Johnson Controls LX Series User manual

Other Johnson Controls Controllers manuals

Johnson Controls

Johnson Controls VA-7010 Series Manual

Johnson Controls

Johnson Controls VA7800 Series User manual

Johnson Controls

Johnson Controls FX-PCG26 User manual

Johnson Controls

Johnson Controls VAP Series User manual

Johnson Controls

Johnson Controls VMA1200 Series Operating instructions

Johnson Controls

Johnson Controls S321-IP Manual

Johnson Controls

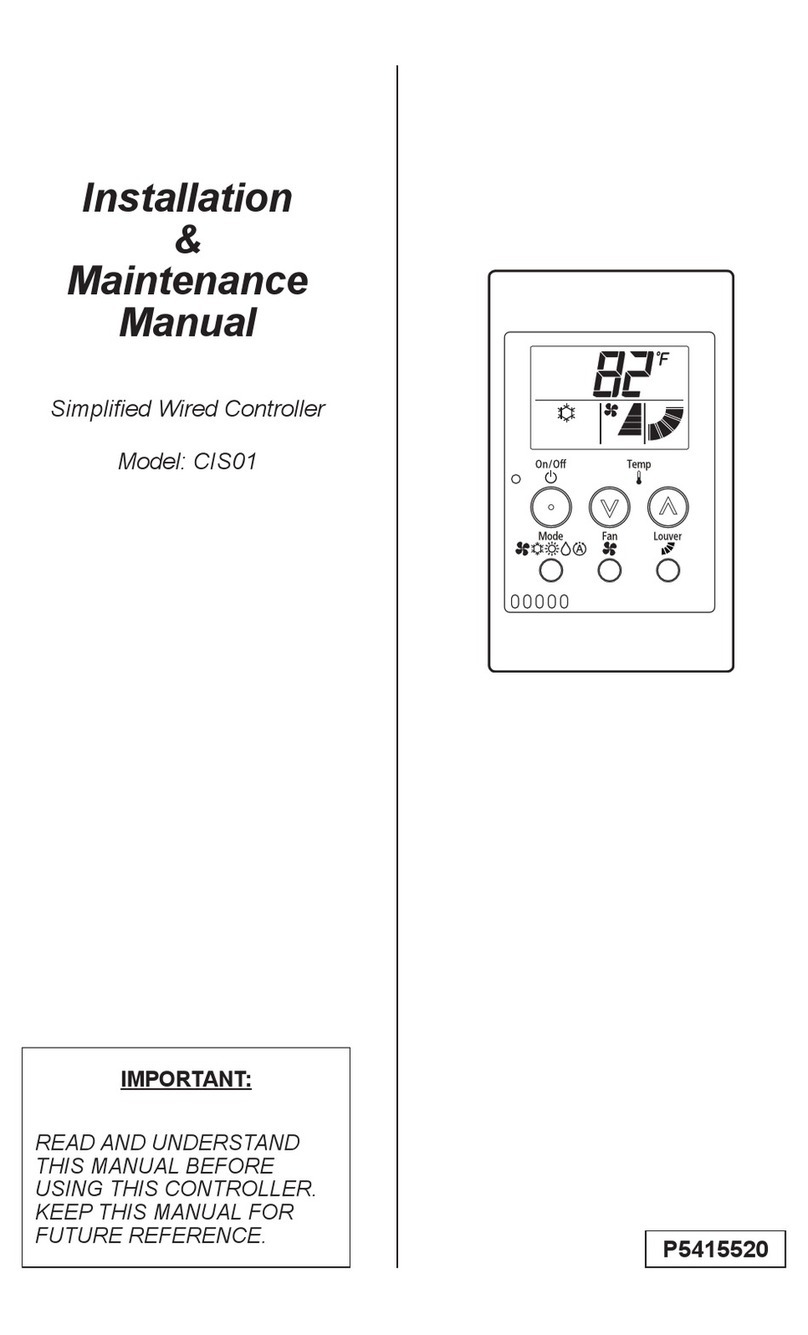

Johnson Controls CIS01 User manual

Johnson Controls

Johnson Controls JCRL120PW User manual

Johnson Controls

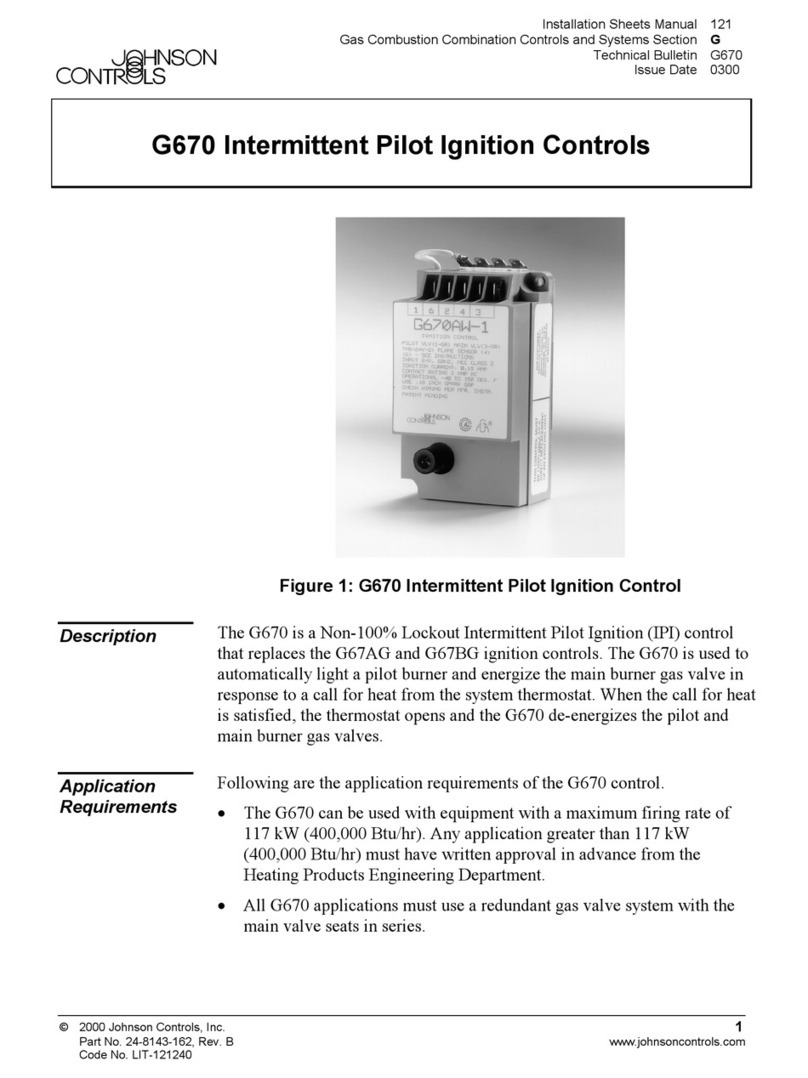

