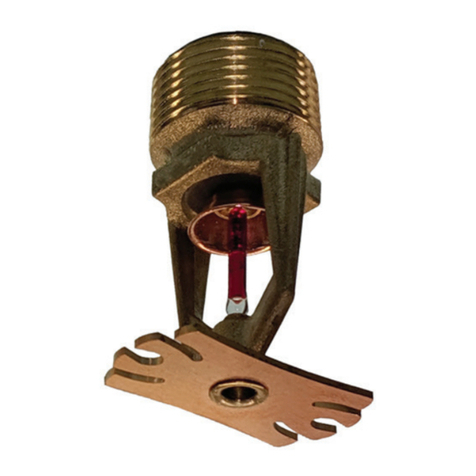

Series TY-FRL – 5.6 K-factor

Horizontal Sidewall Sprinkler

Quick Response, Standard Coverage

Page 1 of 4 AUGUST 2018 TFP140

IMPORTANT

Refer to Technical Data Sheet

TFP2300 for warnings pertaining to

regulatory and health information.

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and

installation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.

Worldwide

Contacts

www.tyco-fire.com

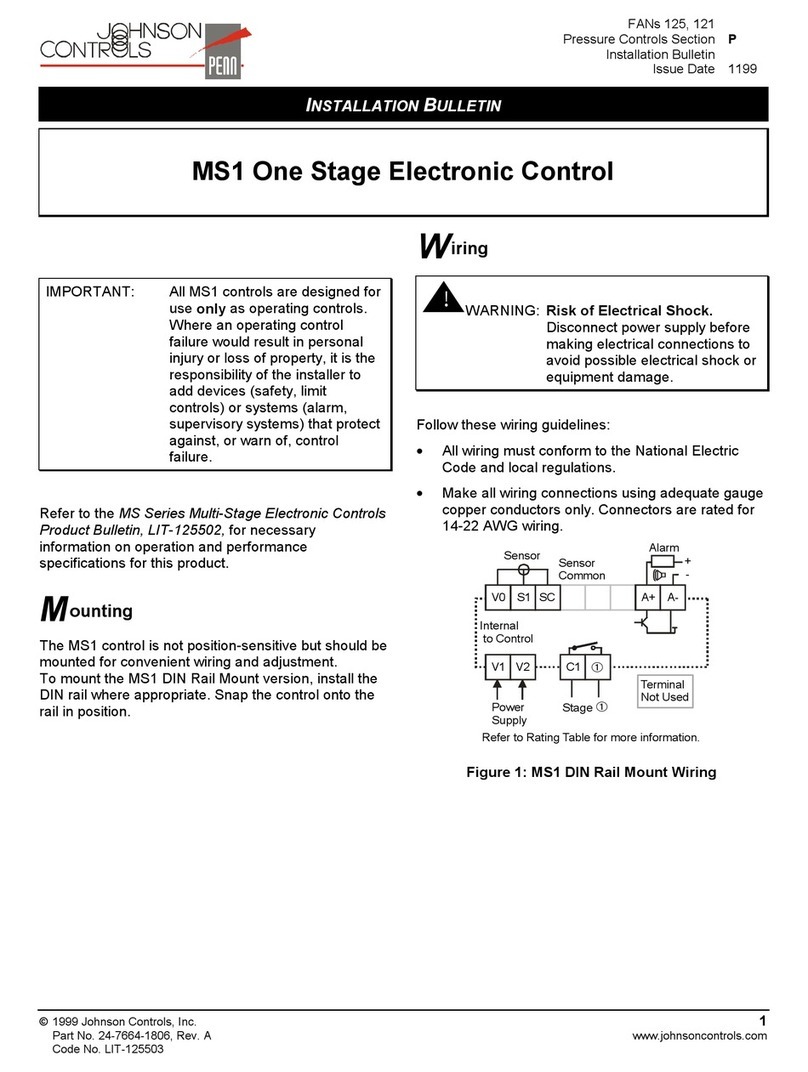

General

Description

TYCO Series TY-FRL 5.6K Horizon-

tal Sidewall Sprinklers (HSW), Quick

Response, Standard Coverage are sol-

der-type spray sprinklers designed for

use in light and ordinary hazard com-

mercial occupancies such as banks,

hotels, shopping malls, offices, etc.

