Introduction........................................................................................................................................1

Verification of packaging items ........................................................................................................1

Security Information..........................................................................................................................2

Precautions for Operation..................................................................................................................2

Chapter 1 Overview............................................................................................................................4

1.1 Introduction..................................................................................................................................4

1.2 Performance characteristics.........................................................................................................4

1.3 Name and operation summary of each part..................................................................................5

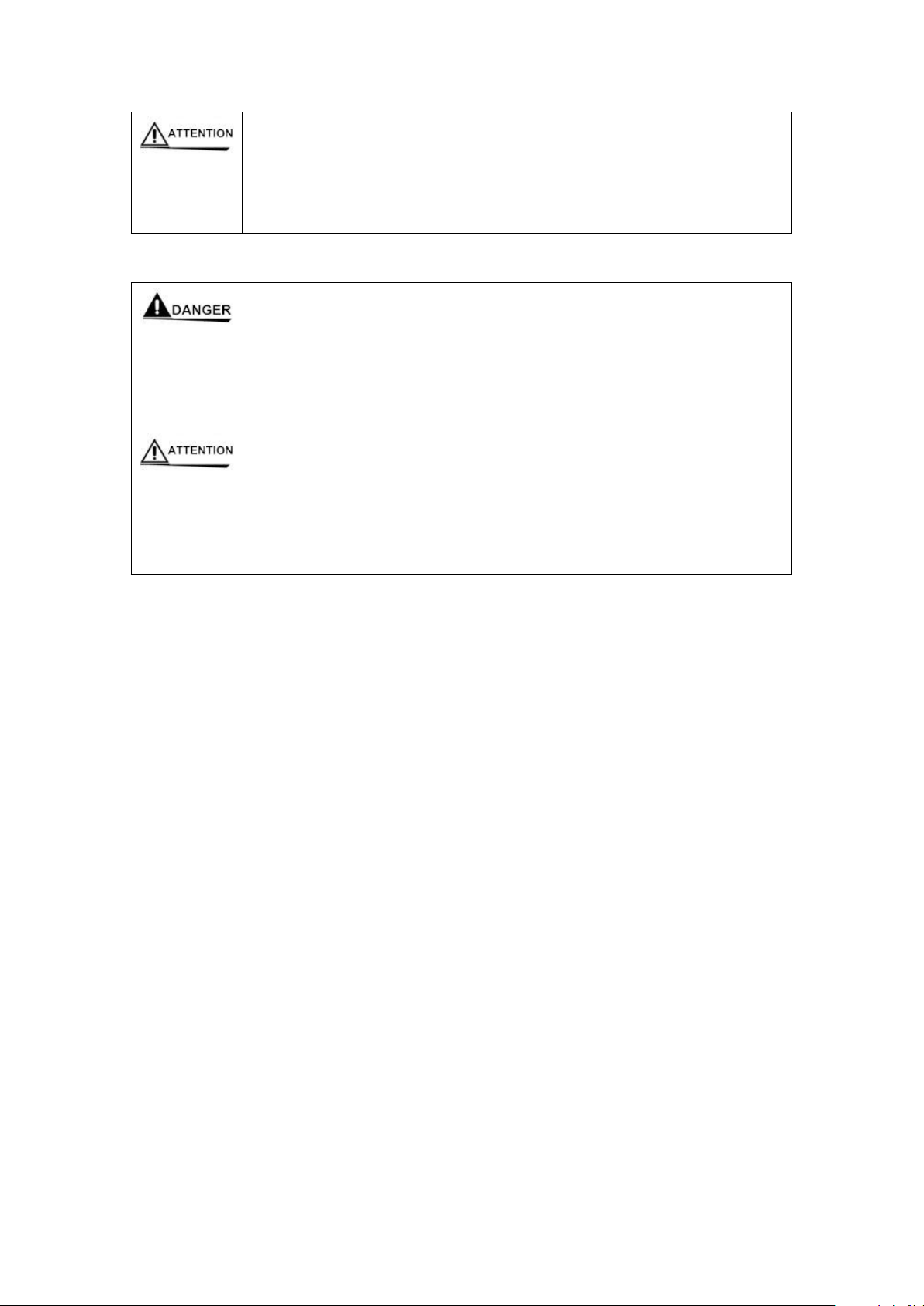

1.4 Dimensions...................................................................................................................................7

