www.johnsonandstarley.co.uk

6

8. FLUE INSTRUCTIONS

NOTE: THIS APPLIANCE MUST ONLY BE INSTALLED WITH THE SUPPLIED ACCESSORIES AND TERMINAL.

8.1 FLUES

NOTE: The ECONOMAIRE 32/INTEJAN can be used with horizontal or vertical flue types C12 and C32. You

should also consult (or be familiar with) British Standards BS 5440 Pt. 1 Flues

8.1.1 All joints must be soundly sealed.

8.1.2 Sufficient support brackets must be used in order to support the total weight of the flue system.

8.1.3 The flue must conform with Building Regulations and British Gas Materials and Installations specification (3rd

edition) regarding clearance and shielding from combustible materials.

8.1.4 ThehorizontalfluelengthMUSTNOTbelessthan300mmplus90˚bendandMUSTNOTexceed12m

excluding terminal.

8.1.5 The total vertical flue length MUST NOT be less than 1m and MUST NOT exceed 12m excluding terminal.

8.1.6 Total length refers to the equivalent worked flue length and therefore includes bends and NOT the distance from

the heater to the flue terminal.

8.1.7 When calculating total flue length, reference MUST be made to the following ‘equivalent lengths’:

a)90˚bend =2m

b)45˚bend =1m

8.1.8 Themaximumnumberof90˚bendsthatcanbeusedis:

a)Horizontal=4

b)Vertical =4

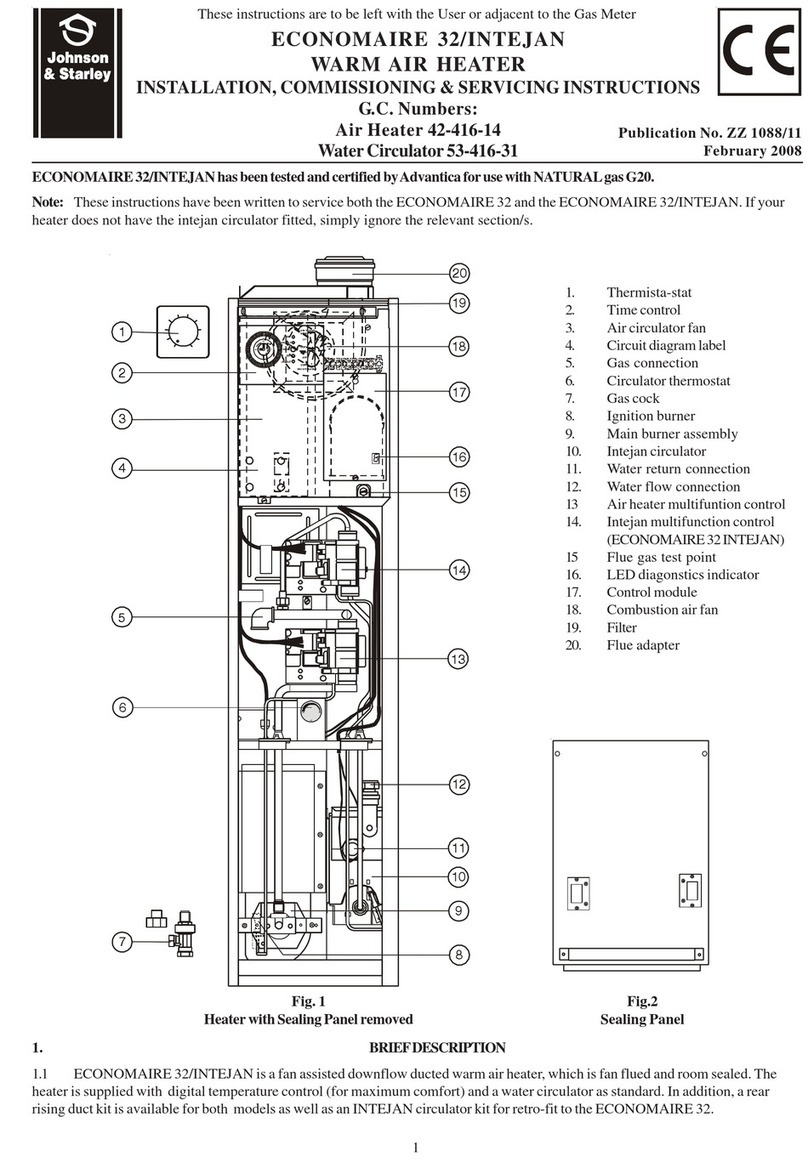

8.1.9 If a ‘short flue’ is used, the factory fitted flue orifice MUST be left

in place (see figure 4).

