ZZ 1019/1E

5

6.3 CONDENSATE

6.3.1 When firing , the unit may produce condensate which must be drained away. A JDT1 kit, which externally drains

the condensate away from the flue terminal is available for horizontal flued applications. Vertical flued

applications require the fitment of an in-line condensate trap within 0.5 m of the unit, in the first vertical flue run,

and before any bends in the flue run. Such a trap, with a 32 mm male drainage connection, is available for this

purpose.

6.3.2 Condensate from vertical flued applications must be drained away using 32 mm or 20 mm internal diameter, rigid

plastic pipe, connected to the condensate drain using KUTERLITE 700 or similar straight coupling. The pipe

should be installed in such a manner, that it forms a continuous downward slope away from the unit at a minimum

3oangle (6 mm per 100 mm, or, 0.75 in per foot run), and that the risk of mechanical damage and interior

interference is minimised. The pipe is to be protected against frost damage.

6.4 ELECTRICAL

6.4.1 Mains: The heater is supplied with mains cable (PVC sheathed, high temperature resistant, 3 core [Brown-

Blue-Green/Yellow], 6A, 0.75mm2), connected to a terminal block and exiting from the heater at the bottom right

hand rear. The cable is suitable for a 230V 50Hz single phase supply and must be protected by a 5A fuse, and an

earth wire must be connected. This cable must only be replaced by either the maunfacturer or a recognised and

qalified service engineer.A double pole switch or fused spur box should also be used. All wiring conform to I.E.E.

regulations, (current edition).

6.4.2 Thermostat: A Thermostat is provided with the appliance. The Thermostat wiring is to be connected to

terminals 6 and 7 on the air heater control panel, (marked ‘THERMOSTAT’), polarity being unimportant. It should

be located where there is free air circulation, and approximately 1.5m (5ft) from the floor. The following

locations should be avoided.

a. In a room where temperature is greatly affected by the sun or any other heat source (e.g. radiant fire, wall

light fitting or TV set).

b. Near an outside door or windows, or on an outside wall.

c. Where it can be affected by warm air ducts, diffusers, waste pipes or the heater itself.

d. Where it can be subject to vibration.

6.4.3 Time Control: If an external time control (not supplied) is to be fitted, connect the live supply to terminal 3,

the neutral to terminal 4, and the time-switch output to terminal 5. If no time control is fitted, link terminal 3

and 5.

6.5 GAS (see BS 5864 and BS 6891)

6.5.1 An independent gas supply pipe from the gas meter is to be preferred wherever possible. However, when this is

not possible, the pipe must be capable of taking the complete input of the heater and all other gas appliances being

served by this same pipe. This supply should be suitably sized to conform to British Standards requirements of no

more than 1.0 mbar (0.4 in. wg.) pressure drop (see table of discharge in BS 6891).

6.5.2 The 1/2in union gas cock (supplied) must be fitted externally in the gas inlet of the heater for easy isolation during

servicing. The gas pipe should be fitted and installed as to be durable, substantial and gas tight. Gas entry to the air

heater may be through the left hand side, right hand side front, or rear, to an Rc1/2(1/2in B.S.P. internal (taper)

thread).

7. COMMISSIONING

7.1 Ensure the following:

7.1.1 Gas and Electrical supplies are OFF.

7.1.2 Filter, fan and fan compartments are free from obstructions.

7.1.3 All registers or grilles are open and conform to design specifications.

7.1.4 Return, relief and ventilation air installations are adequate.

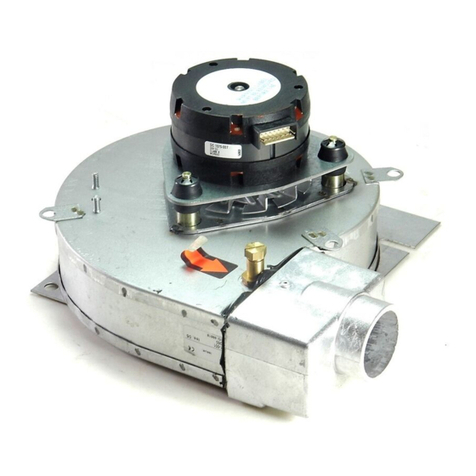

7.1.5 Adhesive label is removed from the centre of the combustion air fan to expose the motor cooling slots.

7.2 Turn ON the gas supply to the heater.

7.3 Test for gas soundness at supply, Multifunctional control and the Main burner using proprietary detection fluid, sealing

any leaks found, and purge the whole gas pipe as described in BS 6891.

7.4 Set the Thermostat to its maximum setting.

7.5 Ensure that the time control (if fitted) is in an ON position.

7.6 Switch on the electrical supply to the heater. The combustion air fan will start up immediately; after a minimum of 30

seconds, the burner will automatically ignite and the green ‘BURNER ON’ indicator will illuminate.

12

ZZ 1019/1E

BURNERNOTOPERATING

Check that the time control is on and Thermostat is calling for heat.

Check mains electrical supply.

Link terminals 3 & 5 (shorts out clock).

Disconnect Thermostat at terminals 6 & 7.

Noresponse Burner lights

Linkterminals 15&16. Reinstate connections at 6 & 7.

Check wiring to, or replace

Thermostat.

Noresponse Burner lights

Checkterminal 14for 230volts. Replace fandelay/limit

control.

No230 volts 230volts detected

CheckICU terminal5 for230 volts. Check wiring to, or replace

multifunctionalcontrol.

No230 volts 230volts detected

CheckICU terminal8 for230 volts. Checkwiring.

No230 volts 230volts detected

Check terminal C4 for230volts. Replace Ignition Control

Unit.

No230 volts 230volts detected

Check terminal C3 for 230 volts. Check wiring.

No230 volts 230volts detected

Checkterminal 5for 230volts Replace Control Module.

No230 volts 230volts detected

Check 3.15 A fuse, if OK check 230 volt Check wiring and Air Heating

input at terminal 1 Switch.

AirHeatingSwitchand

WiringOK

Replace Ignition Control unit

or Pressure switch

BURNERON,BUTAIRCIRCULATIONFANNOTRUNNING

Check for 230 volts at fan terminals 11 & 12

No230 voltsdetected 230voltsdetected

Switchto ‘SummerAirflow’. Switchto ‘SummerAirflow’.

230volts detected

Replace air circulation fan.

Aircirculation fanruns Aircirculationfandoes

Replacefan delay/limit control. notrun

Replace Fan Speed Transformer

BURNERONCONTINUOUSLY

(ROOMTEMPERATURETOOHIGH)

Setthe Air HeatingSwitch to‘Summer Airflow’

Burnerremainsalight Burner goesout

Disconnect solenoid plug at Replace Thermostat.

multifunctionalcontrol.

Burnerremainsalight

Replace multifunctional control.

AIRCIRCULATIONFANCONTINUESTORUNORCYCLES

WHENBURNERISNOTON

Check that Air Heating switch is not set to ‘Summer Airflow’.

Disconnect Thermostat and link terminals 6 & 7.

Disconnect the fan delay/limit control.

Aircirculation fanstops Air circulationfan continuesto run

Replacefan delay/limit ReplaceControl module

control

AIRCIRCULATIONFANON,BUTBURNERCYCLESBEFORE

REQUIREDCOMFORTLEVELISREACHED

Disconnect Thermostat at terminals 6 & 7.

Burnercontinuestocycle Burnerremains on

Check air filter, return air path Thermostat defective.

and outlets for restrictions.

Burnercontinuestocycle

Link terminals 15 & 16 to bypass limit control.

Burnercontinuestocycle Burnerrunsand room

Replace Thermostat. temperaturerises

Check temperature rise.

Less than 60 degrees C Morethan 60degreesC

Replace fan delay/overheat (limit) Replace Thermostat

control.

PRESSURESWITCHDEFECTIVE