Johnson Controls V-4000-1 User manual

Other Johnson Controls Controllers manuals

Johnson Controls

Johnson Controls VA7800 Series User manual

Johnson Controls

Johnson Controls VA9208-AG Series User manual

Johnson Controls

Johnson Controls FMS-1655 Series User manual

Johnson Controls

Johnson Controls TEC3000 Series User manual

Johnson Controls

Johnson Controls EasyIO FW-08 V3 User manual

Johnson Controls

Johnson Controls LN Series User manual

Johnson Controls

Johnson Controls RA-3 Series Owner's manual

Johnson Controls

Johnson Controls ZFR1810 User manual

Johnson Controls

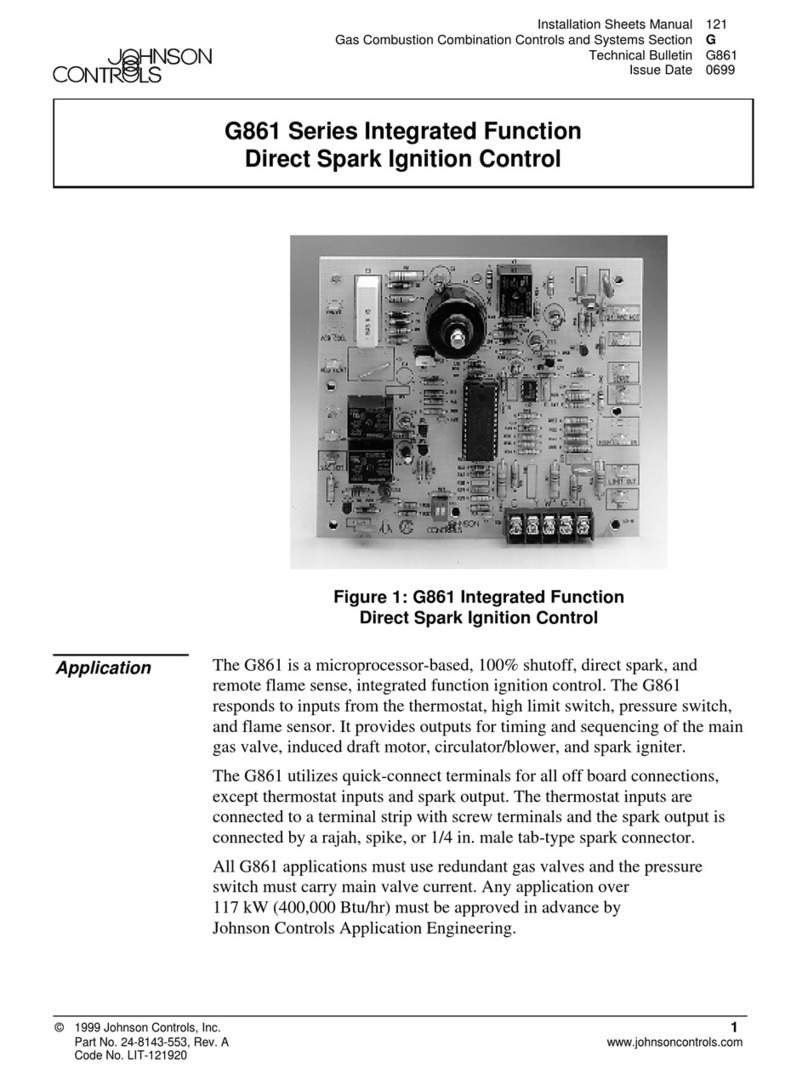

Johnson Controls G861 Series Service manual

Johnson Controls

Johnson Controls LN Series User manual

Johnson Controls

Johnson Controls SE-SPU101 Series User manual

Johnson Controls

Johnson Controls M9216 Series User manual

Johnson Controls

Johnson Controls ER54 User manual

Johnson Controls

Johnson Controls VMA1200 Series User manual

Johnson Controls

Johnson Controls DS-3153 User manual

Johnson Controls

Johnson Controls LX Series User manual

Johnson Controls

Johnson Controls FX-PCG26 User manual

Johnson Controls

Johnson Controls System 350 P352AB Series User manual

Johnson Controls

Johnson Controls G670 Assembly instructions

Johnson Controls

Johnson Controls FW-08 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions