FD-1600 1-1/2 Hour Dynamic Rated Multi-Blade Fire Dampers Installation Instructions2

2. Fasteners and Multiple Section Assembly

When joining multiple damper assemblies or

fastening the damper to the sleeve, dampers shall

be fastened with 1/4-20 (M6) bolts, number 10

(M5) screws, or 1/2 in. (13 mm) long welds

staggered intermittently on both sides. Space

fasteners 6 in. (152 mm) on center and a maximum

2 in. (51 mm) from the ends of the joining sections

or from each corner.

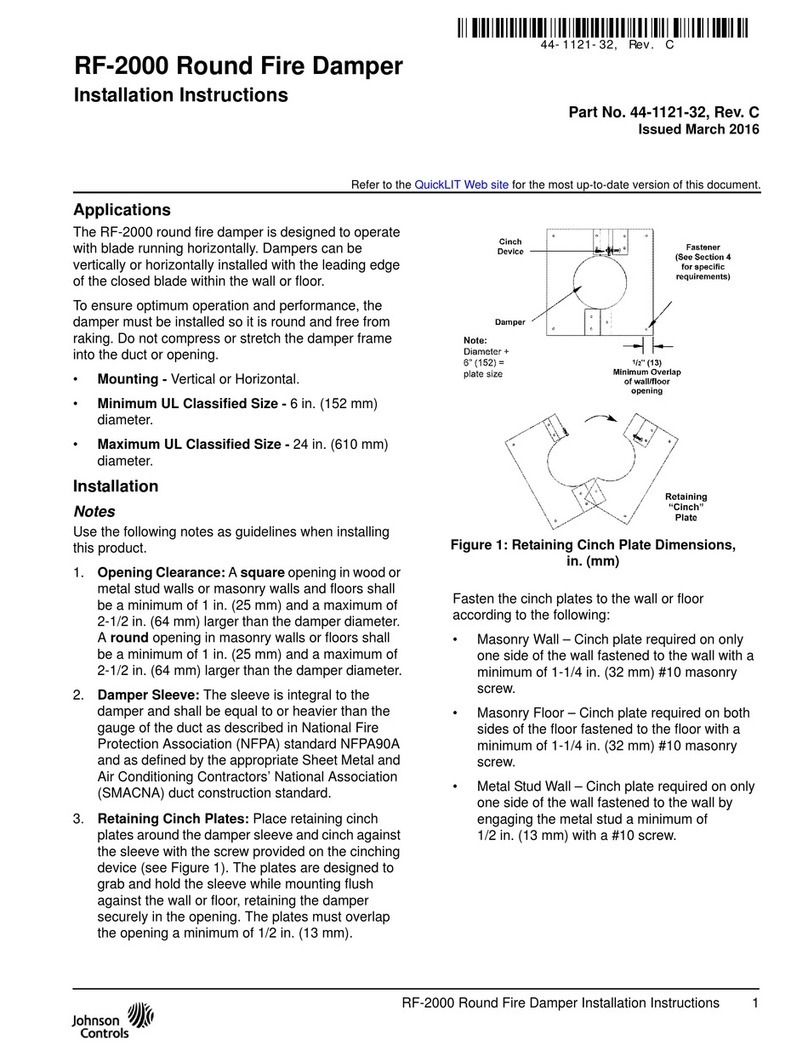

3. Damper Sleeve

Sleeve thickness must be equal to or thicker than

the duct connected to it. Sleeve gage requirements

are listed in the SMACNA Fire, Smoke and

Radiation Damper Installation Guide for HVAC

Systems and in NFPA90A. If a breakaway style

duct/sleeve connection is not used, the sleeve

shall be a minimum of 16 gage (1.6 mm) for

dampers up to 36 in. (914 mm) wide by 24 in.

(610 mm) high and 14 gage (1.9 mm) for dampers

exceeding 36 in. (914 mm) wideby 24 in. (610 mm)

high. Damper sleeve shall not extend more than

6 in. (152 mm) beyond the fire wall or partition

unless damper is equipped with an actuator and/or

factory installed access door. Sleeve may extend

up to 16 in. (406 mm) beyond the fire wall or

partition on sides equipped with actuator and/or

factory installed access door. Sleeve shall

terminate at both sides of wall within dimensions

shown.

