©2004 JoTiKa Ltd. 9

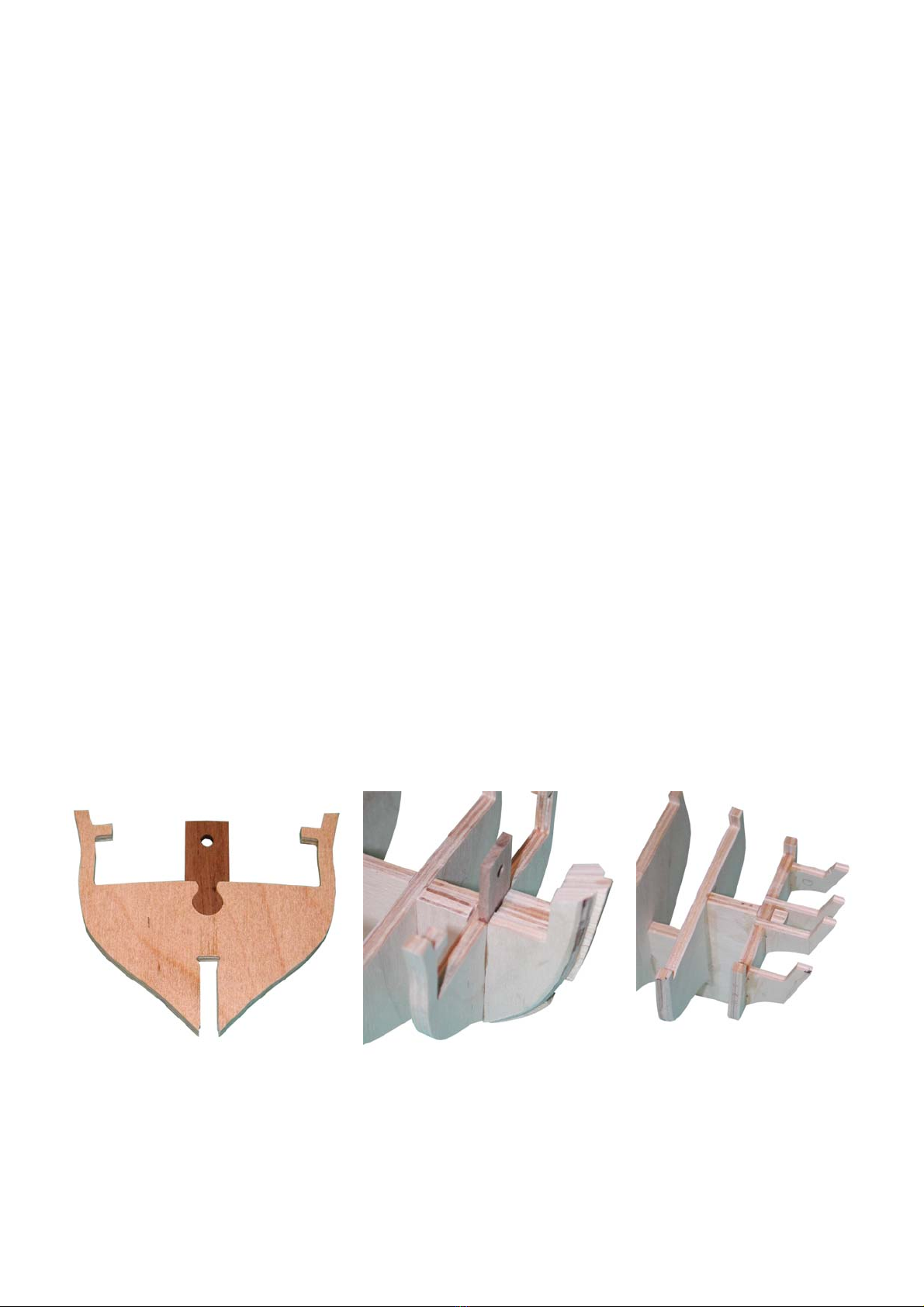

The Mortar Housings

Identify and remove the mortar pit surround base (63), the mortar pit base (155), the mortar pit surrounds (30), and the mortar

pit surround tops (45). Using Plan Sheet 2, ‘Mortar housing assemblies’ for reference, assemble the mortar pit surrounds as

shown, taking care that each component fits true, centrally and square to the mortar pit surround base.

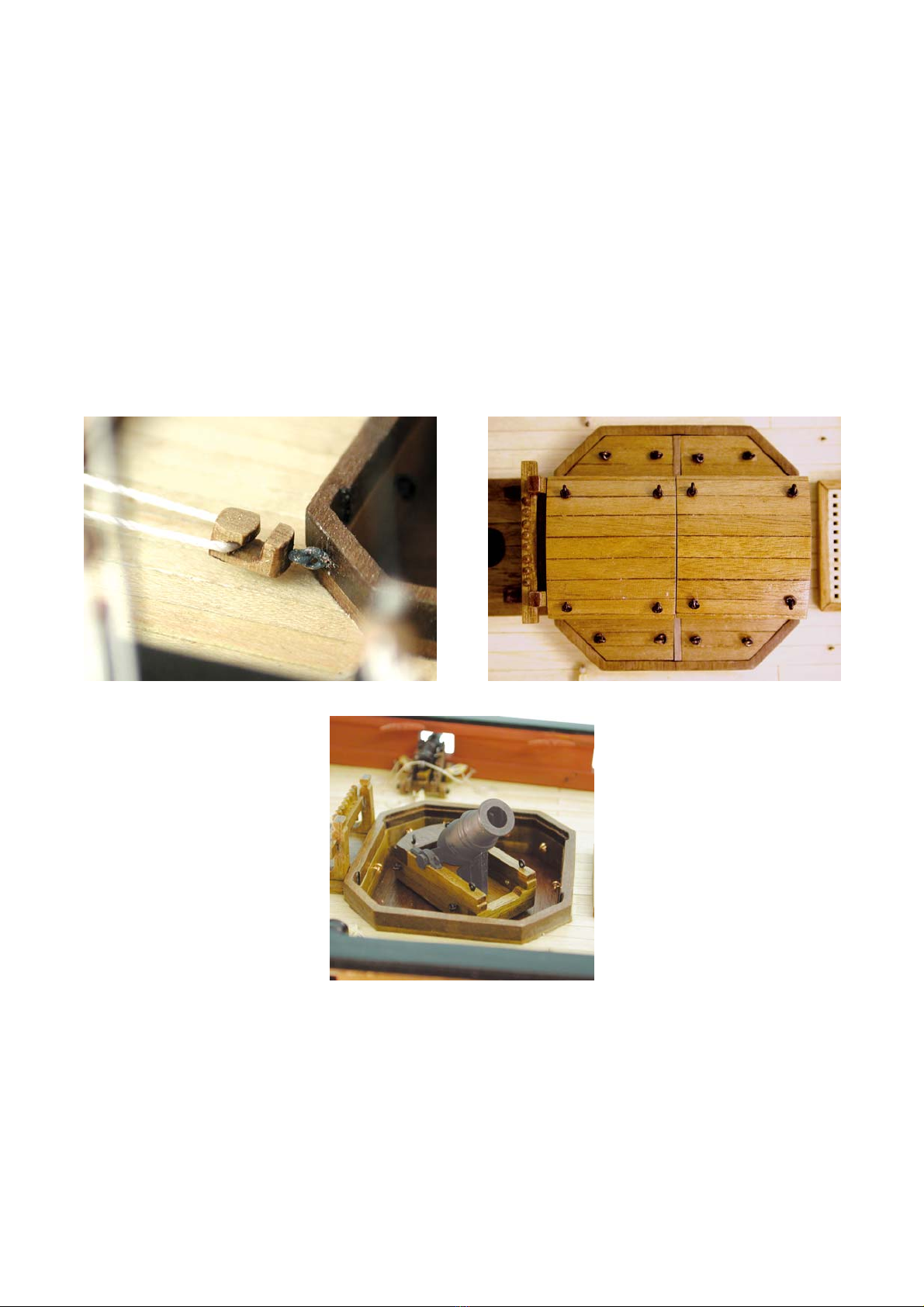

When this basic assembly has thoroughly dried, 10 ringbolts will need to be fitted to each housing. The ringbolts are

constructed using 40 copper eyelets. Gently open one copper eyelet enough to pass the ring of a second copper eyelet through,

with the second copper eyelet in position, gently close the first eye again and trim the ‘stem’ off one eyelet. Repeat this until

you have twenty ringbolts and paint matt (metal) black. Drill 0.65mm holes through the mortar pit surround, from outside in, to

take the ringbolts. The holes should be drilled centrally, on the vertical plane, through the middle mortar pit surround located

as shown on Plan Sheet 9, ‘Mortar housing ringbolt arrangement’. When the ringbolts have been fitted to the inside face of

the mortar pit surround, trim the ‘stem’ flush with the outside of the mortar pit surround.

Once varnished and dried, the housings can be glued into their respective positions. The central locating hole for the mortar

bed should sit directly over the centre line of the keel. Also, the housings should sit level and with the outer faces running

parallel to the keel.

Note: Before gluing the after (10”) mortar housing in position, two 0.65mm holes must be drilled, running fore and aft, into the

forward quarters of the mortar pit surround top, approximately 20mm either side of the centreline and 3.5mm down from the

top face. Into these holes (one each side) glue a copper eyelet, painted matt (metal) black, with the eye running up and down,

ready to accept the messenger snatch block at a later stage of construction as shown (Photo 010).

Again using Plan Sheet 2, ‘Mortar housing assemblies’ for reference, identify and remove the lower longitudinal housing

(60), the upper longitudinal housing (61) and the mortar pit traverse bulkhead (62). Clean up the lower longitudinal housing

and dry fit it into the mortar pit surround as shown, taking care that the profiled ‘slot’ faces outboard. To form the removable

strongback, cut a length of 3x3mm walnut approximately 10.75mm long to fit into the slot between the mortar pit surround and

the lower longitudinal housing. Glue a length of 1.5x1.5mm walnut centrally to the top face of this strongback. Make up the

upper longitudinal housing and mortar pit traverse bulkhead assembly as shown, gluing the mortar pit traverse bulkheads in

between the lower longitudinal housings, taking care that the assembly remains square. This assembly now sits over the lower

longitudinal supports, you will notice that at this stage it will not sit down flush against them, to achieve this you must gently

sand the top face of the 1.5x1.5mm walnut of the strongback, do not sand the bottom face of the 3x3mm walnut.

Identify and remove the mortar pit canopy ends, outer and inner, (156 & 157). The canopies are best assembled ‘in situ’ on the

upper longitudinal housing and mortar pit traverse bulkhead assembly; take care, however, not to glue the canopies to this

assembly.

Position the outer canopy ends on the upper longitudinal housing and mortar pit traverse bulkhead assembly, outside the

rabbet, and position the inner canopy ends half way along (approximately 26mm), on top of the rabbet.

Note: The orientation of the profiled slot on the inner canopy ends is unimportant, this simply marks the cut line for the area

beneath to be removed upon completion of the canopy assembly.

Start by gluing the side planks into place, this plank is from 1x5mm walnut, the bottom edge runs flush along the upper

longitudinal housing, outside the rabbet and flush with the lower edge of the outer canopy end, as the inner canopy end is

raised up on the rabbet it will not be flush to this. These side planks will also sit proud of the top edges of both the inner and

outer canopy ends, do not trim this as it will eventually form a flush edge to the top planking. Repeat for the second half of the

canopy. Allow this assembly to dry thoroughly.

The canopy top planking is constructed next from 1x4mm walnut but each plank is reduced and bevelled slightly to an overall

width of approximately 3.5mm. The first plank is laid down the centre line of the canopy, it is an advantage for the aesthetics

of the ship to construct the pair of canopies for each individual mortar housing from one length of 1x4mm walnut, i.e. lay the

central plank to the first half of the canopies and then, continuing with the same length of walnut lay the central plank of the

second half of the canopy. Three further planks will need to be laid either side of these central planks to finish the assembly.

The outer planks can now be bevelled to the camber of the canopy top planking.

Four ringbolts per canopy half (total 16 ringbolts from 32 copper eyelets), constructed as before, must now be secured one into

each corner of each canopy as shown (Photo 011). With the canopies completed, the area below the profiled slot on the inner

canopy end can now be removed by cutting through at the slot and sanding smooth.

The side housing covers are assembled next from 0.5x3mm walnut. Glue three lengths of 0.5x3mm walnut, each 30mm long,

edge to edge forming a ‘sheet’ 30mm by 9mm. Cut out the paper side housing cover template from Plan Sheet 9, ‘Side

housing cover templates’ and lay it over the ‘sheet’ and trim the sheet to size. When done, remove the paper template and

plank one side of the resultant wooden sheet at right angles, i.e. from port to starboard and trim to size. This will result in side

housing covers approximately 1mm thick, repeat this process until you have 4 port and 4 starboard covers. Each housing cover

should now be offered up into position and gently sanded to fit – with the three fore and aft planks to the top. Two ringbolts

must now be secured to the top face of each side cover as shown (Photo 011) (total 16 ringbolts from 32 copper eyelets).

Upon completion of the mortar housings, the whole assembly and component parts should be lightly varnished and can either

be glued together to form a solid structure or left to dry fit as authentic removable components.