MIN

(in)

MAX

(in)

MIN

(mm)

MAX

(mm)

SHORT MEDIUM LONG WHEEL

0.84 0.94 21 24 0 0 0 0 0.84 0.88

0.94 1.03 24 26 1 0 0 0 1.00

1.02 1.11 26 28 0 0 0 1 1.05

1.11 1.20 28 30 1 0 0 1 1.13

1.20 1.28 30 33 0 0 0 2

1.28 1.37 33 35 1 0 0 2 1.32 1.32

1.37 1.45 35 37 0 0 0 3 1.38

1.45 1.53 37 39 1 0 0 3 1.50

1.53 1.62 39 41 0 0 0 4

1.61 1.70 41 43 1 0 0 4 1.66

1.70 1.78 43 45 0 0 0 5 1.75

1.78 1.86 45 47 1 0 0 5

1.86 1.95 47 49 0 0 0 6 1.90

1.94 2.03 49 51 1 0 0 6 2.00

PIPE OD

(in)

TUBE OD

(in)

LINK TYPEOUTER ∅ RANGE

MIN

(in)

MAX

(in)

MIN

(mm)

MAX

(mm)

SHORT MEDIUM LONG WHEEL

PIPE OD

(in)

TUBE OD

(in)

LINK TYPEOUTER ∅ RANGE

2.01 2.15 51 55 0 1 0 5

2.14 2.28 54 58 1 2 0 4 2.25

2.27 2.41 58 61 0 3 0 4 2.38

2.38 2.52 61 64 0 2 0 6 2.50

2.51 2.64 64 67 1 3 0 5 2.50

2.64 2.77 67 70 0 4 0 5

2.76 2.89 70 73 0 1 2 4 2.88

2.88 3.01 73 76 0 3 1 5 2.88

2.99 3.12 76 79 0 0 3 4 3.00

3.11 3.24 79 82 0 2 2 5

3.23 3.37 82 86 0 4 1 6 3.25

3.34 3.47 85 88 0 1 3 5

3.47 3.60 88 91 0 3 2 6 3.50 3.50

3.57 3.70 91 94 0 0 4 5

3.69 3.83 94 97 0 2 3 6 3.75

3.80 3.93 96 100 1 0 4 6

3.92 4.05 100 103 0 1 4 6

4.00 4.13 101 105 1 1 4 6 4.00 4.00

4.12 4.25 105 108 0 2 4 6

4.19 4.32 106 110 1 2 4 6

4.31 4.45 110 113 0 3 4 6

4.42 4.55 112 115 1 1 5 6 4.50 4.50

4.54 4.67 115 119 0 2 5 6

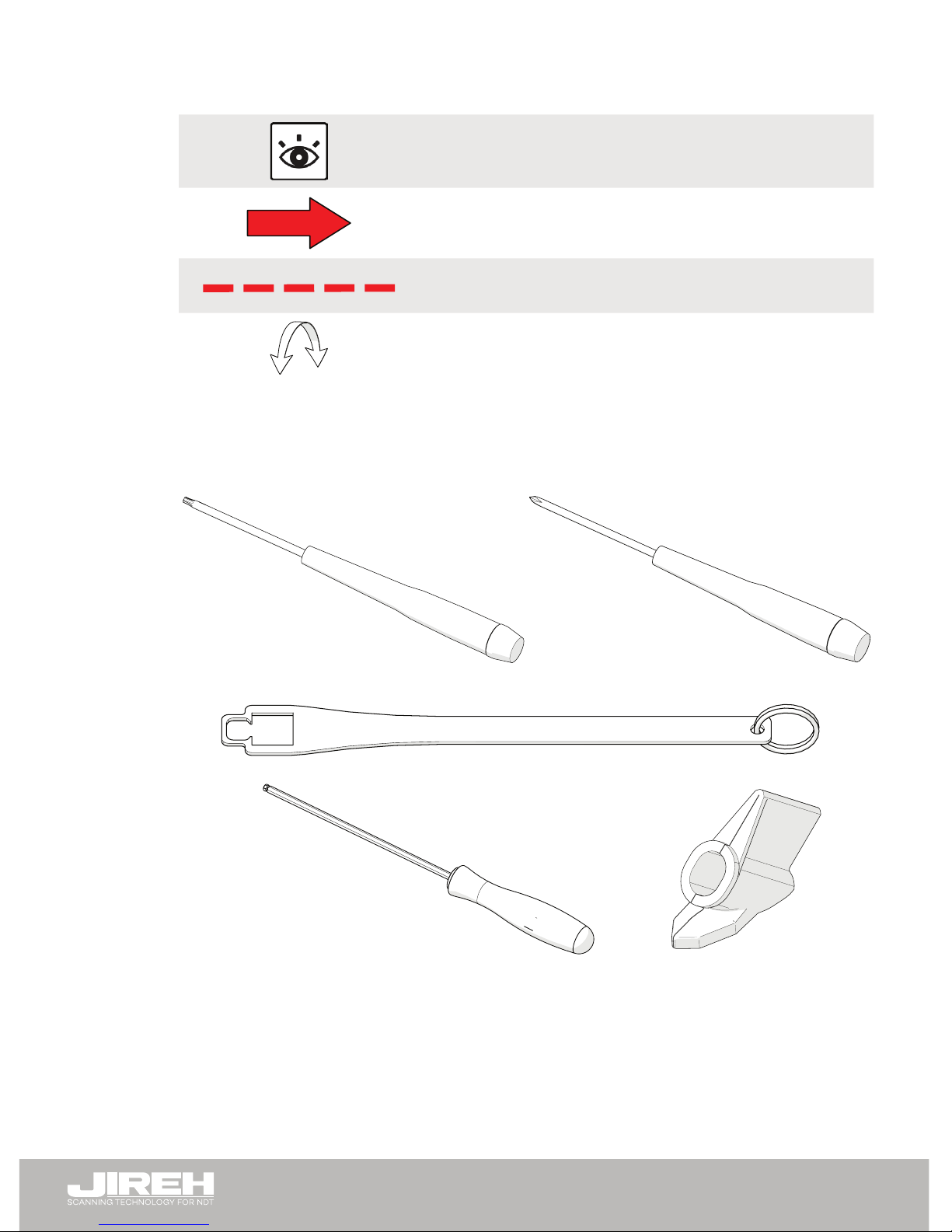

LONG LATCH REQUIRED

SHORT LATCH REQUIRED