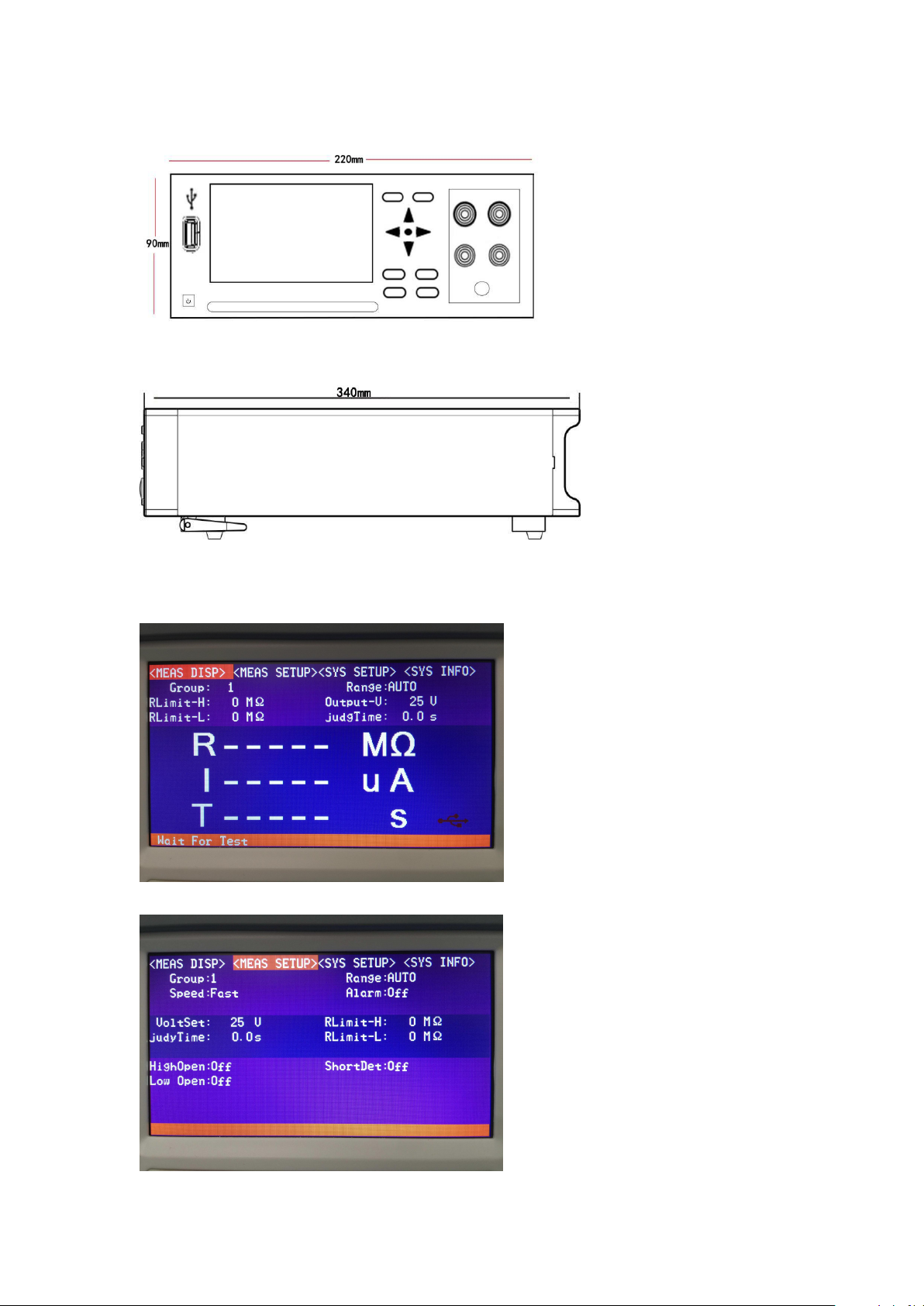

1.5 Page Composition........................................................................................................................7

Chapter 2 Preparations Before Testing..............................................................................................8

2.1 Preview of test process.................................................................................................................8

2.2 Basic parameter setting process...................................................................................................9

2.3 Inspection before measurement..................................................................................................10

