Keep children and visitors a safe distance from the work

area.

Never reach into the machine while it is operating or running

down.

Never leave a running machine unattended. Before you

leave the workplace switch off the machine.

Do not operate the electric tool near inflammable liquids or

gases.

Observe the fire fighting and fire alert options, for example

the fire extinguisher operation and place.

Do not use the machine in a dump environment and do not

expose it to rain.

Wood dust is explosive and can also represent a risk to

health.

Dust form some tropical woods in particular, and from

hardwoods like beach and oak, is classified as a

carcinogenic substance.

Always use a suitable dust extraction device

Before machining, remove any nails and other foreign bodies

from the work piece.

Specifications regarding the maximum or minimum size of

the work piece must be observed.

Cut thin or thin-walled work-piece only with fine-toothed saw

blades.

Never cut several work-pieces at the same time –and also

no bundles containing several individual pieces. Risk of

personal injury if individual pieces are caught by the saw

blade uncontrolled.

When cutting round stock, use a suitable jig to prevent the

work-piece from turning.

Never cut work-pieces containing the following materials:

-Ropes, strings, cords, cables and wires.

Do not force the power tool. It will do a better and safer job

and give you much better service if it is used at the rate for

which it was designed.

Do not remove chips and work piece parts until the machine

is at a complete standstill.

Never operate with the guards not in place –serious risk of

injury!

Do not stand on the machine.

Connection and repair work on the electrical installation may

be carried out by a qualified electrician only.

Always unwind any extension cords fully.

Have a damaged or worn cord replaced immediately.

Do not use the machine when the ON-OFF switch does not

operate correctly.

The use of accessories other than those recommended in

this manual can create a safety hazard.

Make all machine adjustments or maintenance with the

machine unplugged from the power source.

When installing a new sawblade make sure that it matches

the raving knife.

The raving knife thickness must be in between sawblade

body thickness and width of cut.

Make sure that the sawblade is suitable for the work piece

material to be cut.

Use only sawblades according to EN 847-1

Never use sawblades made from High Speed Steel (HSS).

Remove defective sawblades immediately.

A worn table insert must be replaced.

3.3 Remaining hazards

When using the machine according to regulations some

remaining hazards may still exist

The moving sawblade in the work area can cause injury.

Broken saw blades can cause injuries.

Thrown workpieces can lead to injury.

Tipping of the workpiece due to insufficient support can lead

to injury.

Wood chips and sawdust can be health hazards. Be sure to

wear personal protection gear such as safety goggles ear-

and dust protection.

Use a suitable dust exhaust system.

The use of incorrect mains supply or a damaged power cord

can lead to injuries caused by electricity.

The type and condition of the sawblade is important in

keeping the noise level as low as possible.

This does not negate the fact that extra safety equipment

such as ear protection must be used.