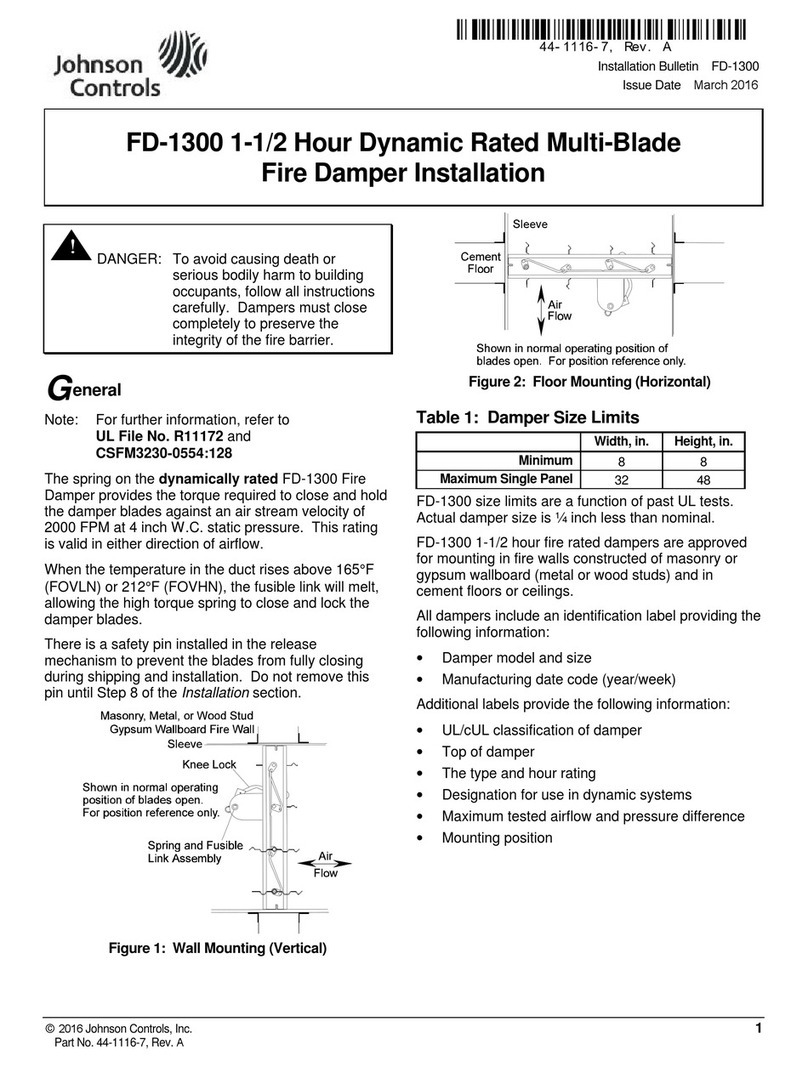

4. Damper Orientation

Damper is designed to operate with blades running

horizontally and must be installed with leading

edge of closed blades within the wall or floor when

they are in the closed position. Use Mount With

Arrow Up label as a guide for proper damper

orientation. Horizontal mount dampers may be

installed with the jackshaft above or below the

floor.

5. Mounting Angles

Mounting angles shall be a minimum of 1-1/2 in. x

1-1/2 in. x 20 gage steel (38 mm x 38 mm x

1.0 mm). For openings in metal stud and wood

stud and concrete/masonry walls of sizes 90 in. x

49 in. or 49 in. x 90 in. (2,286 mm x 1,245 mm or

1,245 mm x 2,286 mm) and less, mounting angles

are only required on one side of the wall or top of

the floor and must be attached to both the sleeve

and the wall.

Mounting angles may be installed directly to the

metal stud under the wallboard on metal stud wall

installations only. Larger openings installations

require mounting angles on both sides of the

partition and must be attached only to the sleeve.

Mounting angles must overlap the partition a

minimum of 1 in. (25 mm). Do not weld or fasten

angles together at corners of dampers. Johnson

Controls® fire/smoke dampers may be installed

using optional fast-mounting (FAST) angle for one

angle installation or the standard Picture Frame

Mounting Angle (PFMA) for two angle installations.

a. Mounting Angle Fasteners

To sleeve #10 bolts or screws, 3/16 in. (5 mm)

steel rivets or 1/2 in. (13 mm) long welds.

Masonry Wall or Floor: #10 self-tapping concrete

screws

Wood/Steel Stud Wall: #10 screws.

b. Mounting Angle Fastener Spacing

For one angle installations, the sleeve fasteners

shall be spaced at 6 in. (152 mm) o.c. and the wall

or floor fasteners shall be spaced at 12 in.

(305 mm) o.c. with a minimum of two fasteners on

each side, top and bottom. Screw fasteners used in

metal stud must engage the metal stud a minimum

of 1/2 in. (13 mm). Screw fasteners used in wood

stud must engage the wood stud a minimum of

3/4 in. (19 mm). Screw fasteners used in masonry

walls or floors must engage the wall or floor a

minimum of 11/2 in. (38 mm). For two angle

installations, the fasteners shall be spaced at 8 in.

(203 mm) o.c.

6. Break-Away Duct/Sleeve Connections

Flanged connection systems manufactured by

Ductmate, Nexus or Ward are approved break-

away when installed as shown in Figure 1.

Transverse Duct Connection (TDC) and

Transverse Duct Flange (TDF) roll-formed flanged

connections using 3/8 in. (10 mm) steel bolts and

nuts, and metal cleats, as tested by SMACNA, are

approved break-away connections when installed

as shown in Figure 1.