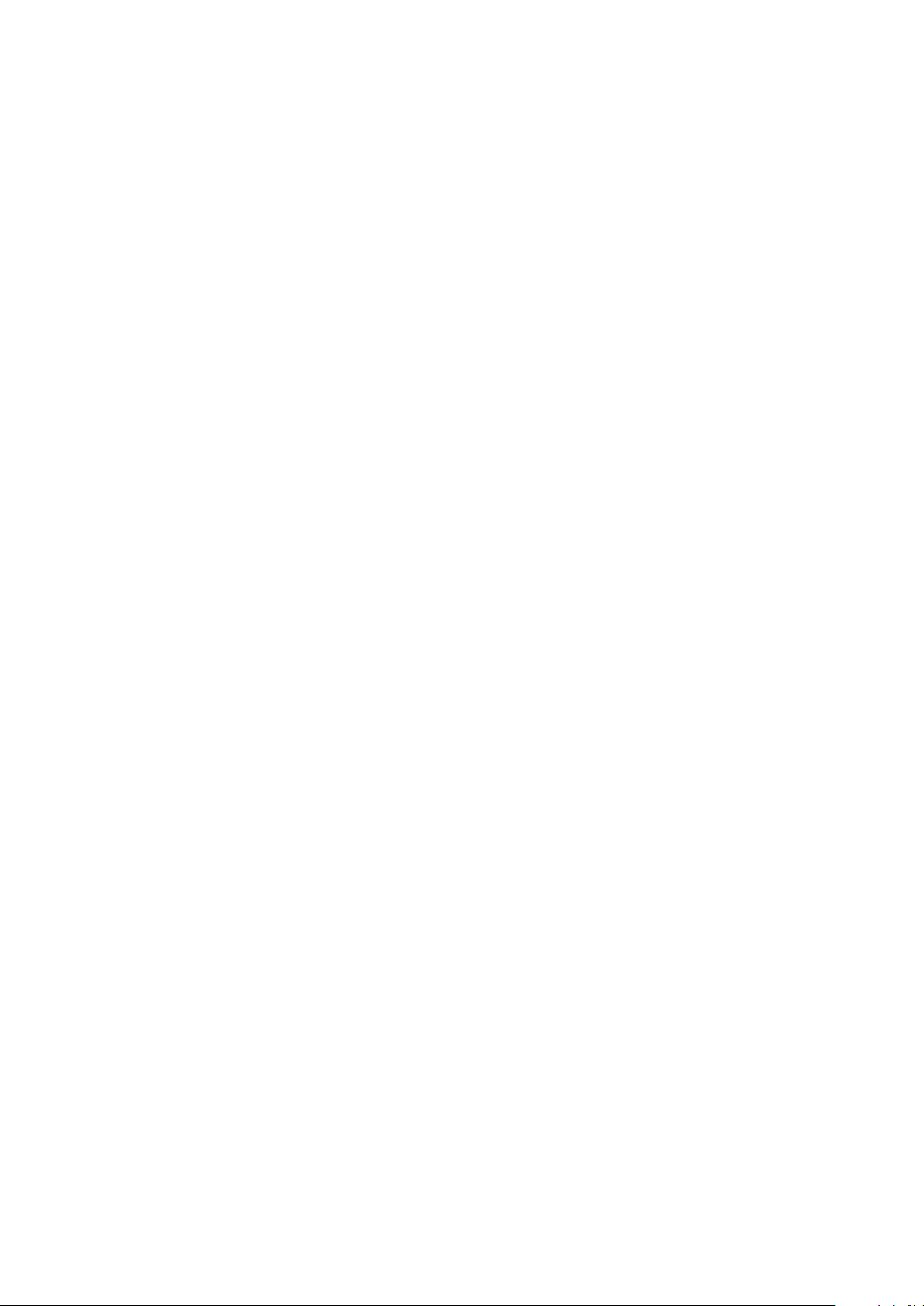

2.4 Connection of test leads.............................................................................................................10

Chapter.3 Basic Settings...................................................................................................................11

3.1 Setting the test voltage...............................................................................................................11

3.2 Setting the test range..................................................................................................................11

3.3 Setting the test speed..................................................................................................................12

3.4 Comparator function..................................................................................................................13

3.4.1 Sorting mode...........................................................................................................................14

3.4.2 Setting the upper and lower limits and sorting mode..............................................................14

3.5 Sounding mode of sorting results...............................................................................................14

3.6 Short-circuit detection function..................................................................................................15

3.7 Group settings............................................................................................................................16

3.8 Setting the voltage setting..........................................................................................................16

3.9 Test time setting.........................................................................................................................17

3.10 High-end open circuit setting...................................................................................................18

3.11 Low-end open circuit setting...................................................................................................18

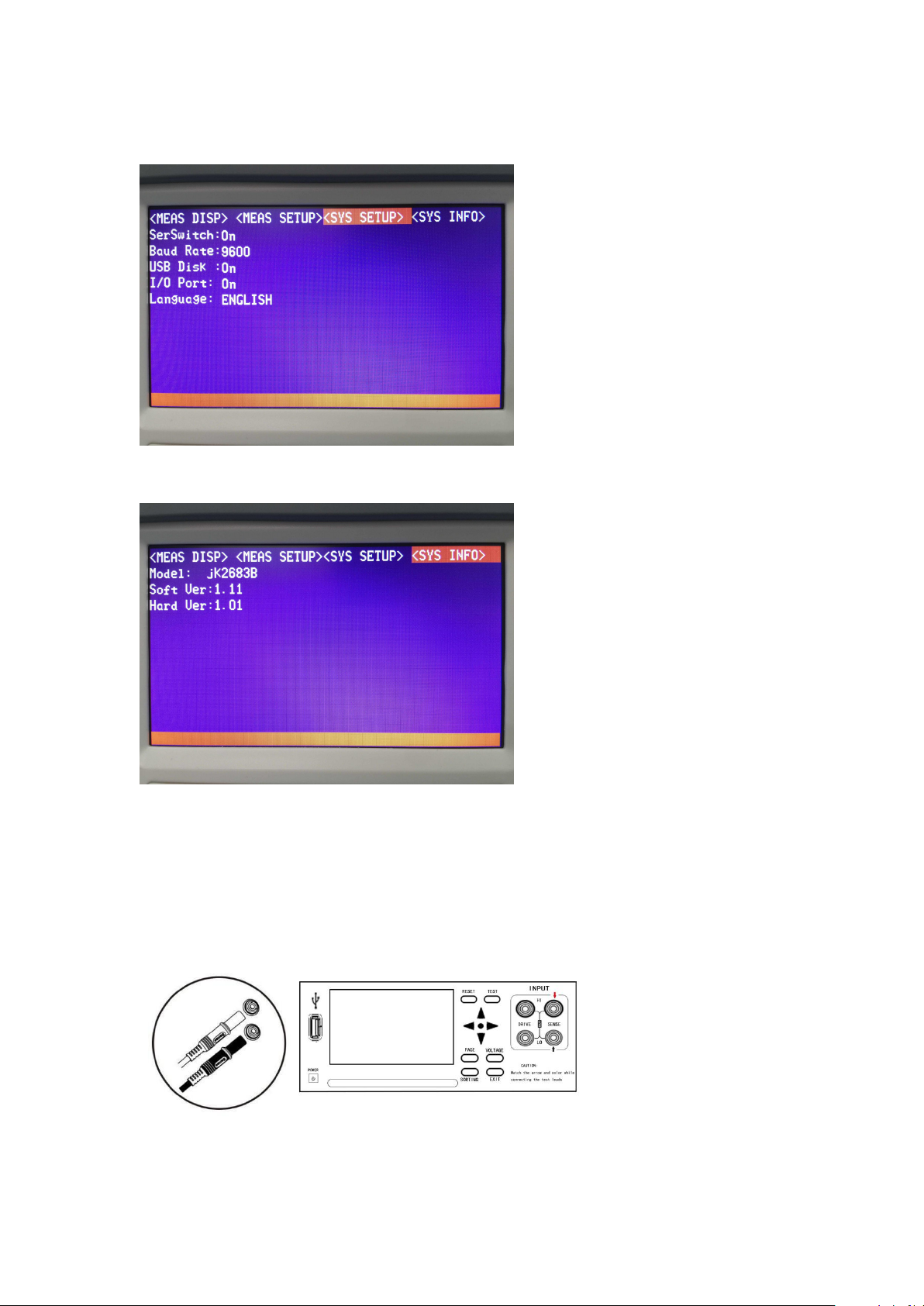

3.12 Serial switch setting.................................................................................................................19

3.13 baud rate setting.......................................................................................................................19

3.14 U disk switch setting................................................................................................................20

3.15 I / O port settings......................................................................................................................20

3.16 Display language setting..........................................................................................................21

Chapter 4 Measurement...................................................................................................................22

4.1 Start test......................................................................................................................................22

4.2 Measured value display..............................................................................................................22

4.3 Test Termination.........................................................................................................................22

Chapter 5 PLC Interface...................................................................................................................23

Chapter 6 Parameters.......................................................................................................................24

6.1 General parameters.....................................................................................................................24

6.2 Accuracy.....................................................................................................................................25