PAGE 1 of 25 BG0088 Rev 03.4

CHAPTER 1

INTRODUCTION

1.1. Product information

1.1.1. Intended use

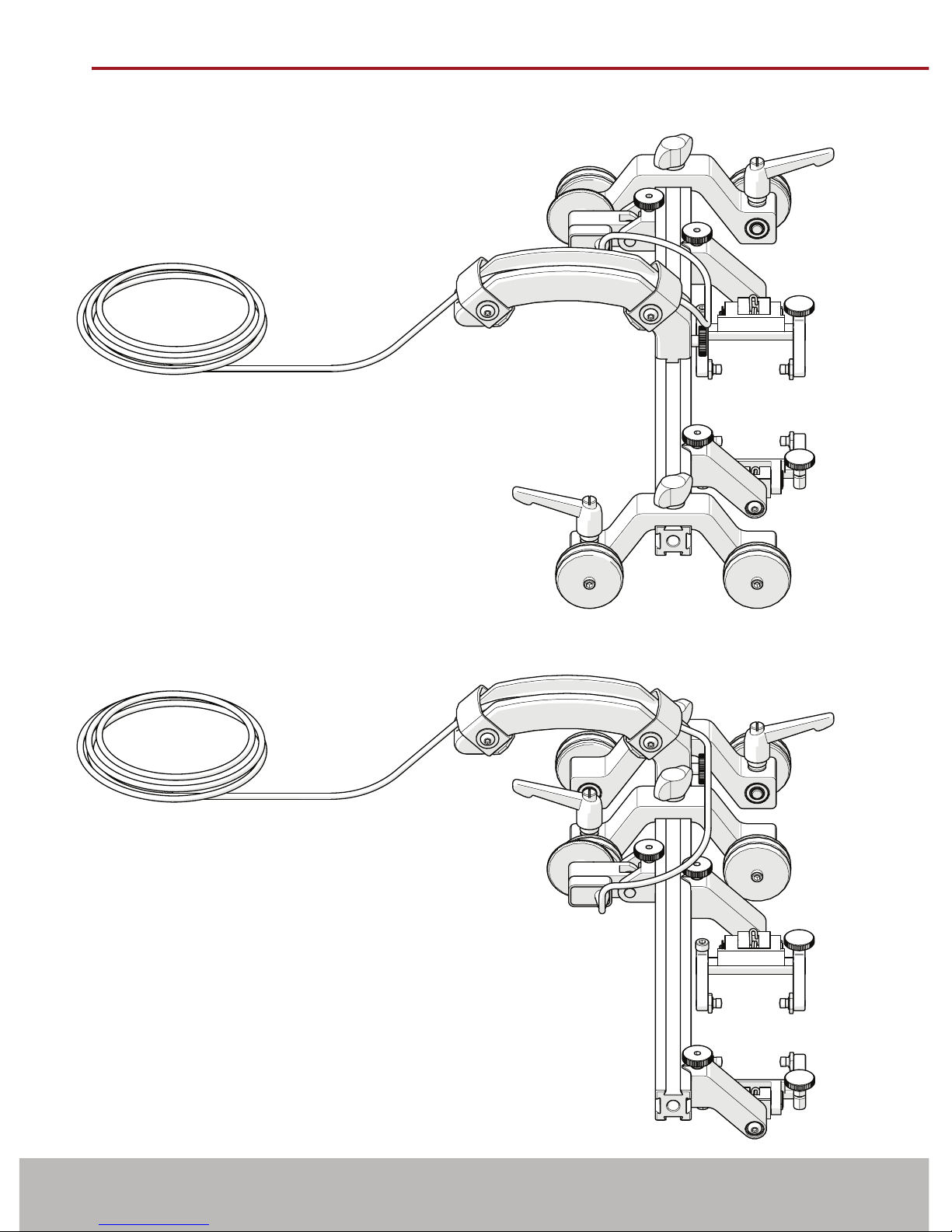

The STIX is a manual magnetic scanner with trailing encoder and magnetic

wheels. It is designed to translate two TOFD probes around ferrous piping and

vessels.

1.1.2. Performance specications

Minimum Maximum

Pipe/Tube Range Outer Diameter 10.2 cm (4 in) Flat

Pipe/Tube Range Inner Diameter Flat 152.4 cm (60 in)

Umbilical Length (Standard Kit) 5 m (16.4 in)

X Axis Encoder Resolution 9.05 counts/mm (230.0 counts/inch)

1.1.3. Operating environment

The STIX is designed for use in industrial environments that are between

-20°C (-4°F) and 50°C (122°F).

1.1.4. Environmental Sealing

Dust tight, water tight (not submersible).

1.2. Denition of symbols

Instructions to ‘look here’ or to ‘see this part’

Denotes movement. Instructing user to carry out

action in a specied direction.

Indicates alignment axis, can also indicate

insertion or movement of parts.

Alerts user that view has changed to a reverse

angle.