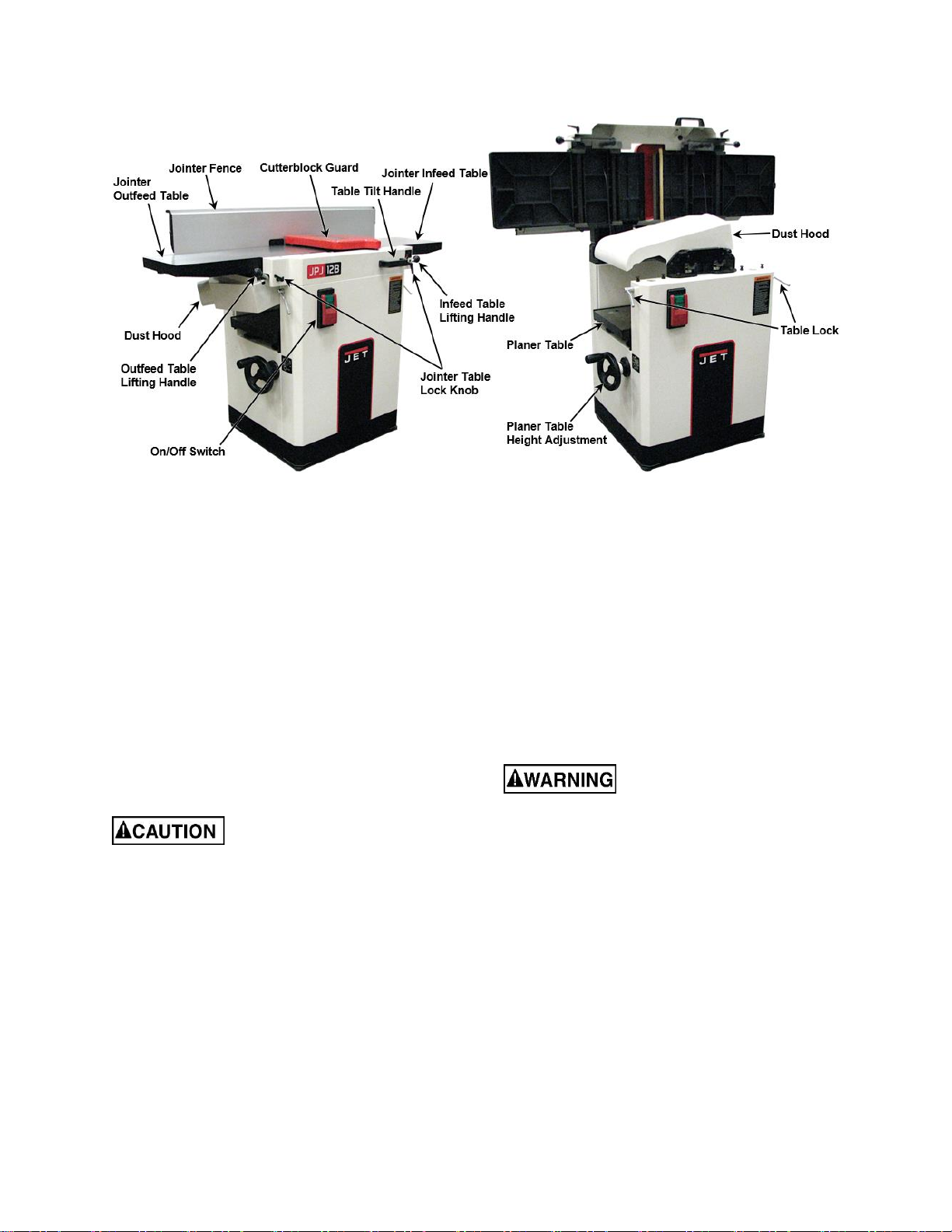

5.0 Features and Terminology .............................................................................................................................7

6.0 Receiving .......................................................................................................................................................7

7.0 Unpacking ......................................................................................................................................................7

9.1 Contents of Shipping Container .................................................................................................................7

8.0 Electrical Connection .....................................................................................................................................7

9.0 Operating Controls.........................................................................................................................................8

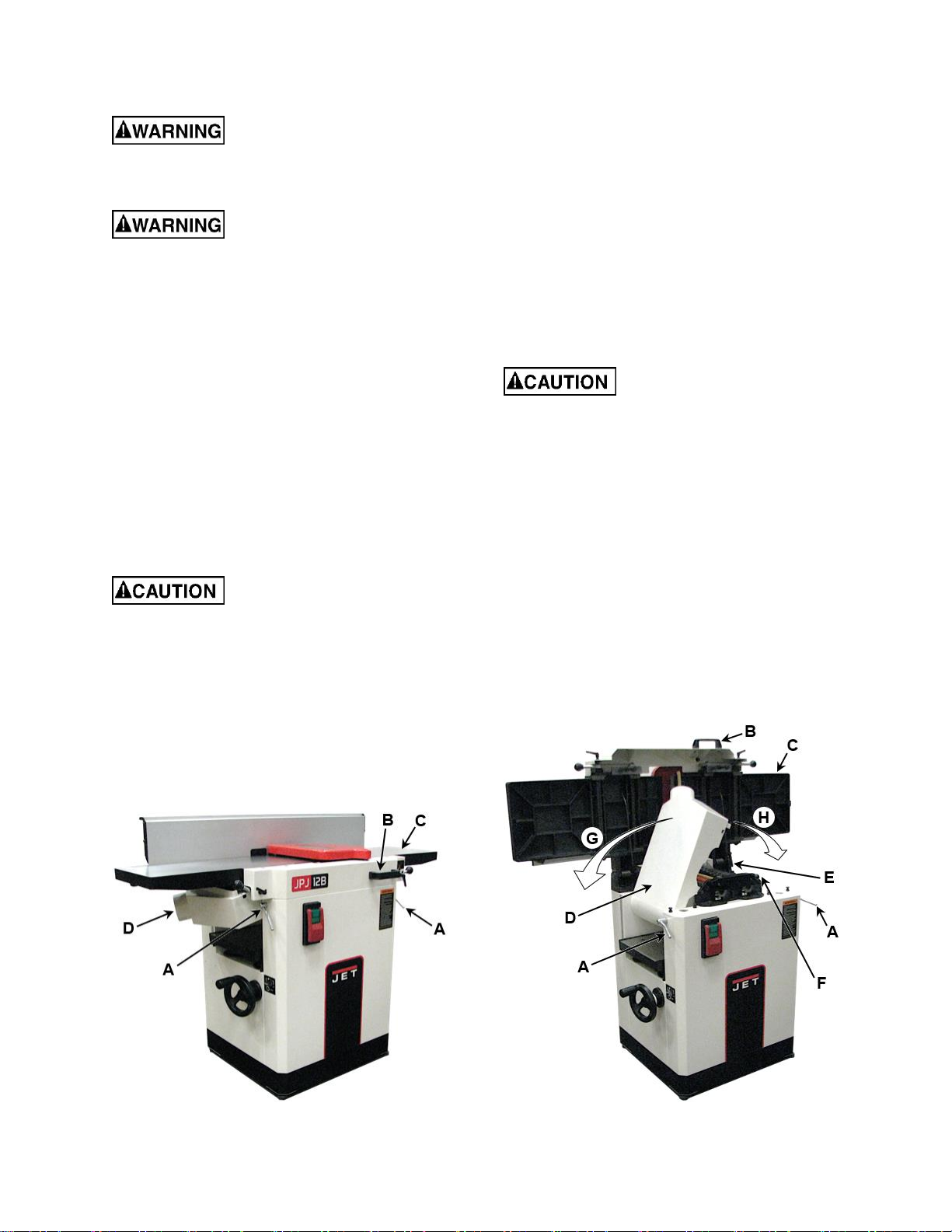

9.1 Jointer to Planer Setup...............................................................................................................................8

9.2 Planer to Jointer Setup...............................................................................................................................8

9.3 Control Switch............................................................................................................................................9

9.4 Planer Controls and Adjustments...............................................................................................................9

9.5 Jointer Controls and Adjustments ..............................................................................................................9

10.0 Adjustments ...............................................................................................................................................10

10.1 Fence Stop Adjustments ........................................................................................................................10

10.2 Table and Knife Adjustments .................................................................................................................11

10.3 Coplanar Alignment................................................................................................................................11

10.4 Setting Knives at Correct Height and Parallel to Outfeed Table ............................................................13

10.5 Replacing Cutterhead Knives (Straight Knives Only).............................................................................15

10.6 Replacing or Rotating Knife Inserts (Helical Cutterhead Only) ..............................................................16

10.7 Jointer Table Lock Handle Adjustment...................................................................................................16

10.8 Belt Replacement...................................................................................................................................17

10.9 Feed Roller Height Adjustment ..............................................................................................................18

10.10 Feed Roller Pressure Adjustment ........................................................................................................18

10.11 Planer Table Adjustment......................................................................................................................19

11.0 Basic Operations........................................................................................................................................20

11.1 Dust Collection .......................................................................................................................................20

11.2 Initial Startup ..........................................................................................................................................20

11.3 Changing Mode of Operation .................................................................................................................20

11.4 Jointer Operations..................................................................................................................................20

11.5 Planer Operations ..................................................................................................................................22

12.0 Maintenance...............................................................................................................................................23

12.1 Blade Care .............................................................................................................................................23

12.2 Sharpening the Knives (Straight Knives Only) .......................................................................................24

13.0 Lubrication..................................................................................................................................................24

14.0 Troubleshooting the JPJ-12B,JPJ-12BHH.................................................................................................25

14.1 Performance Troubleshooting –Jointer.................................................................................................25

14.2 Performance Troubleshooting –Planer..................................................................................................26

14.3 Mechanical Troubleshooting –Planer/Jointer........................................................................................27

15.0 Replacement Parts.....................................................................................................................................27

15.1 Infeed Table Assembly –Exploded View...............................................................................................28

15.2 Infeed Table Assembly –Parts List........................................................................................................29

15.3 Outfeed Table Assembly –Exploded View............................................................................................30

15.4 Outfeed Table Assembly –Parts List.....................................................................................................31

15.5 Cutterhead Assembly –Exploded View.................................................................................................32

15.6 Cutterhead Assembly –Parts List..........................................................................................................33

15.7 Planer Table Assembly –Exploded View...............................................................................................34

15.8 Planer Table Assembly –Parts List .......................................................................................................35

15.9 Blade Guard Assembly –Exploded View...............................................................................................36

15.10 Blade Guard Assembly –Parts List......................................................................................................37

15.11 Gearbox Assembly –Exploded View...................................................................................................38

15.12 Gearbox Assembly –Parts List............................................................................................................39

15.13 Cabinet Assembly –Exploded View.....................................................................................................40

15.14 Cabinet Assembly –Parts List .............................................................................................................41

15.15 Fence Assembly –Exploded View.......................................................................................................43

15.16 Fence Assembly –Parts List................................................................................................................44

16.0 Electrical Connections for JPJ-12B, JPJ-12BHH.......................................................................................45

17.0 Optional Accessories .................................................................................................................................46