8.1.10 ‘Short flue’ refers to a total flue length not exceeding:

a)Horizontal(plus90˚bend) = 0.8m

b)Vertical(includingterminal)=5m

8.1.11 Where the total flue length exceeds these lengths, the flue

orifice MUST be removed.

8.1.12 The heater is supplied with either a horizontal or vertical flue,

dependant upon your specification when ordering. Reference

should be made to Table 3 for extra flue/terminal components.

8.2 HORIZONTAL TERMINAL LOCATION

8.2.1 The terminal must be positioned on the outside of the building

and allow for the free passage of air across it at ALL times.

8.2.2 Avoid positions where the terminal is adjacent to

projections, particularly under a balcony or immediately

adjacent to a drain pipe.

8.2.3 The terminal position must ensure that combustion

products cannot enter the building in which the heater is

installed (or any adjacent building) through windows, doors

or by any others means.

8.2.4 Figure 3 shows recommended terminal positions

8.2.5 It is recommended that the flue is fitted so that the outer part is flush with the wall. However, where this is not the

case, the maximum protrusion of the outer part of the flue through the wall MUST NOT exceed 22mm (see figure 3)

8.2.5 If the heater is to be installed in a timber framed building you MUST consult British Gas publication “Guide for Gas

Installations in Timber Framed Housing DM2” or your local gas region.

8.2.6 Where the lowest part of the flue terminal is located less than 2 metres above the ground, a balcony, or above a flat

roof across which there is access, the terminal MUST be fitted with a Tower Flue Components type K3 guard (or

similar) such that the distance between the guard and the nearest part of the terminal is no less than 50mm.

8.2.7 Reference should be made to Table 3 for required terminal components and guard.

8.2.8 NOTE: TO ENSURE THAT RAINWATER CANNOT ENTER THE HEATER UNIT, THE FLUE MUST BE

INSTALLED WITH A SLIGHT FALL AWAY FROM THE HEATER.

8.3 VERTICAL TERMINAL LOCATION

8.3.1 The ECONOMAIRE 32/INTEJAN is designed to be used with a vertical flue where the installation of a horizontal

flue is either not possible or not desired.

8.3.2 Installationofaverticalfluecanbeoneitheraflatorpitchedroofwithapitchangleofbetween25˚and50˚.

8.3.3 The terminal MUST be positioned on the outside of the building and allow for the free passage of air across it at

ALL times.

8.3.4 Avoid positions where the terminal is adjacent to projections; particularly under a balcony.

8.3.5 The terminal position must ensure that combustion products cannot enter the building in which the heater is

installed (or any adjacent building) through windows, doors or by any other means.

8.3.6 Figure 3 shows recommended terminal positions.

8.3.7 Reference should be made to Table 3 for the required terminal components.

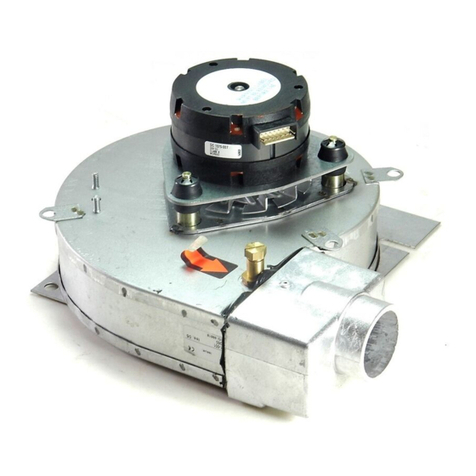

FIGURE 2

FLUE ADAPTOR & ORIFICE