Anhui JNGE Power Co,. Ltd

Address:No.99 Yonghe Road, High-Tech Zone, Hefei City Anhui Province, China Mainland

Tel:0551-65372576 http://www.hfjnge.com

- 1 -

Content

One Safe Instructions..................................................................................................................................- 2 -

1.1 Safe Marks....................................................................................................................................- 2 -

1.2 Safe Notice................................................................................................................................... - 2 -

Two Product Introduction............................................................................................................................- 4 -

2.1 Performance Summary............................................................................................................... - 4 -

2.2 Product Introduction.................................................................................................................... - 5 -

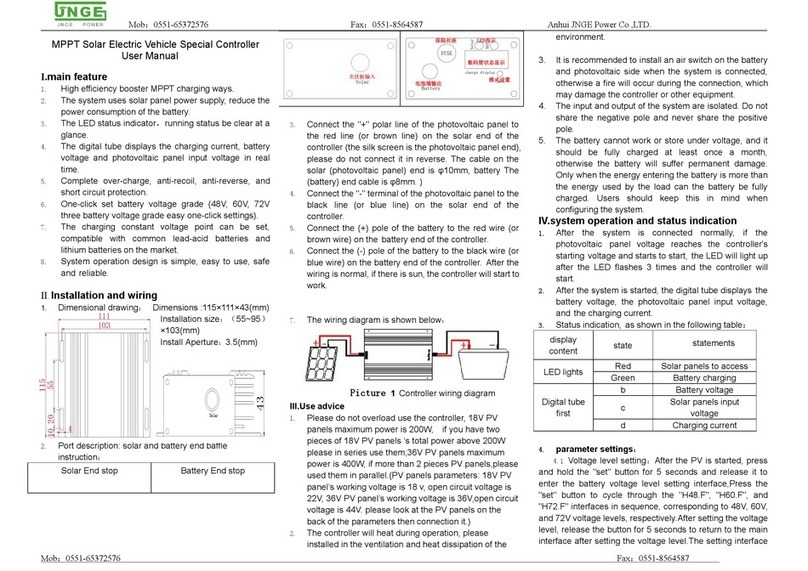

2.2.1 Appearance..........................................................................................................................- 5 -

2.2.2 Product Size.........................................................................................................................- 6 -

Three Installation Instruction......................................................................................................................- 6 -

3.1 Notes..............................................................................................................................................- 6 -

3.2 Installation..................................................................................................................................... - 7 -

3.3 Connect wires...............................................................................................................................- 8 -

3.4 Photovoltaic array requirements................................................................................................- 9 -

3.5 Cable type selection requirements..........................................................................................- 10 -

Four Operation Instruction....................................................................................................................... - 10 -

4.1 Indicator light.............................................................................................................................. - 10 -

4.2 Button...........................................................................................................................................- 11 -

4.3 LCD display screen................................................................................................................... - 11 -

4.4 Set Operation............................................................................................................................. - 13 -

Five Trouble Remove and System Maintenance...................................................................................- 13 -

5.1 Protection Function...................................................................................................................- 13 -

5.2 Trouble Remove.........................................................................................................................- 14 -

5.3 System Maintenance.................................................................................................................- 16 -

Six Warranty............................................................................................................................................... - 16 -

Seven Technical Specifications...............................................................................................................- 17 -

Eight Installation Size................................................................................................................................- 18 -