Johnson Controls G670 Assembly instructions

Johnson Controls

Johnson Controls M4-CGM Series User manual

Johnson Controls

Johnson Controls M9320-AUA-4 User manual

Johnson Controls

Johnson Controls M9316-A Z Series User manual

Johnson Controls

Johnson Controls CIS01 Instruction Manual

Johnson Controls

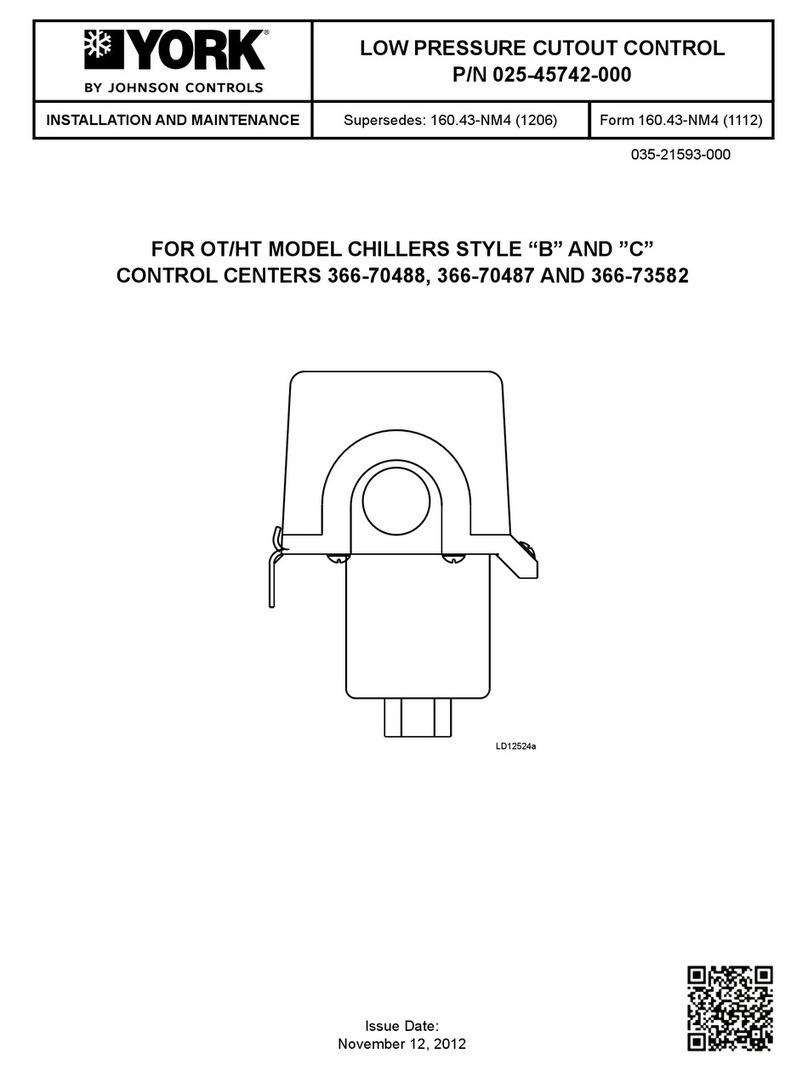

Johnson Controls York 366-70488 Instruction Manual

Johnson Controls

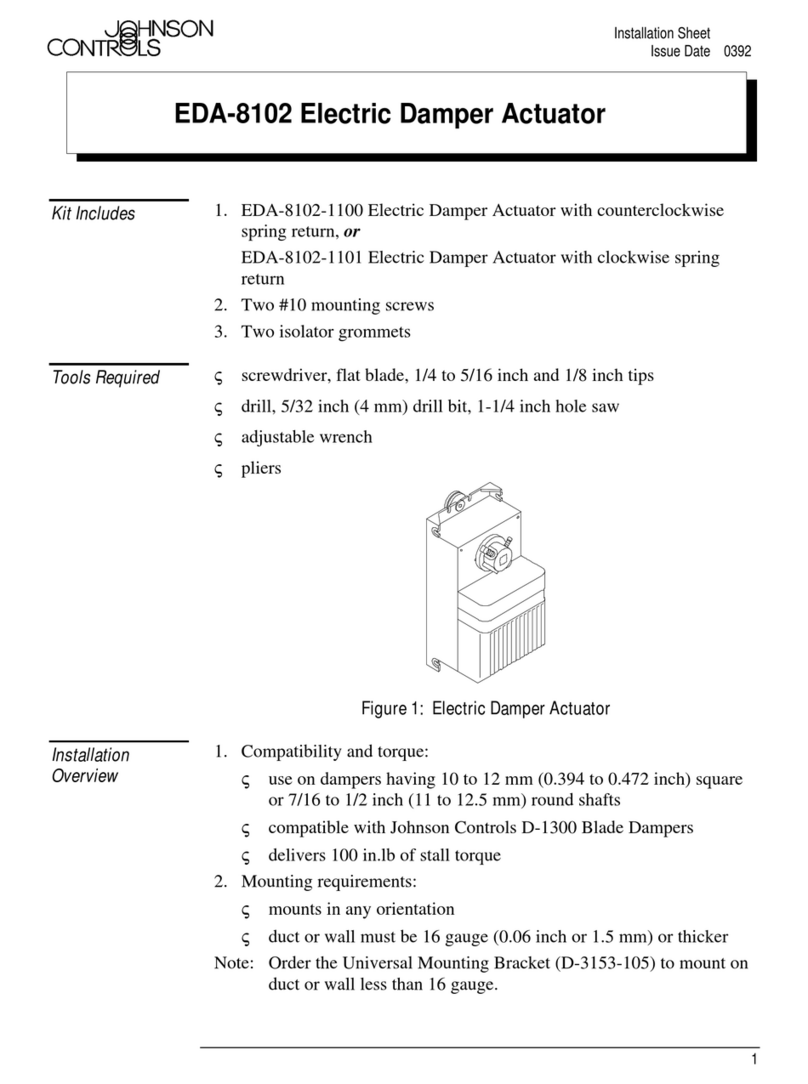

Johnson Controls EDA-8102 Assembly instructions

Johnson Controls

Johnson Controls TEC2245-4 User manual

Johnson Controls

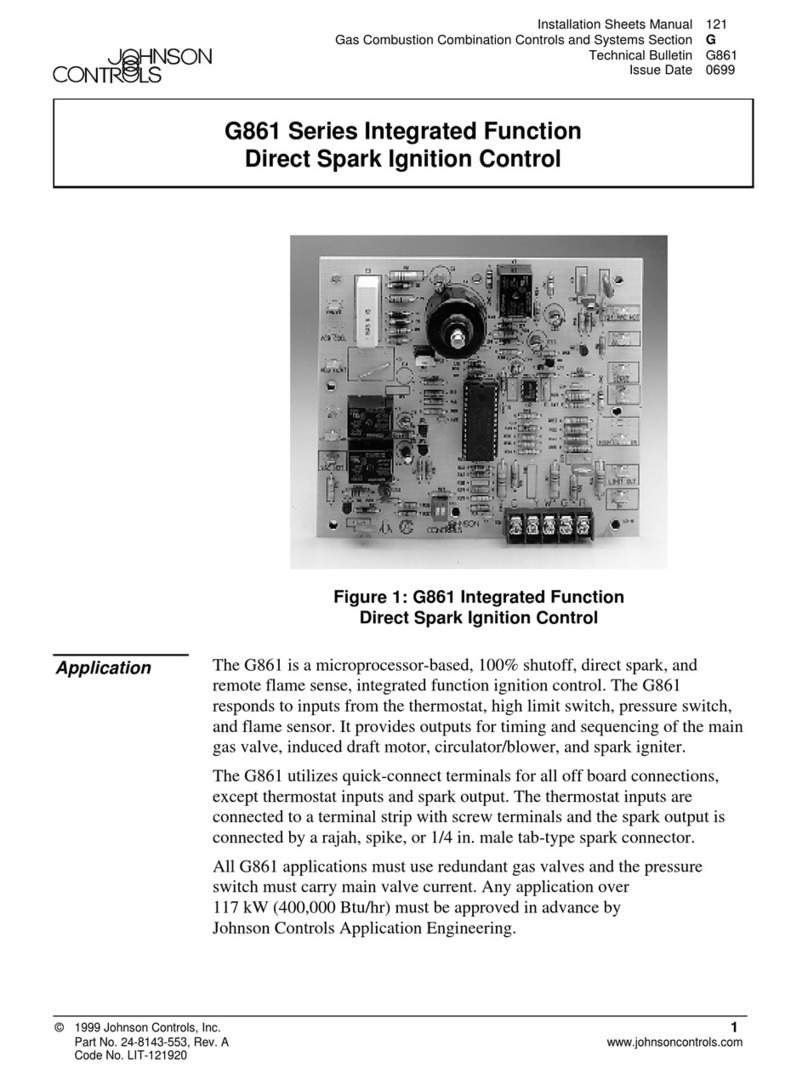

Johnson Controls G861 Series Service manual

