2

23

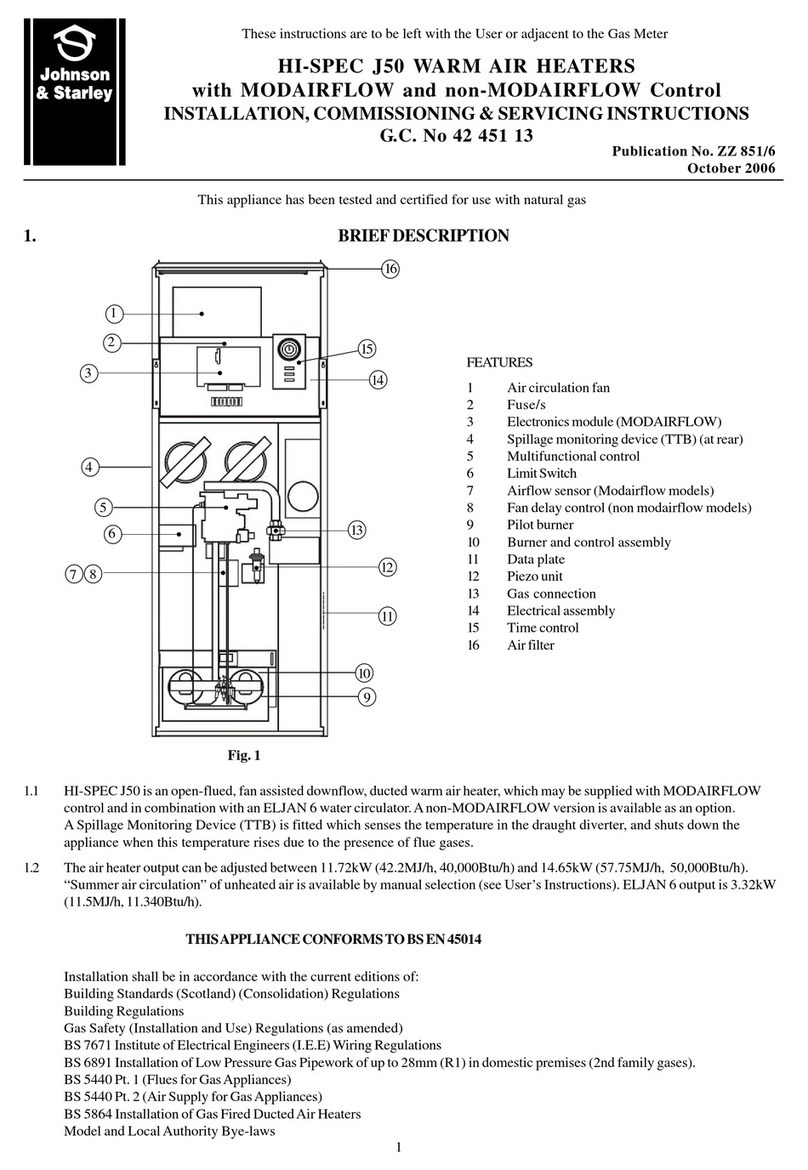

Installation shall be in accordance with the current editions of:-

Building Standards (Scotland) (Consolidation) Regulations

Building Regulations

Gas Safety (Installation and Use) Regulations (as amended)

BS 7671 Institute of Electrical Engineers (I.E.E.) Wiring Regulations

BS 6891 Installation of Low Pressure Gas Pipework of up to 28mm (R1) in domestic premises (2nd family gases).

BS 5440 Pt. 1 (Flues for GasAppliances)

BS 5440 Pt. 2 (Air Supply for GasAppliances)

BS 5864 Installation of Gas Fired DuctedAir Heaters

British System Design Manual “Gas Fired Warm Air Heating”

Model and Local Authority Bye-laws

IMPORTANT:IT ISASTATUTORYREQUIREMENTTHATALLGASAPPLIANCESAREINSTALLEDBYCOMPETENT

PERSONS,(i.e.CORGIREGISTEREDINSTALLERS)INACCORDANCEWITHTHEGASSAFETY(INSTALLATIONANDUSE)

REGULATIONS(CURRENTEDITION).FAILURETOCOMPLYWITHTHESEREGULATIONSMAYLEADTOPROSECUTION.

