FOR ANY SPECIAL, INDIRECT, INCIDENTAL OR CONSEQUENTIAL

DAMAGES OR LOSSES, INCLUDING LOSS OF DATA, WHETHER ARISING

FROM BREACH OF WARRANTY OR BASED ON CONTRACT, TORT,

RELIANCE OR ANY OTHER THEORY.

Changzhou Jinailian Electronic Technology Co., Ltd.

August 2019

Rev.A1

Contents

Statement ...............................................................................................................................................1

Security Information .............................................................................................................................1

Limited warranty and limitation of liability ..........................................................................................2

Contents..................................................................................................................................................3

1. Installation and Setup Wizard .......................................................................................................6

1.1 Packing List ............................................................................................................................6

1.2 Power Requirements ..............................................................................................................6

1.3 Operating Environment ..........................................................................................................6

1.4 Cleaning .................................................................................................................................6

1.5 Replacing the battery .............................................................................................................6

1.6 Adjusting Support ..................................................................................................................7

2. Overview.......................................................................................................................................8

2.1 Introduction ............................................................................................................................8

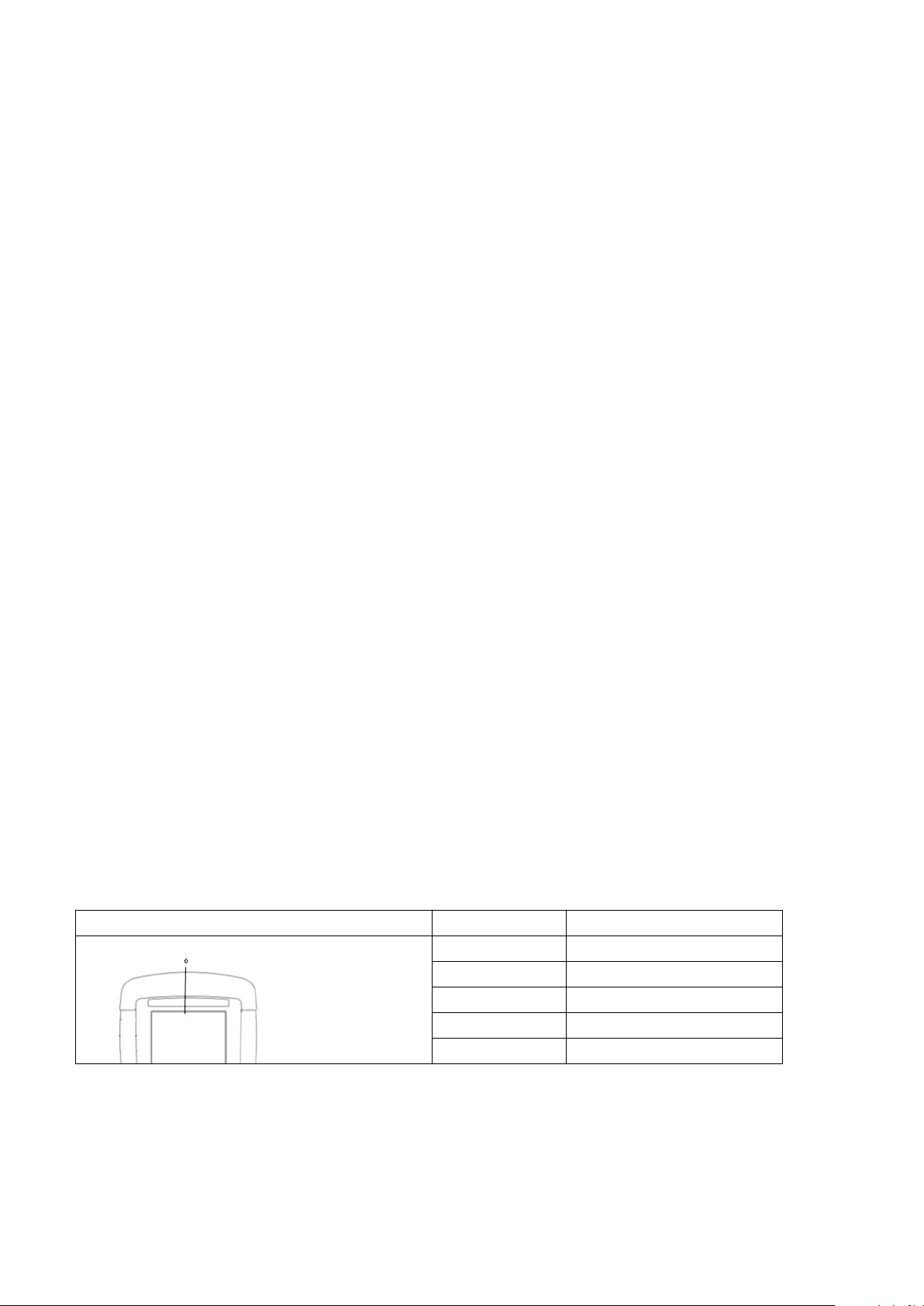

2.2 Main Specifications ................................................................................................................8

2.3 Main functions ........................................................................................................................8

2.3.1 Calibration function..................................................................................................8

2.3.2 Comparator Function (Sorting Function) ................................................................8

2.3.3 System Settings .......................................................................................................9

2.3.4 Remote Control .......................................................................................................9

3. Start...............................................................................................................................................9

3.1 Front Panel ..................................................................................................................................9

3.2 Interface Panel ...........................................................................................................................10

3.3 Using an external power supply.................................................................................................10

3.3.1 Battery charging function............................................................................................10

3.4 Startup .......................................................................................................................................10

3.5 Connection of test terminal .......................................................................................................10

3.5.1 Test fixture and cable ..................................................................................................11

4. [Meas] Measurement display.......................................................................................................11

4.1 <Measurement Display> page....................................................................................................11

4.1.1 Measurement [Trigger] ...............................................................................................12

4.1.2 Measurement [Range] ................................................................................................12