Johnson Controls VA-7010 Series Manual

Other Johnson Controls Controllers manuals

Johnson Controls

Johnson Controls Metasys VMA1610 User manual

Johnson Controls

Johnson Controls FX30E Service manual

Johnson Controls

Johnson Controls TEC3000 Series User manual

Johnson Controls

Johnson Controls Hitachi C4IRK01 User manual

Johnson Controls

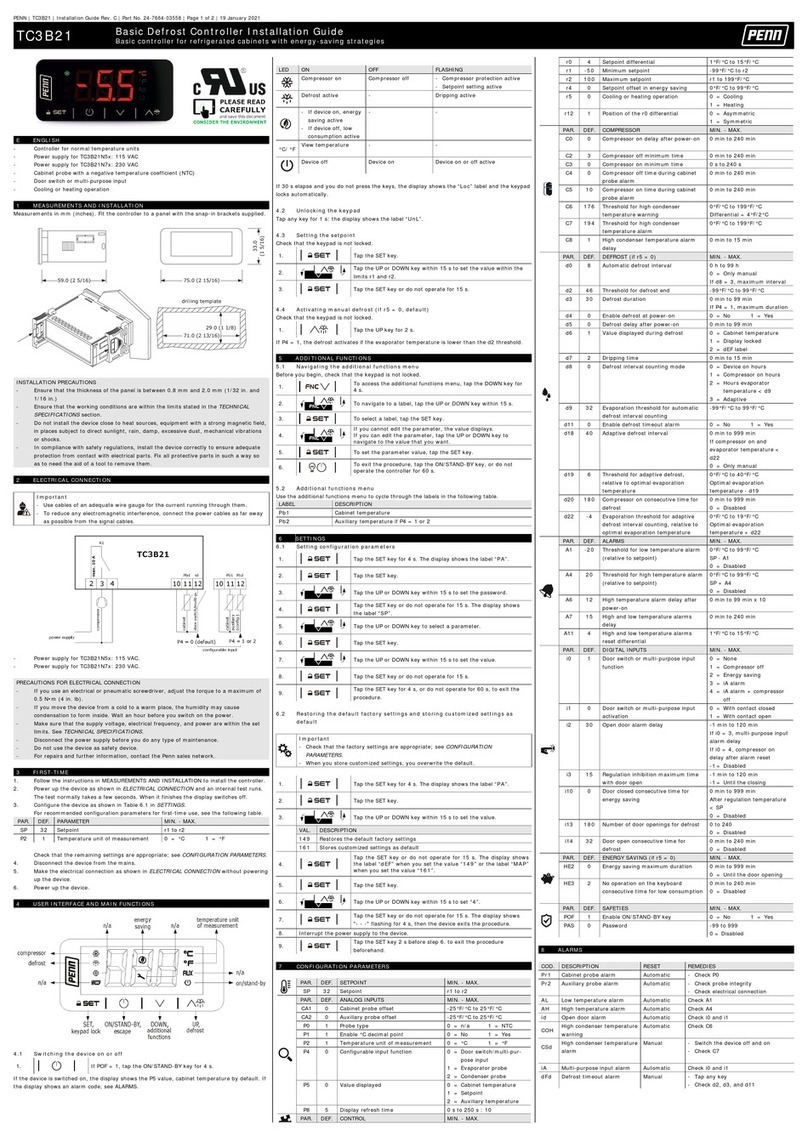

Johnson Controls penn TC3B21 User manual

Johnson Controls

Johnson Controls M9108 Series User manual

Johnson Controls

Johnson Controls TEC3620 Series User manual

Johnson Controls

Johnson Controls Tyco KT-1 User manual

Johnson Controls

Johnson Controls FX-PCG1621 Series User manual

Johnson Controls

Johnson Controls VA-7700 Series User manual

Johnson Controls

Johnson Controls VMA1617 User manual

Johnson Controls

Johnson Controls M4-CGM Series User manual

Johnson Controls

Johnson Controls Tyco Kantech KT-400 Quick start guide

Johnson Controls

Johnson Controls A28 Series User manual

Johnson Controls

Johnson Controls VAP Series User manual

Johnson Controls

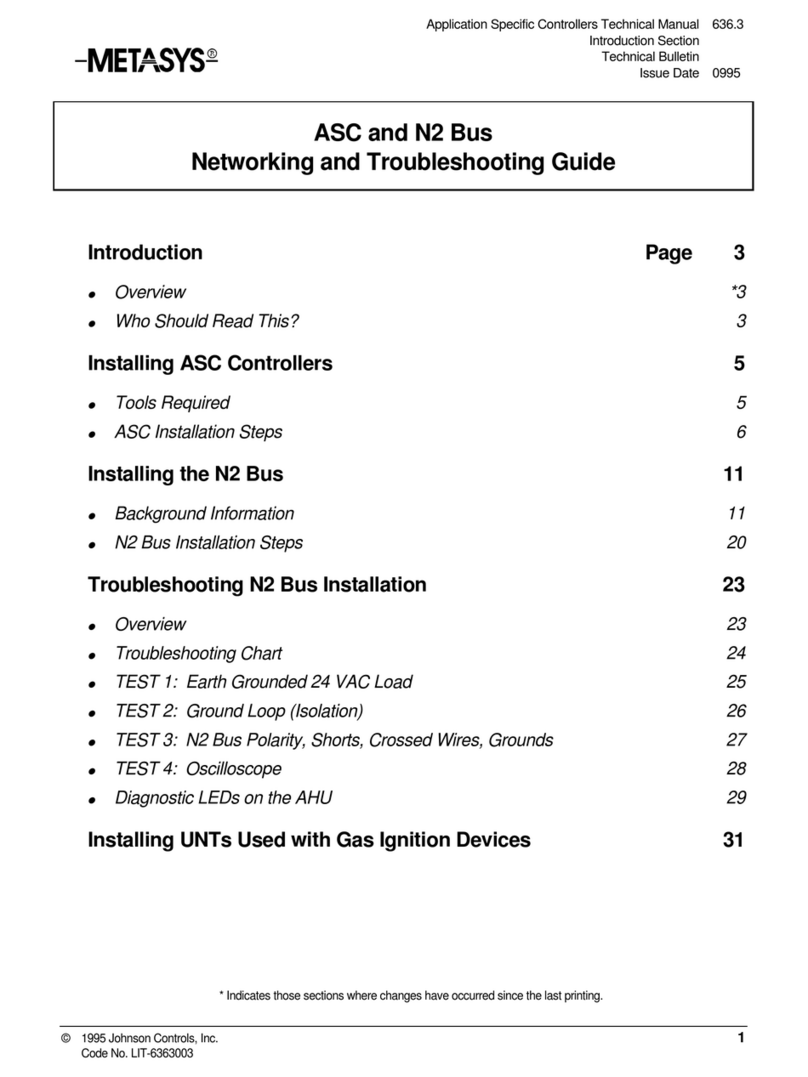

Johnson Controls METASYS ASC User manual

Johnson Controls

Johnson Controls RRS Economizer Controller User manual

Johnson Controls

Johnson Controls S321-IP Manual

Johnson Controls

Johnson Controls FAC2611-0U User manual

Johnson Controls

Johnson Controls TEC3310 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions