TFP223

Page 3 of 4

Installation

The Series EC-8 Sprinklers must

be installed in accordance with this

section.

General Instructions

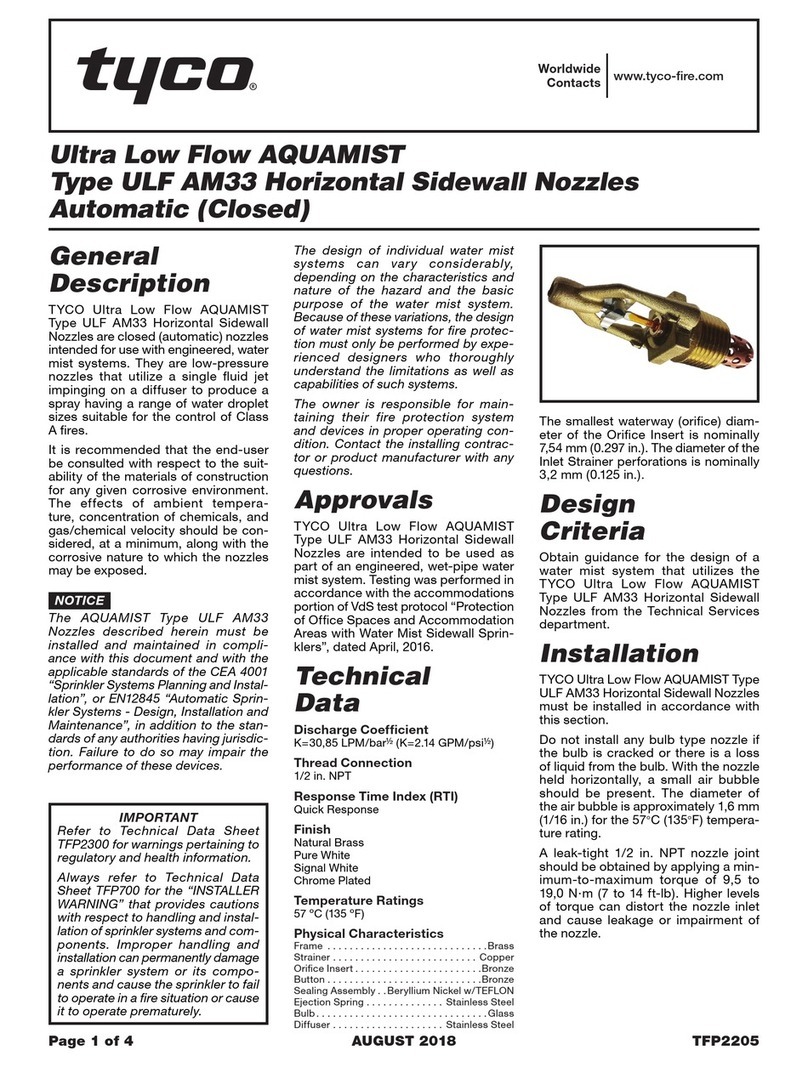

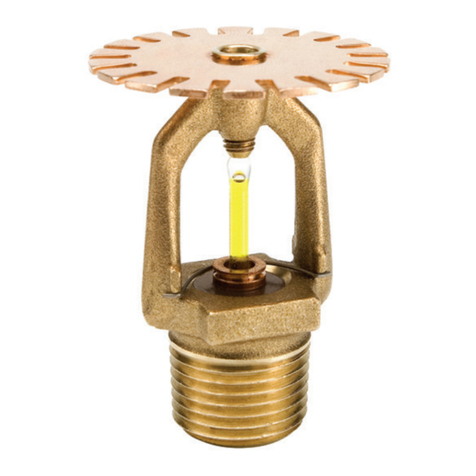

Do not install any bulb type sprinkler

if the bulb is cracked or there is a loss

of liquid from the bulb. With the sprin-

kler held horizontally, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 in.

(1,6 mm).

A leak tight 3/4 in. NPT sprinkler joint

should be obtained with a torque of

10 ft-lb to 20 ft-lb (13,4 N·m to 26,8

N·m). Higher levels of torque may

distort the sprinkler inlet with conse-

quent leakage or impairment of the

sprinkler.

Do not attempt to compensate for

insufcient adjustment of an escutch-

eon plate by under-or over-tightening

the sprinkler. Re-adjust the position of

the sprinkler tting to suit.