They are designed for installation along

a wall or the side of a beam and just

beneath a smooth ceiling. Horizontal

sidewall sprinklers are commonly used

instead of pendent or upright sprin-

klers due to aesthetics or building con-

struction considerations, where piping

across the ceiling is not desirable.

NOTICE

The Series TY-FRL Sprinklers

described herein must be installed

and maintained in compliance with this

document, as well as with the applica-

ble standards of the National Fire Pro-

tection Association (NFPA), in addition

to the standards of any other authori-

ties having jurisdiction. Failure to do so

may impair the performance of these

devices.

The owner is responsible for main-

taining their fire protection system

and devices in proper operating con-

dition. Contact the installing contrac-

tor or product manufacturer with any

questions.

Sprinkler

Identification

Numbers (SINs)

TY3321 – HSW 5.6K, 1/2 in. NPT

TY3321 is a re-designation for Star SIN

S1878 and Gem SIN G8946.

Technical

Data

Approvals

UL and C-UL Listed

FM and NYC Approved

(Refer to Table A for complete approval

information.)

Maximum Working Pressure

175 psi (12,1 bar)

Discharge Coefficient

K=5.6 gpm/psi½(80,6 lpm/bar½)

Temperature Ratings

Refer to Table A

Finishes

Refer to Table A

Physical Characteristics

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Strut. . . . . . . . . . . . . . . . . . . . . . . . . . . . . MONEL

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . MONEL

Link Assembly. . . . . . . . . . . . . . . . . . . . . . Nickel

Ejection Spring . . . . . . . . . . . . . . . . . . INCONEL

Button . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . .TEFLON

Operation

The fusible link (heat collector) assem-

bly is comprised of two halves that

are joined together by a thin layer of

solder. When the rated temperature is

reached, the solder melts and the two

link halves separate, allowing the sprin-

kler to operate.

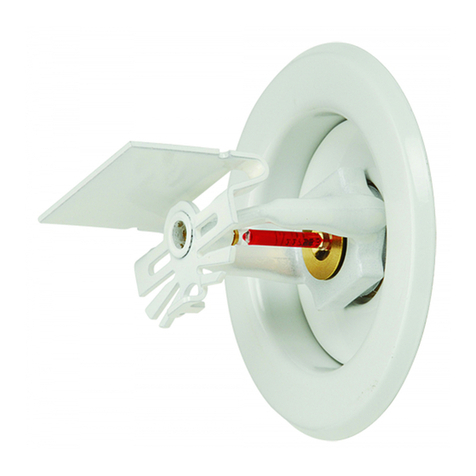

Design

Criteria

TYCO Series TY-FRL 5.6K HSW Sprin-

klers, Quick Response, Standard

Coverage are intended for fire pro-

tection systems designed in accor-

dance with the standard installation

rules recognized by the applicable

listing or approval agency (e.g., UL

Listing is based on NFPA 13 require-

ments); however, the minimum dis-

tance between sprinklers to prevent

cold soldering is 8 ft (2,4 m). The

Series TY-FRL HSW Sprinklers

must be installed with a deflector-

to-ceiling distance of 4 in. to 6 in.

(100 mm to 150 mm). To meet this

requirement the centerline of the

sprinkler waterway must be located

4-5/16 in. to 6-5/16 in. (110 mm to

160 mm) below the ceiling. Installation

of the Series TY-FRL HSW Sprinklers

in recessed escutcheons will void all

manufacturer’s warranties, as well as

possibly void the sprinkler’s approvals

and/or listings.