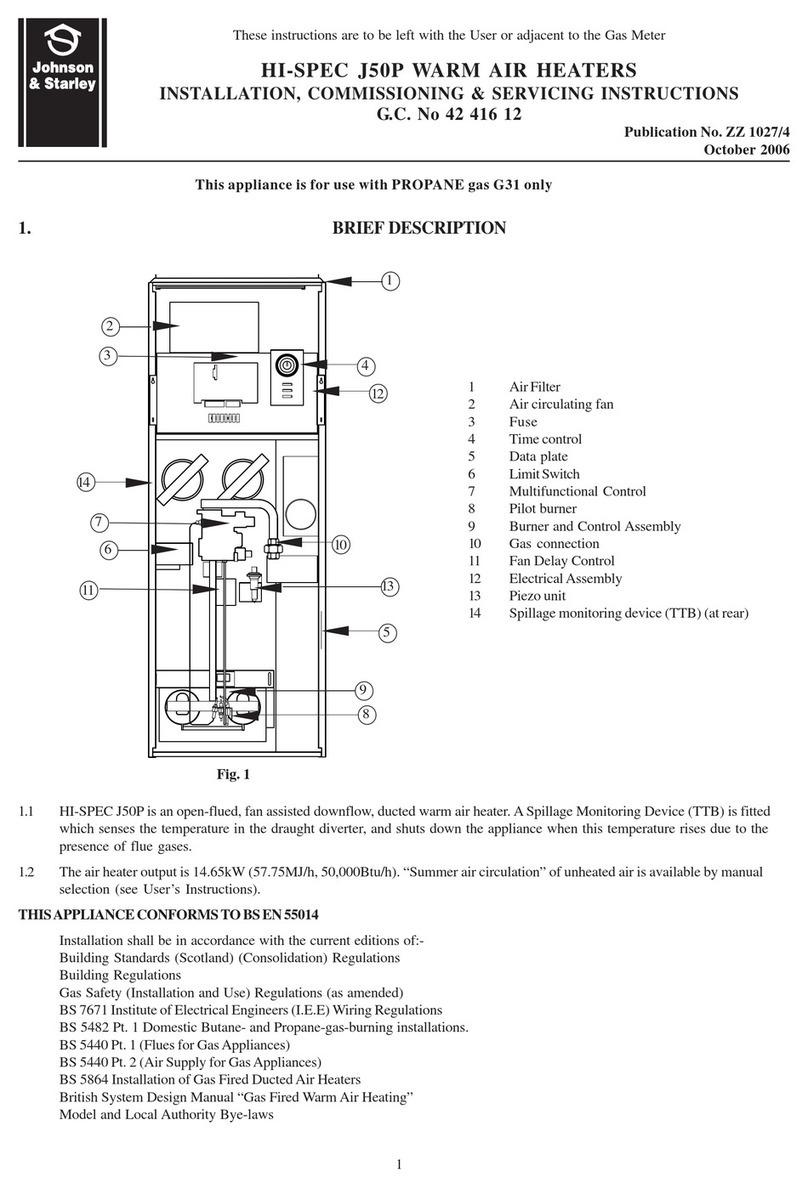

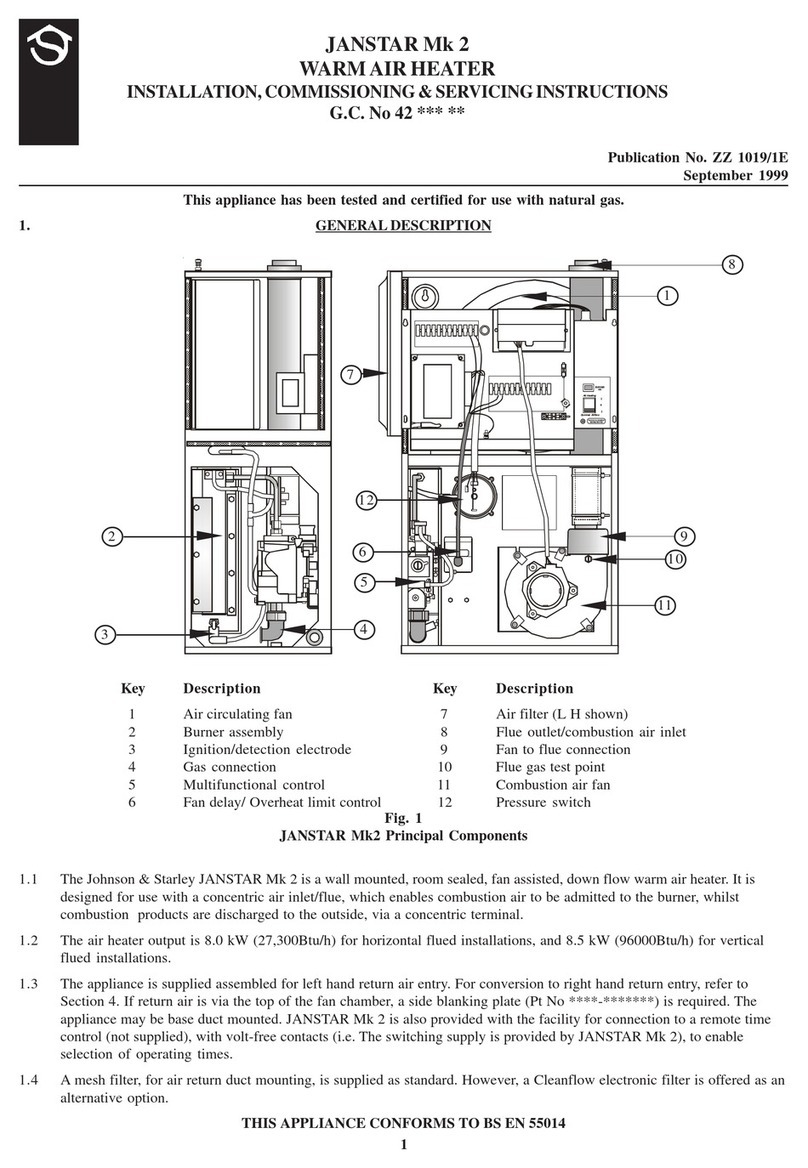

1.3 TECHNICALDATA

2. HEATERCOMPARTMENTANDCLEARANCES(SEEBS5864)

2.1 IMPORTANT: If the heater is to be fitted to an existing base duct (warm air plenum), always ensure that installation is

carried out such that the rear left hand corner of the heater is aligned with the rear left hand corner of the base duct, so that

any overhang or blanking off will be at the front and/or right hand side. In any event, blanking plates must be mechanically

secured and all joints sealed.

2.2 When the heater is fitted into a compartment, a minimum clearance from the compartment walls of 38mm (11/2in) at the rear,

75mm (3in) total at the sides (with a minimum of 25mm (1in) at any one side), and 63mm (21/2in) at the front must be left.

Consideration should also be given to the space required for the removal and replacement of the filter tray and the entry of

the gas and electrical supplies.

2.3 For service access, a minimum of 450mm (18ins) is required at the front of the heater. Space must also be allowed, in a

compartment installation, to permit the removal of the heater. The clearance between the appliance and the compartment

should be not less than 75mm (3 in). However, if clearances are less than 75mm, the internal surface of the compartment

must be lined with non-combustible material and the compartment must be of a fixed rigid structure.

Weight 90Kg

Gas G20

Gas Supply Pressure 20mbar

Gas Category I2H

Countries of Installation GB & IE

Electrical Supply 230 ~ 50Hz fused 5A 570W

Nox Class 1

LOW RATE HIGH RATE

KW MJ/h Btu/h KW MJ/h Btu/h

INPUT (Gross) 27.1 97.6 92,500 33.0 118.70 112,500

OUTPUT 20.5 73.8 70,000 26.4 94.9 90,000

Gas rate cv

1037Btu/ft32.60m3/h (91.8ft3/h) 3.10m3/h (109.4ft3/h)

Burner setting

pressure (hot) 11.8mbar (4.7 in wg) 17.2mbar (6.9 in wg)

Main Injector Bray Cat 23/700

Cross-light injector Bray Cat 10/110

SERVICE INTERVAL RECORD

It is recommended that your heating system is serviced regularly and that your service engineer completes the

appropriate service interval record below.

SERVICE PROVIDER

Before completing the appropriate service interval record below, please ensure that you have carried out the service

as described in the heater manufacturer’s instructions and in compliance with the Gas Safety Regulations

SERVICE1 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE2 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE3 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE4 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE5 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE6 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE7 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE8 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE9 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SERVICE10 Date . . . . . . . . . . . . . . . . . . .

Engineer’sName . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Company Name . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tel No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CORGI ID Serial No . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Signature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

When all of the above services have been completed, please contact your service engineer for an additional

service record sheet.