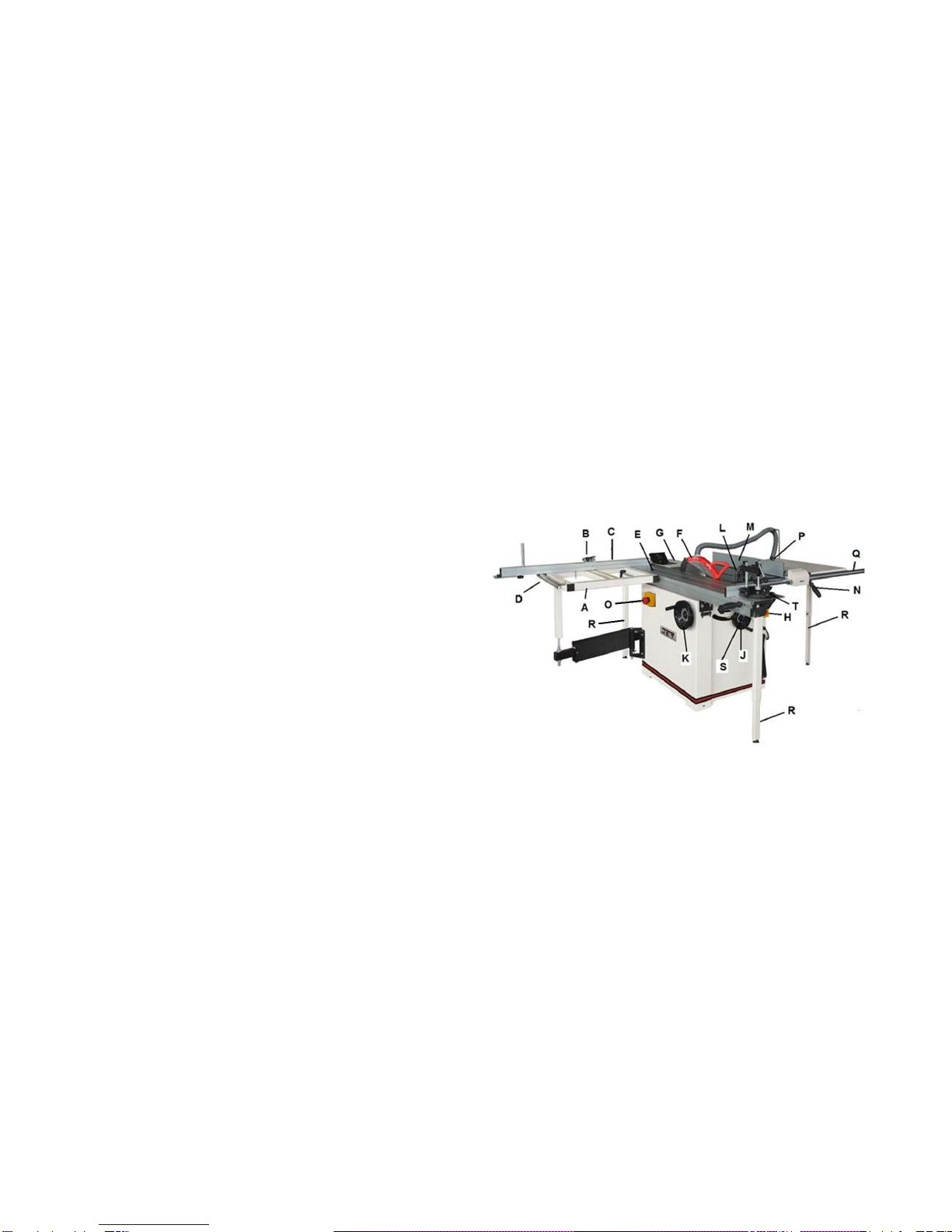

4. Machine specifications

4.1 Technical data

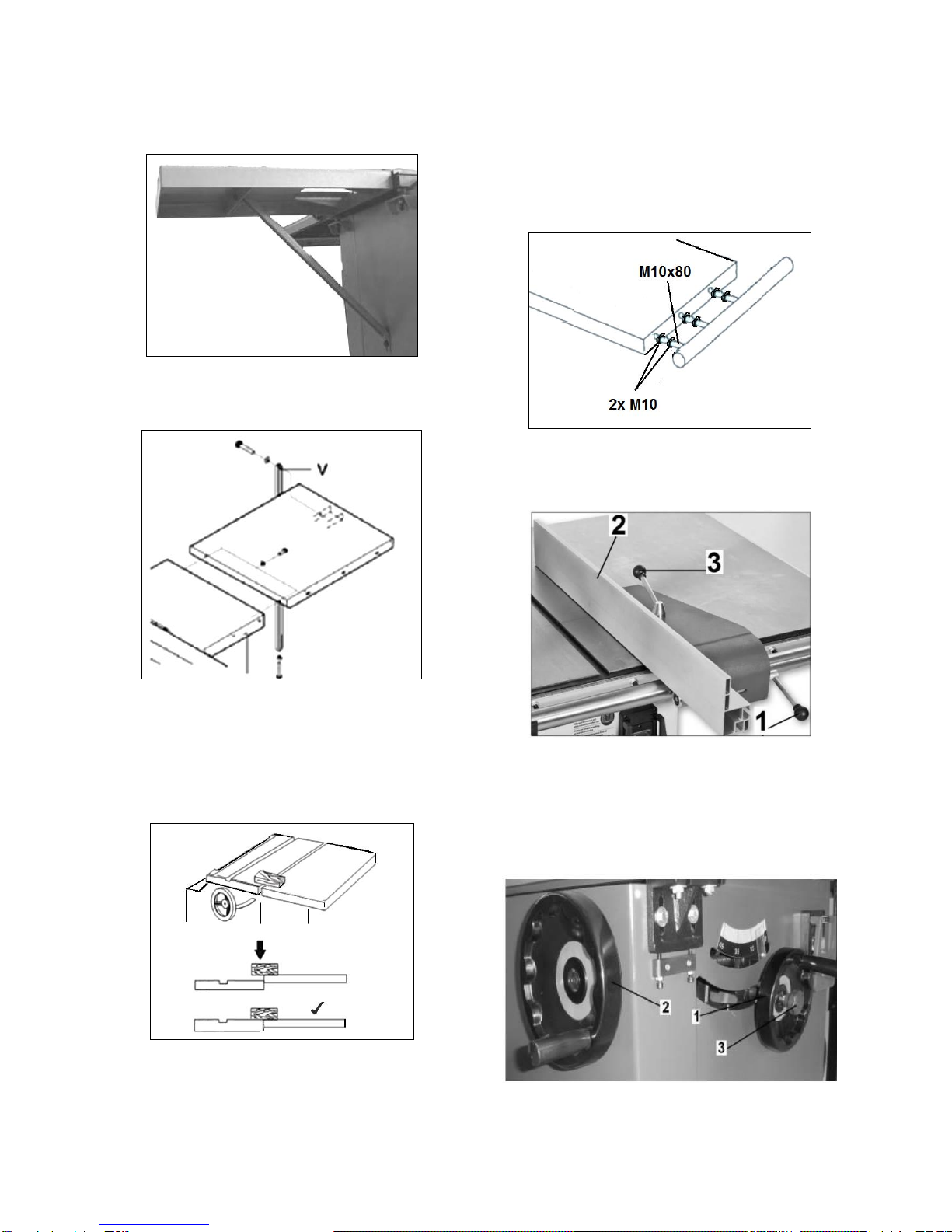

Machine Table 800x385 mm

Rear extension table 310x500mm

Right extension table 800x400mm

Sliding table size 1600x270mm

Max. travel of sliding table 1600mm

Max. length of cut 1350mm

Crosscut table 680 x 580mm

Cross Cut Fence 1200 (2200)mm

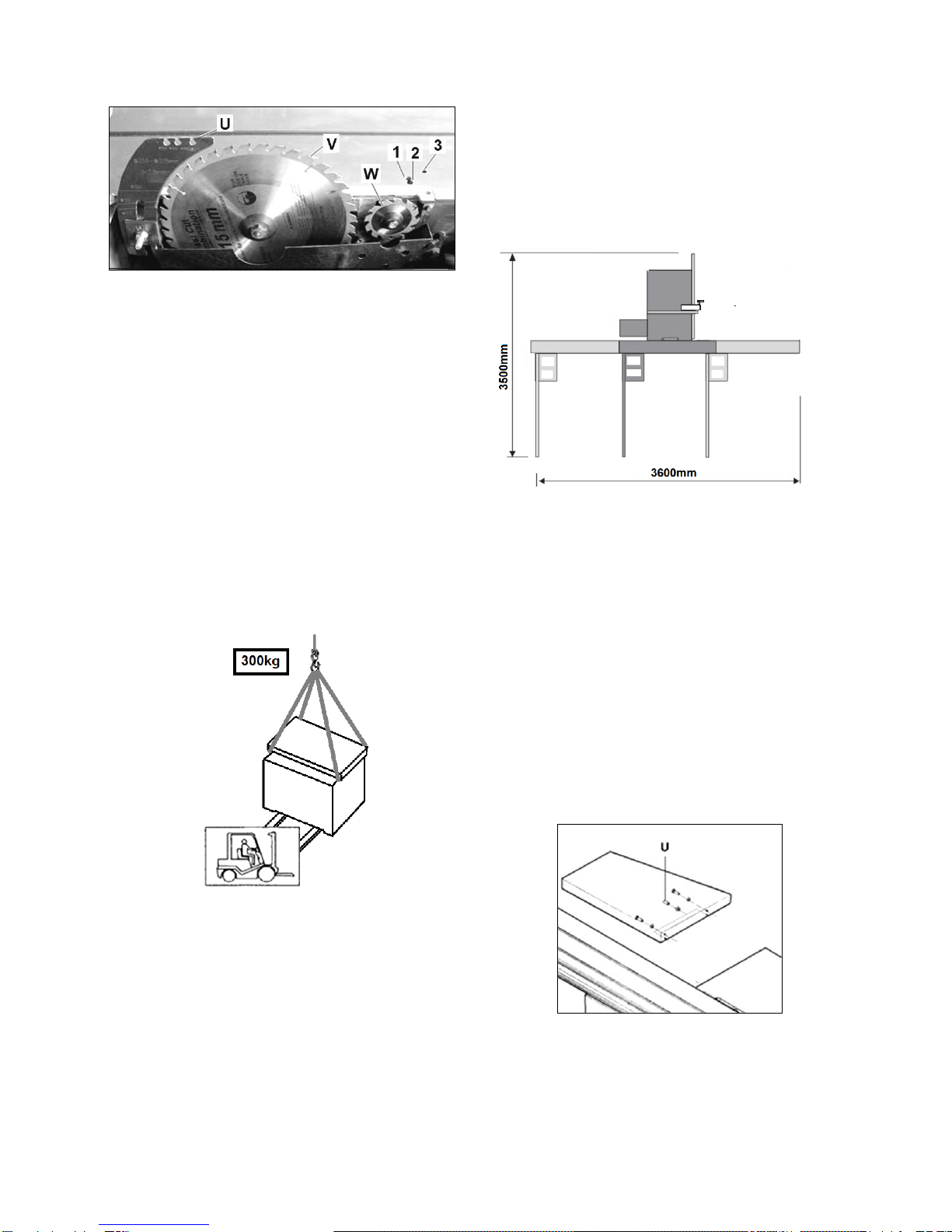

Sawblade diameter Ø 250 - 315 mm

Blade bore diameter Ø 30 mm

Blade speed no 4700 rpm

Scoring blade diameter Ø90mm

Scoring blade bore diameter Ø 20mm

Scoring blade speed no 8700 rpm

Cutting height at 90°/45° 100 / 80 mm

Tilting range of blade 90°- 45°

Max Distance-blade to rip fence 1220mm

Dust port diameter 100mm

Weight 250 kg

Mains 400V ~3/PE 50Hz

Motor output power P2=3.0 kW S1

Reference current 6.6 A

Extension cord (H07RN-F) 4x1,5mm²

Installation fuse protection 16A