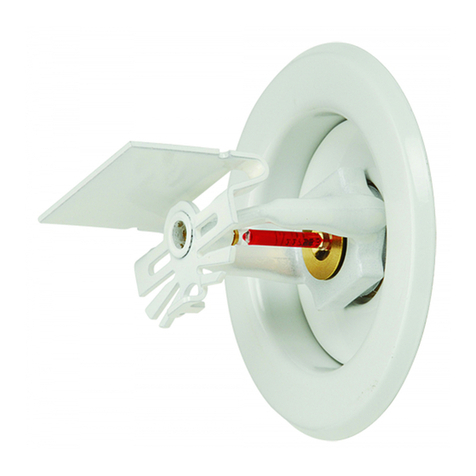

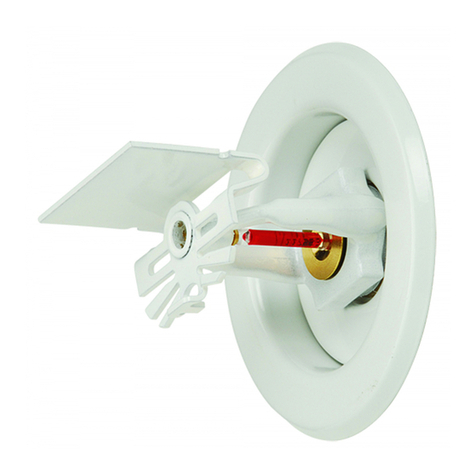

Step 1. The sprinkler must be installed

with the deector parallel to the mount-

ing surface. Pendent sprinklers must

be installed in the pendent position.

Step 2. After installing the style 30 or

40 mounting plate (or other escutch-

eon, as applicable) over the sprinkler

pipe threads, and with pipe thread

sealant applied to the pipe threads,

hand tighten the sprinkler into the

sprinkler tting.

Step 3. Wrench tighten pendent sprin-

klers using only the W-Type 3 (End A)

Sprinkler Wrench. Wrench tighten the

recessed pendent sprinklers using

only the W-Type 23 Sprinkler Wrench.

The wrench recess of the applicable

sprinkler wrench as shown in Figures

4 and 5 is to be applied to the sprinkler

wrench ats as shown in Figure 1.

Care and

Maintenance

The Series EC-8 Sprinklers must be

maintained and serviced in accordance

with this section.

Before closing a re protection system

main control valve for maintenance

work on the re protection system that

it controls, permission to shut down the

affected re protection systems must

be obtained from the proper authorities

and all personnel who may be affected

by this action must be notied.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or other-

wise altered after leaving the factory.

Modied sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid

damage to the sprinklers before,

during, and after installation. Sprin-

klers damaged by dropping, striking,

wrench twist/slippage, or the like, must

be replaced. Also, replace any sprin-

kler that has a cracked bulb or that has

lost liquid from its bulb. For informa-

tion about replacing a sprinkler, see the

Installation Section.)

Frequent visual inspections are rec-

ommended to be initially performed

for corrosion resistant coated sprin-

klers, after the installation has been

completed, to verify the integrity of

the corrosion resistant coating. There-

after, annual inspections according

to NFPA 25 should sufce; however,

Area Style 135°F (57°C) 155°F (68°C)

16 x 16 Pendent QR QR

16 x 16 Style 30 Recessed QR QR

16 x 16 Style 40 Recessed QR QR

18 x 18 Pendent QR QR

18 x 18 Style 30 Recessed QR SR

18 x 18 Style 40 Recessed QR SR

20 x 20 Pendent QR SR

20 x 20 Style 30 Recessed QR SR

20 x 20 Style 40 Recessed SR SR

NOTES

• QR: Quick Response

Area Style 135°F (57°C) 155°F (68°C)

16 x 16 Pendent QR QR

16 x 16 Style 30 Recessed QR N/A

16 x 16 Style 40 Recessed N/A N/A

18 x 18 Pendent QR QR

18 x 18 Style 30 Recessed QR N/A

18 x 18 Style 40 Recessed N/A N/A

20 x 20 Pendent QR QR

20 x 20 Style 30 Recessed QR N/A

20 x 20 Style 40 Recessed N/A N/A

NOTES

• QR: Quick Response

• SR: Standard Response

Description Area gpm psi

TY4232 (K=8.0)

Pendent

16 x 16 26 10.6

18 x 18 33 17.0

20 x 20 40 25.0

NOTES

• 1 ft = 0.3048 m

• 1 gpm = 3.785 Lpm

• 1 psi = 0.06895 bar

• 1 gpm/ft2= 40.74 mm/min

TABLE B

SENSITIVITY RATING FOR UL AND C-UL LISTING

OF SERIES EC-8 SPRINKLERS

TABLE C

SENSITIVITY RATING FOR FM APPROVAL

OF SERIES EC-8 SPRINKLERS

TABLE D

FLOW CRITERIA FOR UL AND C-UL LISTING

OF SERIES EC-8 SPRINKLERS