Johnson Controls

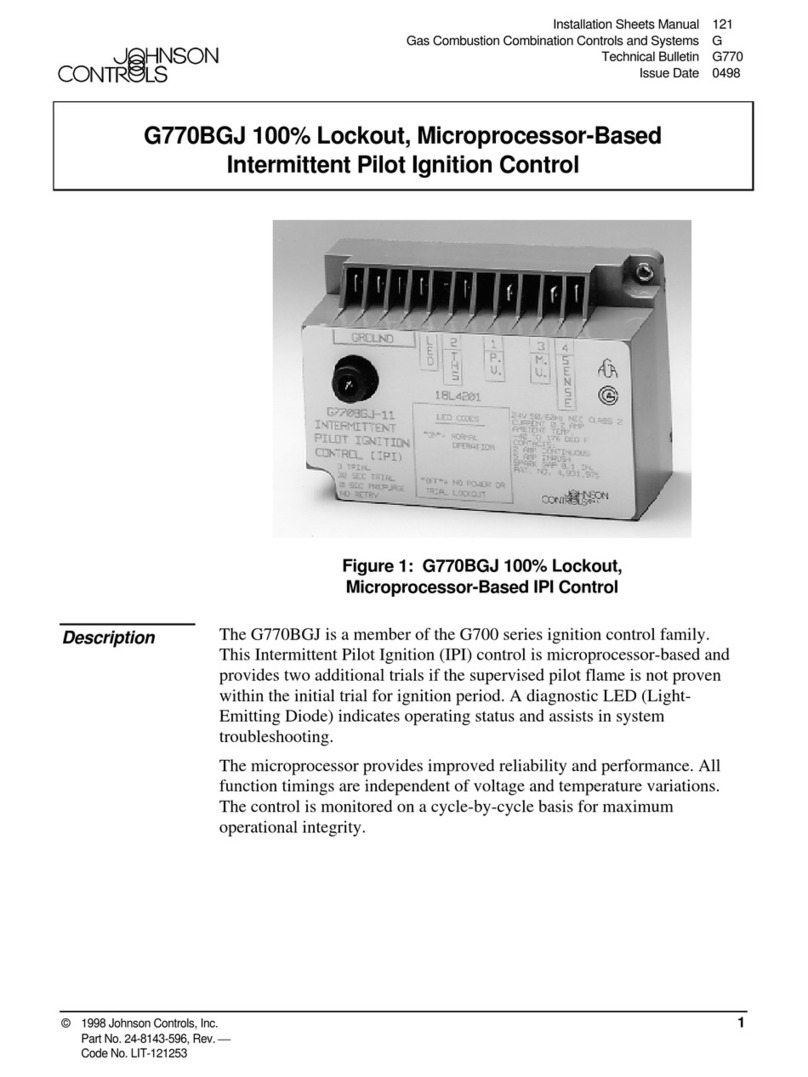

Johnson Controls G770BGJ User manual

Johnson Controls

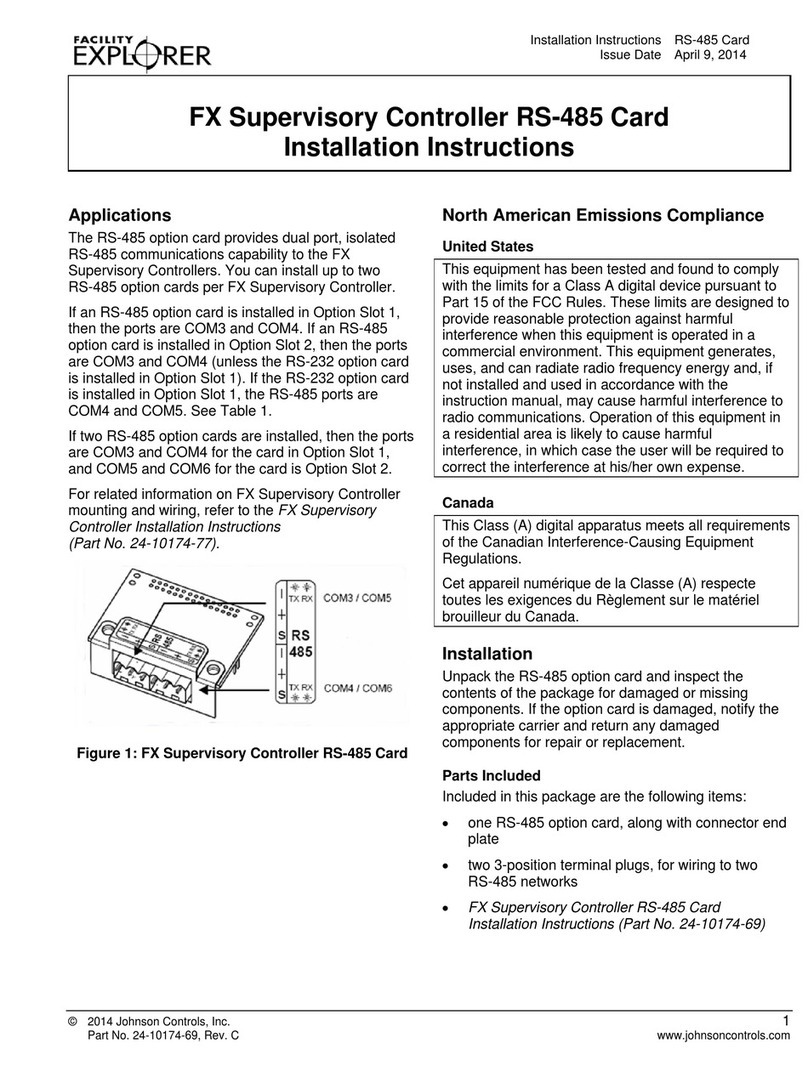

Johnson Controls FX Supervisory Controller RS-485 Card User manual

Johnson Controls

Johnson Controls VA-7700 Series User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions